Carbonizing kiln for charring wet or dry fibrous residue containing carbon

A carbonization kiln and carbon fiber technology, which is applied in carbonization furnaces, special forms of carbonization, petroleum industry, etc., to achieve the effects of reducing drying process, reducing energy consumption, and excellent carbonization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

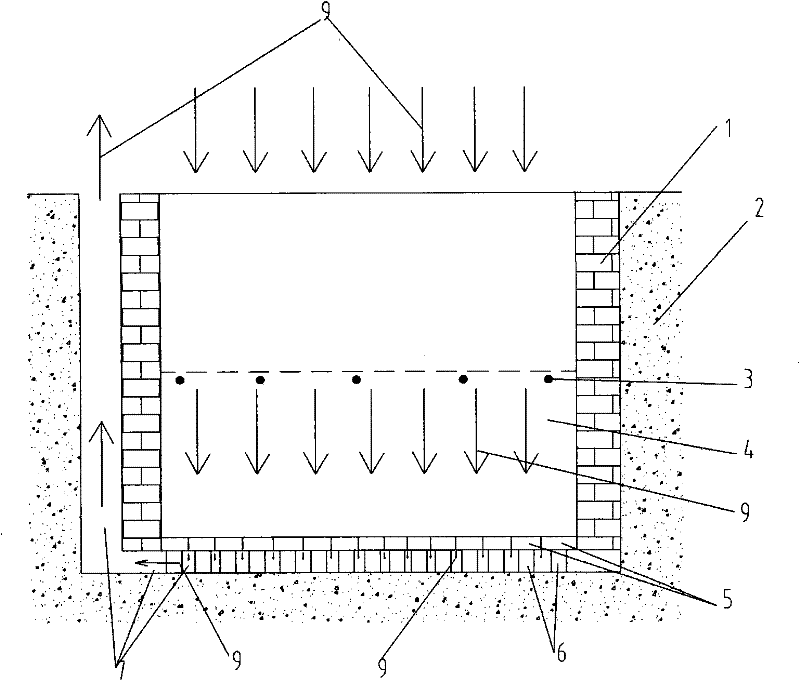

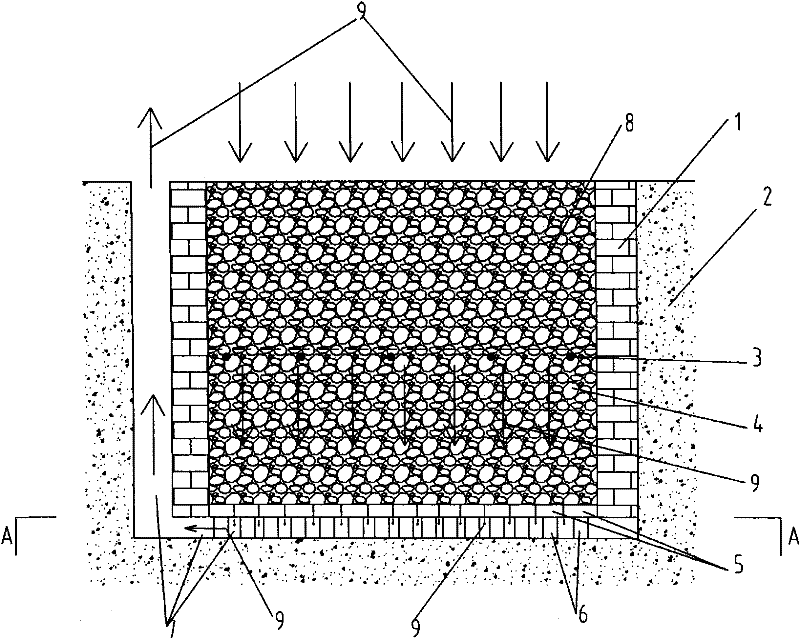

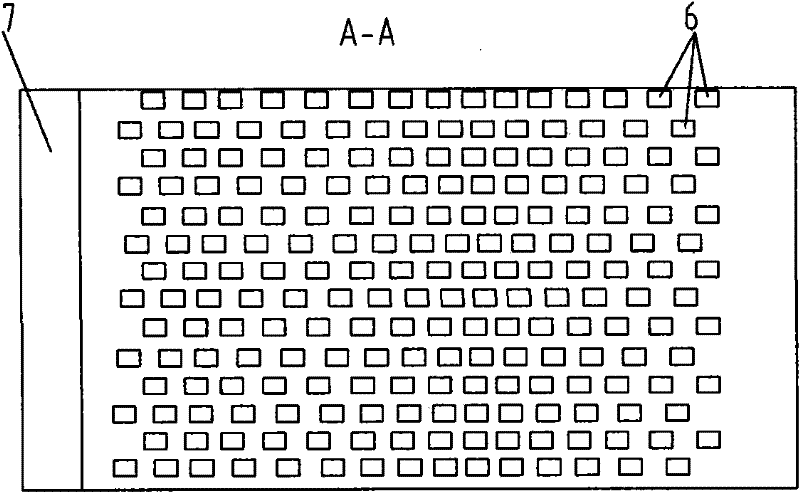

[0017] Such as figure 2 As shown, the bagasse 8 is placed upside down in the kiln body 4 to the middle of the kiln body to stop dumping, the ignition point 3 is ignited in the middle of the kiln body, the induced draft fan is turned on, and the airflow 9 passes through the sky above the ground, the interior of the kiln body 4, and the kiln bottom brick 5. The air gap between the supporting bricks, the channel between the supporting bricks 6, the air duct 7 to the induced draft fan; after that, the bagasse 8 is continuously poured into the kiln body until it is flush with the ground. The carbonization kiln of the present invention starts the carbonization work, and after the carbonization is completed, the upper layer of uncarbonized bagasse is removed, and the carbonized bagasse is taken out.

Embodiment 2

[0019] Such as figure 2 As shown, put the furfural slag upside down in the kiln body 4 to the middle of the kiln body and stop dumping, ignite the ignition point 3 in the middle of the kiln body, turn on the induced draft fan, and the airflow 9 passes through the sky above the ground, inside the kiln body 4, and between the kiln bottom bricks 5 The air gap between the supporting bricks, the channel between the supporting bricks 6, the air duct 7 to the induced draft fan; after that, the furfural slag is continuously poured into the kiln body until it is flush with the ground. The carbonization kiln of the present invention starts the carbonization work, and after the carbonization is completed, the upper layer of uncarbonized furfural slag is removed, and the carbonized furfural slag is taken out.

Embodiment 3

[0021] Such as figure 2 As shown, put the xylose slag upside down in the kiln body 4 to the middle of the kiln body and stop dumping, light the ignition point 3 in the middle of the kiln body, turn on the induced draft fan, and the airflow 9 passes through the sky above the ground, the inside of the kiln body 4, and the kiln bottom brick 5 The ventilation gap between the supporting bricks, the channel between the supporting bricks 6, the air duct 7 to the induced draft fan; after that, the xylose slag will continue to be poured into the kiln body until it is flush with the ground. The carbonization kiln of the present invention starts the carbonization work, and after the carbonization is completed, removes the uncarbonized xylose residue in the upper layer, and takes out the carbonized xylose residue.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com