Fixed rotating shaft type hydraulic opening bridge

A fixed shaft, hydraulic technology, applied in the direction of opening bridges, bridges, bridge forms, etc., can solve problems such as safety accidents, high requirements for hydraulic cylinders, and high pressure of hydraulic cylinders

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

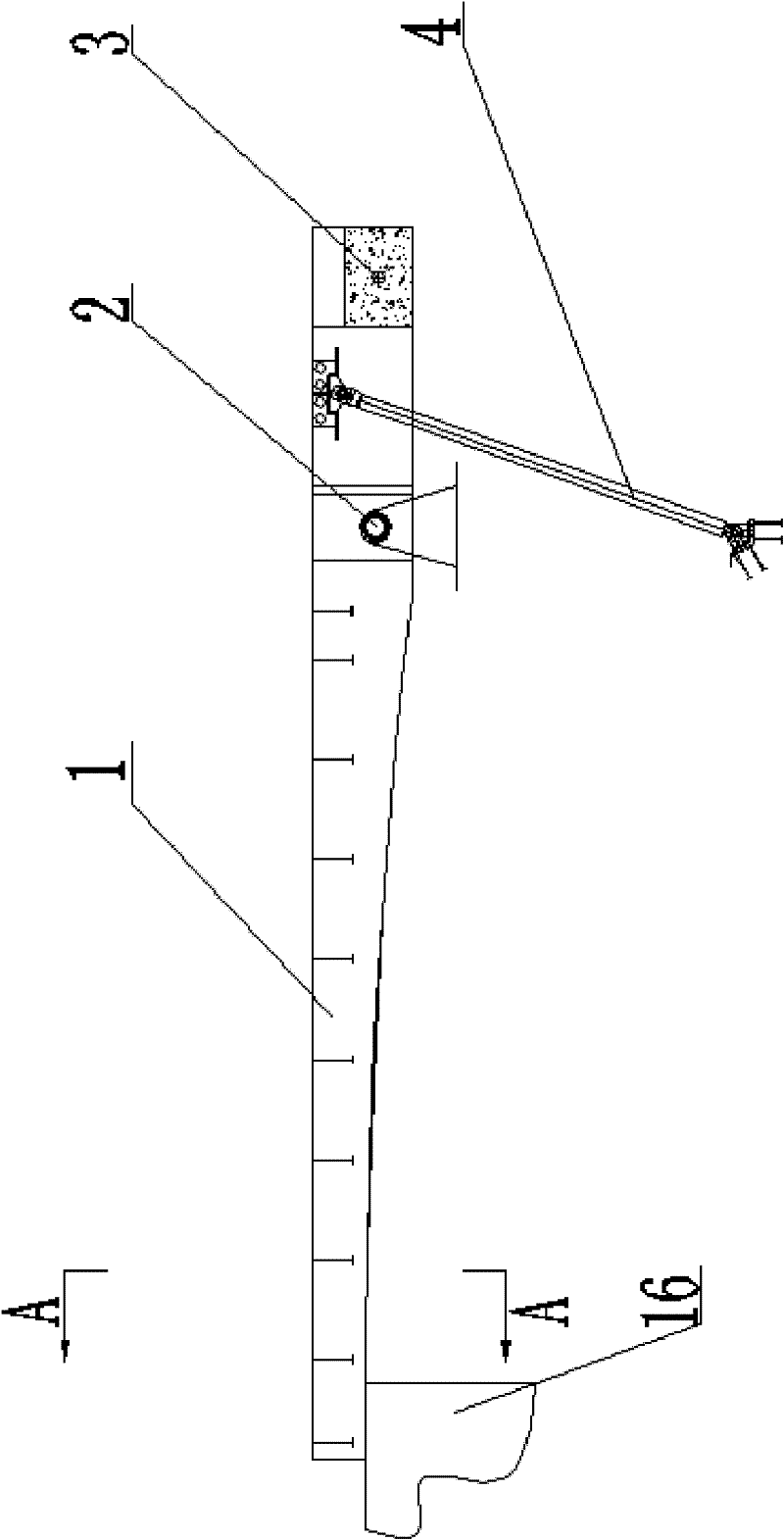

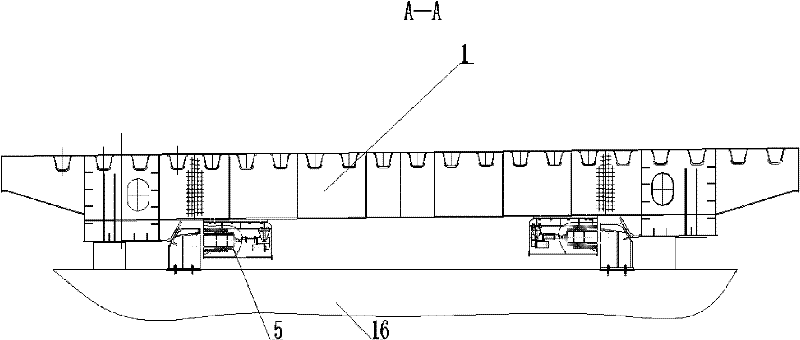

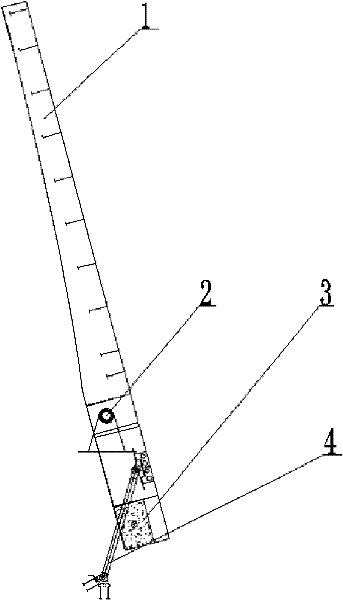

[0017] Now further illustrate how the present invention is implemented in conjunction with accompanying drawings:

[0018] This design fixed shaft type hydraulic opening bridge includes main steel bridge 1, main bearing mechanism 2, balance counterweight 3, hydraulic cylinder 4, locking and centering device 5, hydraulic system 6, control system 7, and locking and centering device 5 Set at the front end of the main steel bridge 1, the main bearing mechanism 2 and the hydraulic cylinder 4 are connected between the rear of the main steel bridge 1 and the foundation 17, the balance counterweight 3 is set at the rear end of the main steel bridge 1, and the main bearing mechanism 2 is composed of Box-shaped stringer web 10, main bearing seat 11, adjustable pivot 12, fixed pivot 19, maintenance-free bearing 13 and base 14, maintenance-free bearing 13 is installed on main bearing seat 11, adjustable pivot 12 It is arranged symmetrically with the fixed pivot 19 and respectively install...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com