Framework prestress anchor rod-reinforced supporting structure for gravity type retaining wall and construction method thereof

A supporting structure and prestressing technology, applied in foundation structure engineering, excavation, sheet pile walls, etc., can solve problems such as poor seismic performance, overturning of retaining walls, and poor overall stability, so as to improve seismic performance and overcome high construction costs , the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

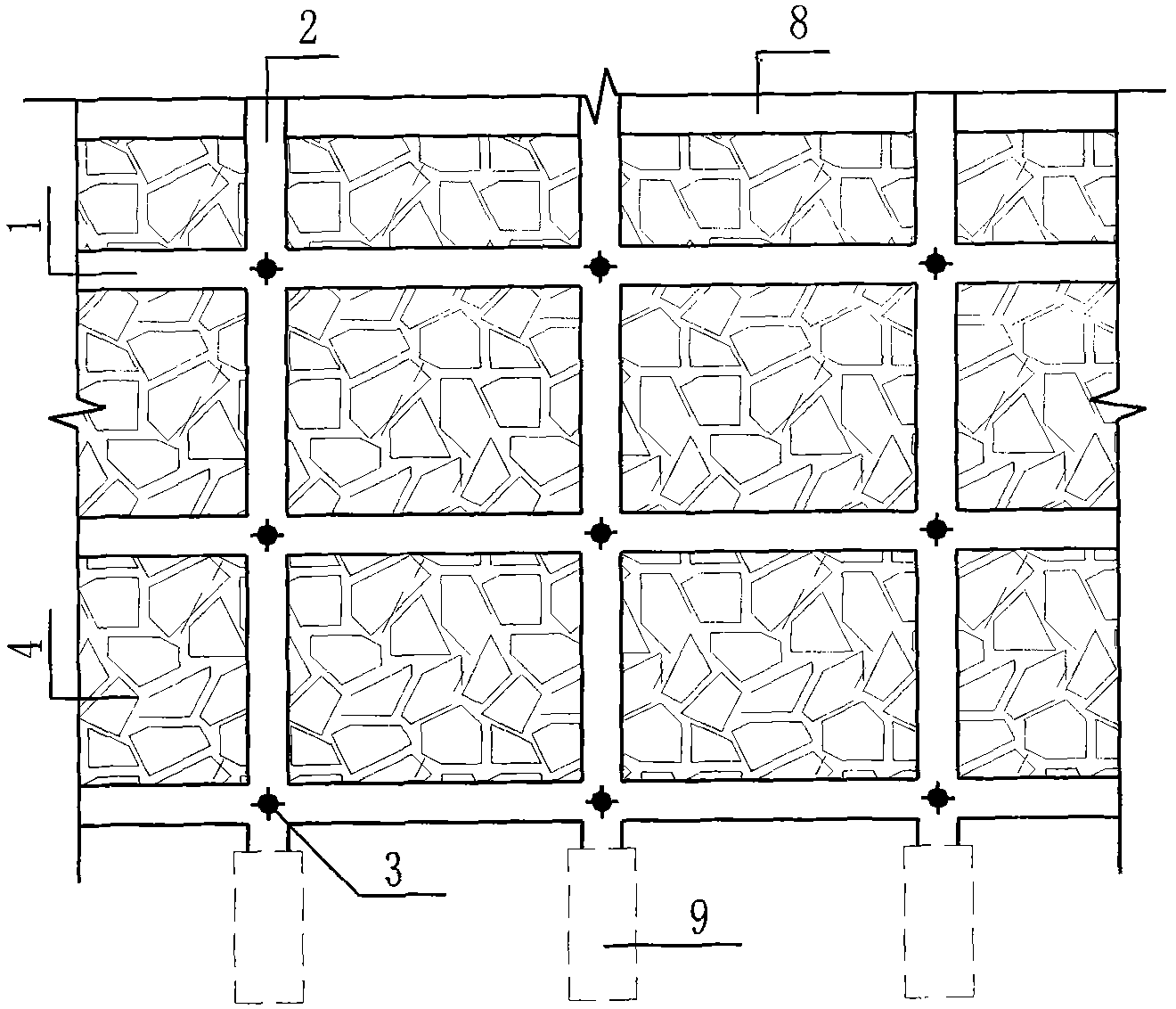

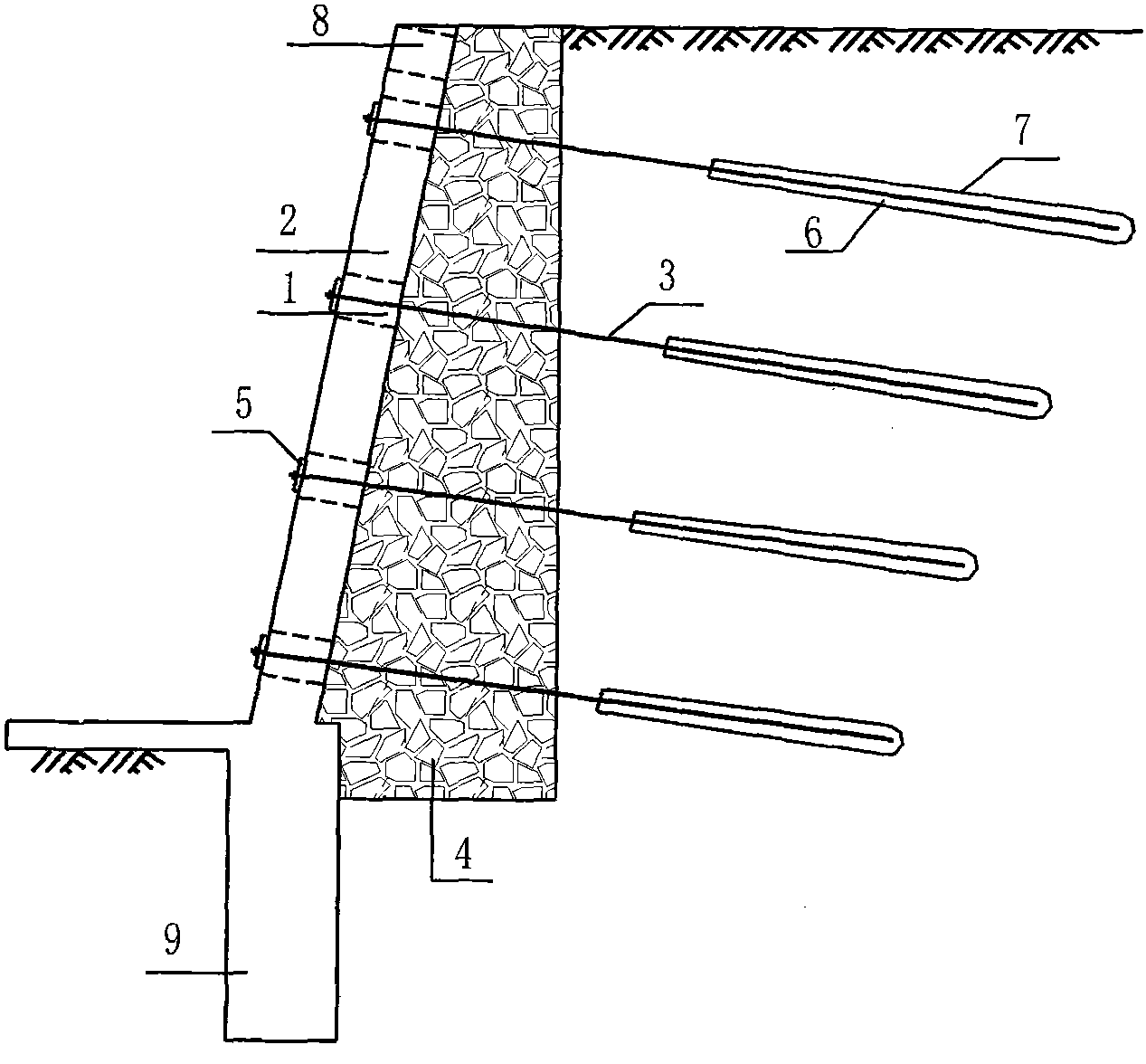

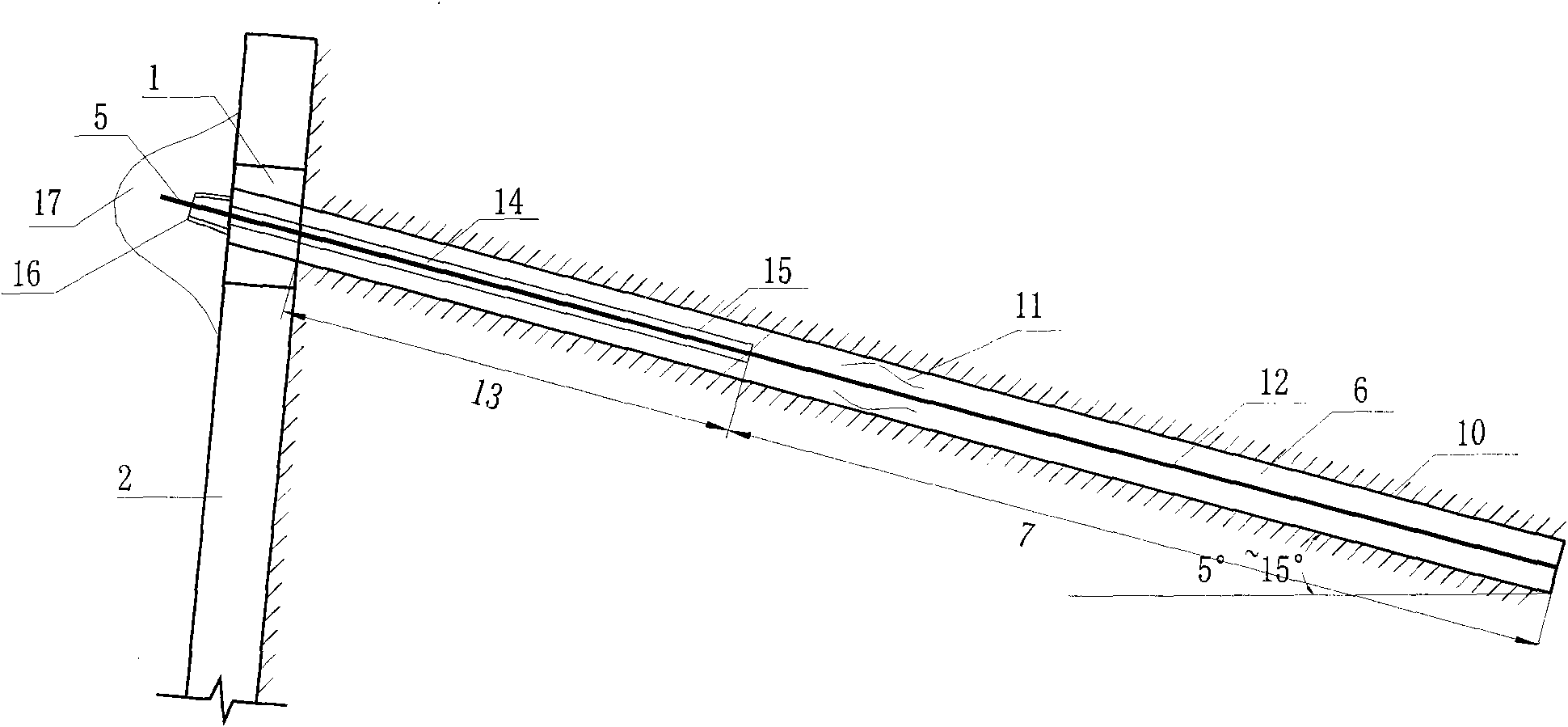

[0015] The present invention is a frame prestressed anchor bolt reinforced gravity retaining wall support structure and its construction method, such as figure 1 , figure 2 , image 3 As shown, there is a gravity retaining wall 4 with a trapezoidal cross-sectional shape in its support structure, and the reinforced soil is behind the gravity retaining wall 4, and the beam 1, column 2 and the gravity retaining wall 4 thereafter form a space frame. The prestressed anchor 3 passes through the intersection of the beam 1 and the column 2, and the gravity retaining wall 4 is embedded in the reinforced soil, and the anchorage section 7 of the prestressed anchor 3 is wrapped with cement mortar. A layer of anti-corrosion material 14 is coated on the free section 13 of 3, and a PVC plastic casing 15 is set outside the anti-corrosion material 14, and cement mortar is wrapped around the PVC plastic casing 15, and the anchor head 5 connects the end of the prestressed anchor rod 3 Anchore...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com