Heat dissipation and circuit insulating device of high-power light emitting diode (LED) lamp

A technology for LED lamps and insulating devices, which is applied to circuit layout, lighting devices, components of lighting devices, etc., can solve the problem of unfavorable heat dissipation of the insulating layer, and achieve the effects of improving heat dissipation effect, reducing light decay, and reliable insulation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

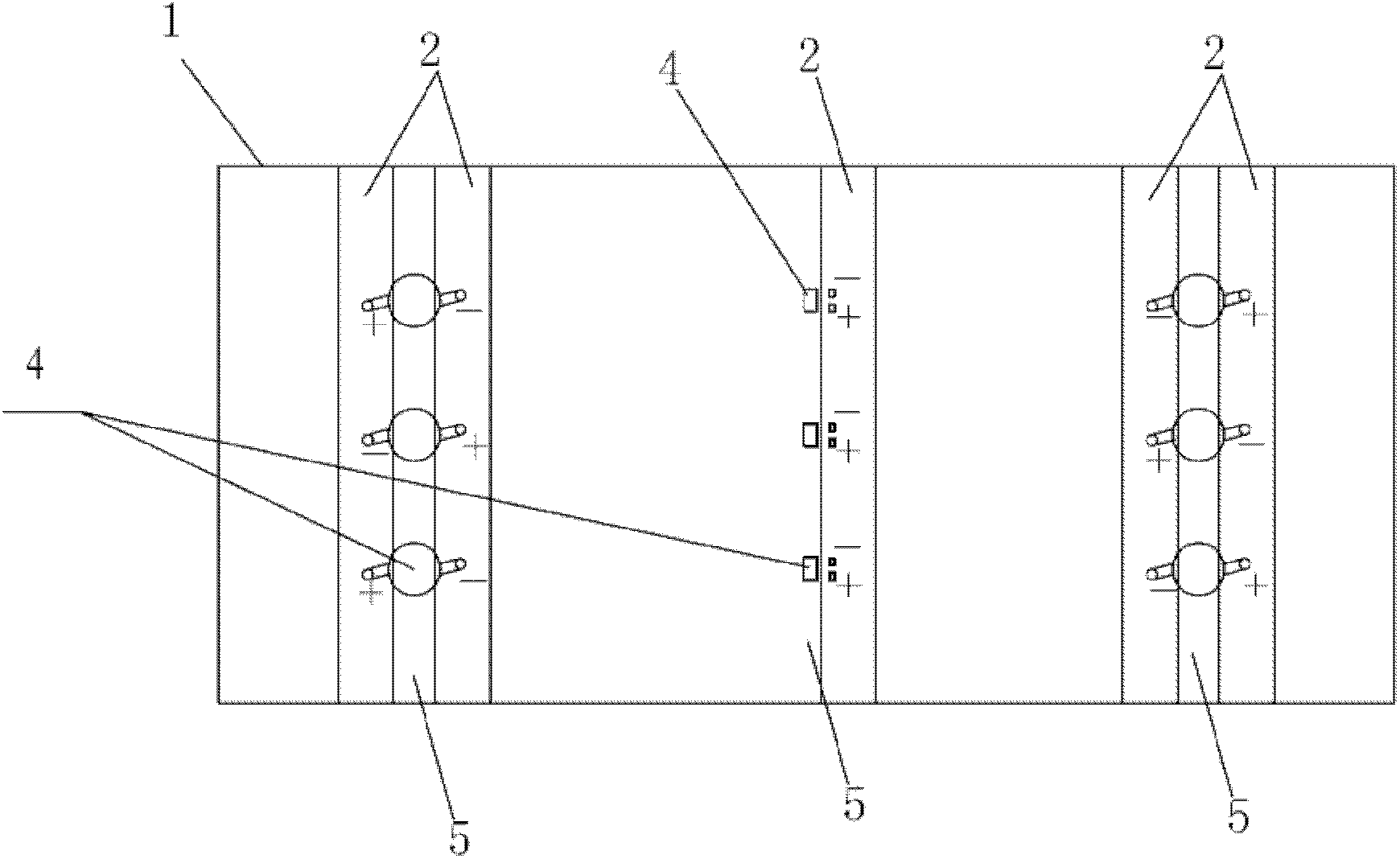

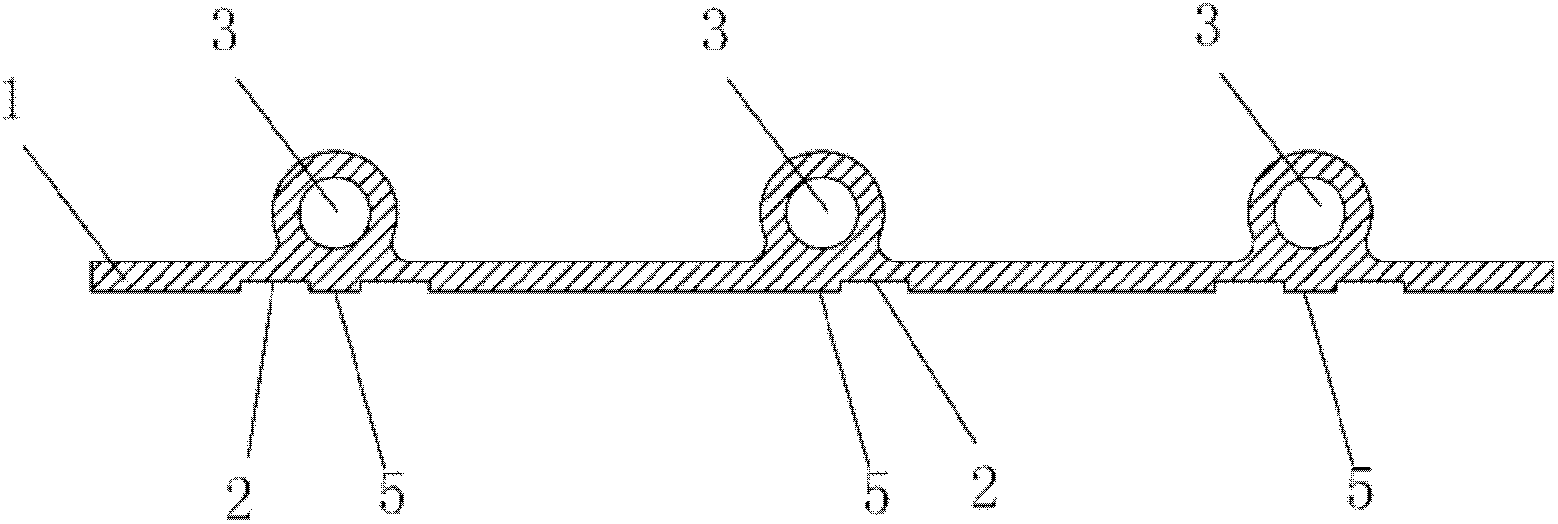

[0020] See figure 1 The heat dissipation and circuit insulation device for high-power LED lamps in this embodiment includes: a heat conduction plate 1, and a plurality of bar-shaped grooves 2 provided on the front side of the heat conduction plate 1 for setting power supply circuit slats.

[0021] The high-power LED lamp of this embodiment has a plurality of parallel light-emitting strips, and the strip grooves 2 form a light-emitting strip in two ways:

[0022] The first type: a pair of bar-shaped grooves 2 are arranged adjacent to each other in parallel, and the mesa between the pair of bar-shaped grooves 2 is a bonding surface 5, and the light-emitting parts 4 of the large-power LED chips on the same light-emitting strip are bonded to the bonding surface. On the joint surface 5, and the positive and negative poles of the large power LED chips are connected in series or in parallel through the power supply circuit slats arranged in the pair of strip grooves 2.

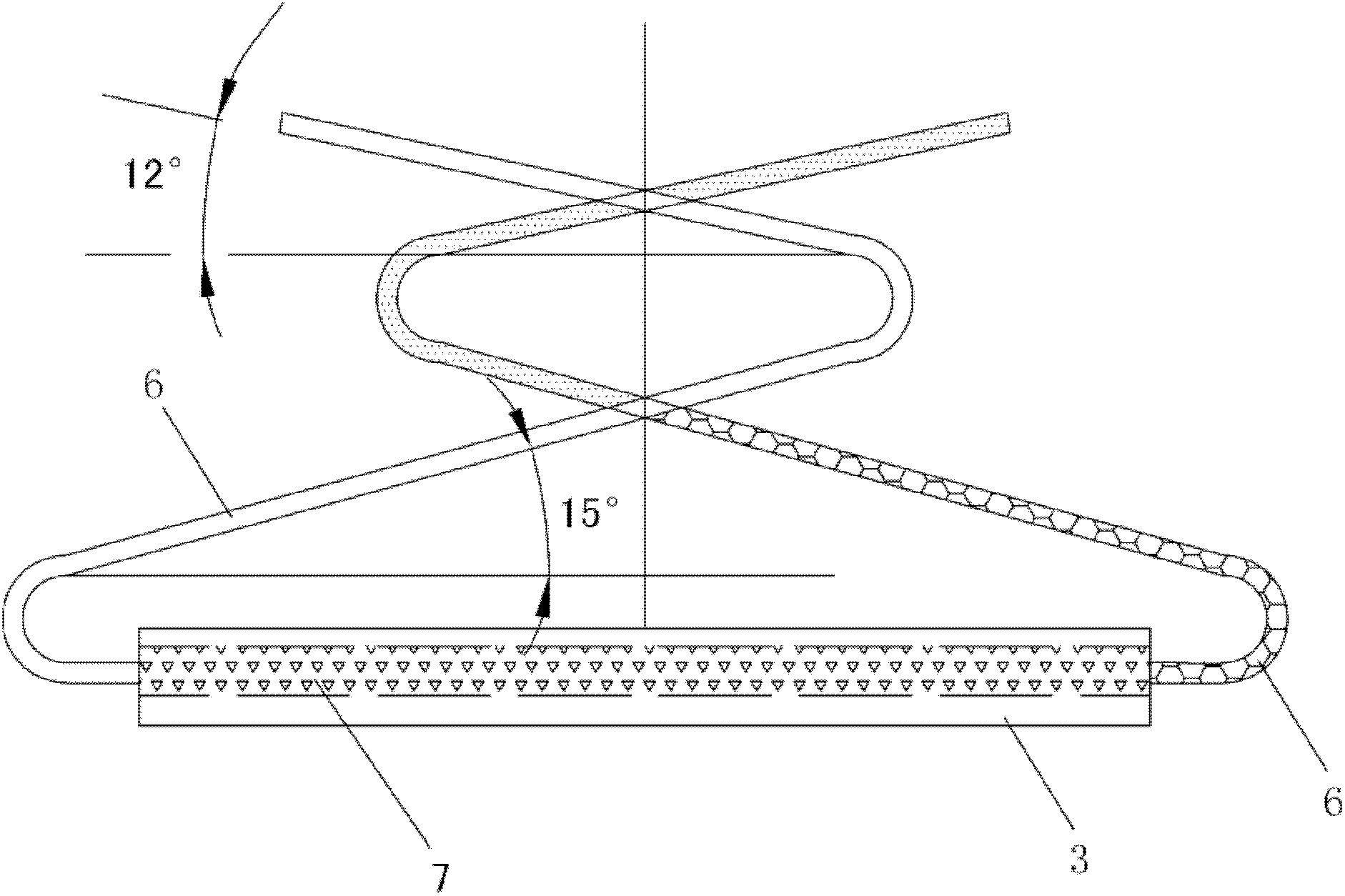

[0023] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com