Temperature-measurement compensating method and corrective type high-accuracy thermometer

A compensation method and thermometer technology are applied in the field of temperature measurement compensation and correction type high-precision thermometer, which can solve problems such as increasing cost and achieve the effect of high measurement accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

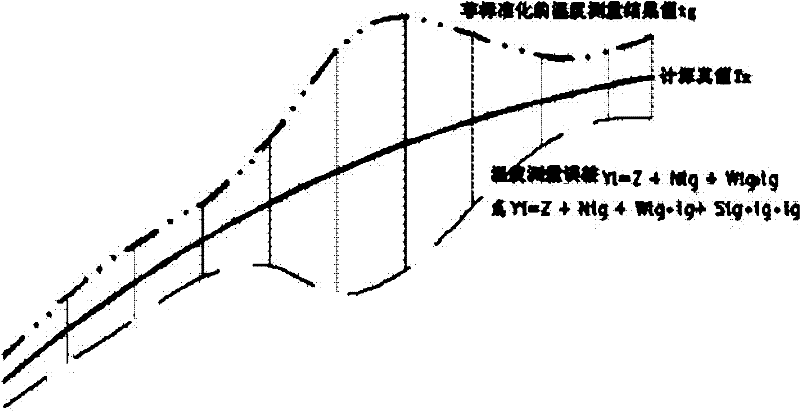

Method used

Image

Examples

Embodiment 1

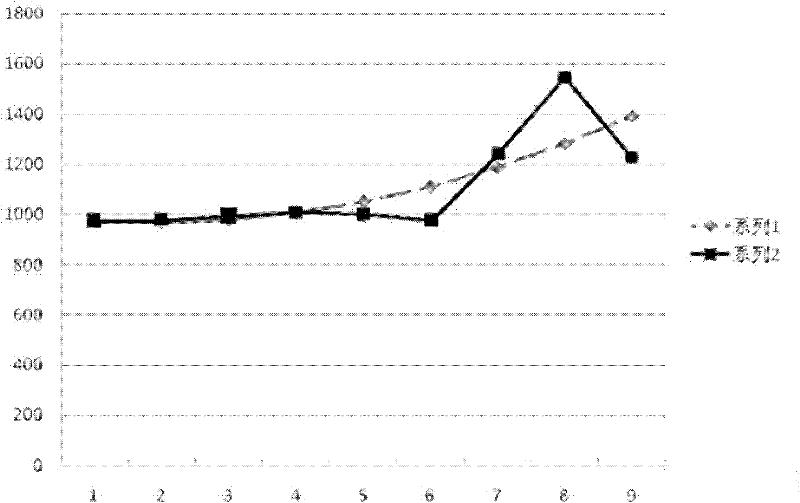

[0058] Method A: In the calibration experiment, the true temperature value T is used as the input value 1...i-the non-standardized thermometer measurement result value tg and the output value 1...i. In this embodiment, the test range recognized by the laboratory is 0-100°C , Using Pt1000 platinum thermal resistance temperature sensing element. The comparison is shown in Table 1.

[0059] Table 1 Calibration test temperature true value T- non-standardized thermometer measurement result value tg output value comparison table

[0060] Laboratory Accreditation Test

Thermometer system input value Ti

Unnormalized thermometer output value tgi

1

0

tg1

2

10

tg2

3

20

tg3

4

30

tg4

5

40

tg5

…i

Ti

tgi

[0061] In actual operation, the laboratory determines that the test consists of at least three groups: T1-tg1, T2-tg2, T3-tg3..., and the up...

Embodiment 2

[0075] Method B: In the calibration experiment, the true temperature value T is used as the input value 1...i-the non-standardized resistance measurement result value Rtg output value 1...i. In this example, the test range recognized by the laboratory is 0-100°C, Adopt Pt1000 platinum thermal resistance temperature sensing element.

[0076] Table 3 Schematic diagram of the corresponding relationship between the input value Ti of the thermometer system and the output value Rtgi of the non-standardized resistance measurement result

[0077]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com