Device and method for detecting surface defects of surface with periodical patterns

A defect detection and periodic technology, applied in the direction of measuring devices, material analysis through optical means, instruments, etc., can solve the problems of poor stability, high equipment cost, slow processing speed, etc., to reduce requirements, solve high equipment cost, The effect of increasing the matching speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0036] In this embodiment, the selected object to be inspected is a strip photo frame, which is characterized in that the surface of the photo frame is flat and has periodic patterns on the surface.

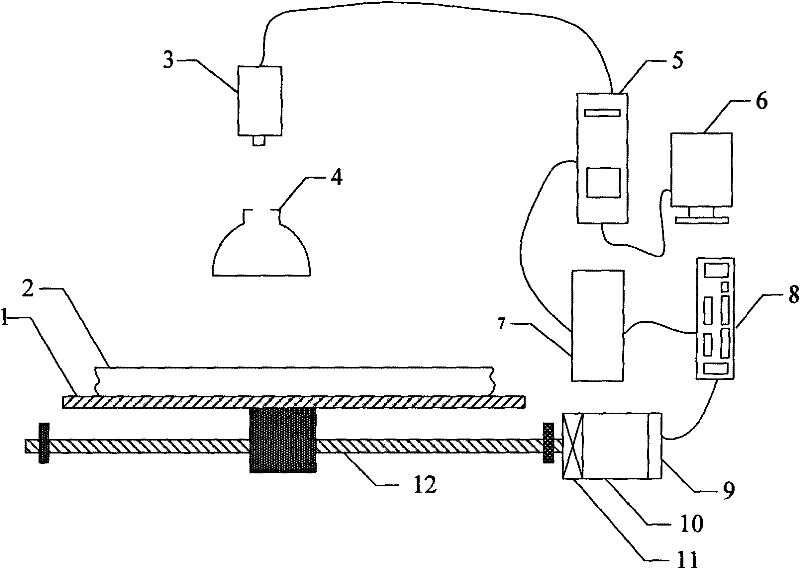

[0037] as attached figure 1 The schematic diagram of the structure and principle is shown. In this embodiment, the CCD black and white area array GigE camera adopts the DALSA M1400 type, the resolution is 1360*1024, and the lens matched with the camera is a Computar2 / 3 "JC series lens with a focal length of 25mm. The light source Ose DM-75 is used, Intel PRO / 100MT is used for gigabit network card, McBean SBN04SDK is used for motor, McBean VN04N is used for driver, and Omron CP1H is used for PLC.

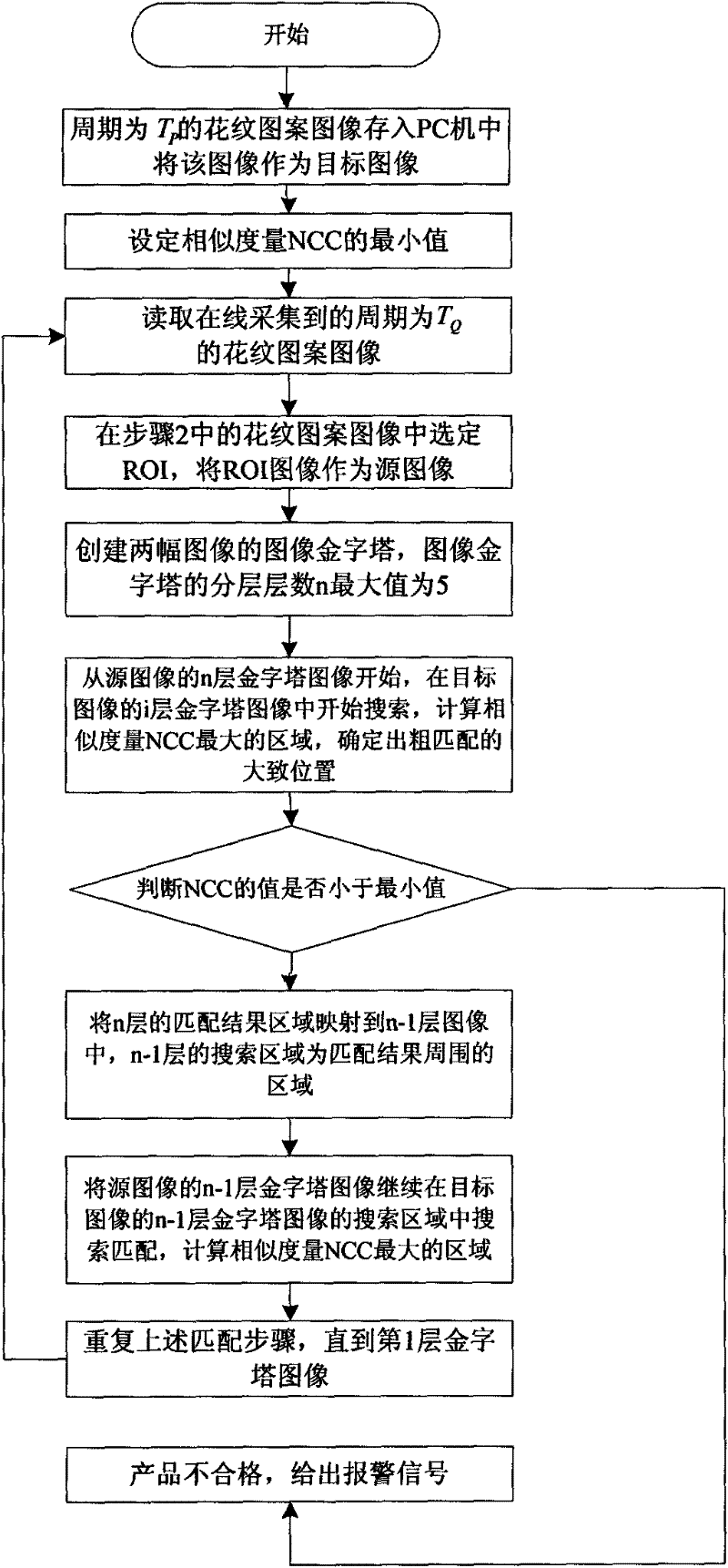

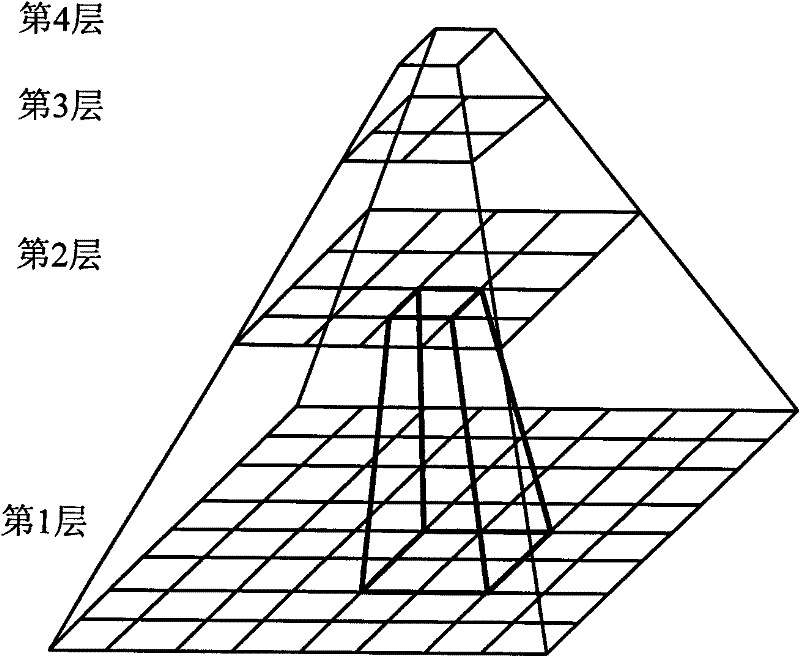

[0038] The operation flow of the whole detection process is as follows:

[0039] After the entire detection system is turned on, the motor is connected with the ball screw through the reducer to realize the horizontal movement of the workbench and the strip photo frame. The driver is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com