Proportional hazard rate model method for estimating operation reliability of tool

A failure rate and reliability technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problems of inconsistent equipment operating conditions, difficulty in obtaining failure life data, etc., and achieve good real-time performance and evaluation results. reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

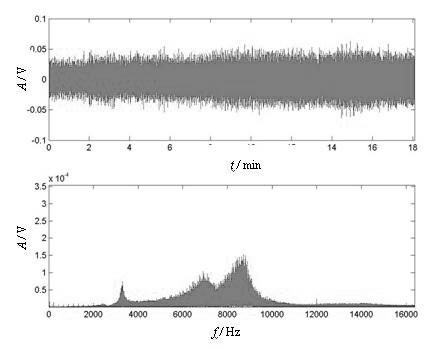

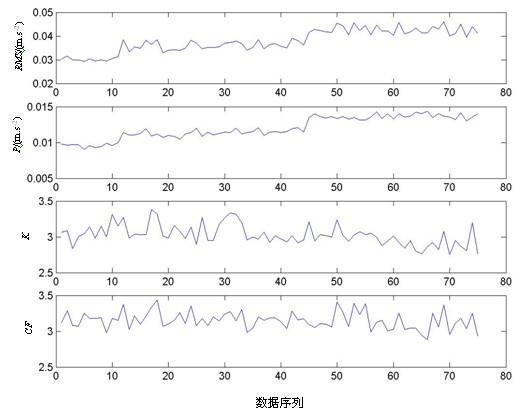

[0062] figure 1 Vibration signal and its frequency spectrum from t=84min to t=104min when machining workpiece for tool 1, it can be seen from the figure that the energy of the signal is mainly concentrated in the frequency band between 3000 and 9000Hz. figure 2 It is the time-domain index change diagram of tool 1. It can be observed that during the tool degradation processing time, the effective value (RMS) and peak value (P) change trends are obvious, and the kurtosis (K) and peak index (CF) change trends Not very obvious.

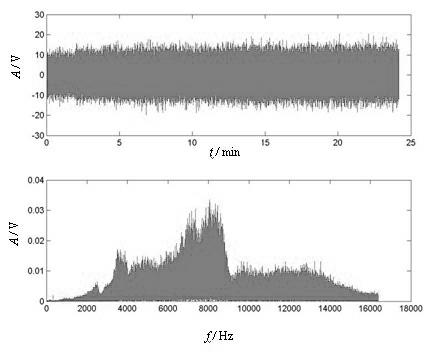

[0063] image 3 Vibration signal and its frequency spectrum from t=75min to t=100min when machining workpiece for tool 2, it can be seen from the figure that the energy of the signal is mainly concentrated in the frequency band between 3000 and 9000Hz. Figure 4 It is the time-domain index change diagram of tool 2. It can be observed that during the tool degradation processing time, the effective value (RMS) and peak value (P) change trends are more...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com