Heat management system and method for battery pack of electric automobile

A battery management system, electric vehicle technology, applied in the direction of secondary batteries, circuits, electrical components, etc., can solve problems such as easy leakage, complex liquid circulation structure, etc., to achieve the effect of simplified structure and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

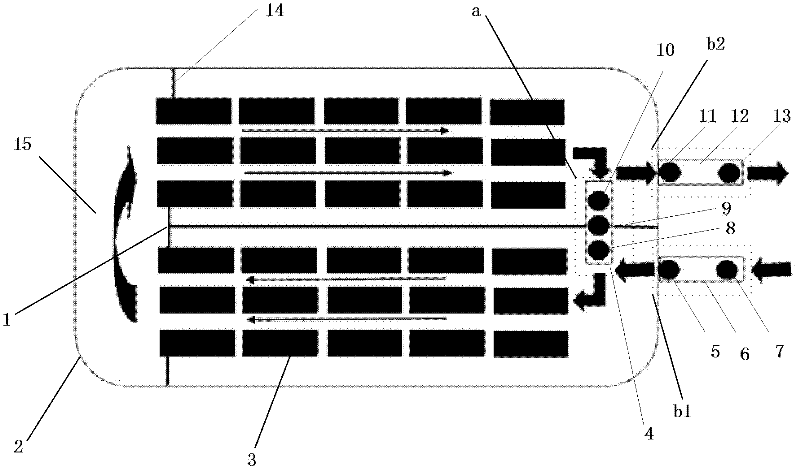

[0040] See figure 1 , The embodiment of the present invention provides a thermal management system for an electric vehicle battery pack, including a battery pack shell 2, a battery cell 3, a heating system, a heat dissipation system, and a BMS (Battery Management System, battery management system) (not shown in the figure) ). A plurality of battery cells 3 are evenly arranged in the battery pack shell 2, and the battery pack shell 2 is provided with a "T"-shaped middle wind deflector 1, such as figure 1 As shown, the length of the long plate arranged parallel to the battery cell 3 in the middle wind deflector 1 is slightly shorter than the length of the long side of the battery casing 2. One end of the long plate of the middle wind deflector 1 and the battery casing 2 The right end is connected, the short plate is set close to the left end of the battery pack shell 2, and the long plate of the middle wind deflector 1 separates the battery pack shell 2 into two spaces. The two sp...

Embodiment 2

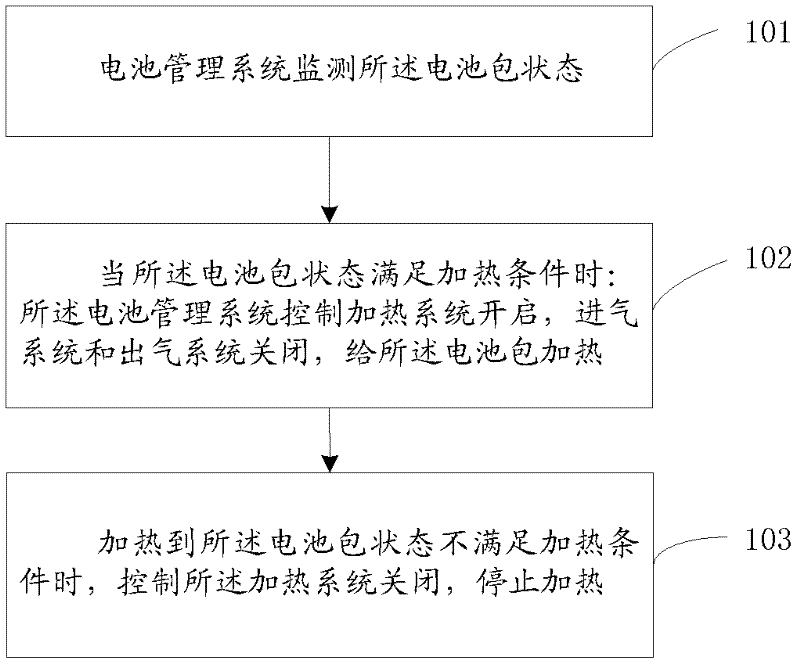

[0050] See also Figure 1-Figure 3 The embodiment of the present invention utilizes the thermal management system provided in embodiment 1 to provide a thermal management method for an electric vehicle battery pack, the method includes:

[0051] 101: BMS monitors the state of the battery pack;

[0052] 102: When the state of the battery pack meets the heating condition:

[0053] BMS controls the heating system to be turned on, and the air inlet system and the air outlet system are turned off to heat the battery pack;

[0054] At this time, the heating system heats up, and the gas inside the battery pack follows figure 1 Flow in the direction indicated by the arrow in the middle, heating each single battery.

[0055] 103: When the state of the battery pack does not meet the heating conditions, control the heating system a to turn off and stop heating;

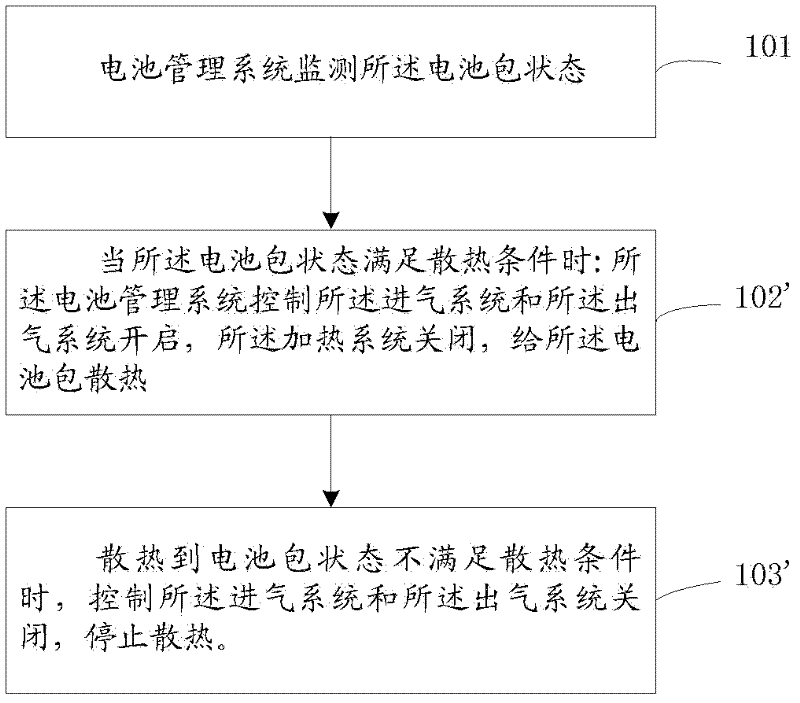

[0056] 102': When the state of the battery pack meets the heat dissipation condition:

[0057] The BMS controls the intake system b1 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com