Wet grinding device

A wet-type, suction device technology, applied in the direction of grinding machines, grinding/polishing equipment, metal processing equipment, etc., can solve the problems that debris and larger solid particles cannot be collected, and dusty gas cannot be absorbed and filtered in a large area. Achieve the effects of low noise, high air flow, and anti-rebound effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

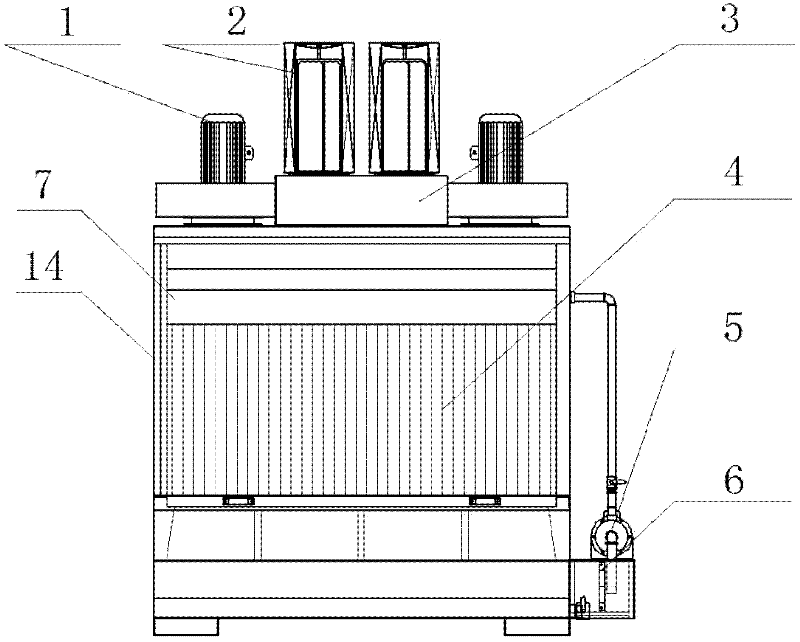

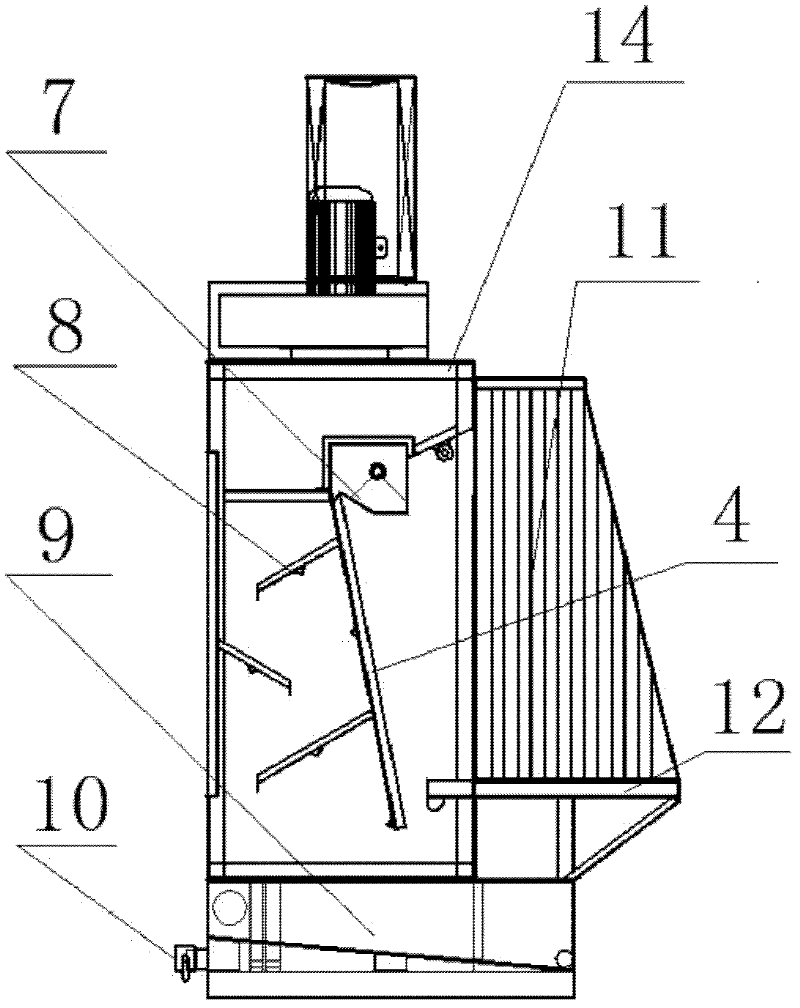

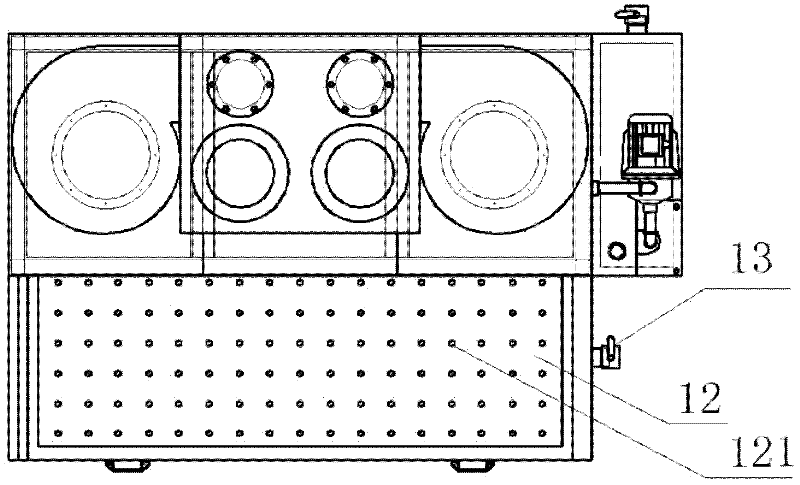

[0024] Such as Figure 1~3 The preferred embodiment of the present invention shown is composed of a workbench 12 and a box body 14 arranged in front of the workbench 12 and fixedly connected with the workbench 12 . A plurality of through holes 121 are defined on the workbench 12 . The water curtain dedusting device includes a water supply device 5, a water curtain plate 4, an overflow tank 7 and a water tank 9. In the present embodiment, the water supply device 5 is a stainless steel self-priming water pump, but it is not limited thereto. The water curtain plate 4 is located at In front of the workbench 12, the water curtain plate 4 is provided with an air duct baffle device 8 on the opposite side forming the water curtain surface, and the device is composed of a plurality of staggered baffles. One side of the workbench is provided with a spark rebound device 11, which is set to the right side in a preferred embodiment of the present invention, but is not limited thereto. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com