Solar silicon wafer suction pen

A technology of solar silicon wafers and absorption parts, applied in the field of tools, can solve problems such as low operating efficiency, low operating efficiency, and surface damage of silicon wafers, and achieve the effects of simple operating methods, high operating efficiency, and surface structure protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

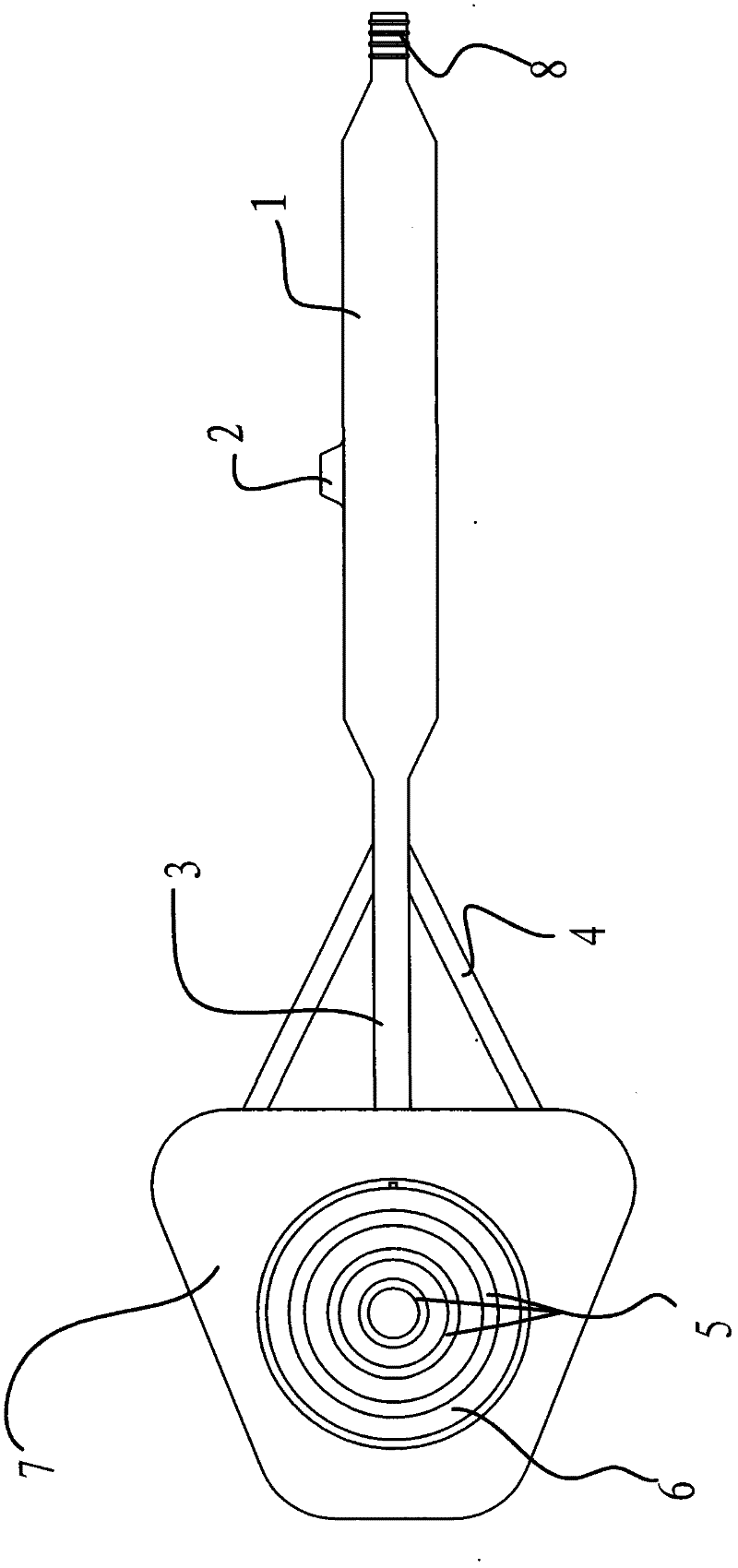

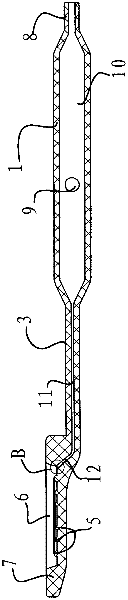

[0019] The solar silicon chip suction pen is made of glass, and its structure includes a suction part 7 and a grip part 1 connected together. The suction part 7 is in the shape of a plate for sucking silicon wafers; For gripping by an operator's hand, the diameters of the two ends of the gripping part 1 are smaller than the diameter of the middle part thereof. One end of the grip part 1 is connected to the back of the suction part 7, and the other end of the grip part 1 is provided with a connector 8, the connector 8 is used to be inserted into the suction pipe, and the suction pipe is connected with the suction pump. connect.

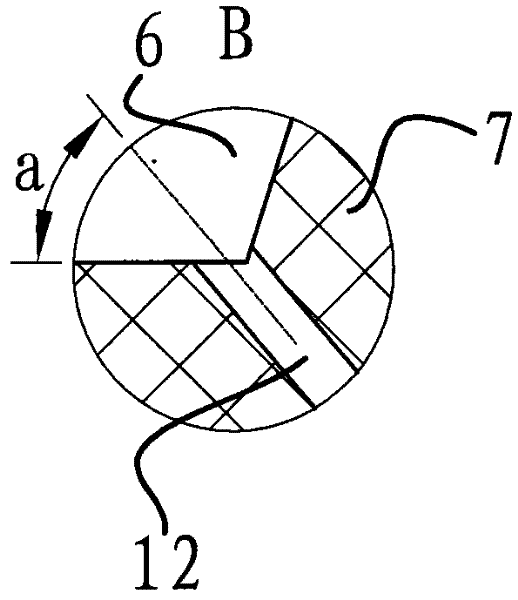

[0020] The grip part 1 is hollow, and a through hole 10 is arranged in the grip part 1 along its axial direction. A through hole 9 is provided in the middle of the grip portion 1 , and the through hole 9 communicates with the outside world and the through hole 10 . A sinkhole 6 is arranged on the front of the suction part 7 , the depth of the sinkhol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com