Cable shield connection method and structure

A technology of cable shielding and connection structure, which is applied in the direction of connection, parts and circuits of connection devices, etc. It can solve the problems of damage to the insulation layer, impact on the life of cables and electrical connectors, and the inability to adjust special connection parts and titanium-nickel alloy rings, etc. , to achieve the effect of meeting the correct termination conditions, eliminating oxidation and corrosion, and good industrial applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific embodiment of the present invention is described in detail below in conjunction with accompanying drawing:

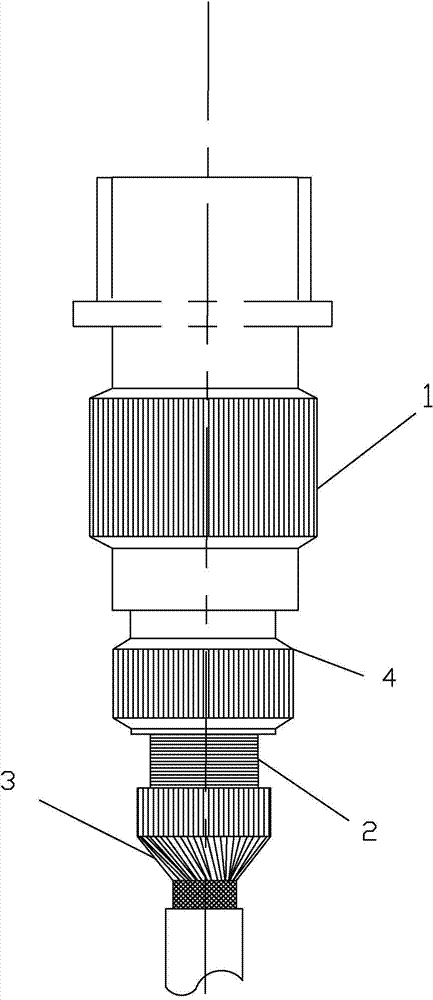

[0020] Such as figure 2 As shown, in one embodiment of the cable shielding connection method and structure of the present invention, it includes an electrical connector 1 and a heat-shrinkable tube type tail cover 4 connected to the electrical connector 1, and the heat-shrinkable tube type tail cover 4 includes a There are nuts, round tubes and connectors. There are external threads on the outer wall of the round tube, and a nut with internal threads is movably connected to the upper end. The electric connector 1 and the heat-shrinkable tube type tail cover 4 are reliably connected through the nut. The lower end of the round pipe is fixed with a connecting piece, and the lower end of the connecting piece is connected with a cable.

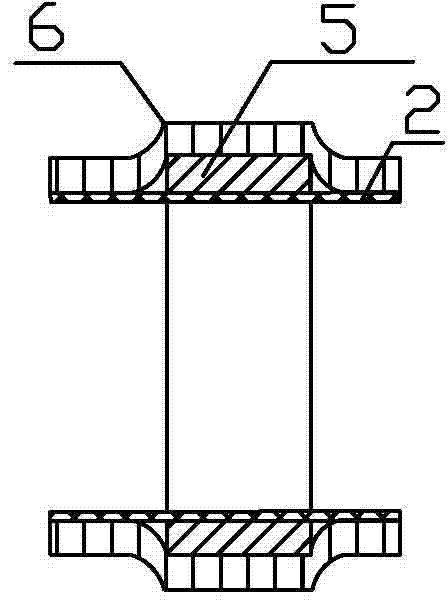

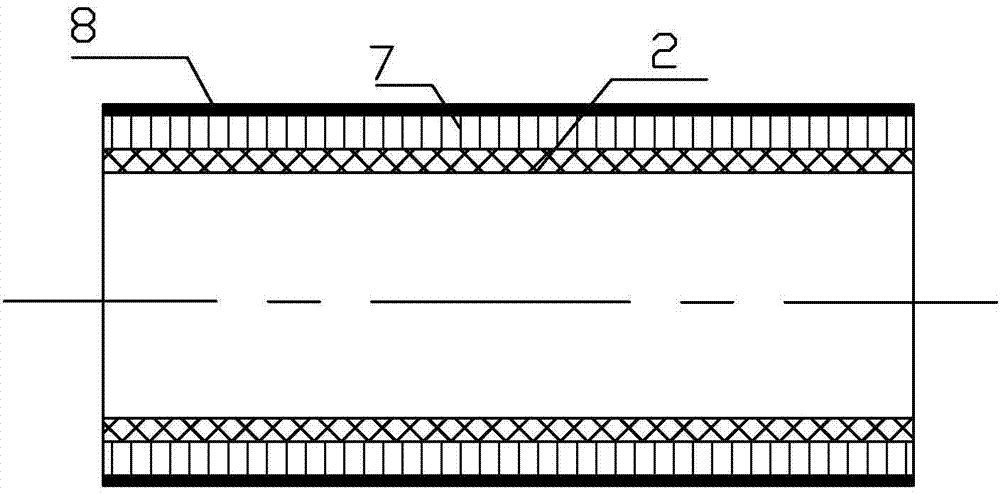

[0021] The cable shielding 2 on the outer layer of the cable is in the form of a mesh, and the cable shielding 2 cove...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com