A dual-hull trailing suction dredger without a mud tank and its construction method

A technology of trailing suction dredger and construction method, which is applied in the directions of earth mover/shovel, mechanically driven excavator/dredger, construction, etc. Reducing the unit price of dredging and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

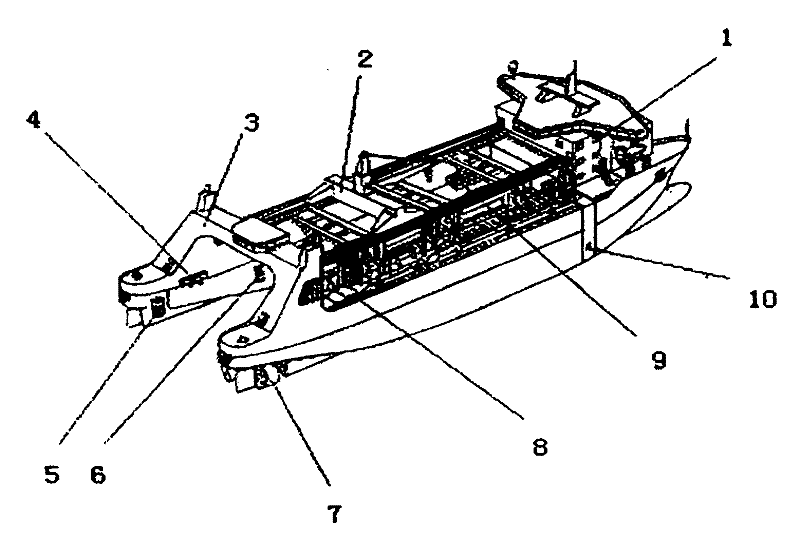

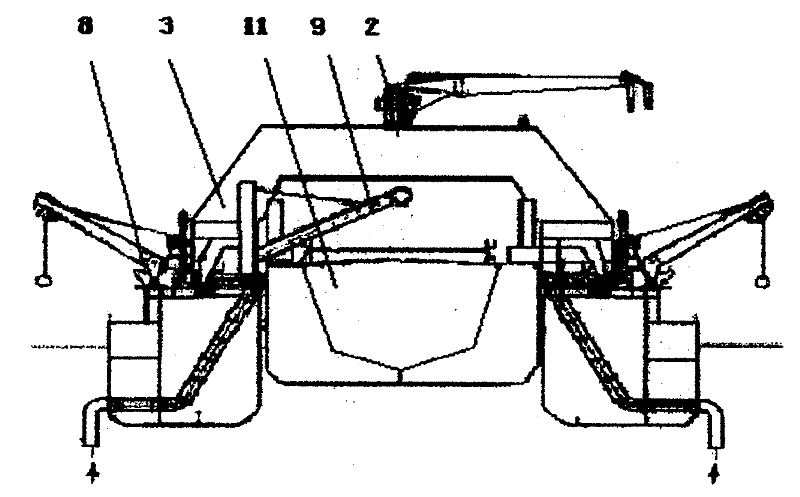

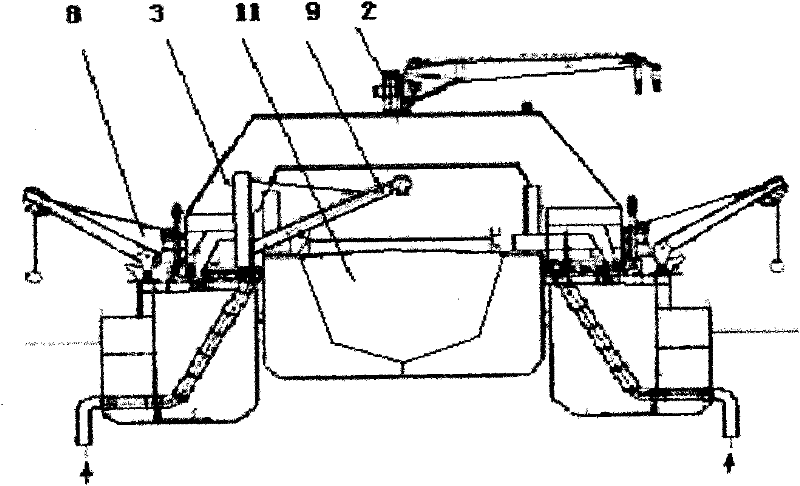

[0010] Double-hull trailing suction dredger without mud tank (see figure 1 , figure 2 ) adopts the bow connecting bridge and its superstructure 1, the midship connecting frame, and the stern connecting frame 3, and connects two hulls with a large separation distance into a rigid connection through a longitudinal beam structure.

[0011] The bulbous bow improves sailing performance. The bow is provided with a side thruster 10 to improve the dynamic positioning capability and help the mud barge to enter and exit the double body room. The propulsion devices are located at the rear of the two hulls, and the tail propeller 7 adopts a variable pitch propeller to enhance the maneuverability of the ship and facilitate the safe entry and exit of mud barges. The stern adopts a diversion skeg stern design, and the stern of both hulls has a skeg, which can enhance the structural strength of the stern, facilitate the mud barge to enter and exit the double hull, and protect the propeller...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com