Installation method for heat insulated decorative composite board

An installation method and composite board technology, which are applied in covering/lining, building, building structure, etc., can solve the problems of reducing the hidden danger of thermal insulation effect, reducing thermal insulation performance, reducing construction efficiency, etc., to simplify the installation construction process and improve the installation. Efficiency, the effect of improving the thermal insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

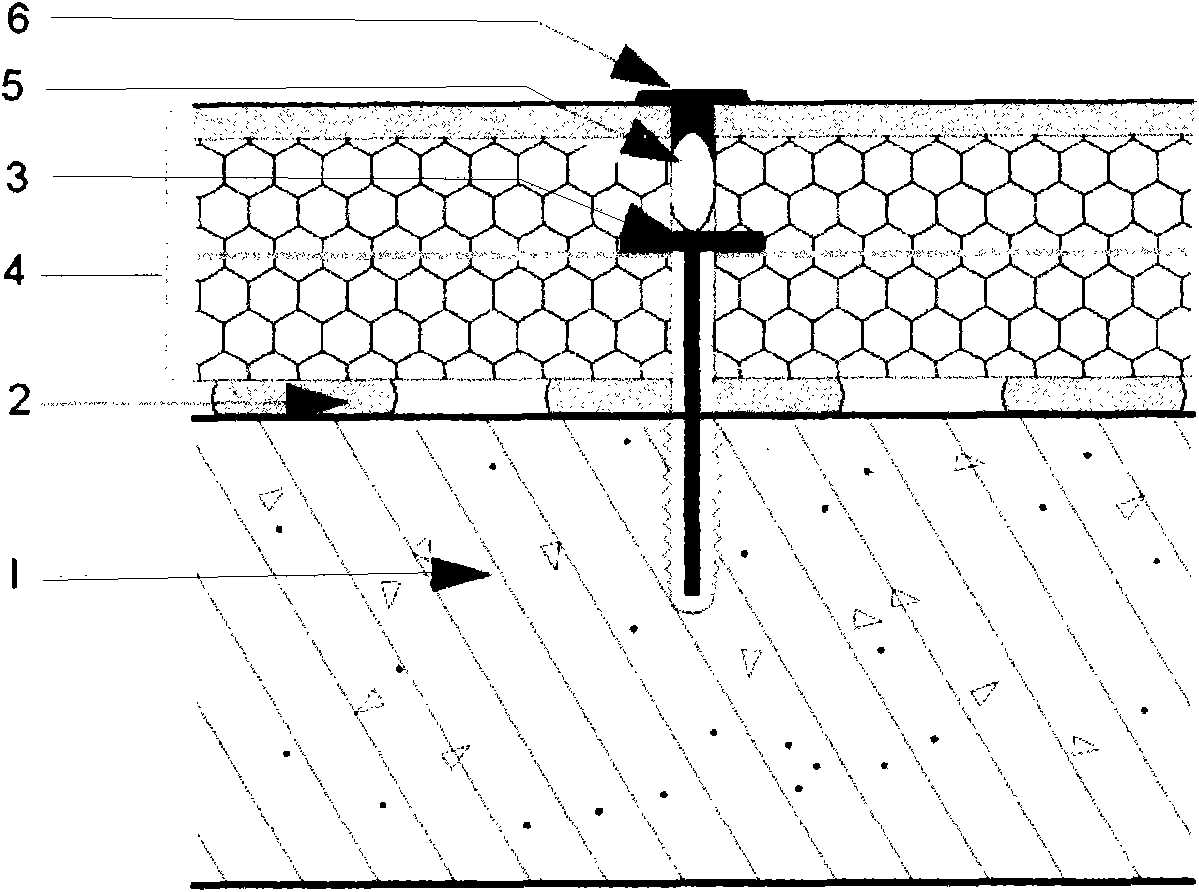

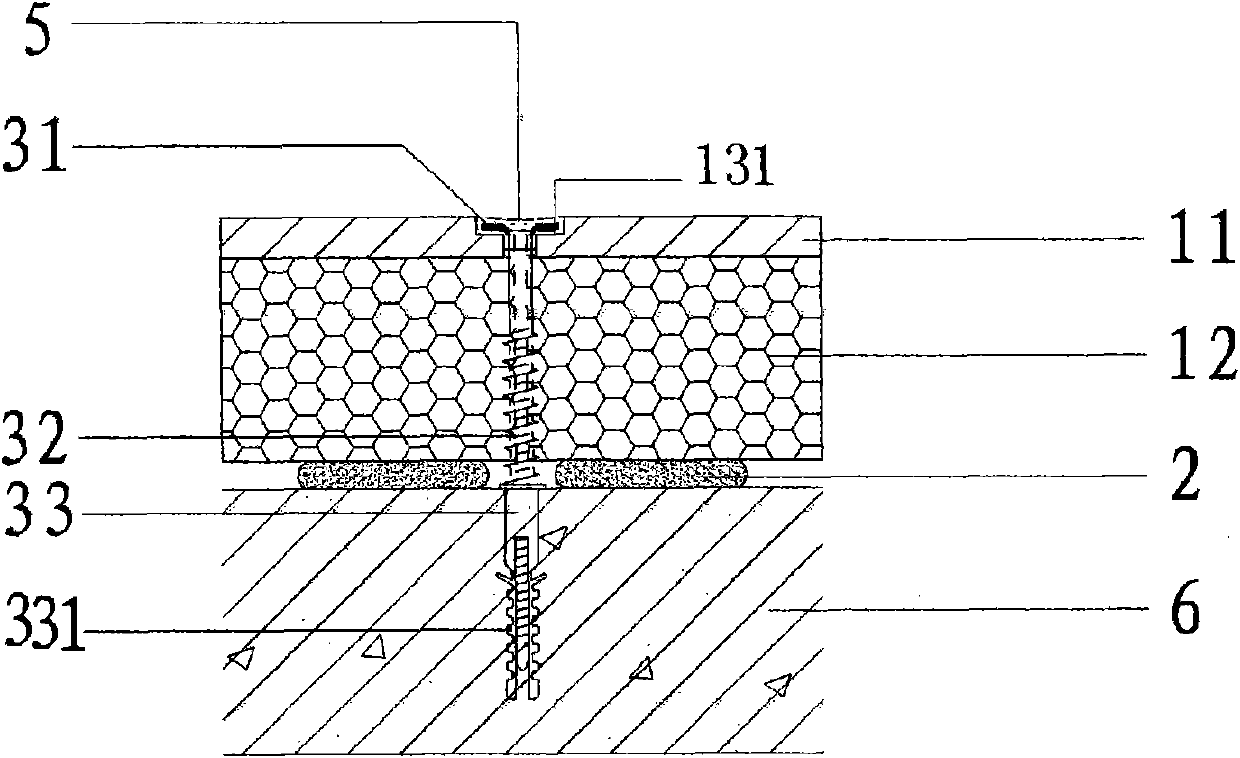

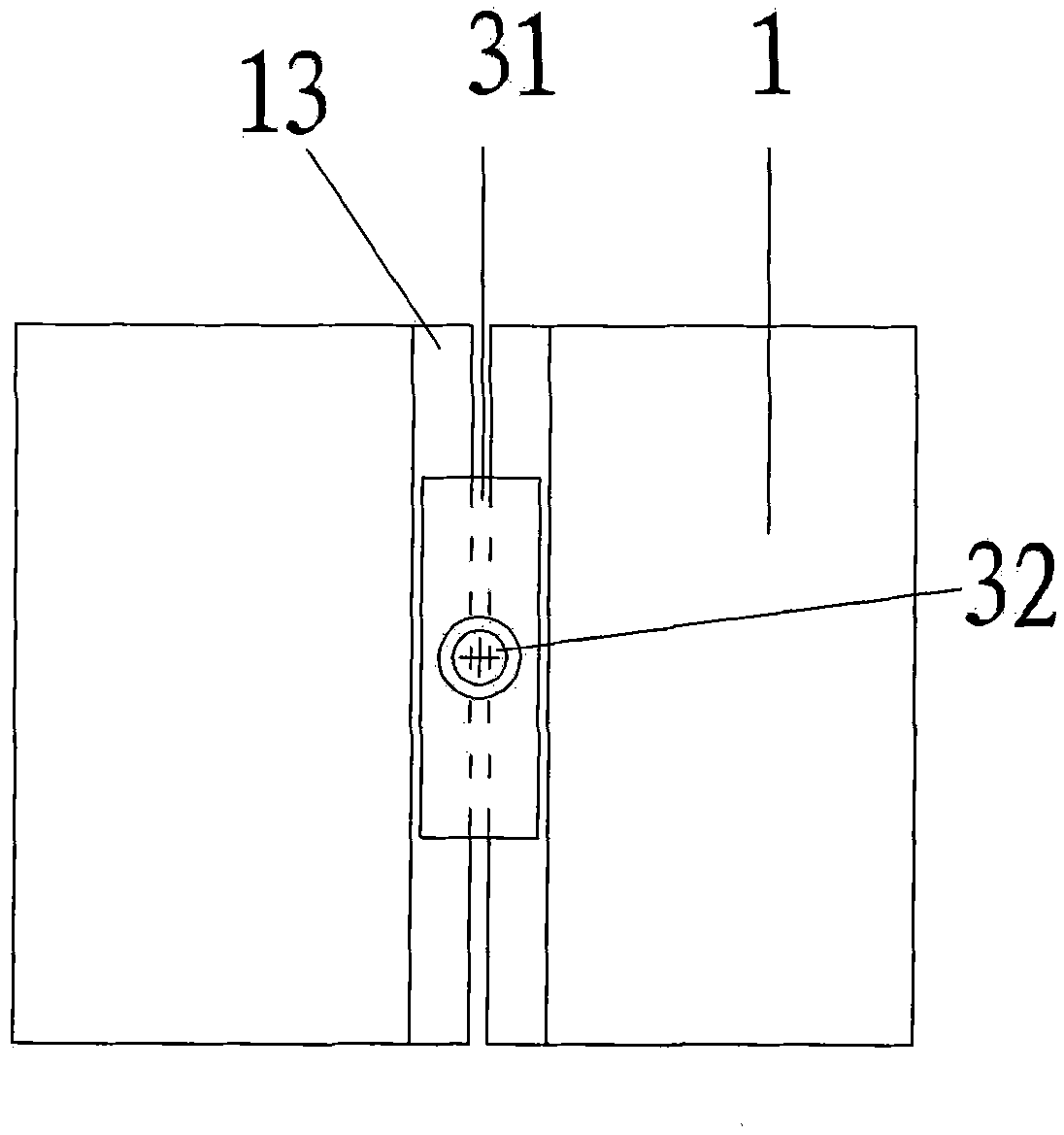

[0028] Embodiment one: figure 2 and image 3 It shows a schematic cross-sectional view of an embodiment of the installation method of the thermal insulation and decorative composite board according to the present invention after installing the thermal insulation and decorative composite board. The installation method of the thermal insulation and decorative composite board includes the following steps:

[0029] A. Set up a right-angled step 13 around the panel layer 11 of the thermal insulation and decorative composite board 1 to be installed, and the right-angled step 13 is directly processed and formed in the factory. The thermal insulation and decorative composite board 1 has a panel layer 11 and a thermal insulation Layer 12 consists of;

[0030] B. Sequential splicing and using adhesive mortar 2 to preliminarily fix the thermal insulation and decorative composite panels 1 with the rectangular steps 13 to the designated positions on the wall 6, and control the adjacent t...

Embodiment 2

[0036] Embodiment two: Figure 4 and Figure 5 It shows a schematic cross-sectional view of another embodiment of a method for installing a thermal insulation and decorative composite panel according to the present invention after installing the thermal insulation and decorative composite panel, including the following steps:

[0037] A. An arc-shaped step 13 is provided around the panel layer 11 of the thermal insulation and decoration composite board 1 to be installed. The arc-shaped step 13 is directly processed and formed in the factory. The thermal insulation and decoration composite panel 1 has a panel layer 11 and an insulation layer 12 components with invisible lock 14;

[0038]B. Sequentially splicing and using adhesive mortar 2 to preliminarily fix the thermal insulation and decorative composite board 1 with the arc-shaped steps 13 to the specified position on the wall 6, and control the adjacent thermal insulation and decorative composite panels during splicing Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com