A multifunctional outburst prevention drill pipe

A multi-functional, anti-outburst technology, applied to drill pipes, drill pipes, drilling equipment, etc., can solve problems such as hole plugging, drilling slag deposition, and reduction of drilling power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

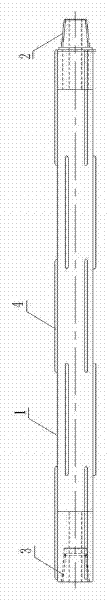

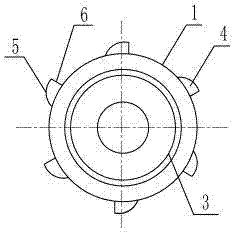

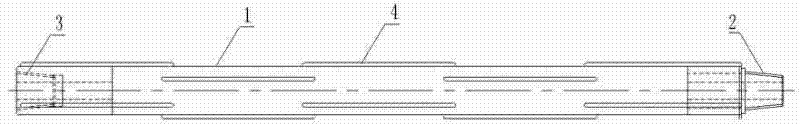

[0011] like figure 1 and figure 2 As shown in the figure, a multifunctional anti-outburst drill rod of the present invention includes a hollow cylindrical rod body 1, two ends of the rod body 1 are respectively provided with a male connector 2 and a female connector 3, and the rod body 1 is axially provided with at least one set of The rib structure, each group of rib structures is composed of line segment-shaped rib strips 4 axially arranged on the surface of the rod body 1, and the rib strips 4 in each group of rib structures are uniformly arranged three times along the circumference of the rod body . The rib 4 is arranged on the rod body 1 by plasma cladding technology, and the rib 4 of the adjacent two groups of rib structures has an axial cross section, and one rib 4 is connected to two adjacent rib. The bars 4 are equally spaced vertically. The outer edge of the cross-section of the rib 4 is formed by a circular arc line segment 5 and a straight line segment 6 extend...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com