Indirect-evaporative-cooling-based small and large environment energy-saving air conditioning system for spinning mill

An evaporative cooling air-conditioning and evaporative cooling technology, which is applied in air conditioning systems, ventilation and heating energy recovery systems, ventilation systems, etc., can solve the problems of large air supply volume, large initial investment and operating costs, and energy waste, and achieve reduction Equipment investment, save equipment investment and operation, reduce the effect of equipment volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

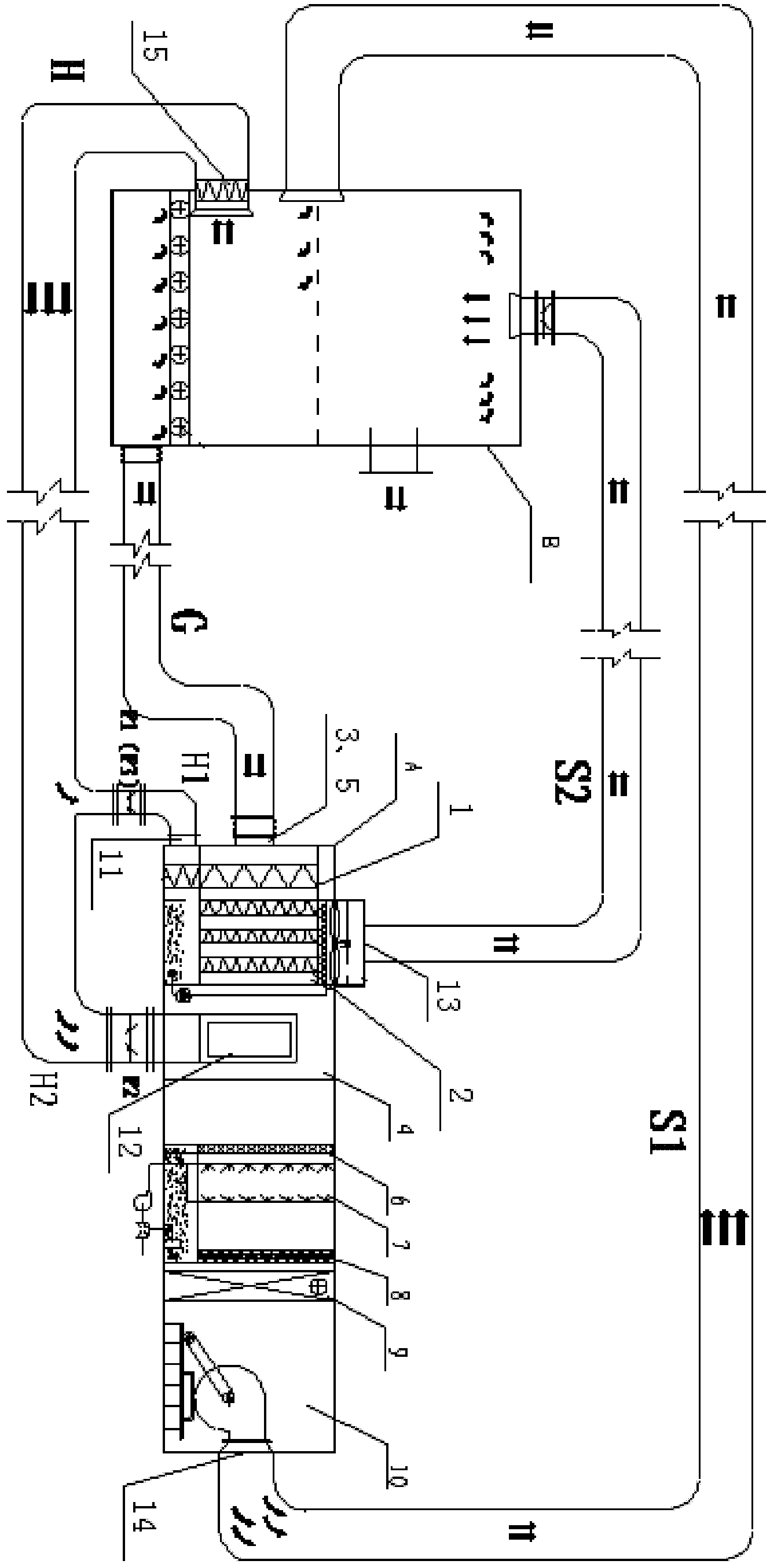

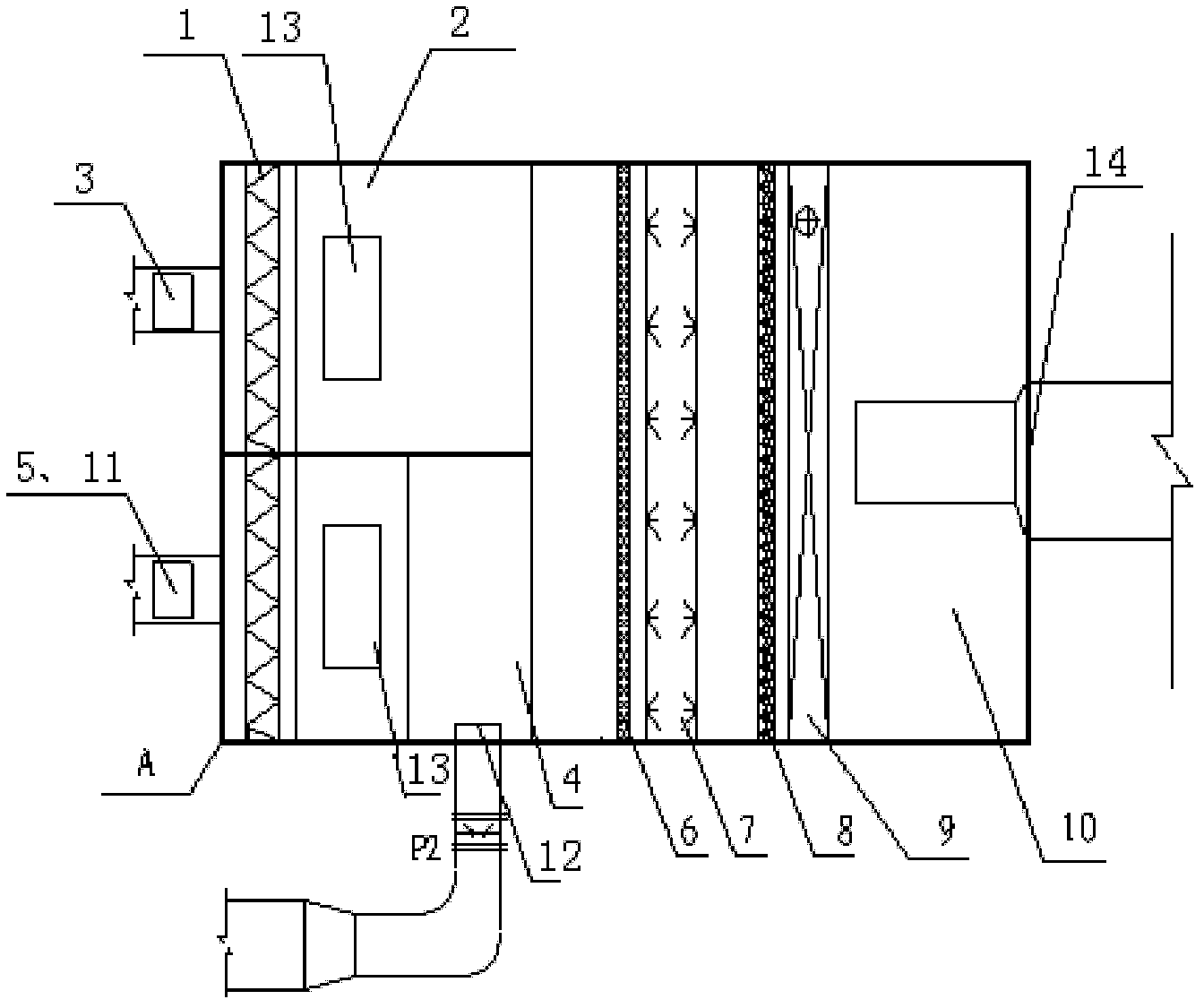

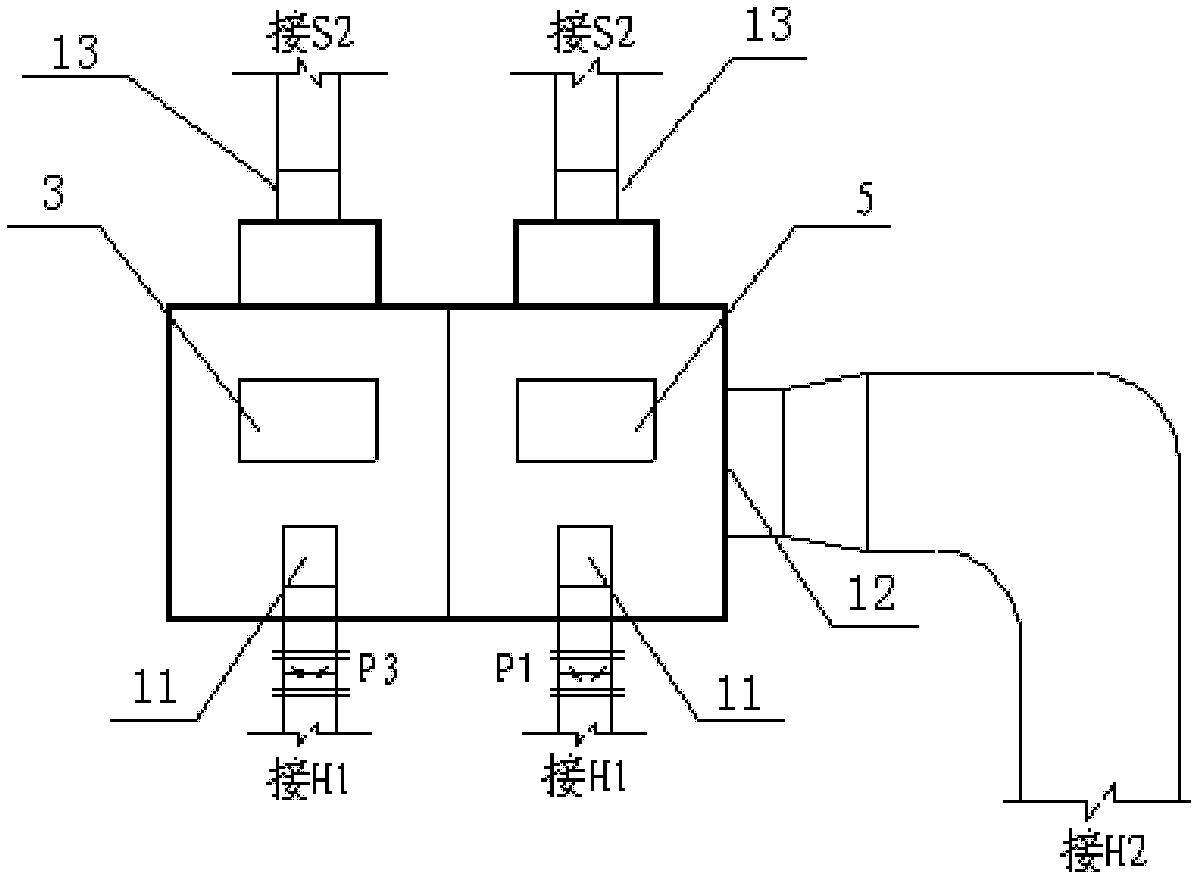

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0022] The energy-saving air-conditioning system for the environment of textile mills based on indirect evaporative cooling of the present invention has a structure such as figure 1 , figure 2 , image 3 As shown, it includes the evaporative cooling air-conditioning unit A and the pipes connecting the evaporative cooling air-conditioning unit A to the inside of the textile workshop B. The interior of the textile workshop B is divided into the concepts of large environment area and small environment area. The small environment area is defined as the area below 2m in height, and the large environment area is defined as the overall environment.

[0023] Evaporative cooling air conditioning unit A includes filter 1, plate indirect evaporative cooler 2, return air and process exhaust air mixing box 4, rectifying grille 6, water spray chamber 7,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com