Button protrusion structure and its manufacturing method

A protruding body and button technology, applied in the direction of electrical components, electric switches, circuits, etc., can solve the problems of difficult matching of materials and sizes, cumbersome steps, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

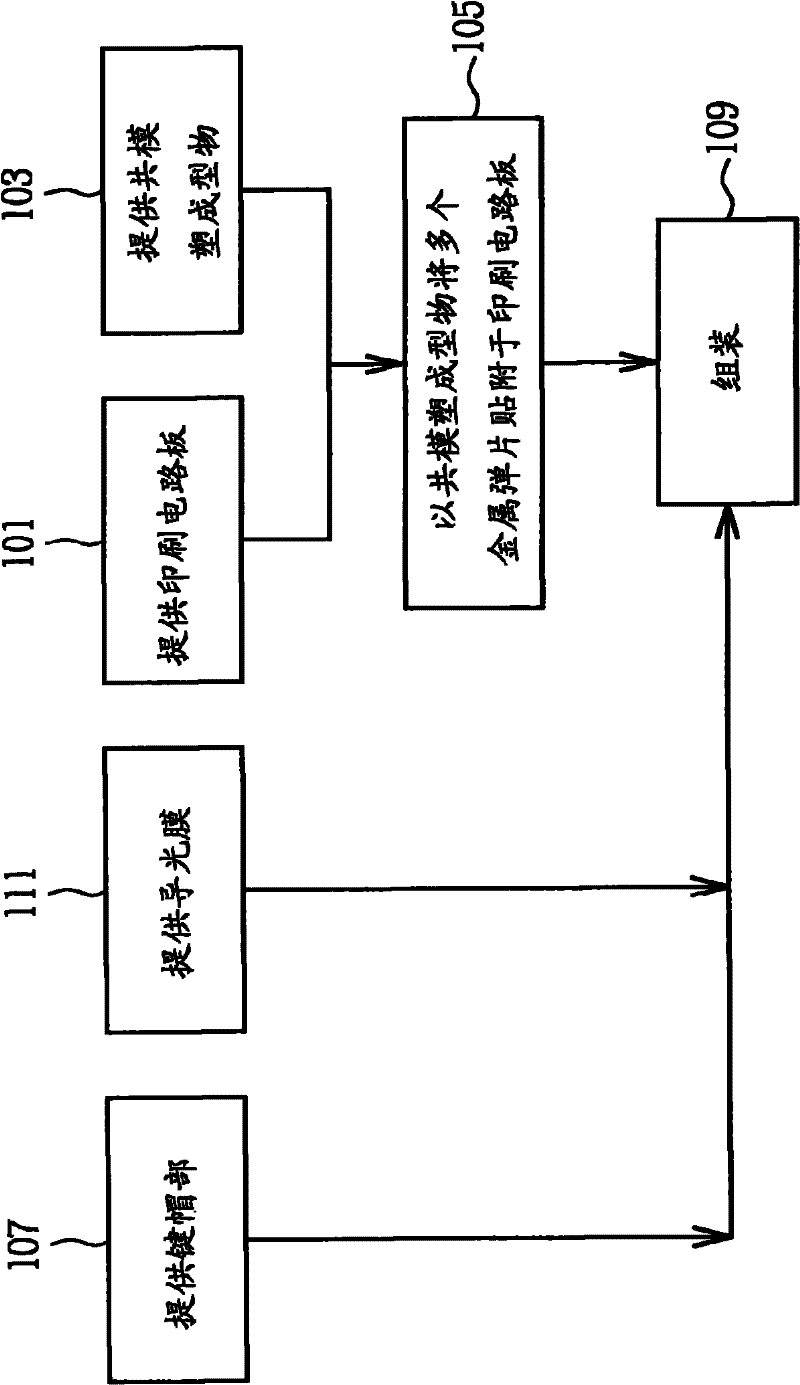

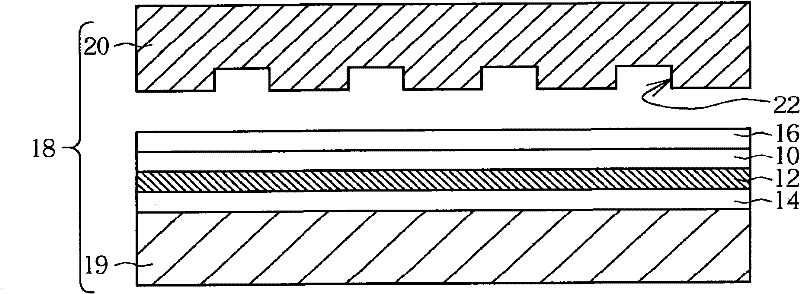

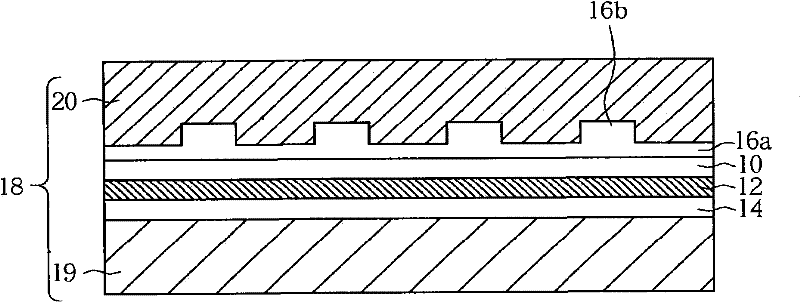

[0056] For a specific embodiment of the method for manufacturing the key convex structure according to the present invention, please refer to figure 1 Flow chart. Proceed to step 101 to provide a printed circuit board. Proceed to step 103 to provide a co-molded product, which includes a polymer film and a plurality of protrusions. The polymer film includes a first side and a second side. The protrusions are formed by a co-molding process and a polymer film. The first side is combined. Proceed to step 105 to attach a plurality of metal shrapnels to the printed circuit board with a co-molding molding. Make the positions of the protrusions correspond to the metal shrapnel respectively. Proceed to step 107 to provide a keycap part. Perform the assembly of step 109, and set the keycap structure above the co-molded product. Step 111 can be performed as needed to provide a light guide film. The light guide film can be arranged above the co-molding molding, and then the keycap str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com