Multi-pole DC molded case circuit breaker

A technology for plastic shells and circuit breakers, which is applied to circuit breaker components, circuit breaker contacts, circuits, etc., can solve the problems of difficult to break the DC fault arc and working voltage, and achieve low arc and working voltage, design Reasonable, the effect of increasing the rated working voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

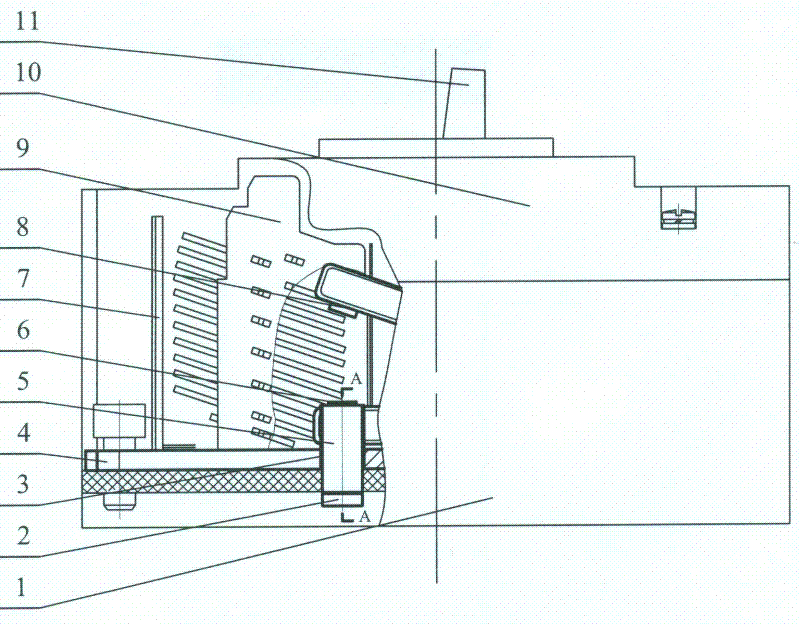

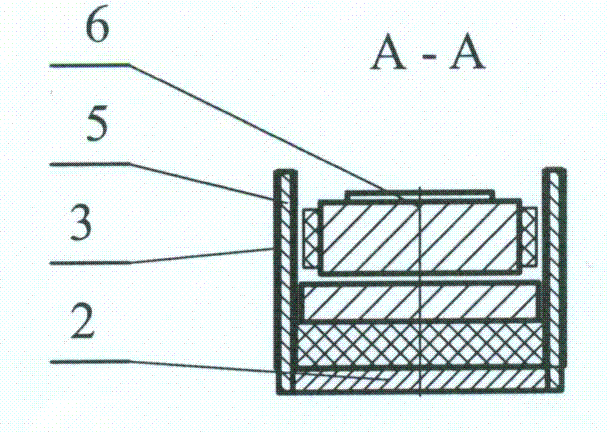

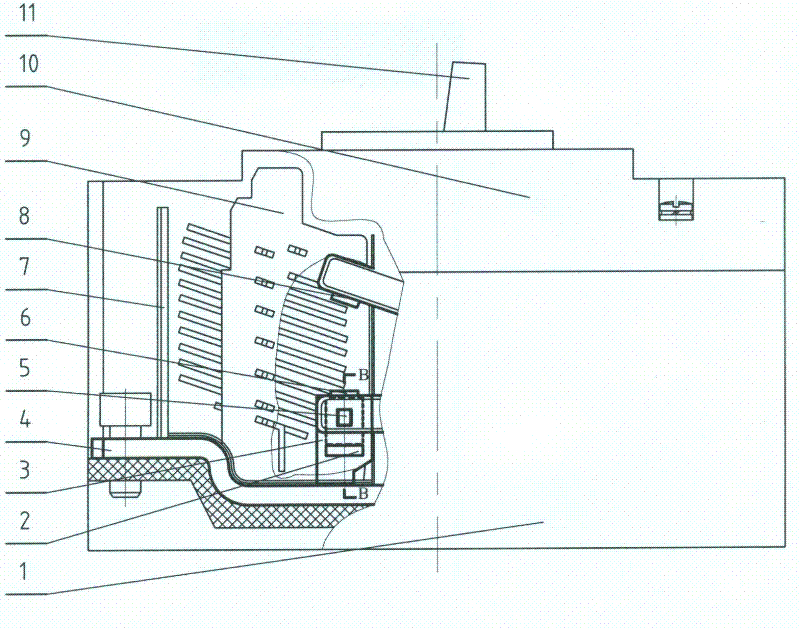

[0014] according to Figure 1~4 The specific structure of the present invention will be described in detail. The multi-pole DC plastic case circuit breaker is improved on the basis of the structure of the single break point contact system of the existing AC plastic case circuit breaker. The contact system in each breakpoint is mainly composed of moving contact 8 and static contact 6, overload protection release, short circuit protection release, terminal board 4, arc extinguishing chamber 9 of each pole and permanent magnet magnetic blower. Arc extinguishing mechanism. The specifications of the main components should meet the requirements of relevant standards, and the shell is made of bulk molding compound (DMC, also known as unsaturated polyester bulk molding compound). The permanent magnet magnetic blowing arc extinguishing mechanism includes a permanent magnet 2 and two magnetic guide plates 5, which are arranged at a single break point between the moving contact 8 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com