Devices for sorting and feeding tablets for forming

A tablet and holding groove technology, applied in the field of tablet devices, can solve the problems of increased tablet supply time cycle, low productivity, and simultaneous sensing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Reference will now be made in detail to these specific embodiments of the invention, examples of which are illustrated in the accompanying drawings.

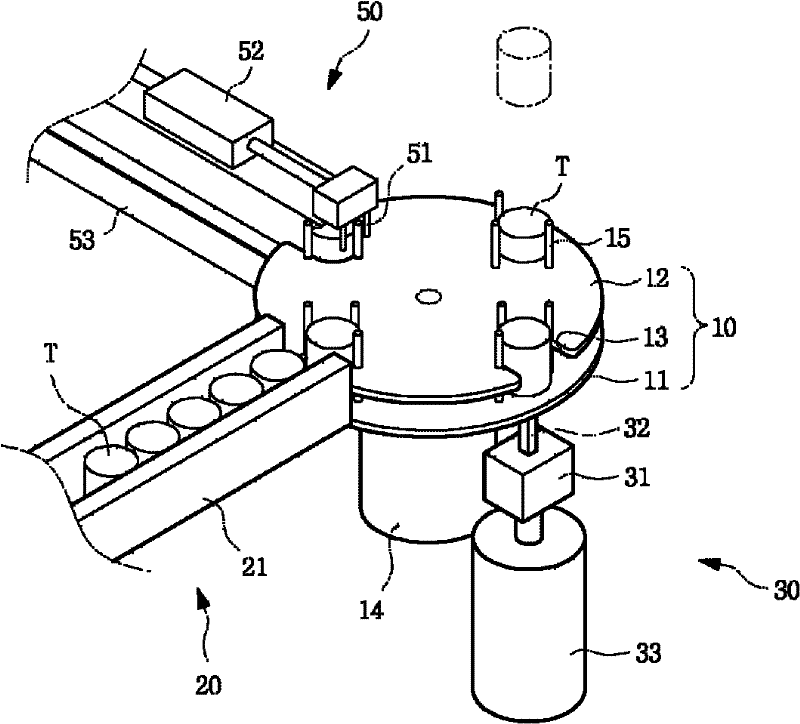

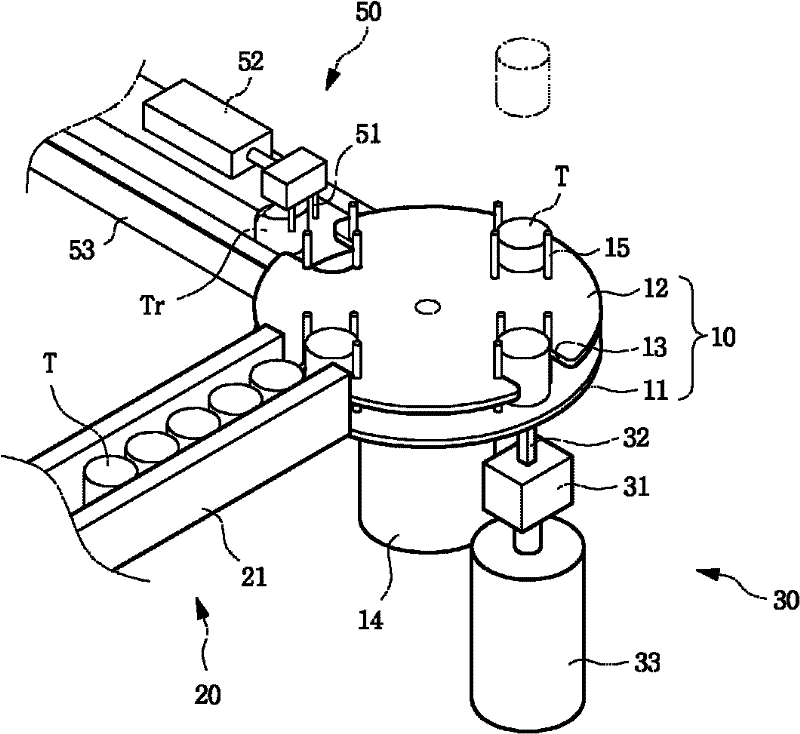

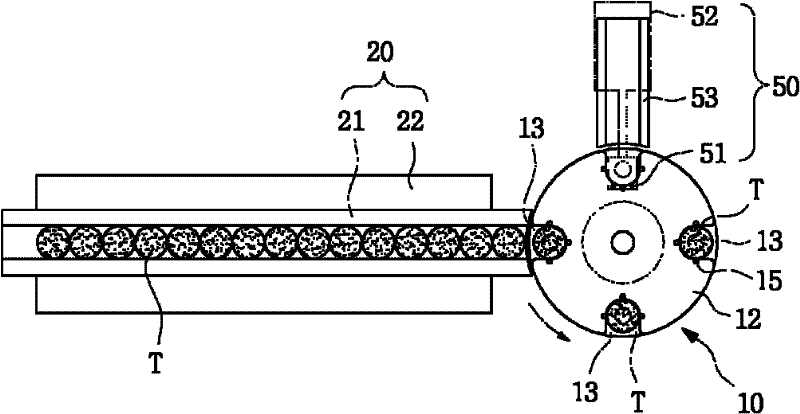

[0045] Figures 1 to 7 Each illustrates a device for sorting and feeding tablets according to a preferred embodiment of the present invention. refer to figure 1 , 3 and 6, the device for classifying and supplying tablets for molding comprises: a tablet supply unit 20, which supplies a cylindrical tablet T for molding; a rotary block 10, which is formed at intervals of 90 degrees in the circumferential direction There are a plurality of (4 in this specific embodiment) holding grooves 13, and each of these holding grooves 13 is used to hold the tablet T from the tablet supply unit 20; a detection unit 30, which is used to detect the rotary block 10 Whether there is any defect in the tablet T in the holding tank 13; a tablet transfer unit 40, which is used to transfer the tablet T determined to be of high quality from the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com