Subsea Control System Diagnostics

A technology of hydraulic control system and subsea control module, which is applied in fluid pressure actuation system testing, wellbore/well components, instruments, etc., and can solve the problems of expensive and time-consuming subsea equipment failure intervention or maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

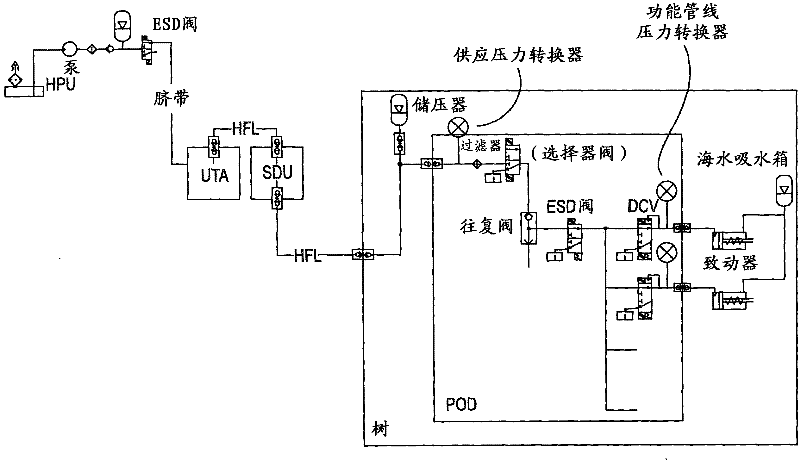

[0018] Introduction to the control system

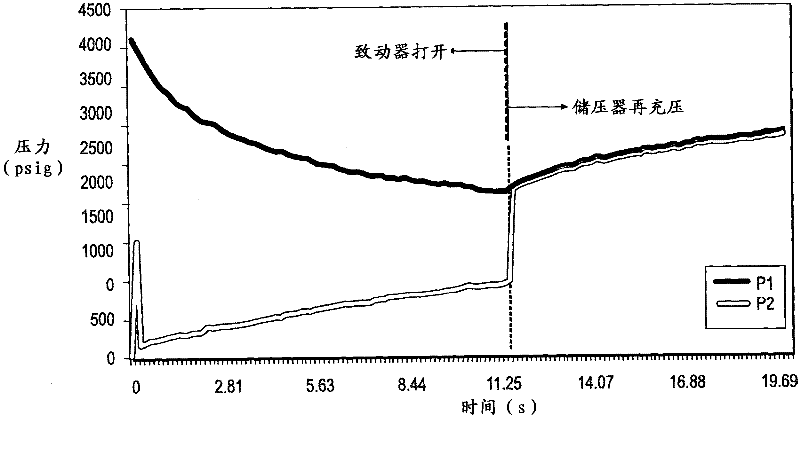

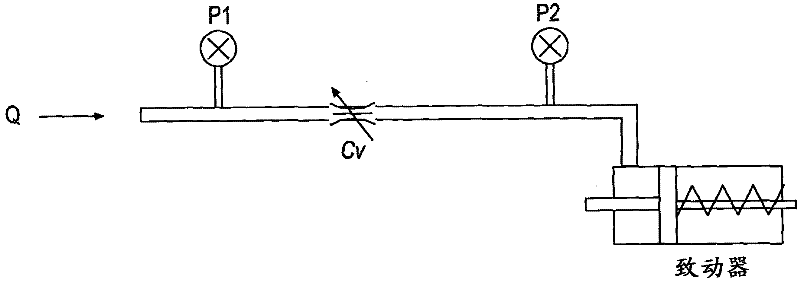

[0019] figure 1 is a schematic diagram of a general hydraulic control system. At sea, hydraulic fluid is pumped from a hydraulic power unit (HPU) into an umbilical that terminates in an umbilical termination assembly (UTA). For projects with long guy lines, the control fluid should be modeled as a compressible flow in the umbilical. Through the Subsea Distribution Unit (SDU), a series of tree valves are opened through DCVs controlled by the SCM. Subsea accumulators provide a localized source of pressure to help open valves faster, as well as cushioning to absorb shocks and irregularities in the flow. Leakage of the precharge gas may cause the pressure accumulator to lose its function, and thus, may affect the performance of the entire hydraulic control system. Subsea filters help keep hydraulic fluid clean. Dirty fluids can cause damage to the flow passages, as well as failure of, for example, solenoid valves. The actuator used...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com