Patents

Literature

71results about How to "Predict failure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

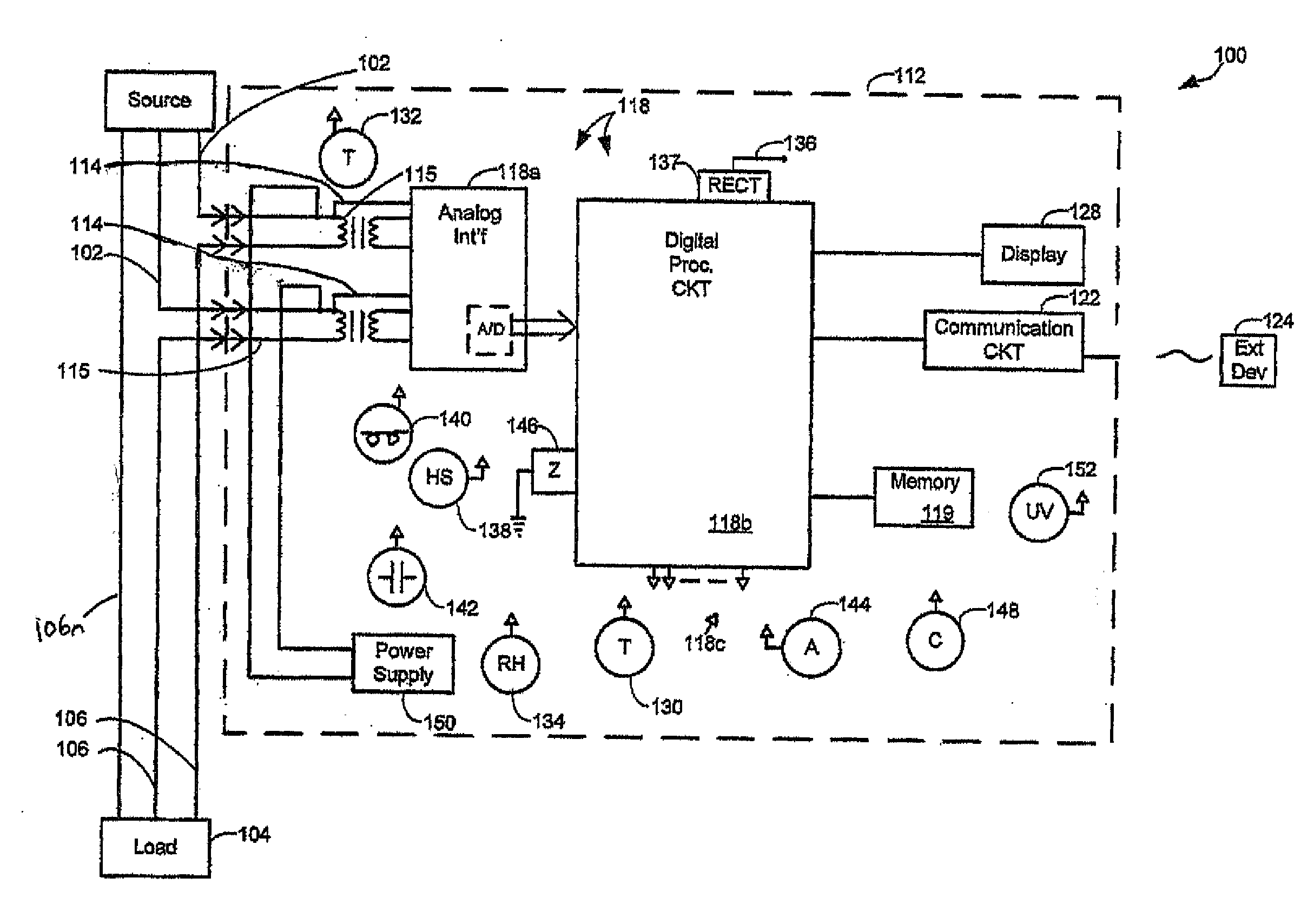

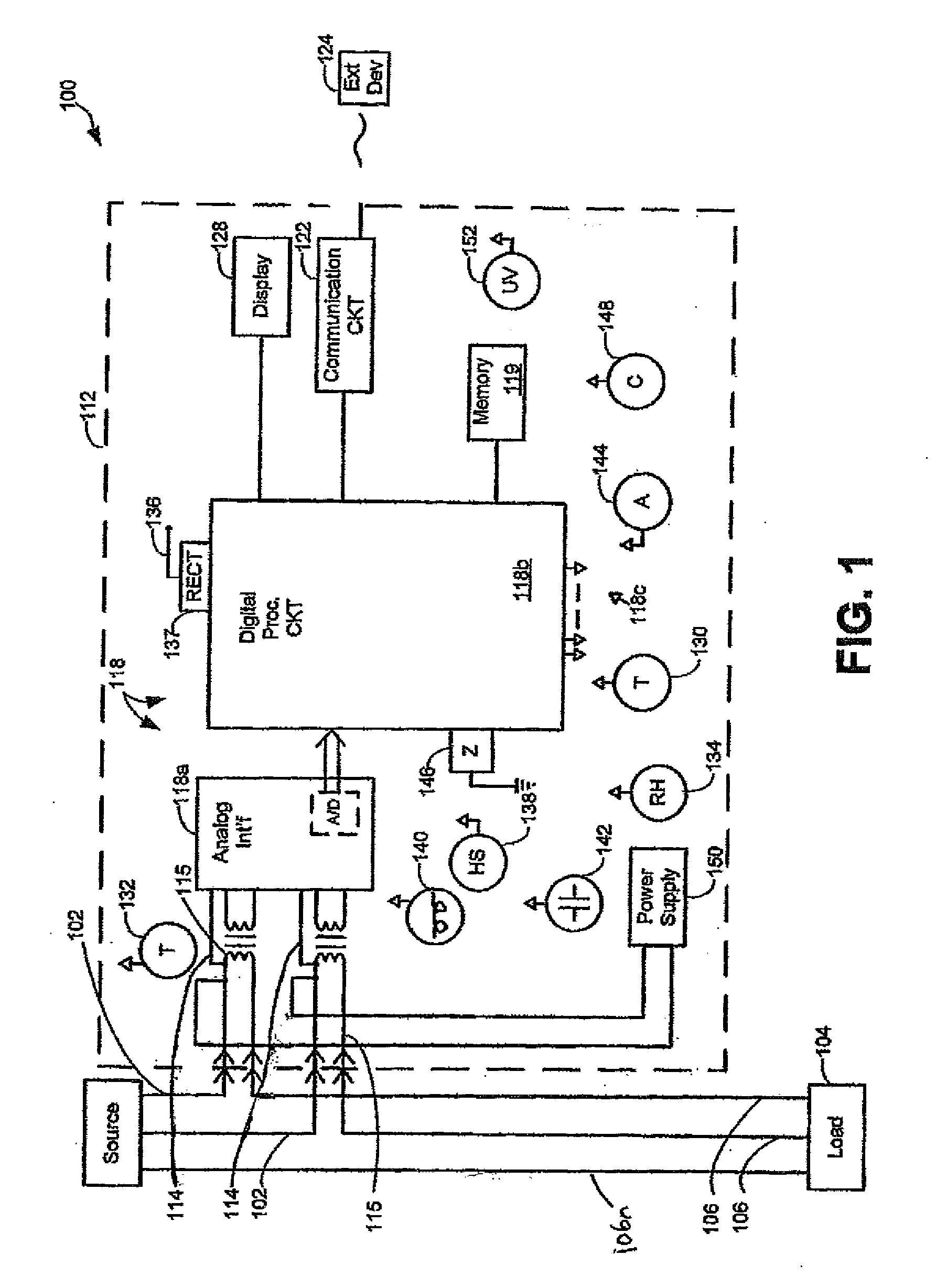

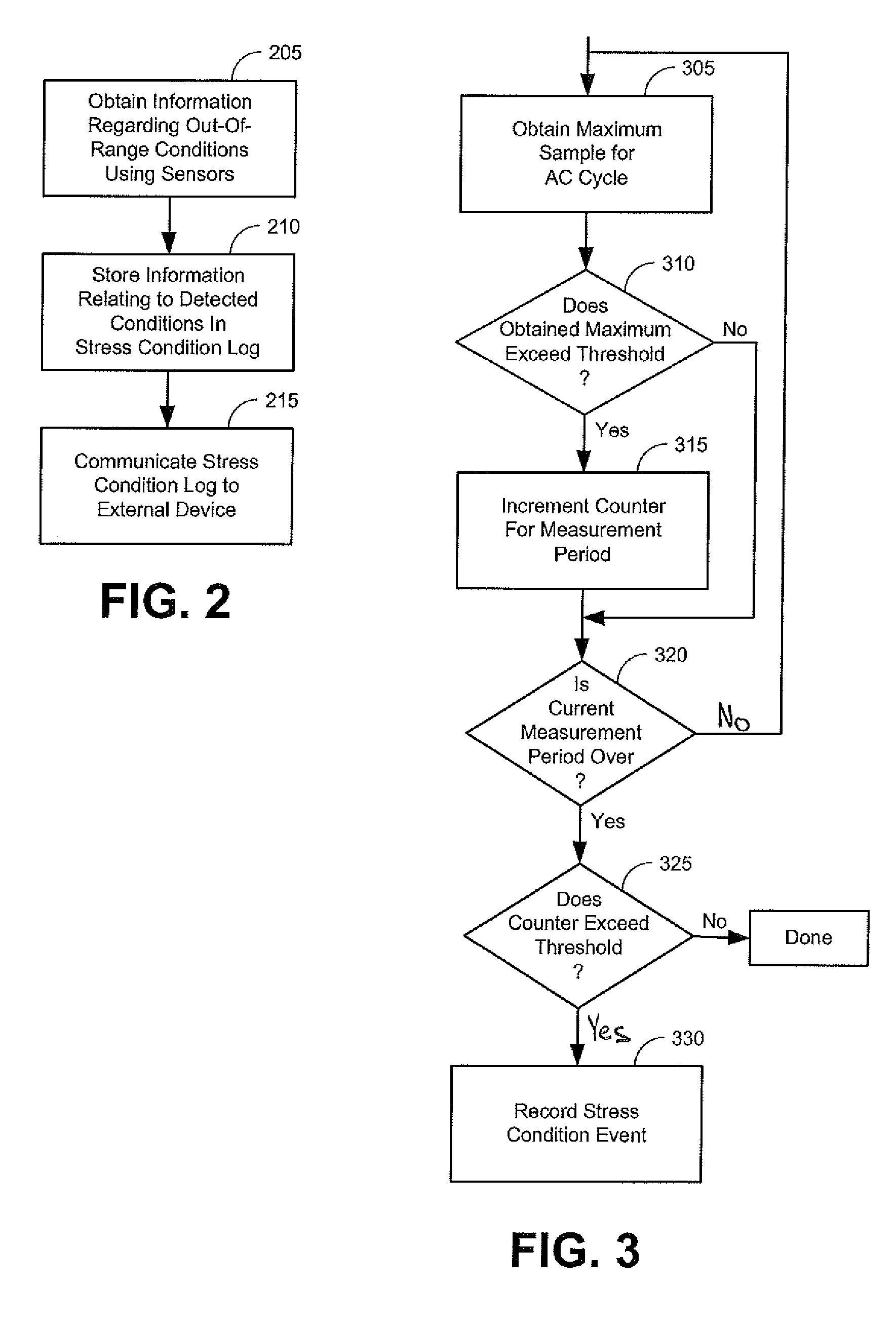

Stress condition logging in utility meter

InactiveUS20100036624A1Reduce numberReduce in quantityThermometer detailsElectric devicesEngineeringStress conditions

An arrangement includes a utility meter housing that contains or supports a first sensor, a second sensor, and a processing circuit. The first sensor is configured to measure a first parameter, the first parameter relating to an environmental condition within the meter housing. The second sensor is configured to measure a second parameter. The processing circuit is operably connected to the first sensor and to the second sensor, and is configured to record information relating to one or more events, each event corresponding to a detection of an out of range condition by each of the first sensor and the second sensor.

Owner:LANDIS GYR LLC

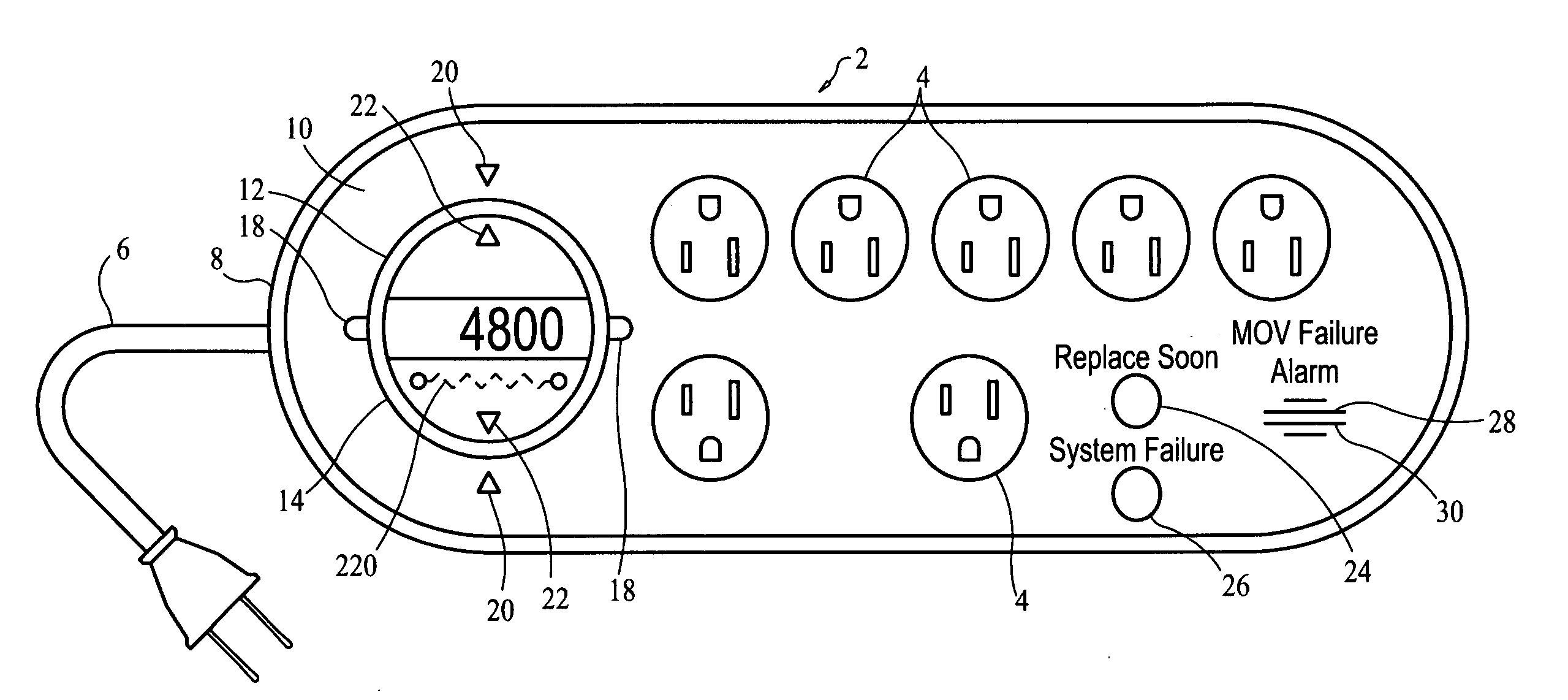

Home control protection system

InactiveUS20090207034A1Improve working conditionsStop workingEmergency protective arrangement detailsAlarmsProtection systemHome control

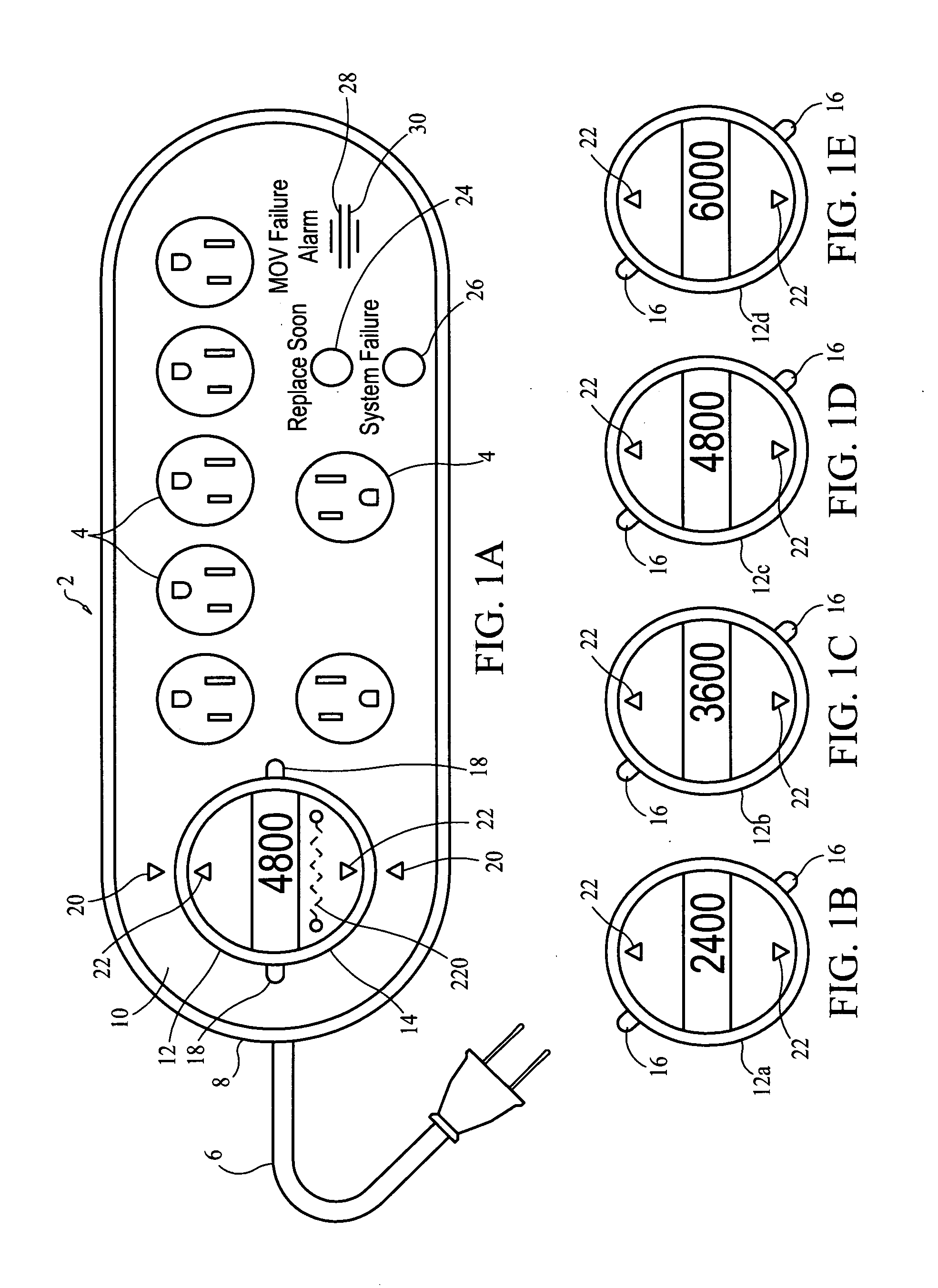

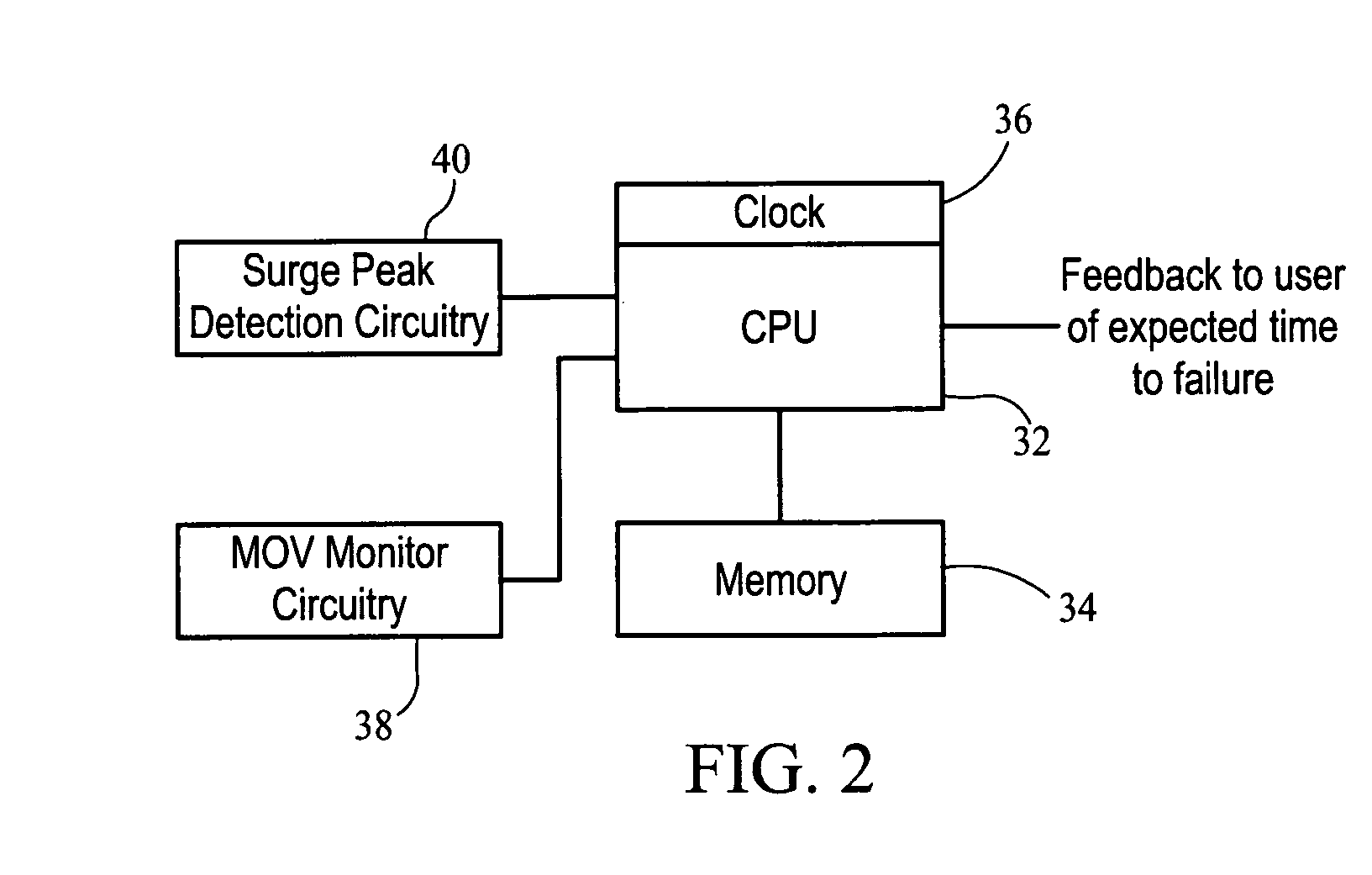

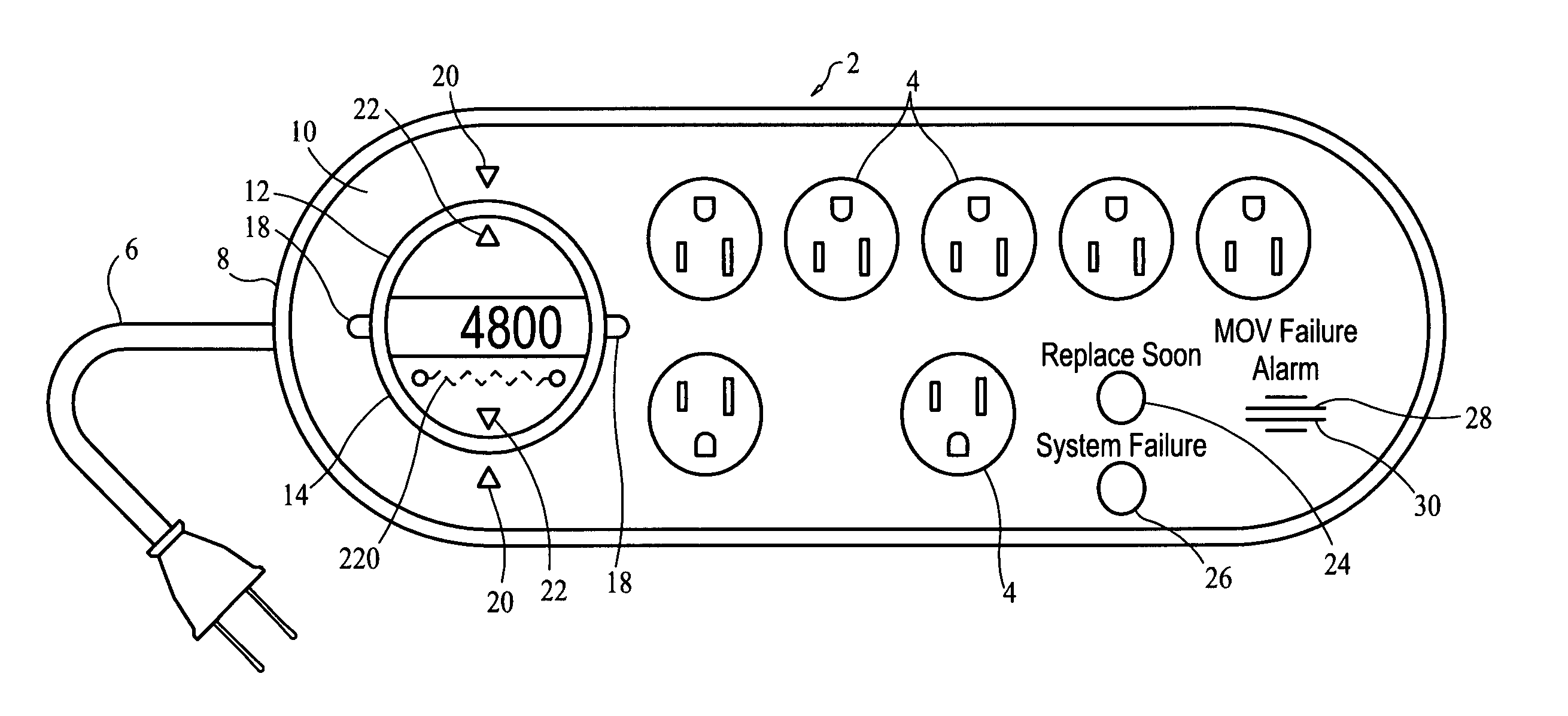

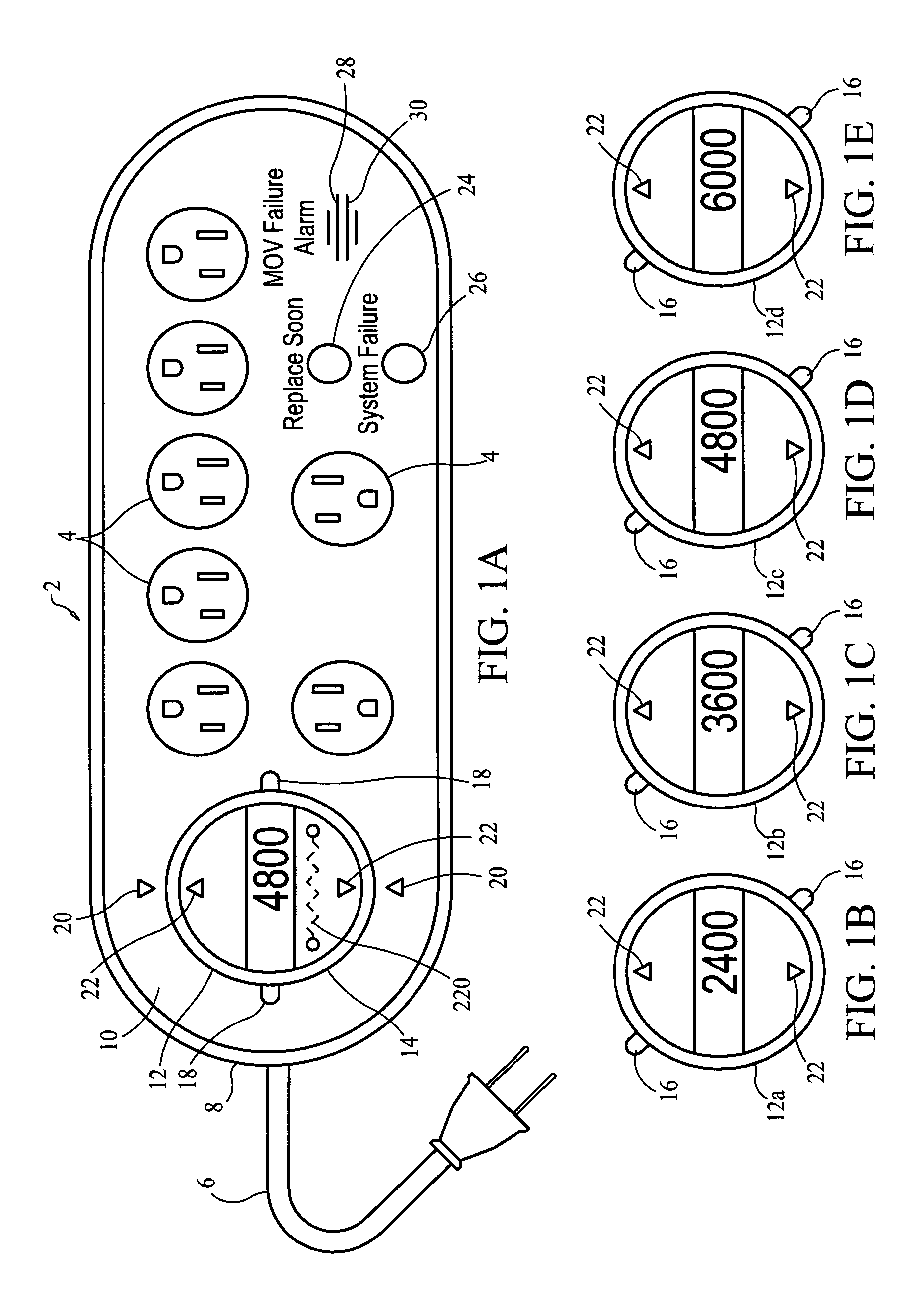

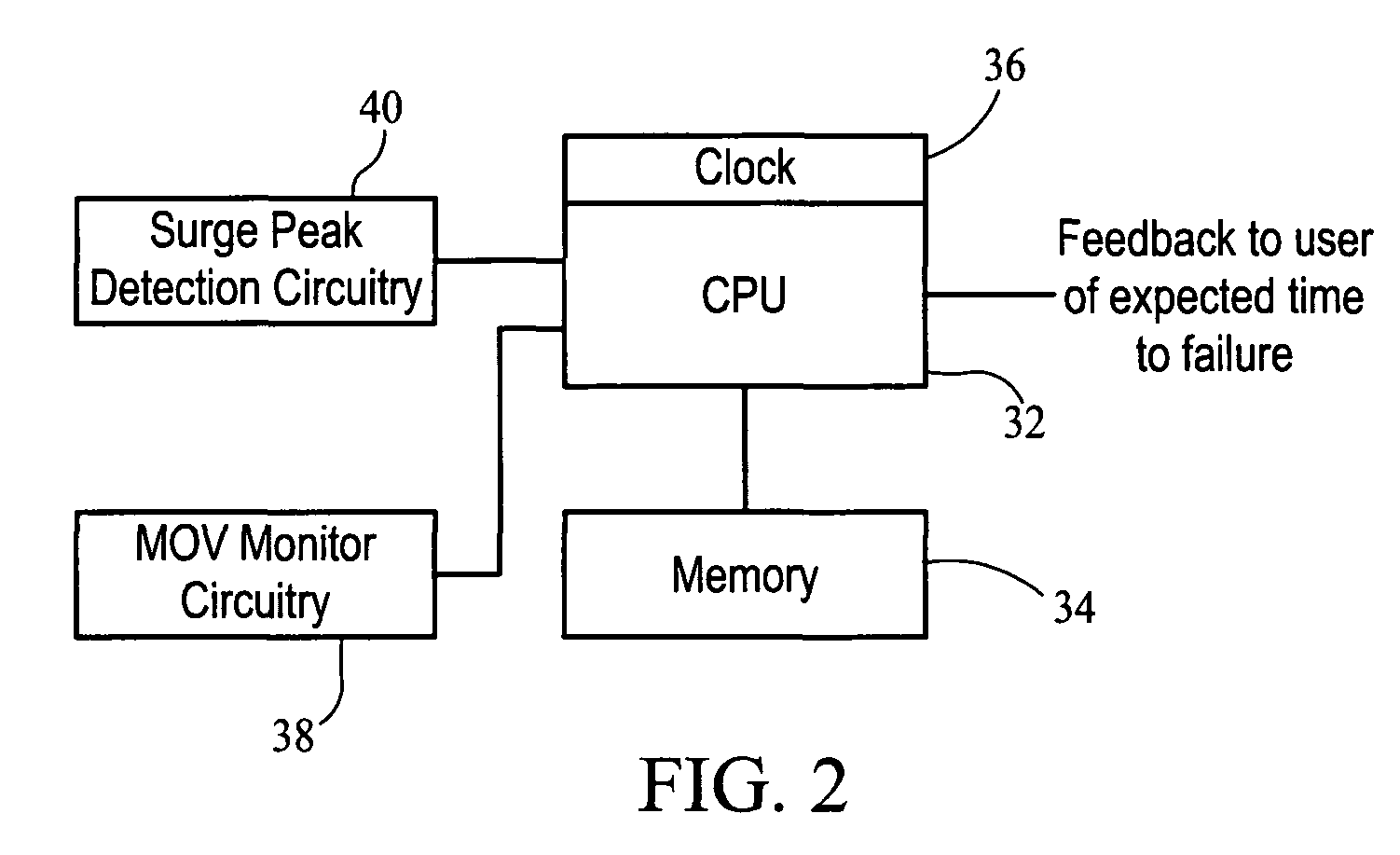

A home control protection system includes at least one surge protection strip having a plurality of power outlet receptacles, and a wall mountable central control unit that is in electrical communication with the at least one surge protection strip. The surge protection strip includes a replaceable surge protector module. The surge protection strip includes a circuit for detecting and counting the number of power surges which are shunted by the surge protector module, and compares the number of power surges with a predetermined threshold power surge number that corresponds to a predicted maximum number of power surges before failure of the surge protector module will occur.

Owner:VOXX INTERNATIONAL

Home control protection system

InactiveUS7961111B2Improve working conditionsStop workingEmergency protective arrangement detailsAlarmsComputer moduleProtection system

A home control protection system includes at least one surge protection strip having a plurality of power outlet receptacles, and a wall mountable central control unit that is in electrical communication with the at least one surge protection strip. The surge protection strip includes a replaceable surge protector module. The surge protection strip includes a circuit for detecting and counting the number of power surges which are shunted by the surge protector module, and compares the number of power surges with a predetermined threshold power surge number that corresponds to a predicted maximum number of power surges before failure of the surge protector module will occur.

Owner:VOXX INTERNATIONAL

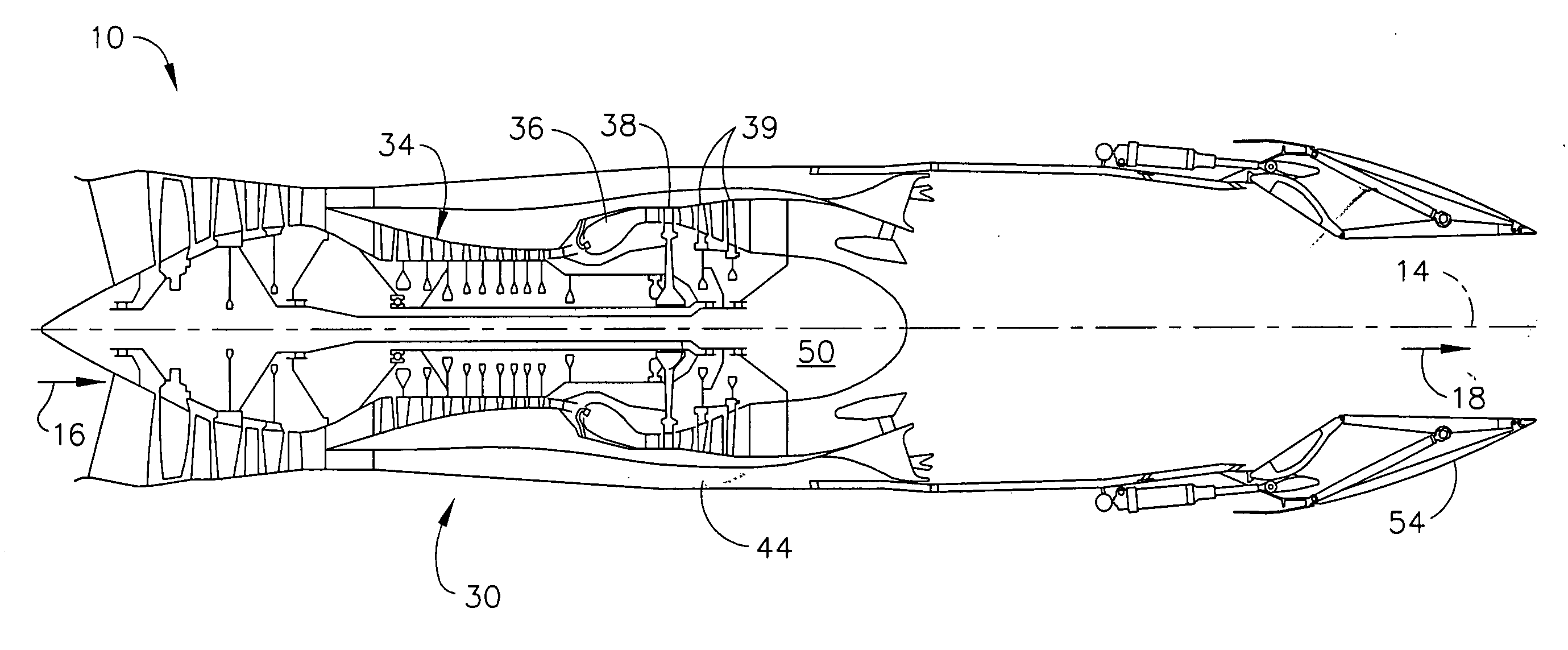

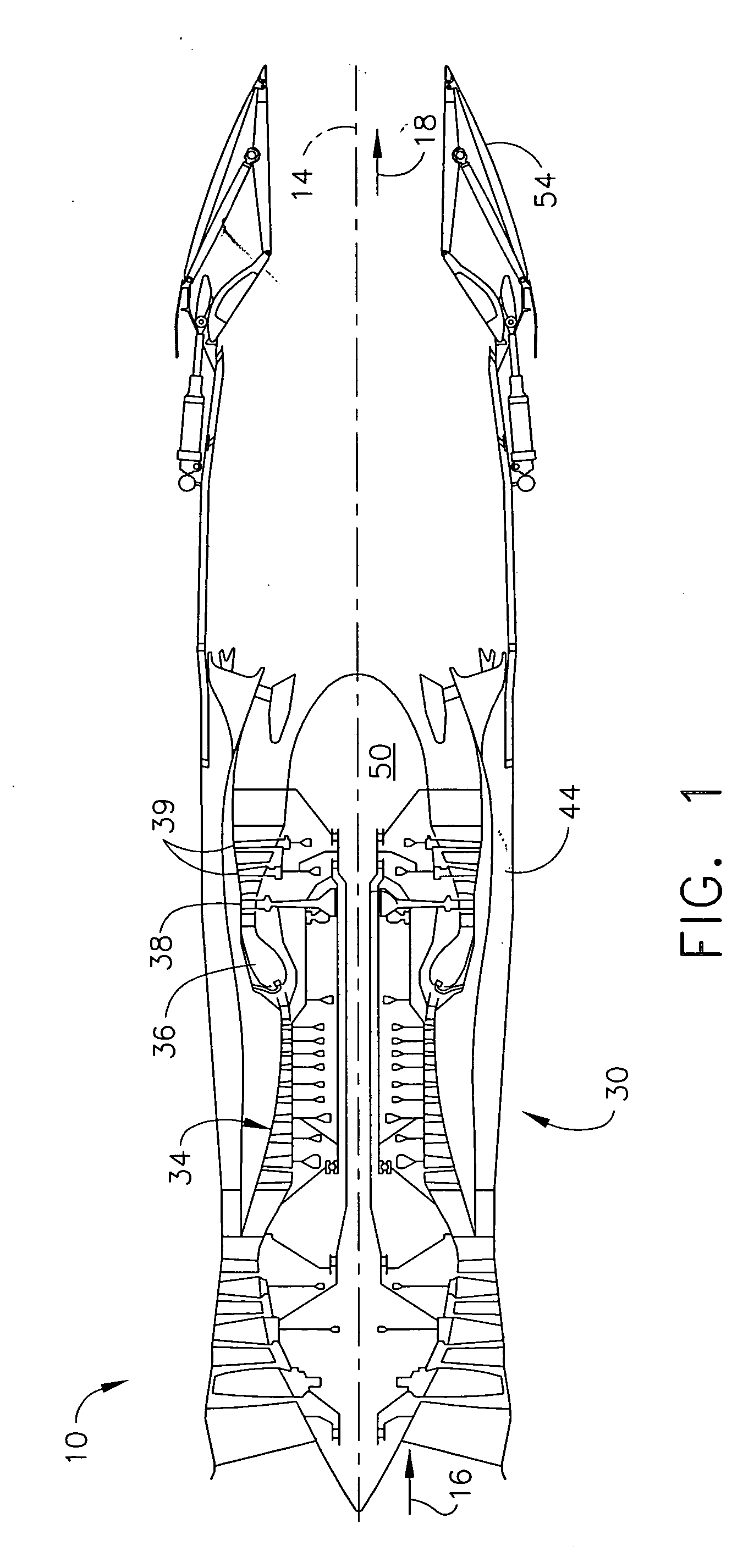

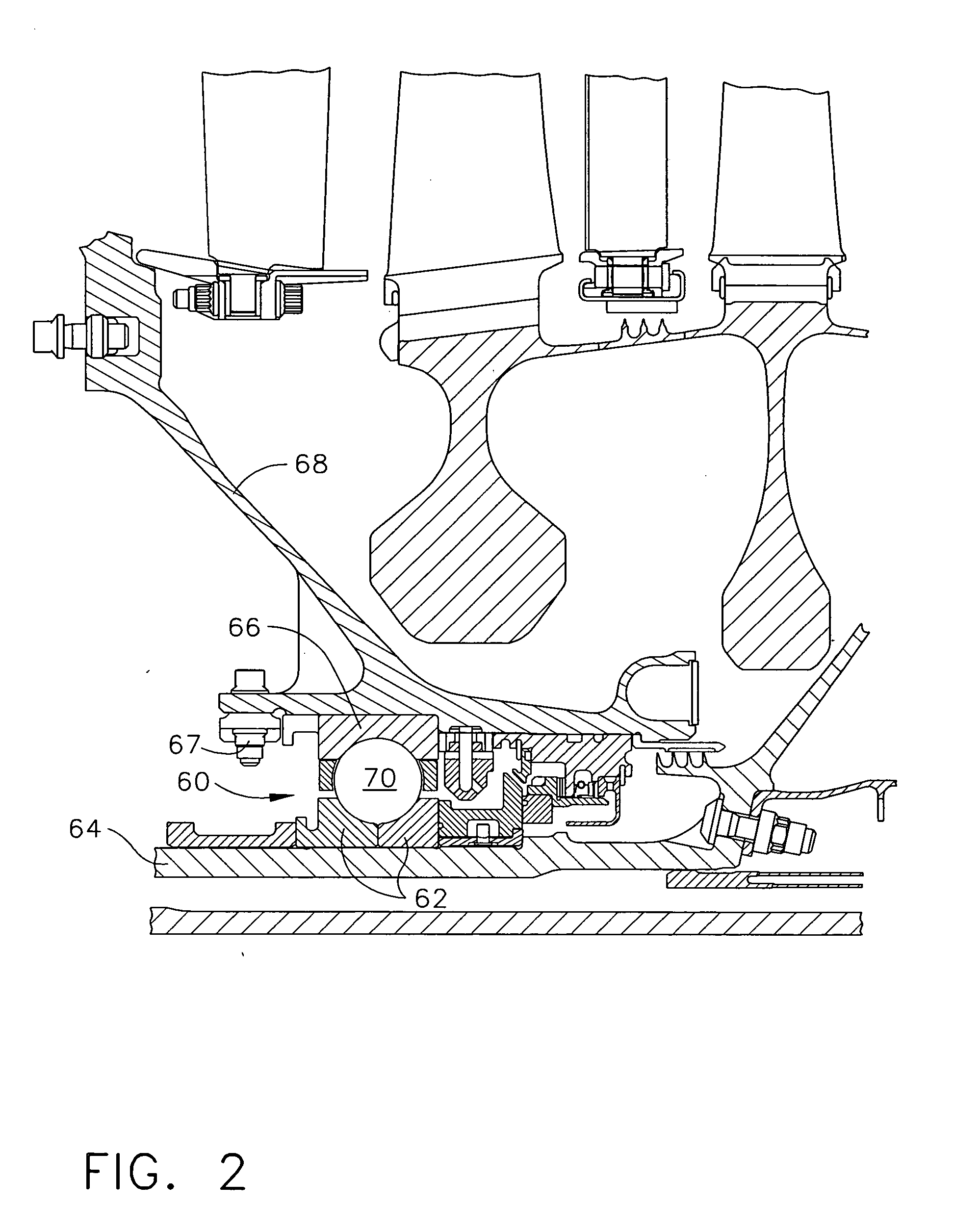

Methods and apparatus for assembling a bearing assembly

InactiveUS20050286823A1Predict failureVibration measurement in solidsMachine part testingPerformance modelElectrical and Electronics engineering

A method for predicting bearing failure, wherein the bearing includes an inner race, an outer race, and a plurality of rolling elements between the inner and outer race. The method includes coupling a sensor assembly to the outer race, the sensor assembly including at least one temperature sensor and at least one acoustic sensor, generating a bearing performance model based on an initial signal received from the sensor assembly, receiving a second signal from the sensor assembly, and comparing the second signal to the bearing performance model to predict a bearing failure.

Owner:GENERAL ELECTRIC CO

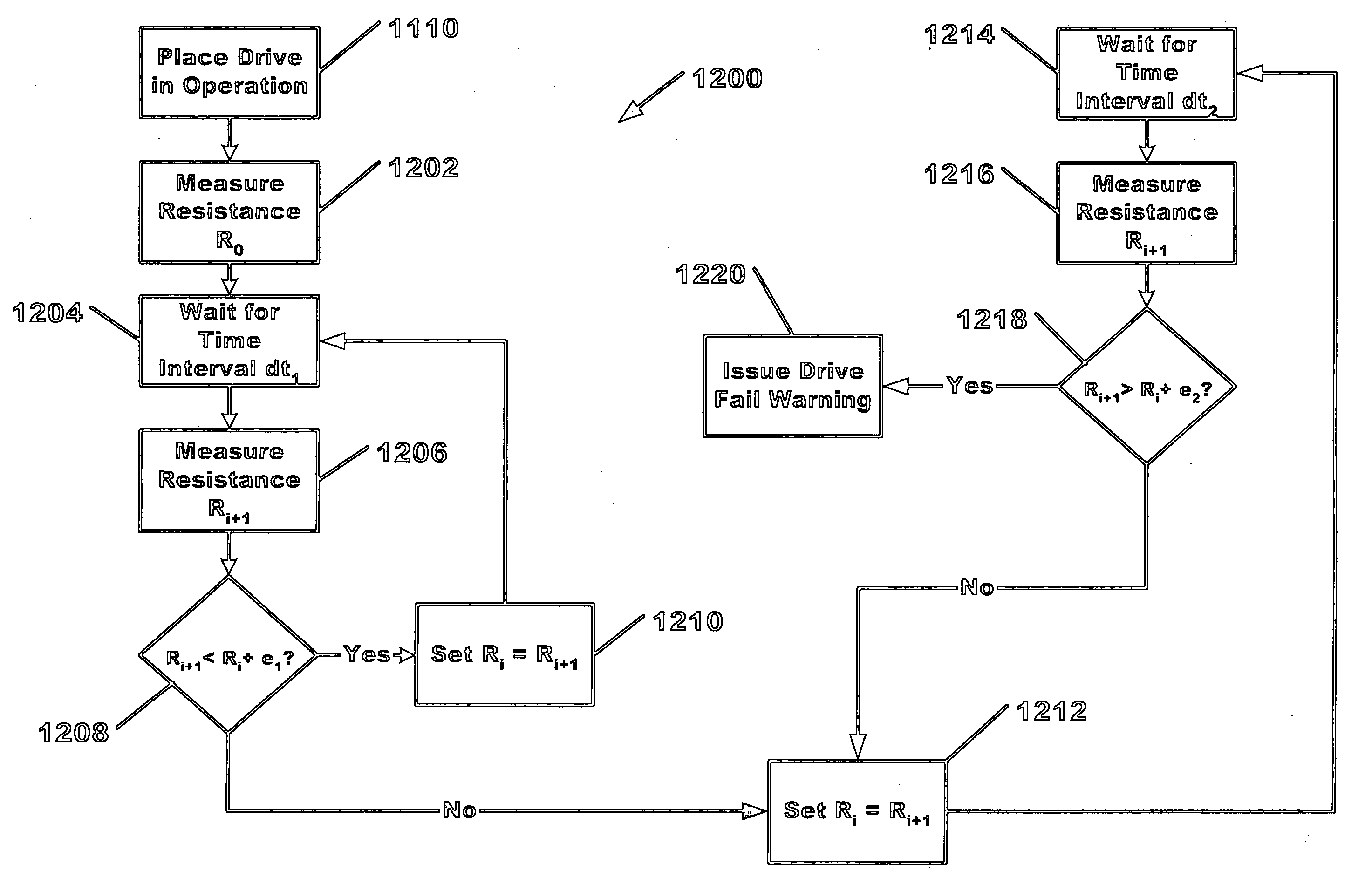

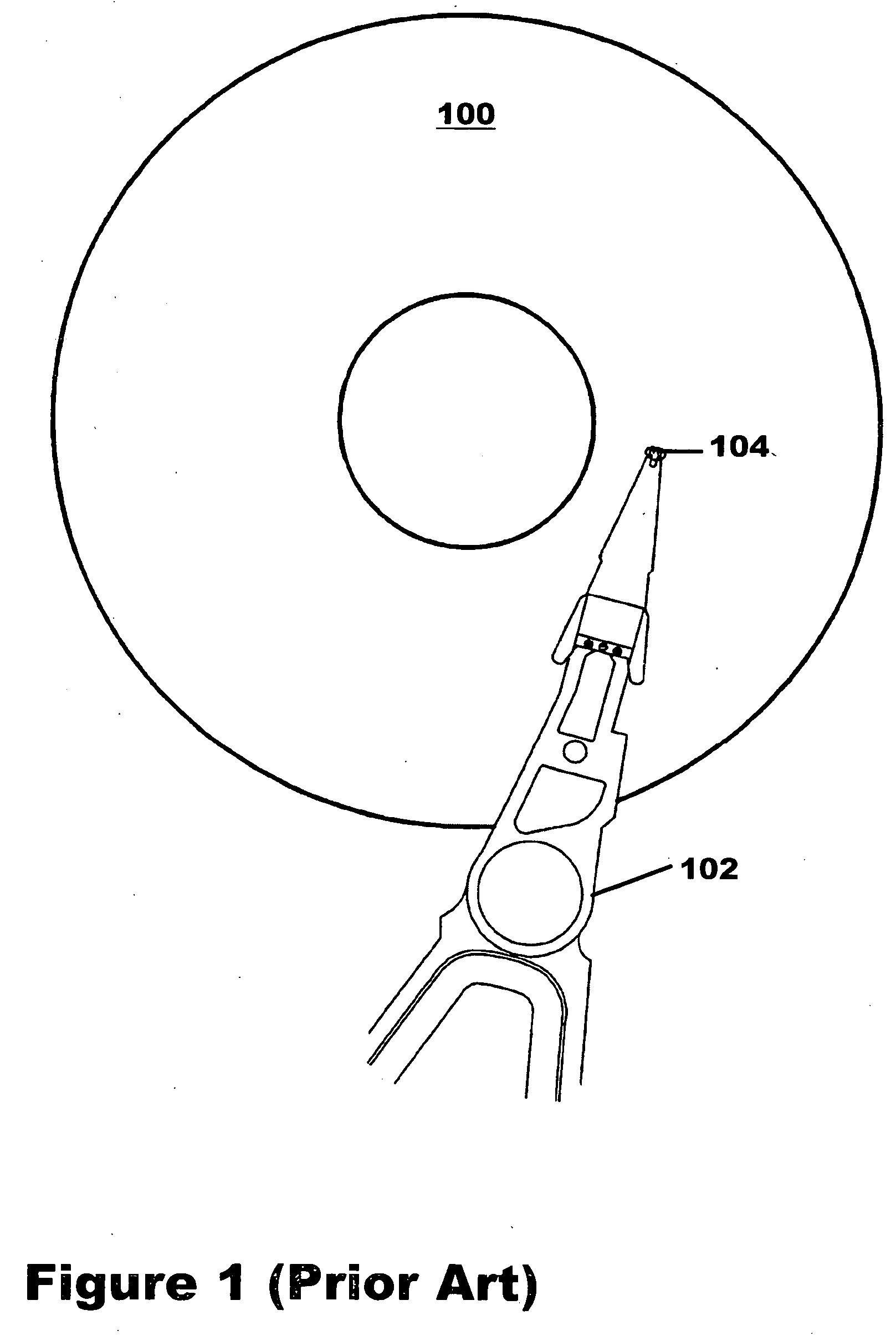

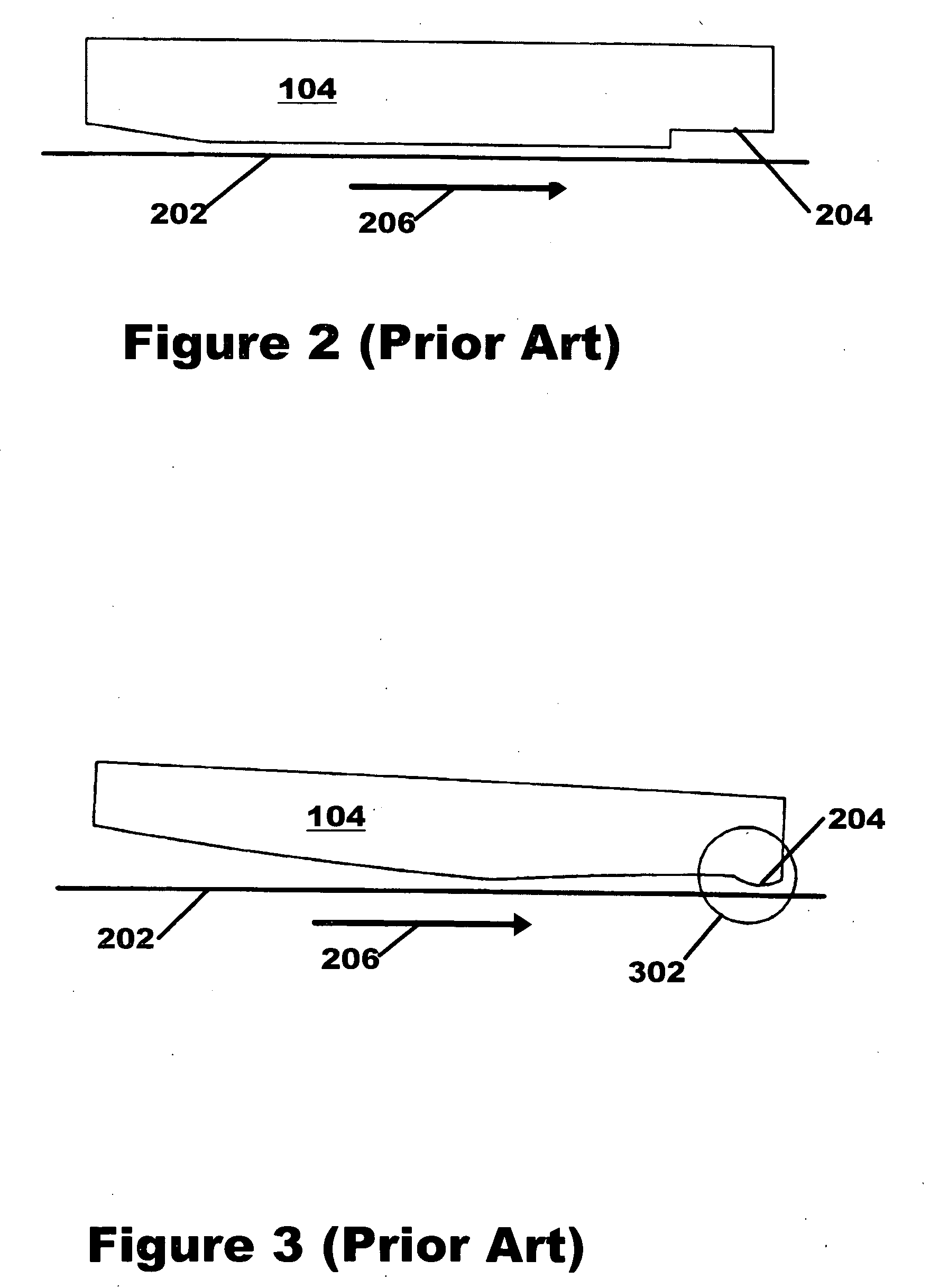

Predictive failure analysis of thermal flying height control system and method

InactiveUS20070014041A1Predict failureDriving/moving recording headsRecord information storageControl systemPredictive failure analysis

A method for predicting the failure of a data storage device having a slider heater is disclosed. For slider heaters exhibiting a decreasing resistance aging characteristic, a failure warning is produced when heater resistance suddenly increases 2 to 5%, or dR / dt changes sign from negative to positive. For slider heaters exhibiting an increasing resistance aging characteristic, a failure warning is produced when the heater resistance suddenly drops 2 to 5%, or dR / dt changes sign from positive to negative. Additionally, random changes in heater resistance exceeding nominal measurement error may also be utilized to produce a failure warning. This method provides advance warning of potential data read / write errors well before the open circuit failure of the slider heater occurs.

Owner:WESTERN DIGITAL TECH INC

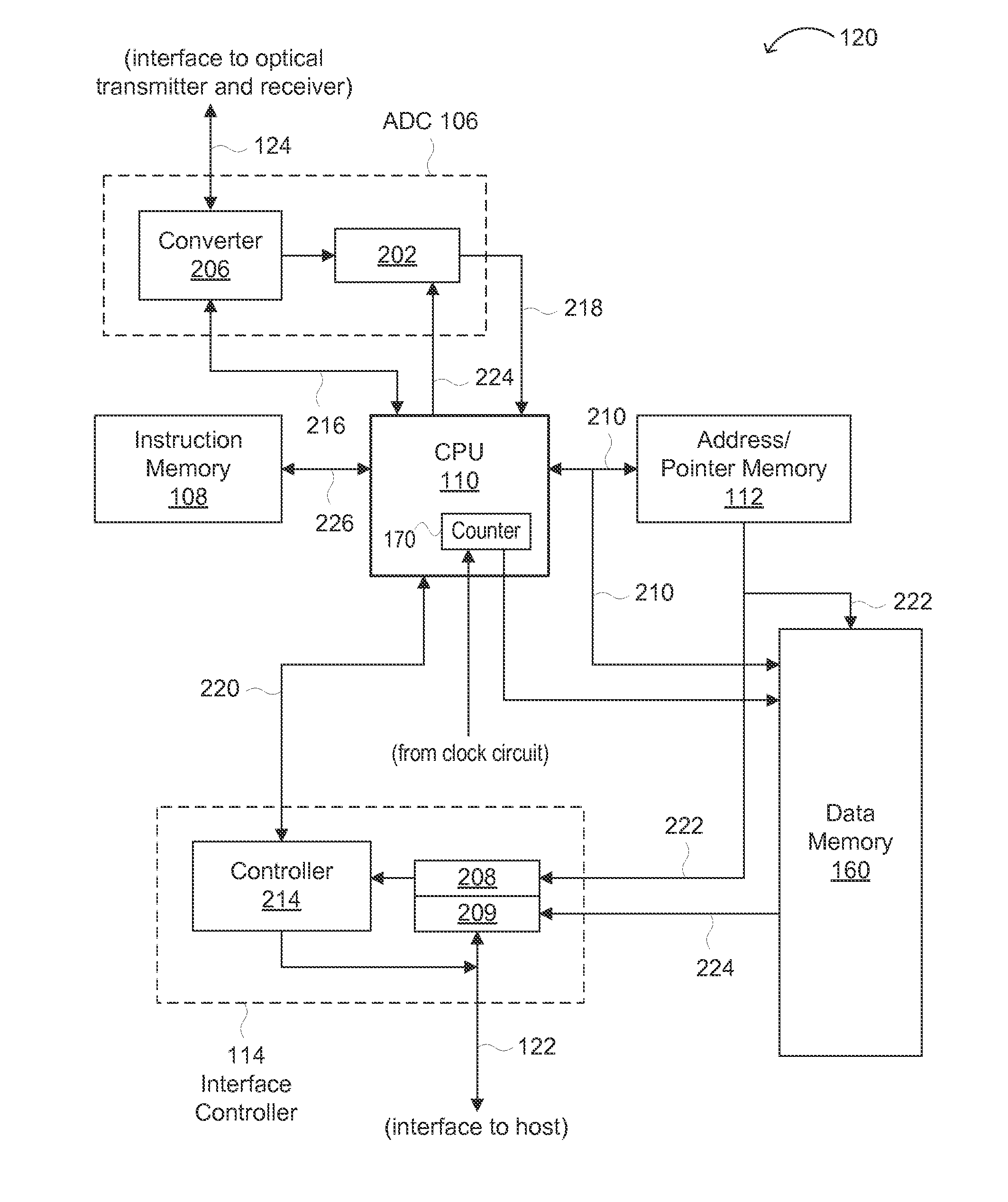

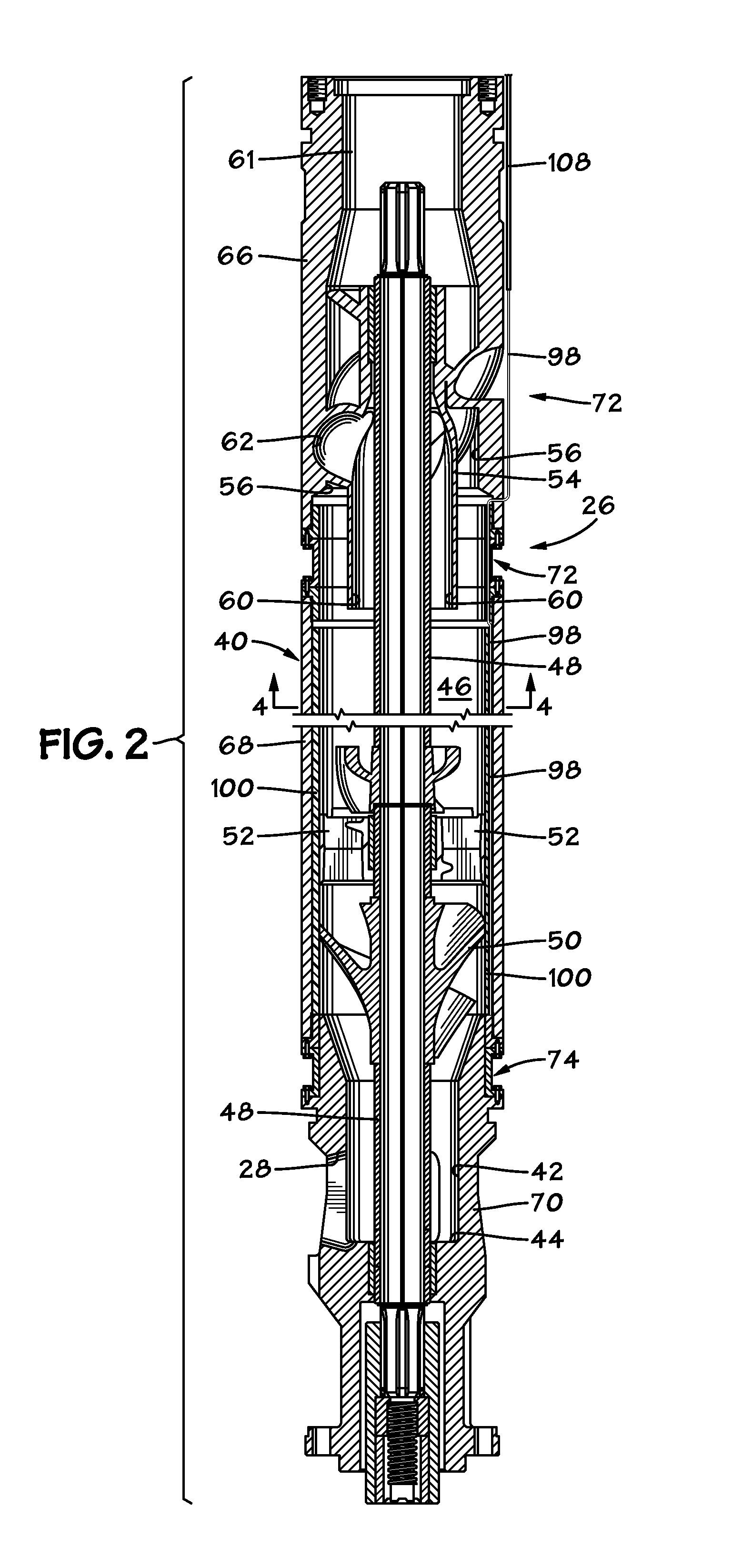

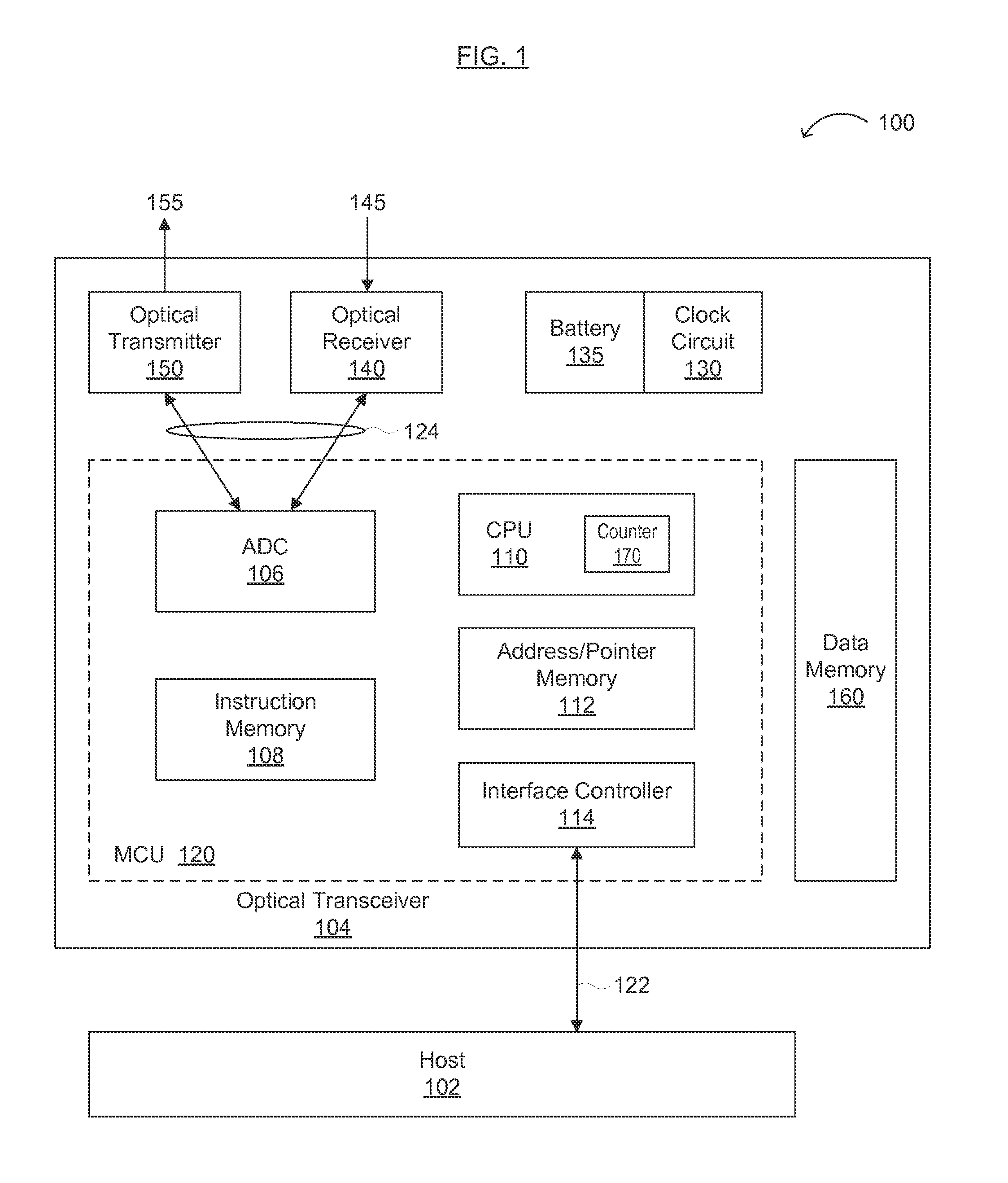

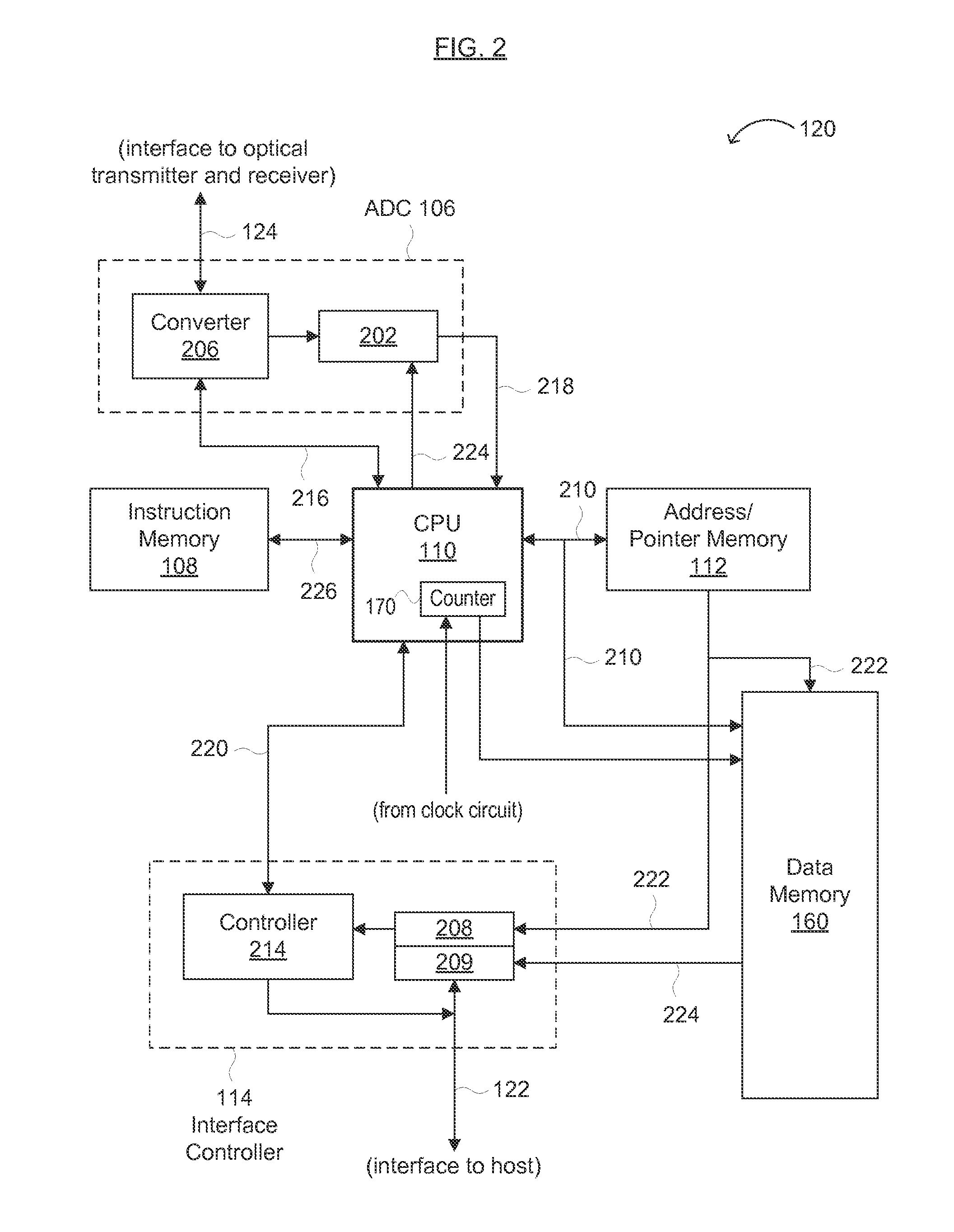

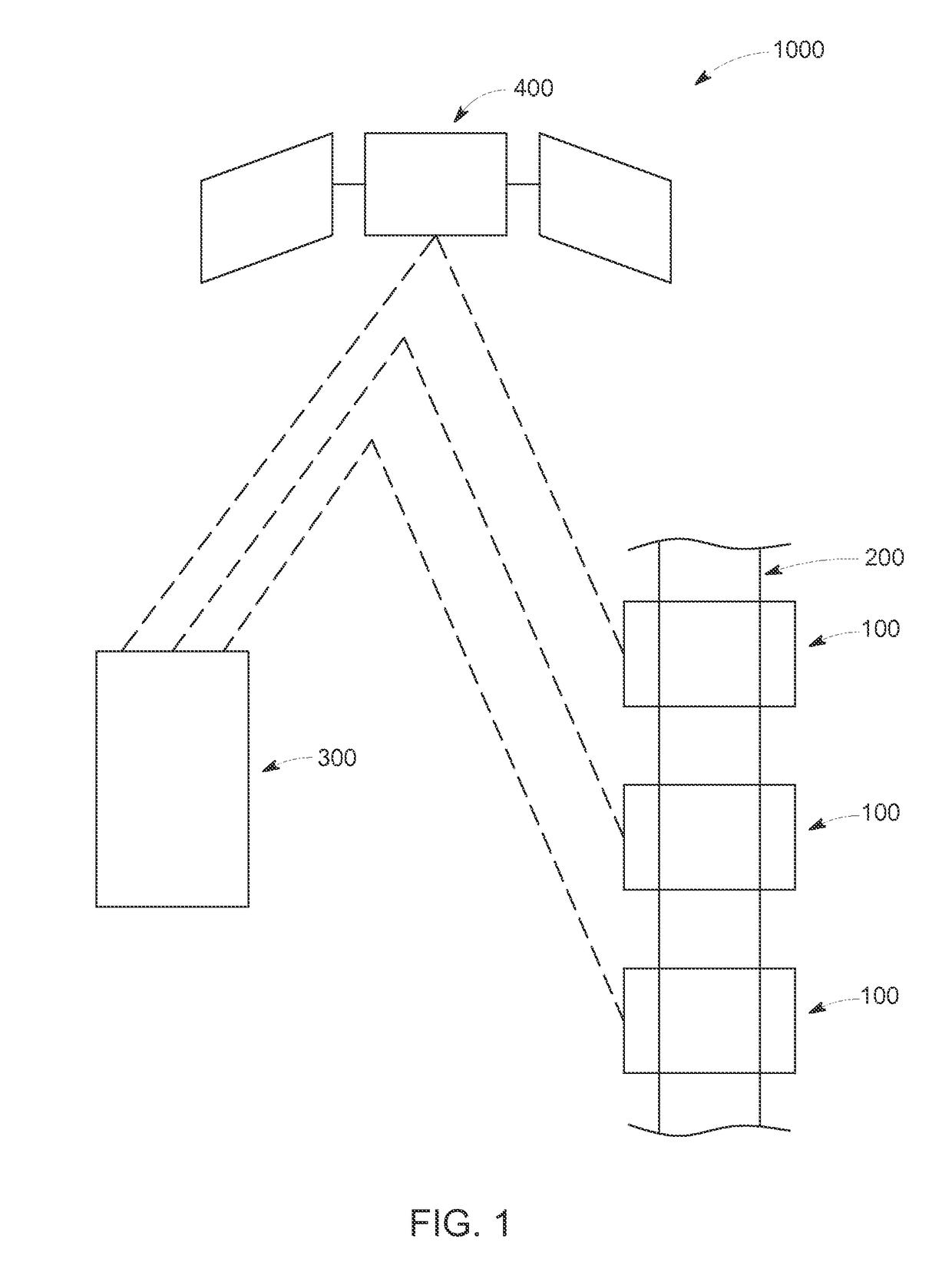

Enhanced Status Monitoring, Storage and Reporting for Optical Transceivers

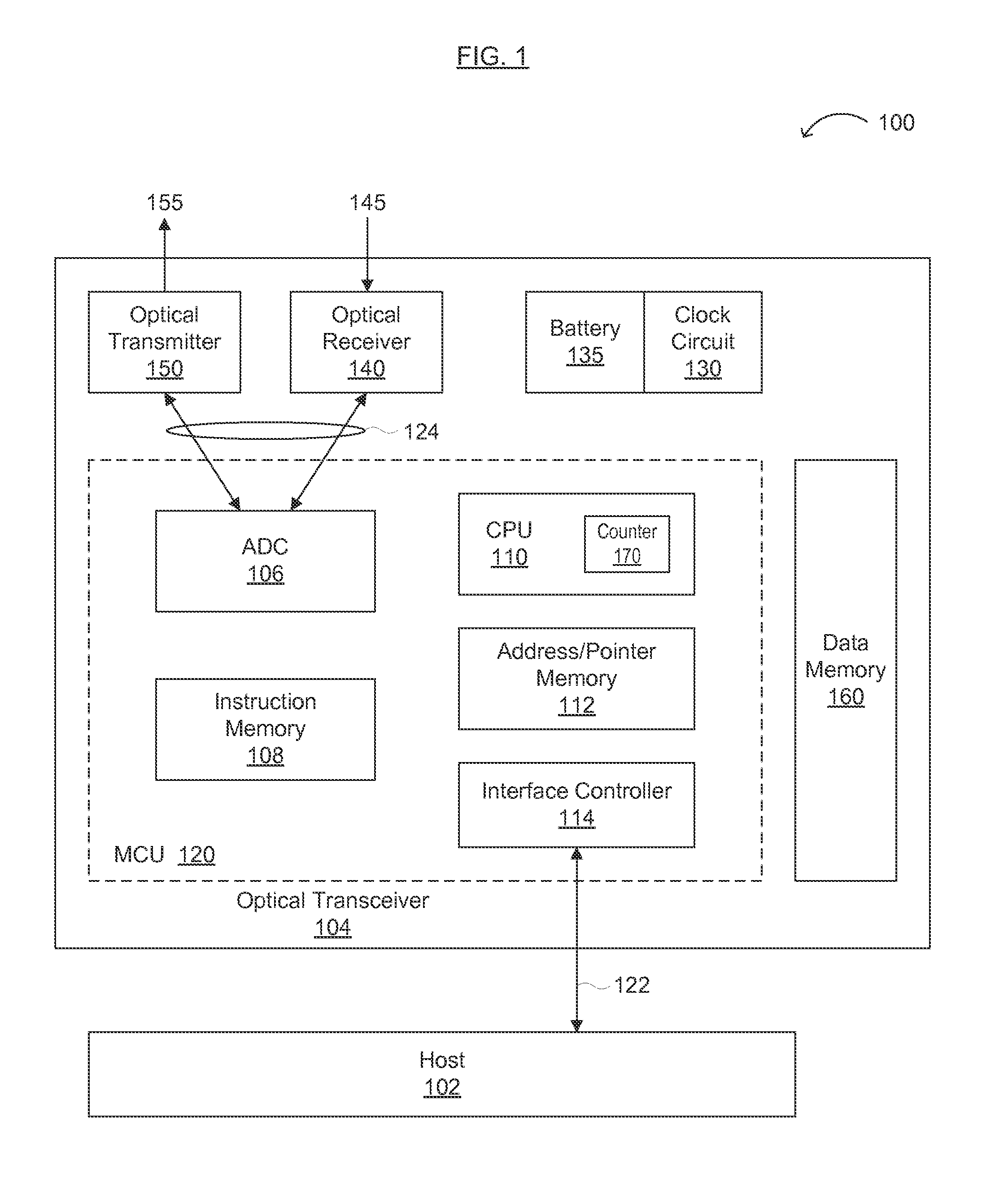

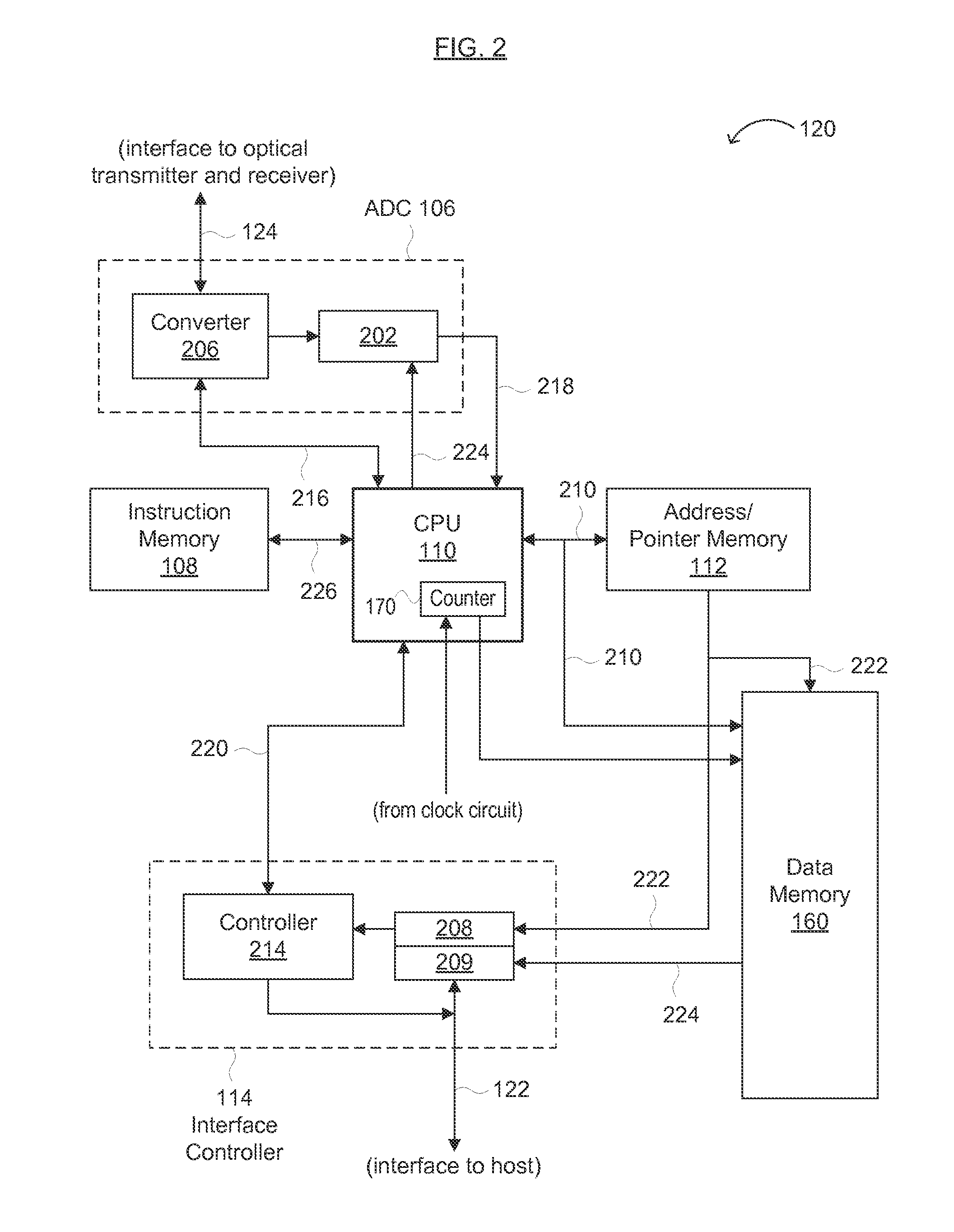

ActiveUS20130251361A1Accurate informationEnhance failure analysisTransmission monitoringTransmission monitoring/testing/fault-measurement systemsTransceiverEngineering

An optical transceiver and methods for using the same are disclosed. The optical transceiver and methods may be useful for providing more accurate information regarding trends in operation of the optical transceiver, predicting an impending failure of the optical transceiver, and providing details of the optical transceiver prior to failure. The optical transceiver generally includes (1) at least one of (i) a receiver configured to receive optical information and (ii) a transmitter configured to transmit optical information, (2) circuitry configured to sample data for one or more operational parameters of the receiver and / or transmitter, (3) logic configured to perform one or more statistical calculations on the sampled data to generate statistical information, and (iv) one or more memories configured to store the sampled data and the statistical information.

Owner:SOURCE PHOTONICS

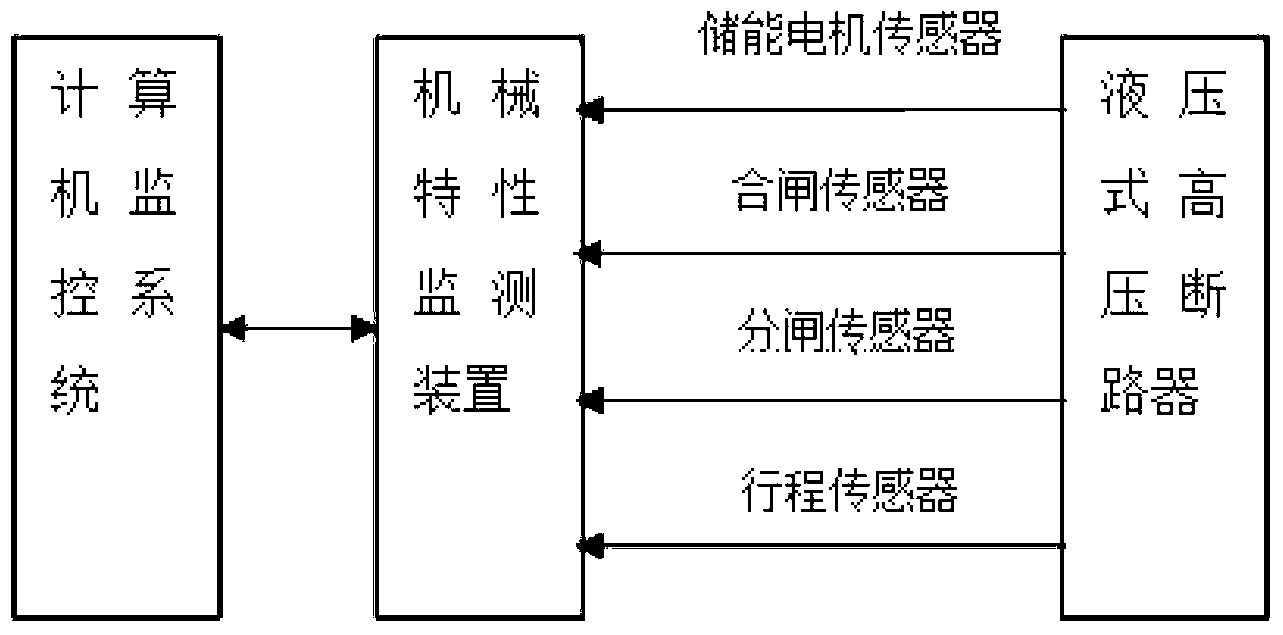

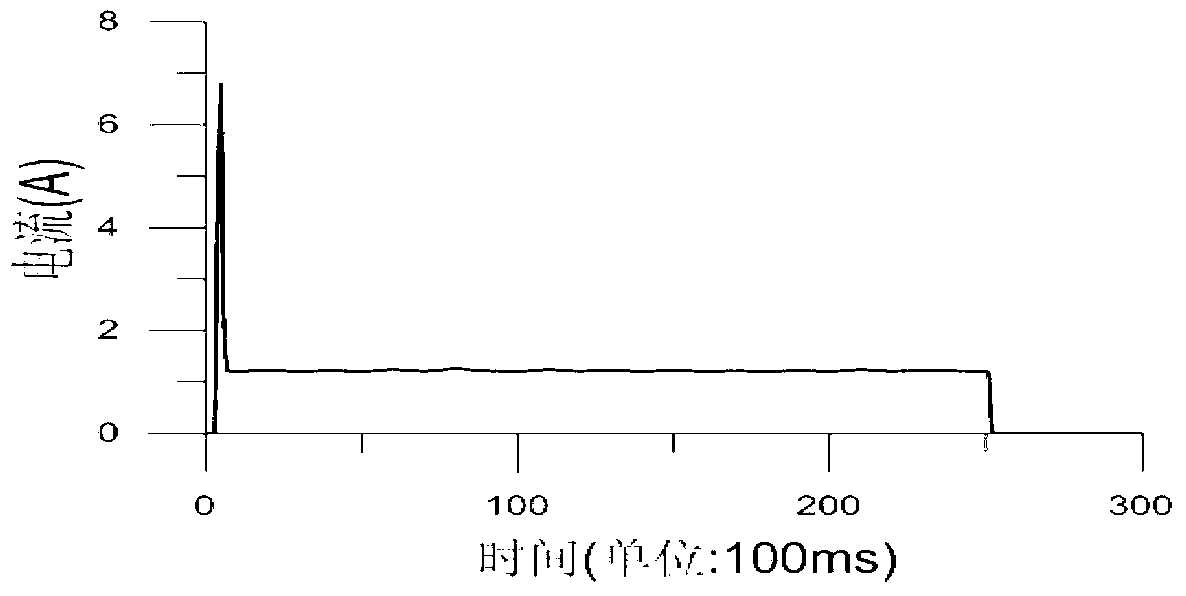

High-voltage breaker mechanical characteristic fault probability monitoring method and system based on on-line monitoring

InactiveCN103323771APredict failureReal-time grasp of working conditionsCircuit interrupters testingMonitoring systemEngineering

The invention discloses a high-voltage breaker mechanical characteristic fault probability monitoring method and system based on on-line monitoring. The method comprises the steps that (1) the mechanical characteristic curve of the breaker is read by an on-line monitoring system under the normal circumstance of the breaker; (2) when the breaker is put into operation in the field, the mechanical characteristic curve of the breaker is read by the on-line monitoring system under the operation circumstance of the breaker; (3) fault probabilities, of energy storage motor fault probability, tripping fault probability and closing fault probability, showed by all characteristic values are respectively calculated by the on-line monitoring system; (4) the total on-line monitoring fault probability, namely, the sum of the fault probabilities worked out according to the third step: F=FM+FF+FH, of the breaker is calculated; (5) whether alarming should be conducted or not is judged by the on-line monitoring system according to the fault probabilities, and a fault alarming signal is generated by the on-line monitoring system when the fault probability is equal to or larger than an threaded alarming value and is not generated by the on-line monitoring system when the fault probability is smaller than the threaded alarming value.

Owner:UNIV OF JINAN +1

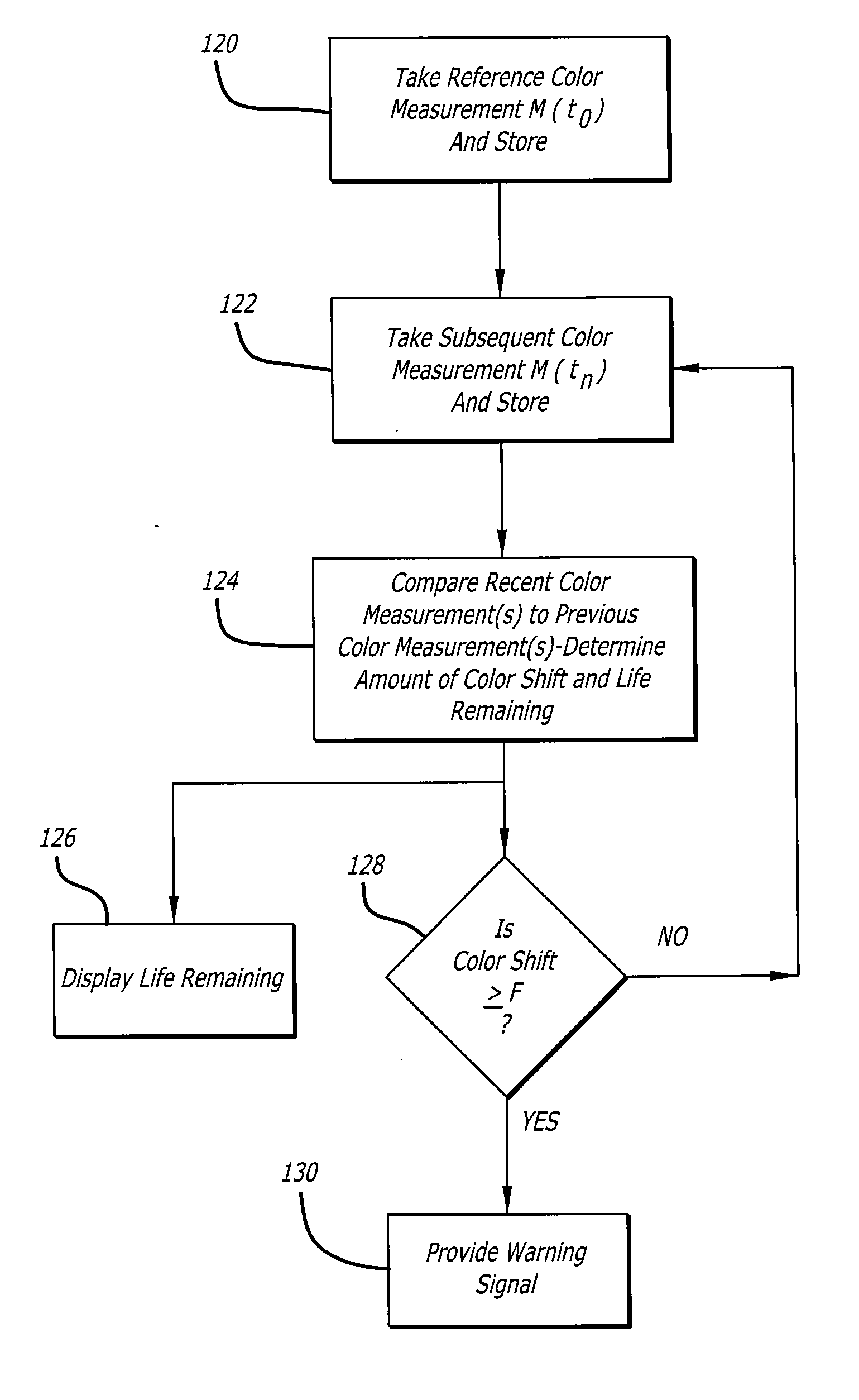

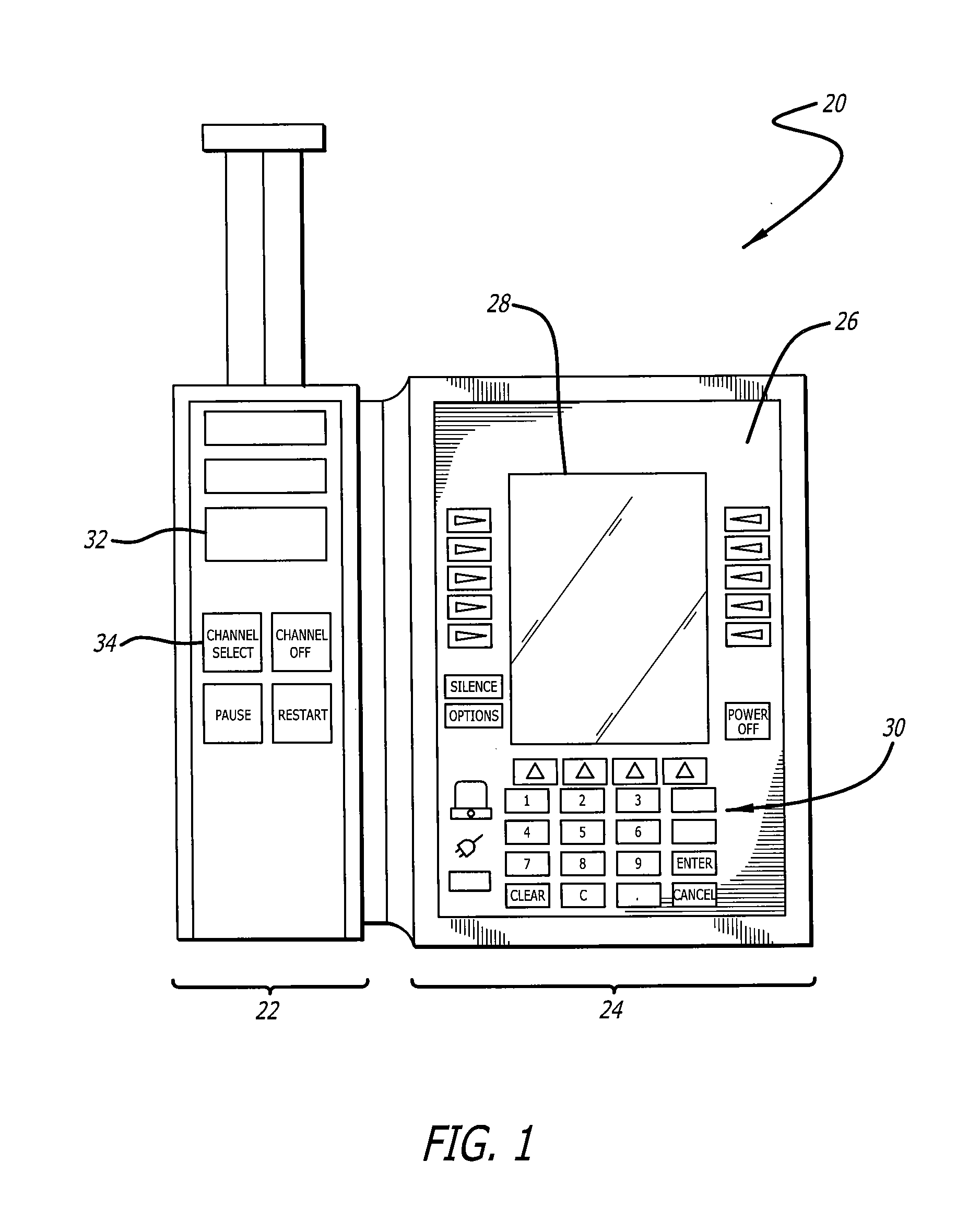

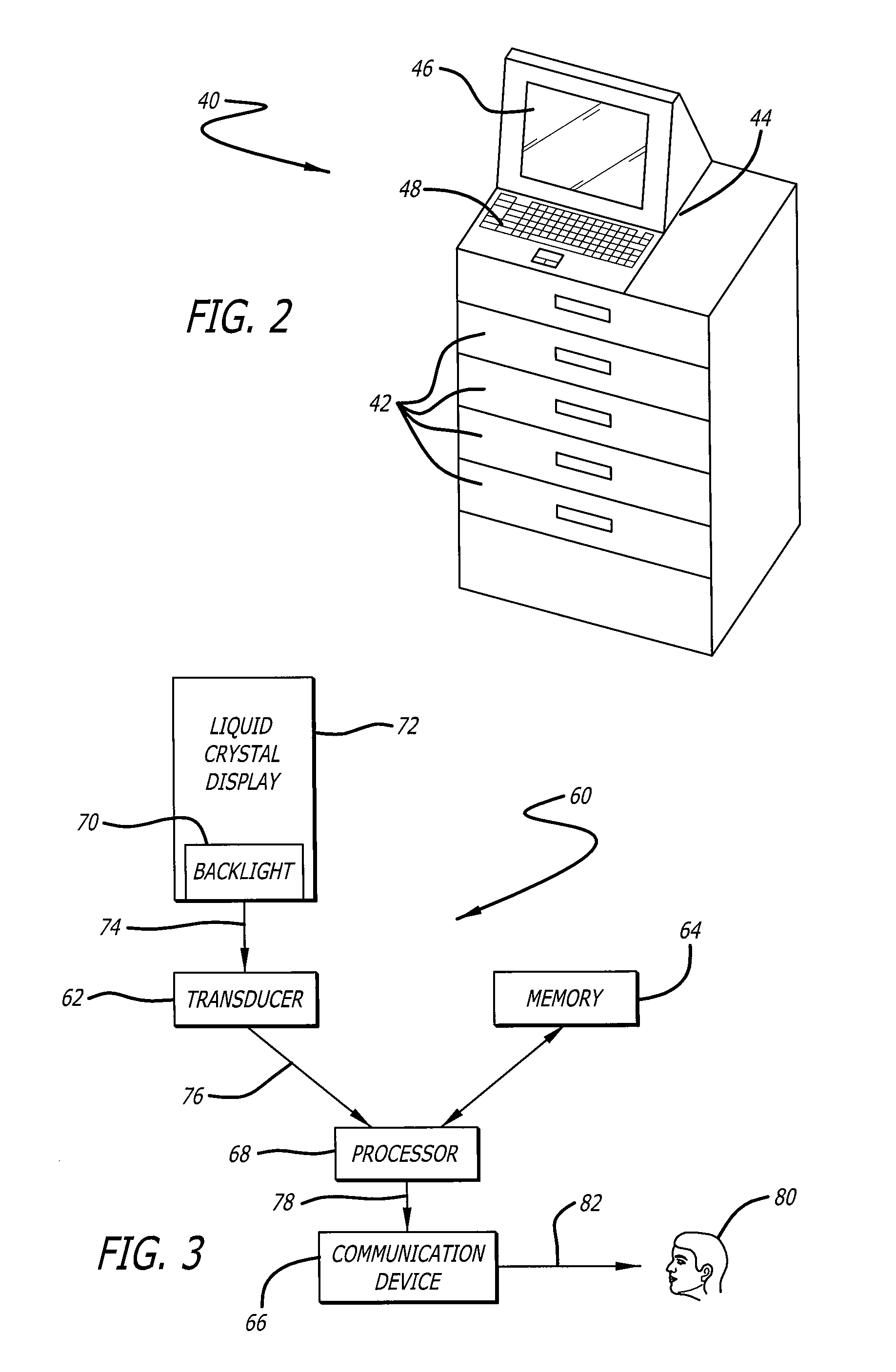

System and method for predicting a failure of a backlight for an LCD display

An early warning system and method for predicting a failure of a backlight of any display that uses internal illumination, such as a liquid crystal display (LCD), digital light processing™ (DLP), or liquid crystal on silicon (LCoS). This display could be a flat screen type or a projector type. A display indicating that failure is imminent within a certain period of time is provided. A countdown display of life remaining may also be provided. Color temperature of the backlight is monitored and compared over time to form the prediction of failure. Measurements may also include measurements of individual components of light, such as the red, green, and blue components. Components may be compared individually over time to detect a color shift that reaches a threshold of prediction failure.

Owner:CAREFUSION 303 INC

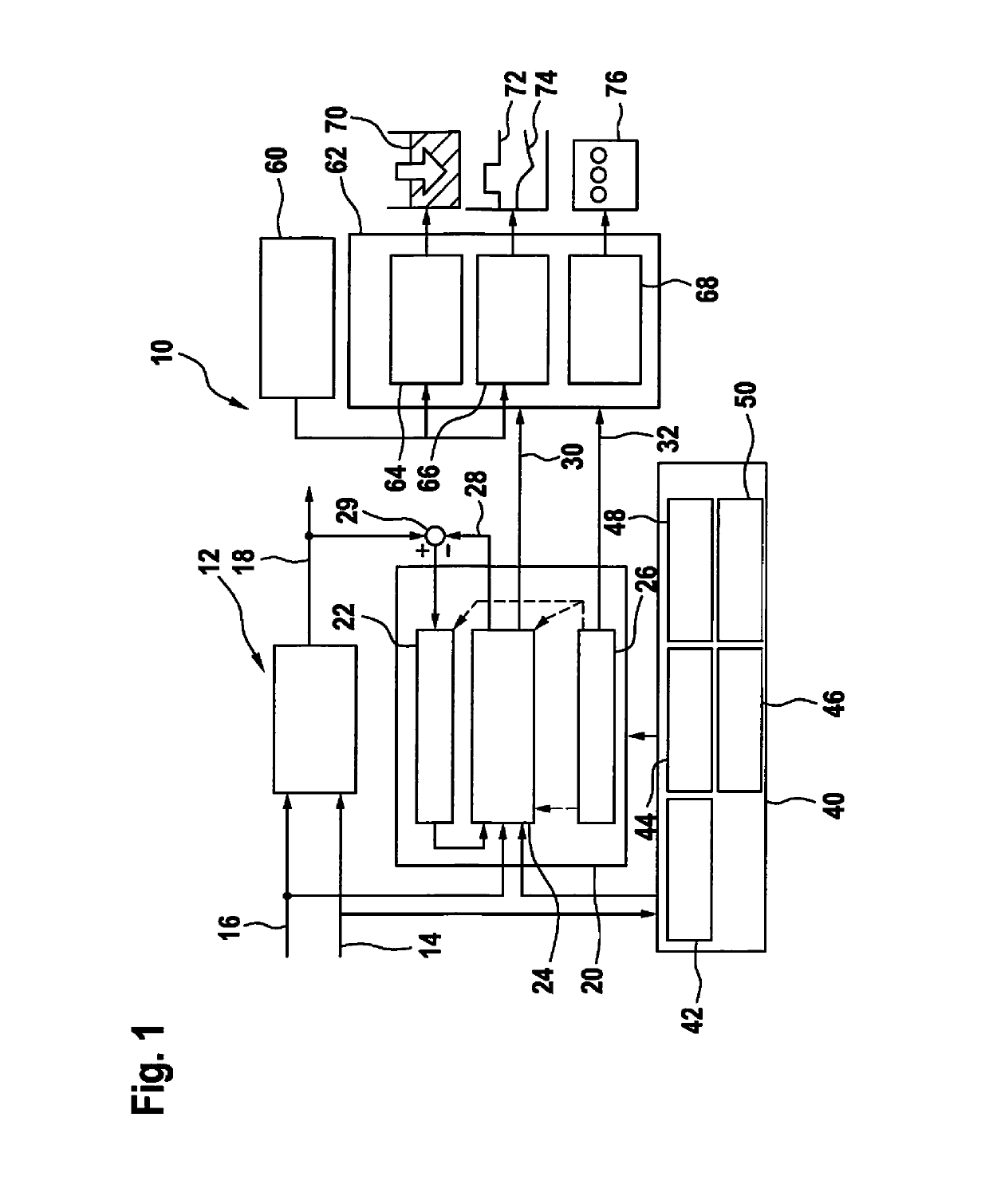

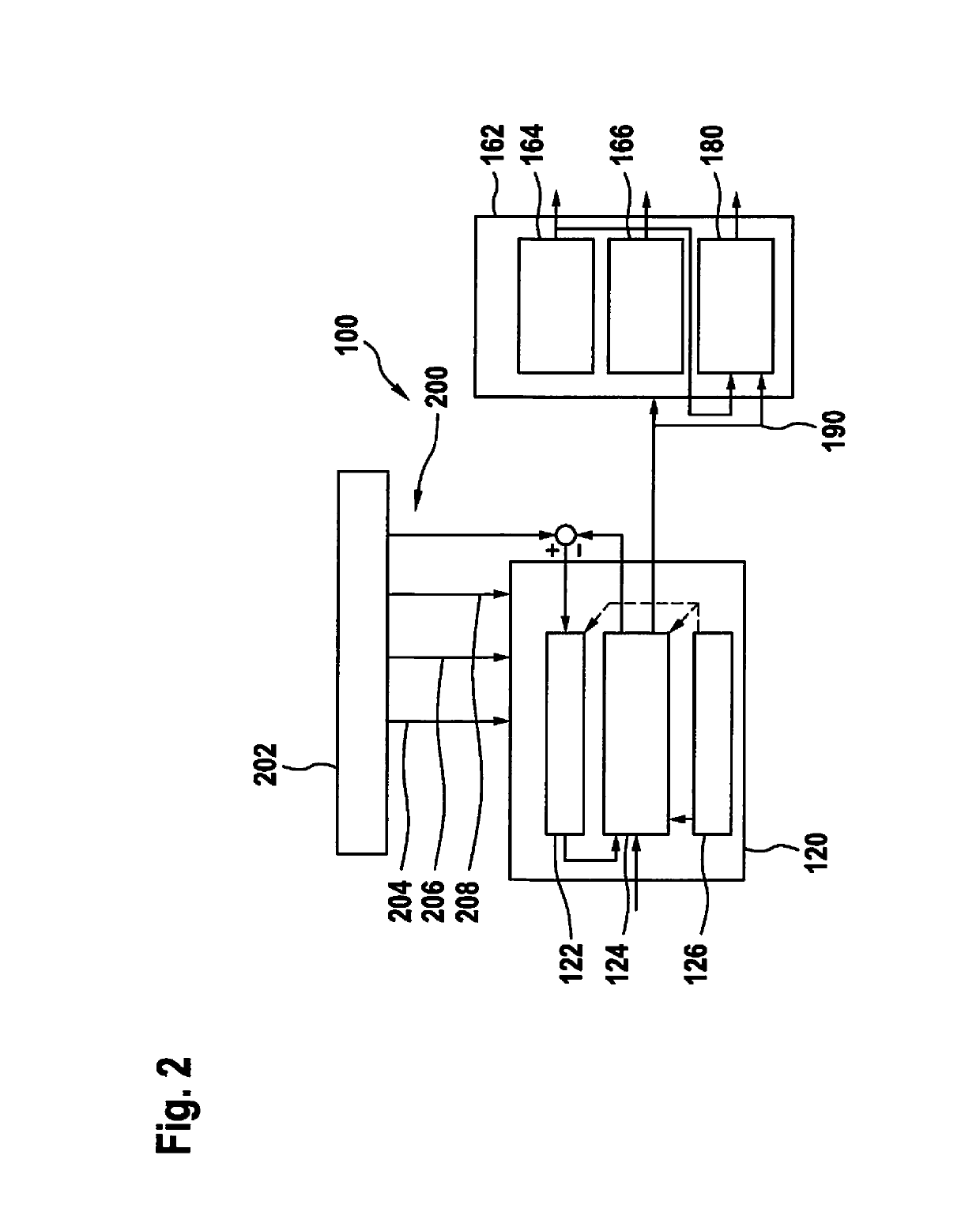

Method for monitoring a battery

InactiveUS20190212391A1Easy to optimizePredict failureElectrical testingVehicular energy storageEngineeringLoad capacity

A method and a system are presented for monitoring a battery in a motor vehicle. In the method, a first module ascertains operating quantities of the battery. Variables that represent the operating quantities are compared with a load capacity model in order to ascertain quantities characterizing the reliability of the battery, so that a future behavior of the battery can be predicted.

Owner:ROBERT BOSCH GMBH

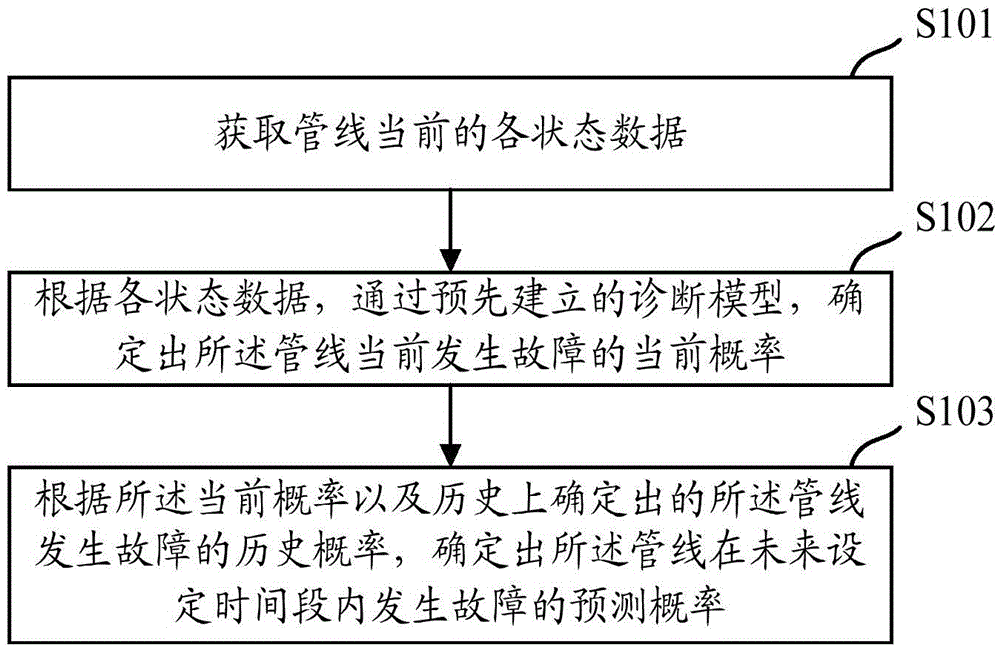

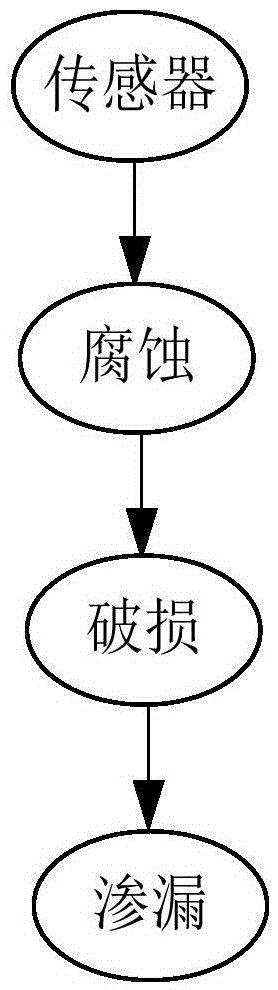

Pipeline fault prediction method and apparatus

The invention discloses a pipeline fault prediction method and apparatus. The method is applied to a pipeline to be predicted, and the method comprises the following steps: obtaining current state data of the pipeline by prediction device at first, determining a current probability of generating faults of the pipeline at present according to the state data by a pre-established diagnostic model, and determining a predicted probability of generating faults of the pipeline within a set time period in the future according to the current probability and a historical probability of generating faults of the pipelines determined in the history. By adopting the method, the faults of the pipeline can be predicted, and corresponding maintenance and management of the pipeline can be carried out according to the prediction result.

Owner:BEIJING INST OF RADIO METROLOGY & MEASUREMENT

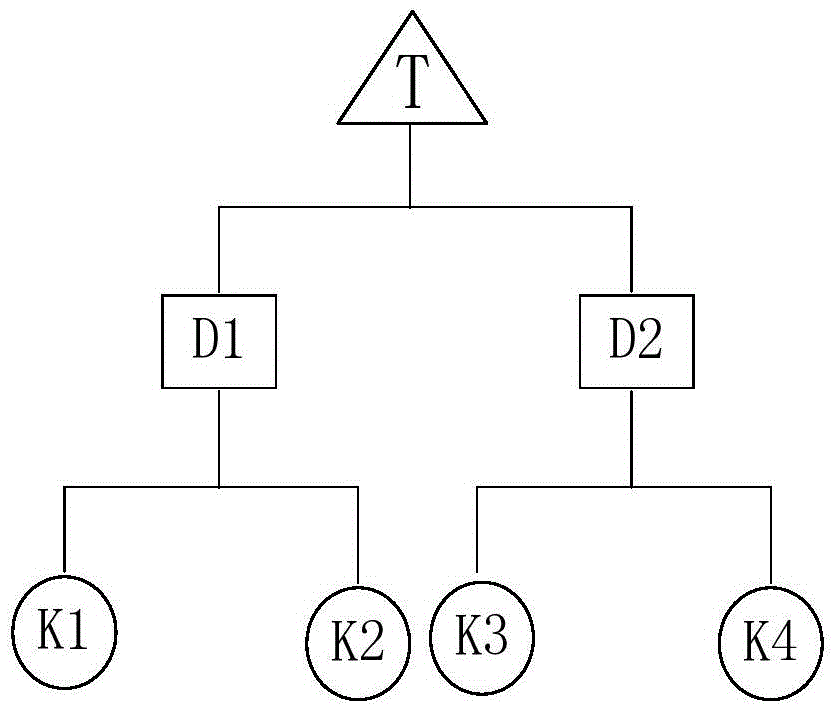

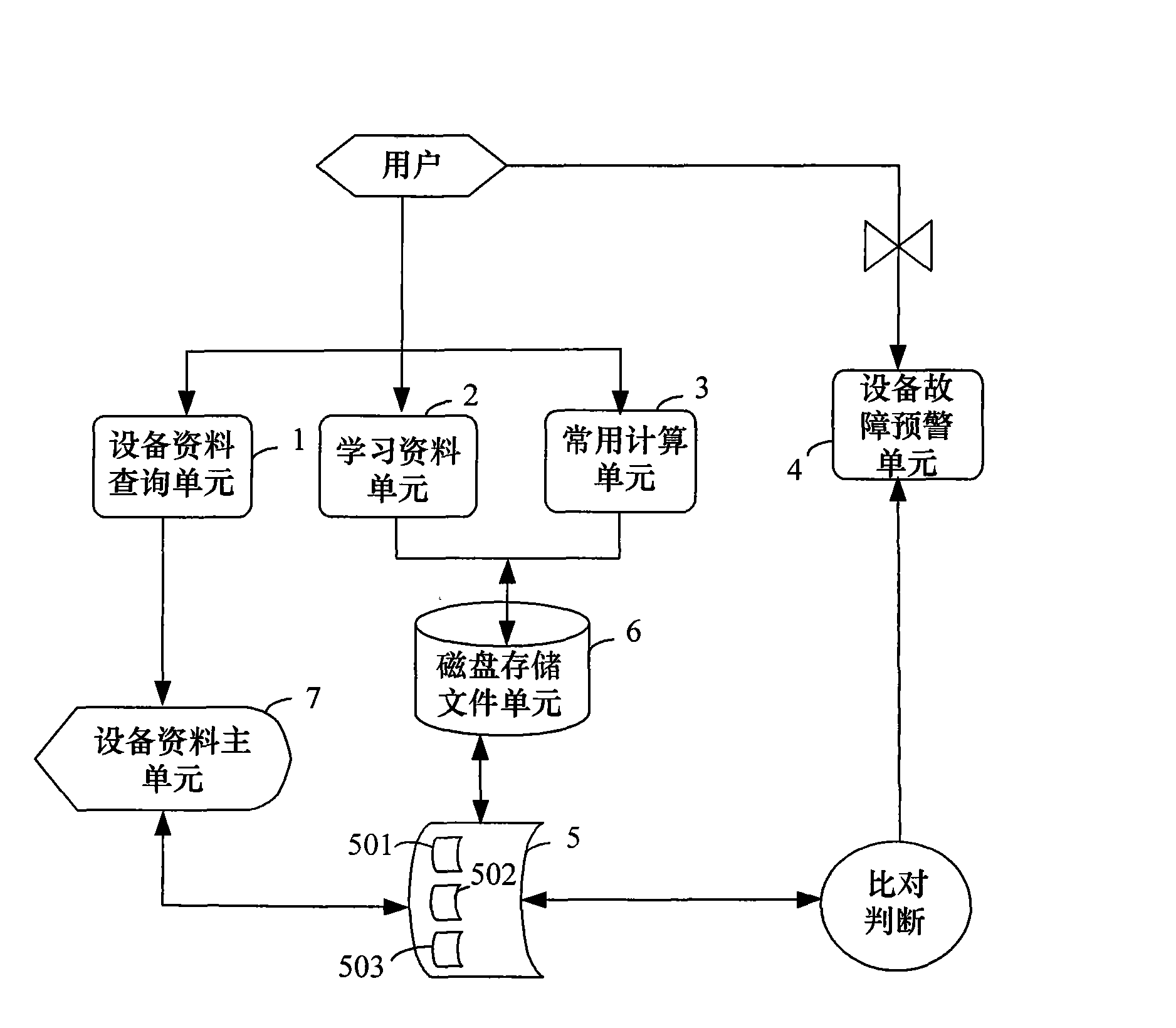

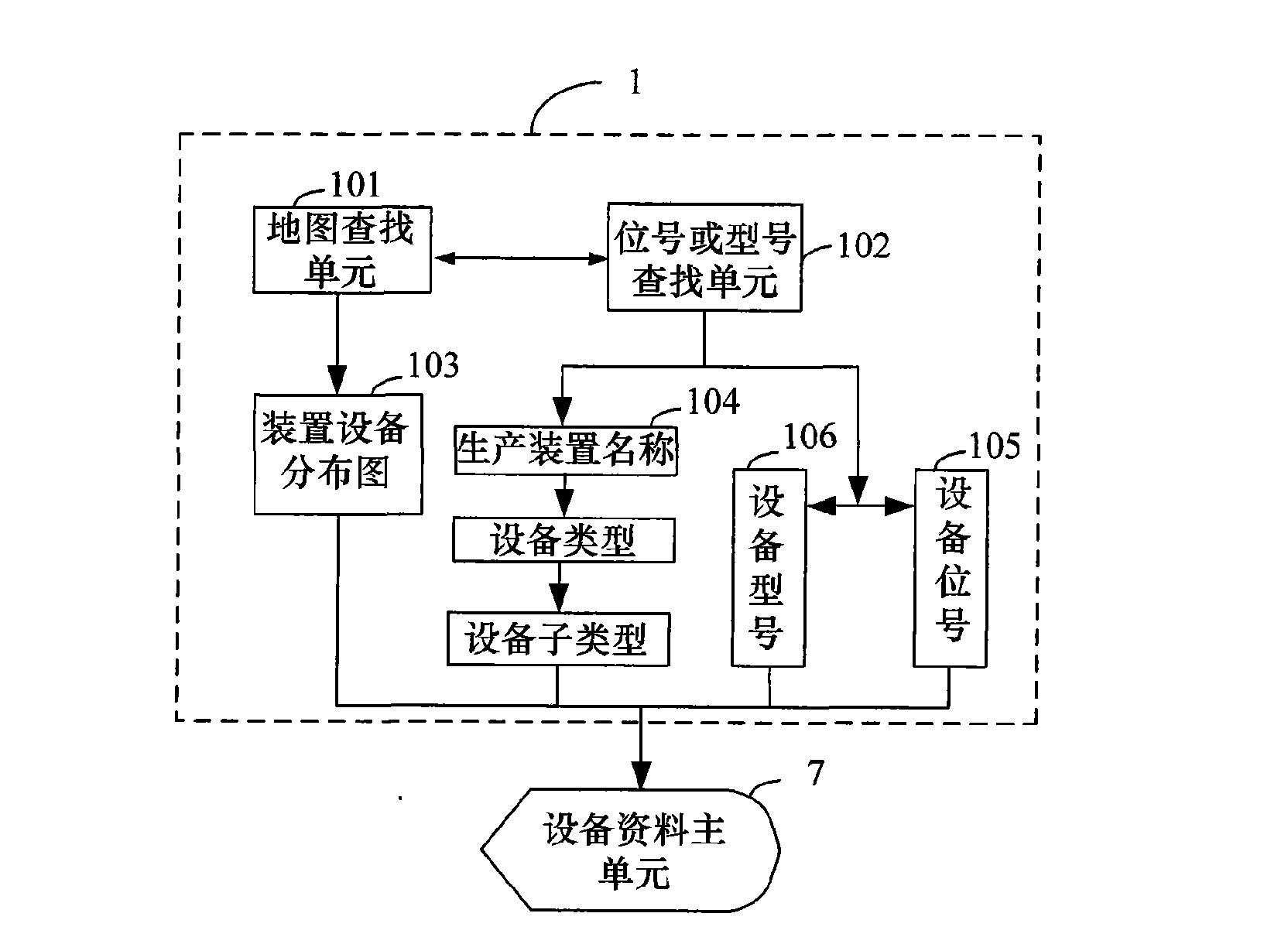

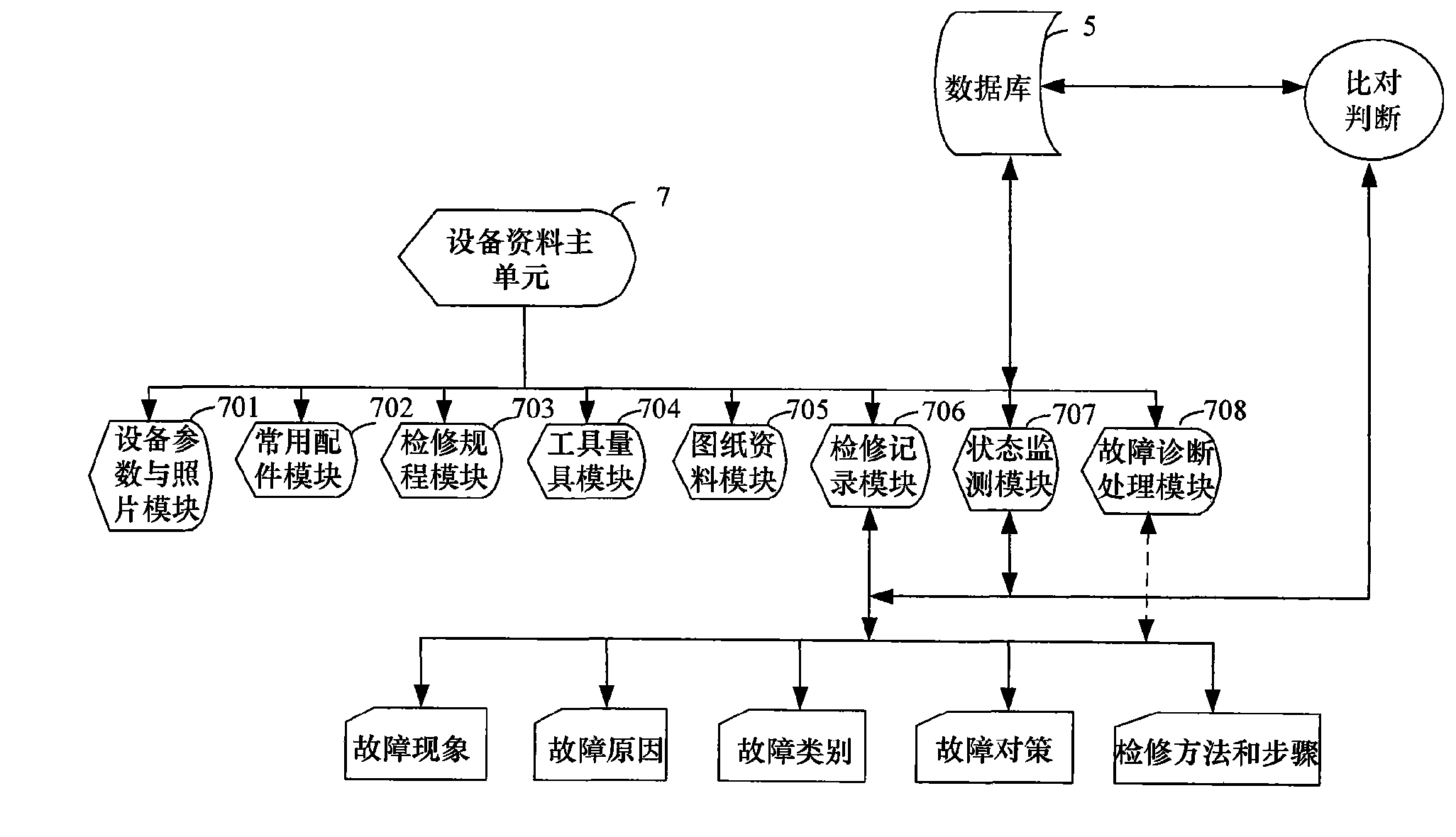

Petrochemical equipment refinement maintenance system

InactiveCN101515315APredict failureOptimize maintenance processElectric testing/monitoringSpecial data processing applicationsPetrochemicalDevice failure

A petrochemical equipment refinement maintenance system is disclosed in the invention, which is mainly composed of: an equipment information inquiry element, a learning resource element, a general computing element and an equipment failure early warming element. The learning resource element and general computing element read the content from a database via a disk storage file element and displays the learning resource and the computed result; the equipment failure early warming element is used for predicting the failure according to the failure period prewarning and the state monitor prewarning so as to provide equipment failure prewarning and failure shooting information; the equipment information inquiry element performs the equipment inquiry according to a map inquiry element or a position number or a model inquiry element and displays various information and equipment operation device in the equipment information main element. Compared with the existing state monitoring technology, the method of the invention can completely pre-warn the equipment failure, improve technical level of various operators, and increase learning approaches of the knowledge base resources.

Owner:北京燕化正邦设备检修有限公司

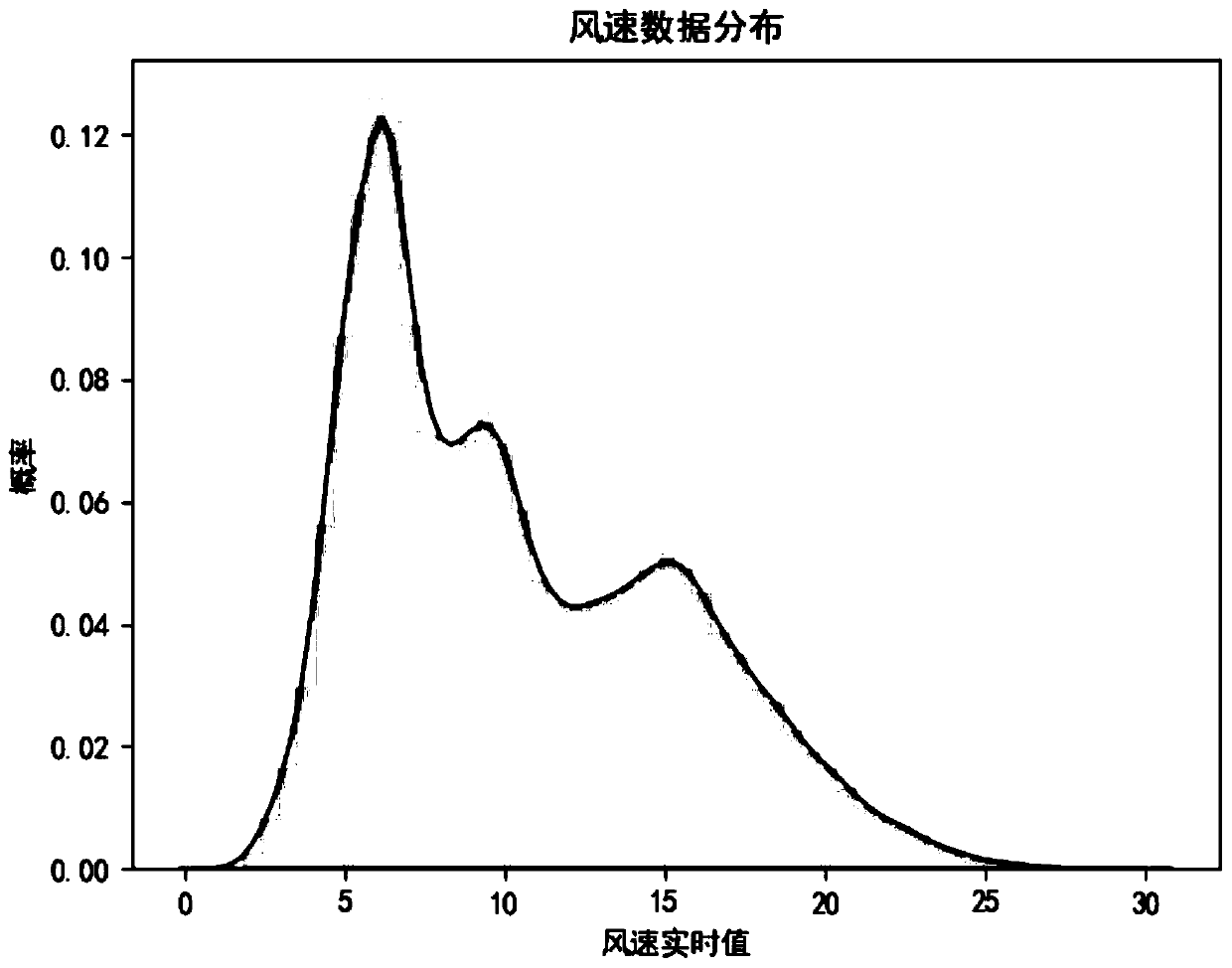

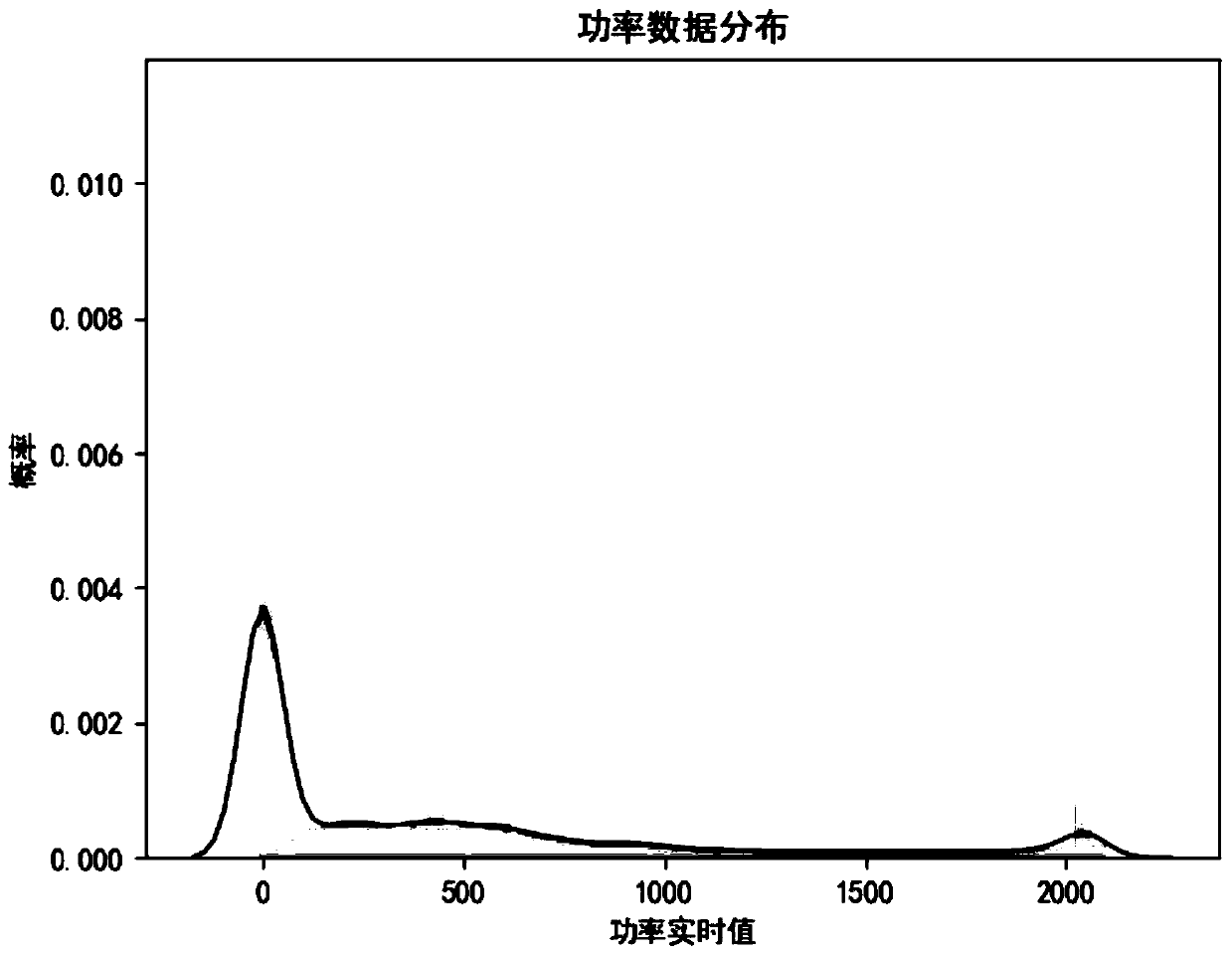

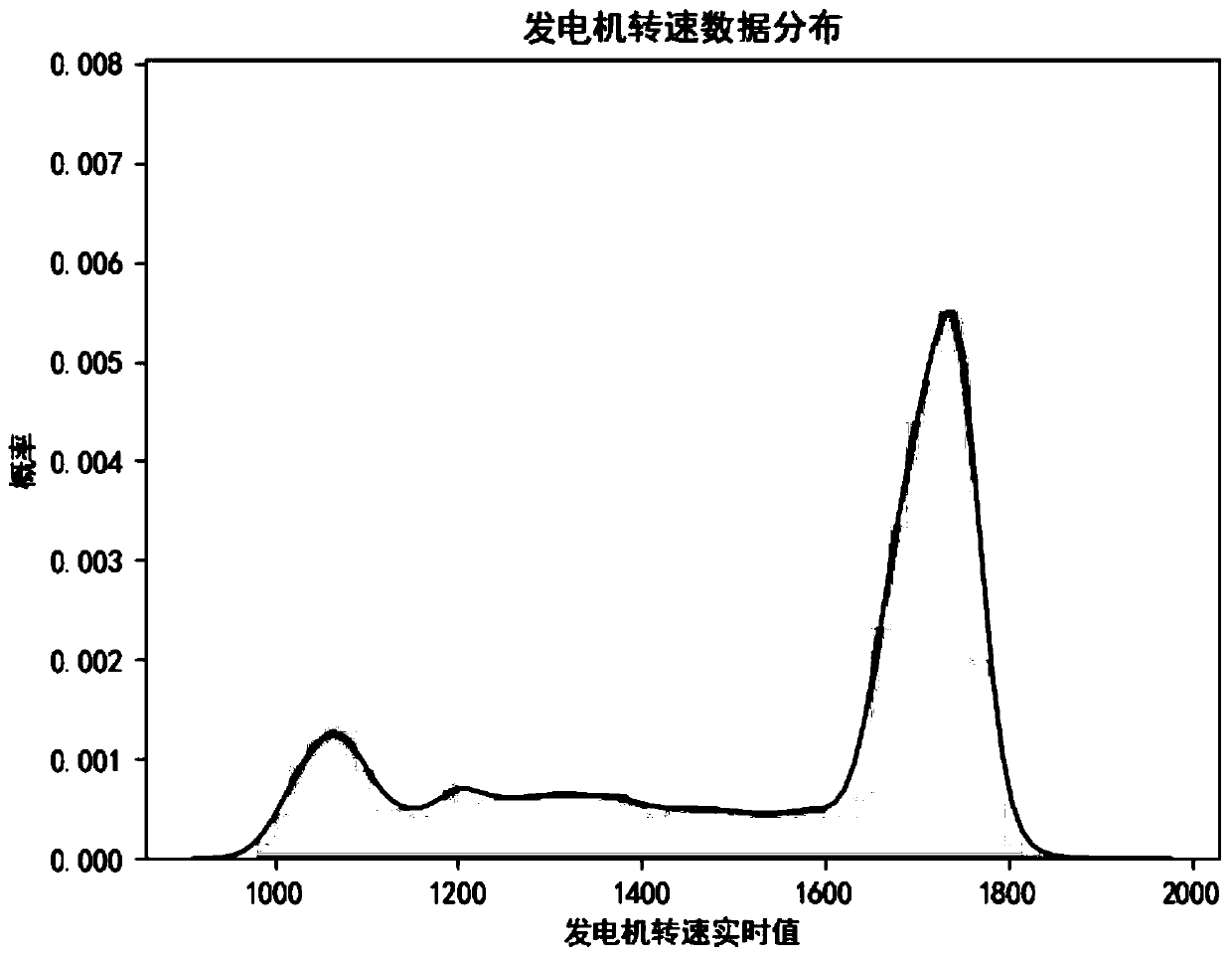

Wind turbine generator main shaft bearing fault prediction method

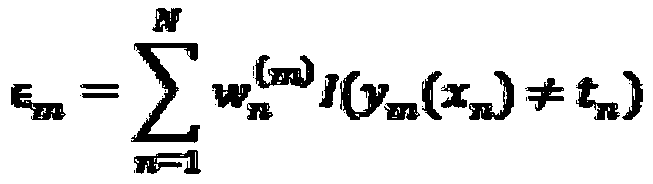

InactiveCN110674842AShort timeImprove classification accuracyMachine bearings testingCharacter and pattern recognitionPrediction methodsSystems engineering

The invention discloses a wind turbine generator main shaft bearing fault prediction method. According to the method, based on historical fault maintenance data of a main shaft bearing of a draught fan, statistics and a machine learning method are combined, multiple monitoring indexes of the draught fan serve as input variables, the state of the main shaft bearing serves as a prediction output variable, statistical analysis is conducted on a prediction value of the output variable, and a threshold value is set for fault prediction. The method has high accuracy and stability, and can predict the fault of the main shaft bearing one week in advance and discover early abnormality as soon as possible.

Owner:GUANGDONG MINGYANG WIND POWER IND GRP CO LTD

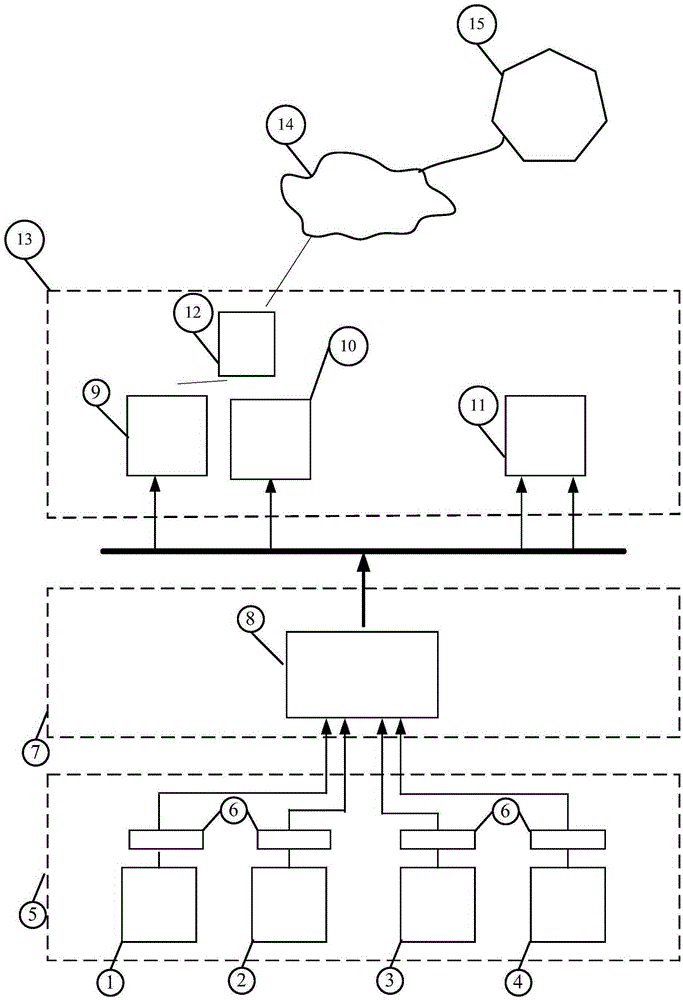

Large pump unit on-line monitoring and diagnosis system

InactiveCN105298823AReal-time monitoring of operating conditionsMonitor the air gapPump testingPositive-displacement liquid enginesWeb serviceStop time

The invention discloses a large pump unit on-line monitoring and diagnosis system. The large pump unit on-line monitoring and diagnosis system comprises an air gap sensor, an electric eddy sensor, an acceleration sensor, a temperature sensor, a signal conditioner, a signal processor, a WEB server, a data server, a user client, a fire wall, a router and a remote expert sub-system. Information collected by the four sensors is conditioned through the signal conditioner and then sent to the signal processor, data processed through the signal processor are transmitted to the WEB server, the data server and the user client, the data of the user client are checked by a user, and the data of the WEB server are sent to the remote expert sub-system through the fire wall and the router; the remote expert sub-system provides corresponding maintenance measures according to the operation state of a unit. The large pump unit on-line monitoring and diagnosis system can monitor the operation conditions of the unit in real time, monitor the changes of the air gap and the magnetic flux of a motor, predict faults of the unit, shorten the stop time and reduce the overhaul cost.

Owner:WUHAN UNIV

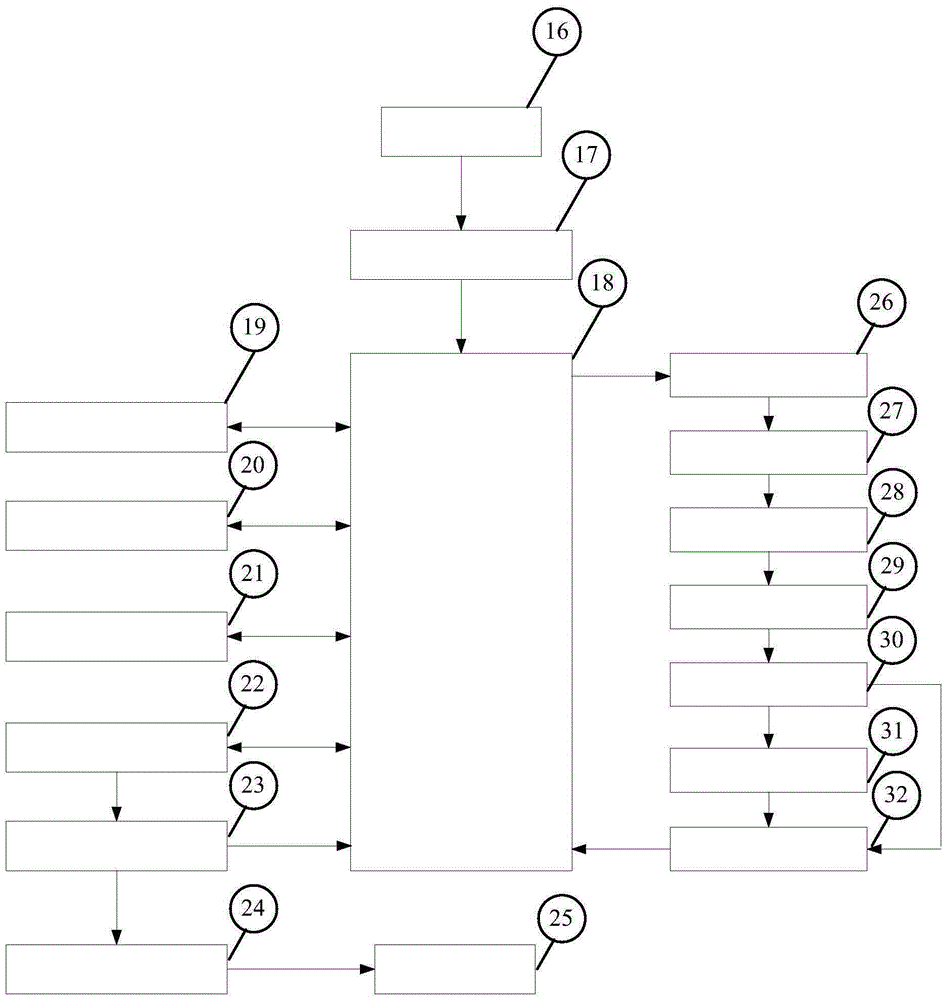

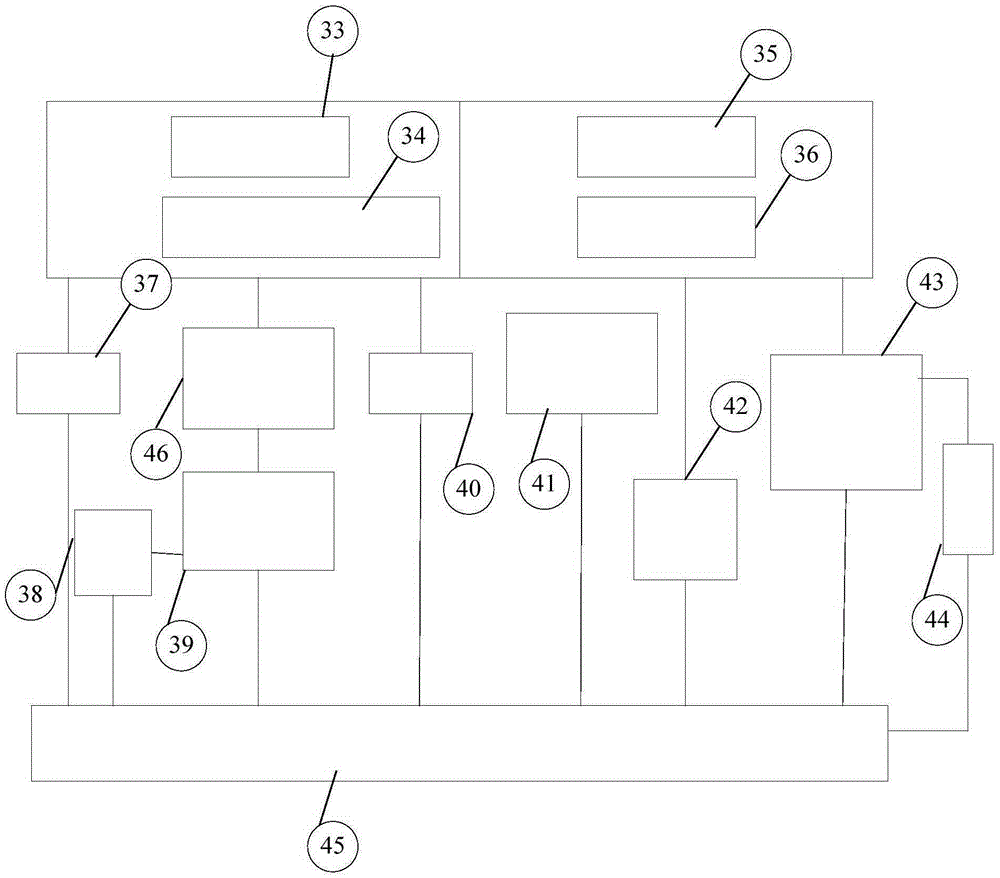

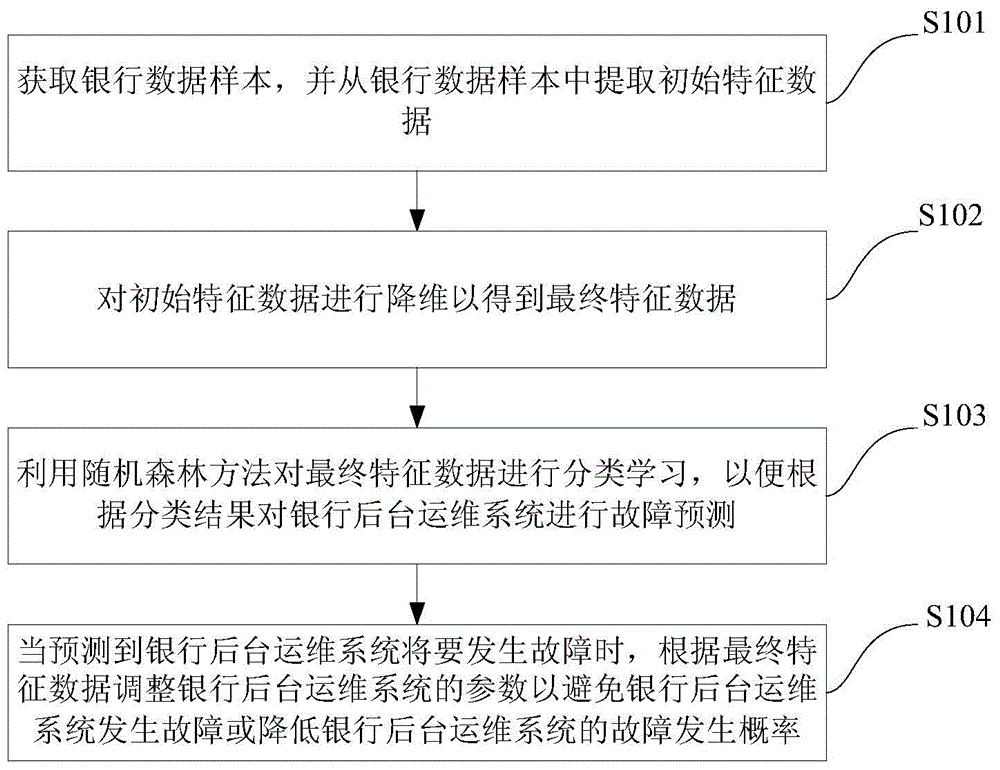

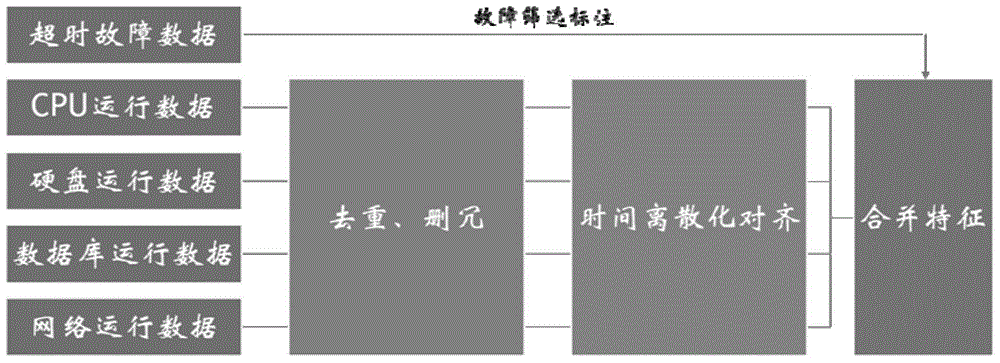

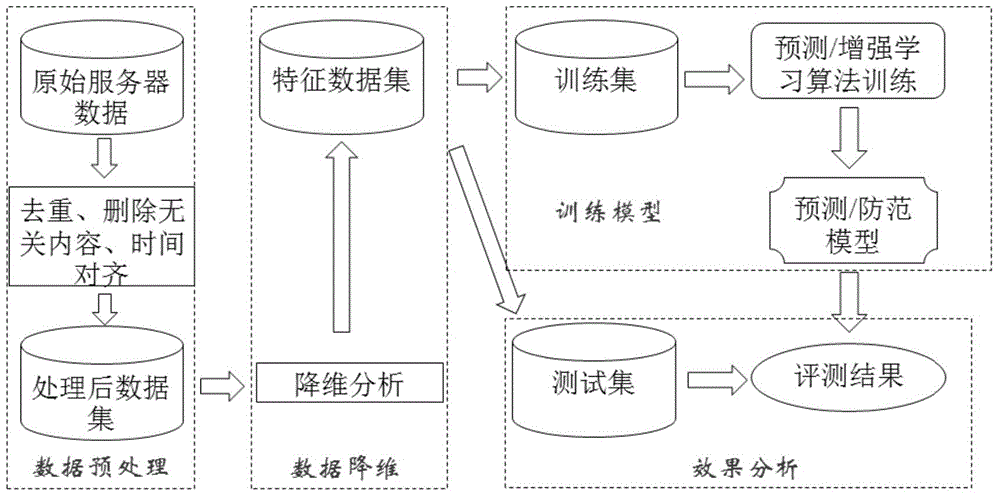

Failure predication system and failure predication method for background operation and maintenance system of bank

InactiveCN104156562APredict failureFailure avoidance or reductionSpecial data processing applicationsPrediction systemClassification result

The invention provides a failure predication method for a background operation and maintenance system of a bank. The method includes the steps: acquiring a bank data sample and extracting initial feature data from the bank data sample; subjecting the initial feature data to dimensionality reduction to obtain final feature data; using a random forest method for classified cleaning of the final feature data so as to carry out failure predication on the background operation and maintenance system of the bank according to classification results; when failures of the background operation and maintenance system of the bank is predicated, adjusting parameters of the background operation and maintenance system of the bank according to the final feature data to avoid failures of the background operation and maintenance system of the bank or lower failure occurrence probability of the background operation and maintenance system of the bank. According to the method, failures of the background operation and maintenance system of the bank can be effectively predicated, and the failures can be avoided or the failure occurrence probability can be lowered effectively by precaution. The invention further provides a failure predication system for the background operation and maintenance system of the bank.

Owner:TSINGHUA UNIV

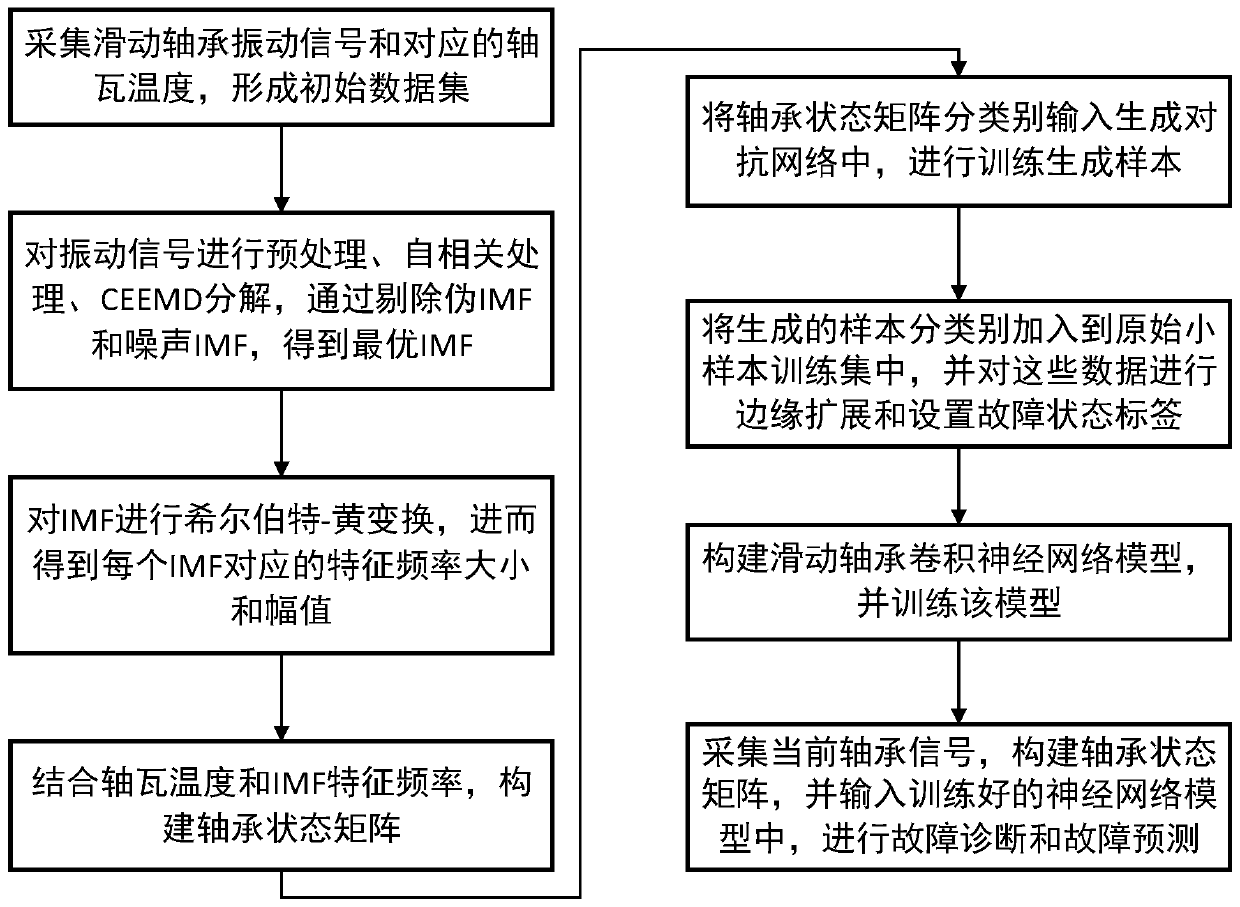

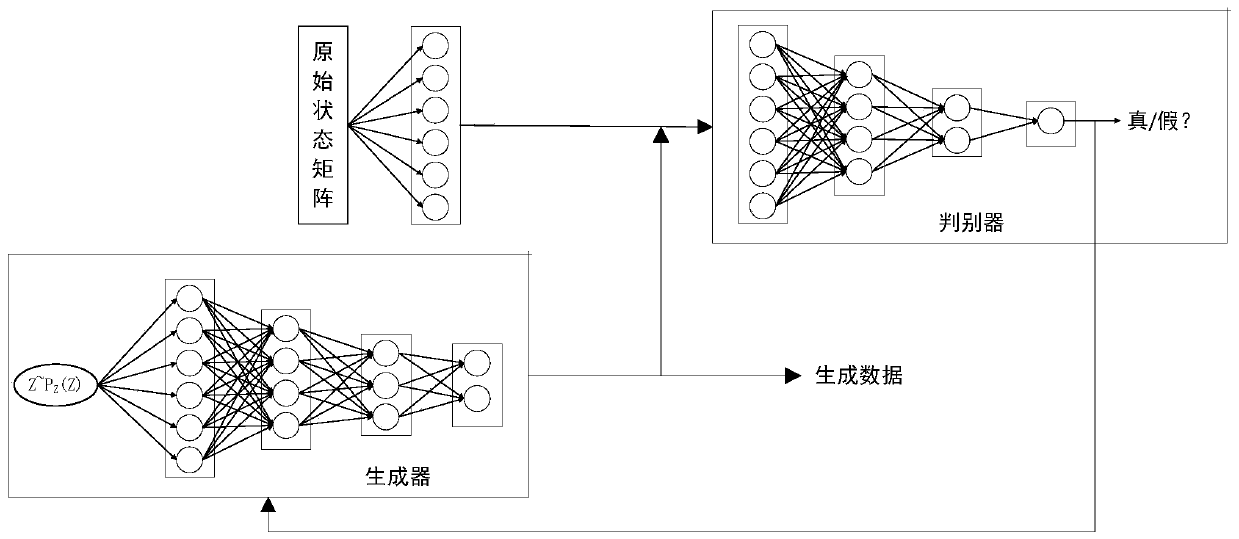

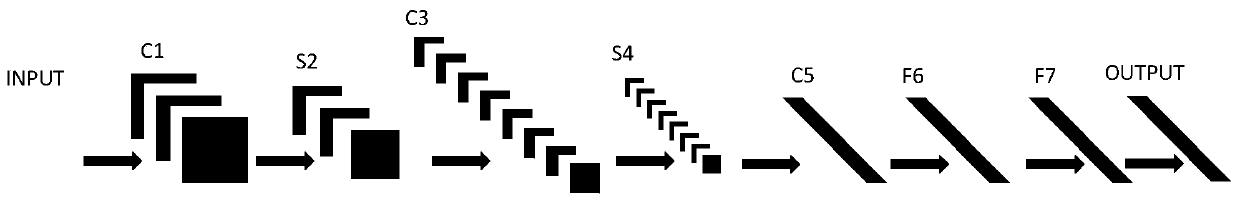

Sliding bearing fault diagnosis method based on generative adversarial network and convolutional neural network

ActiveCN111458142AAddress underutilizationSolve the problem of inaccurate diagnosisSustainable transportationMachine bearings testingData setGenerative adversarial network

The invention provides a sliding bearing fault diagnosis method based on a generative adversarial network and a convolutional neural network. The method comprises the steps of: collecting vibration signals and bearing bush temperatures of a sliding bearing under no fault and different fault conditions, and carrying out preprocessing; carrying out ensemble average empirical mode decomposition on the vibration signals to obtain an optimal intrinsic mode function and a characteristic frequency corresponding to the optimal intrinsic mode function; constructing state matrixes on the basis of the bearing bush temperatures, and respectively inputting the state matrixes into the generative adversarial network according to categories to generate samples; carrying out edge expansion on the data of an initial sample set, and setting fault state labels; constructing a sliding bearing convolutional neural network model, and training the model by using the data set and the corresponding fault labels; and collecting data of the current sliding bearing, constructing a state matrix, inputting the state matrix into the trained neural network model, and carrying out fault diagnosis and prediction. With the method of the invention adopted, the problems of unobvious vibration fault signals, poor diagnosis effect, insufficient bearing bush temperature utilization and insufficient sample size are effectively solved.

Owner:苏州新传品智能科技有限公司

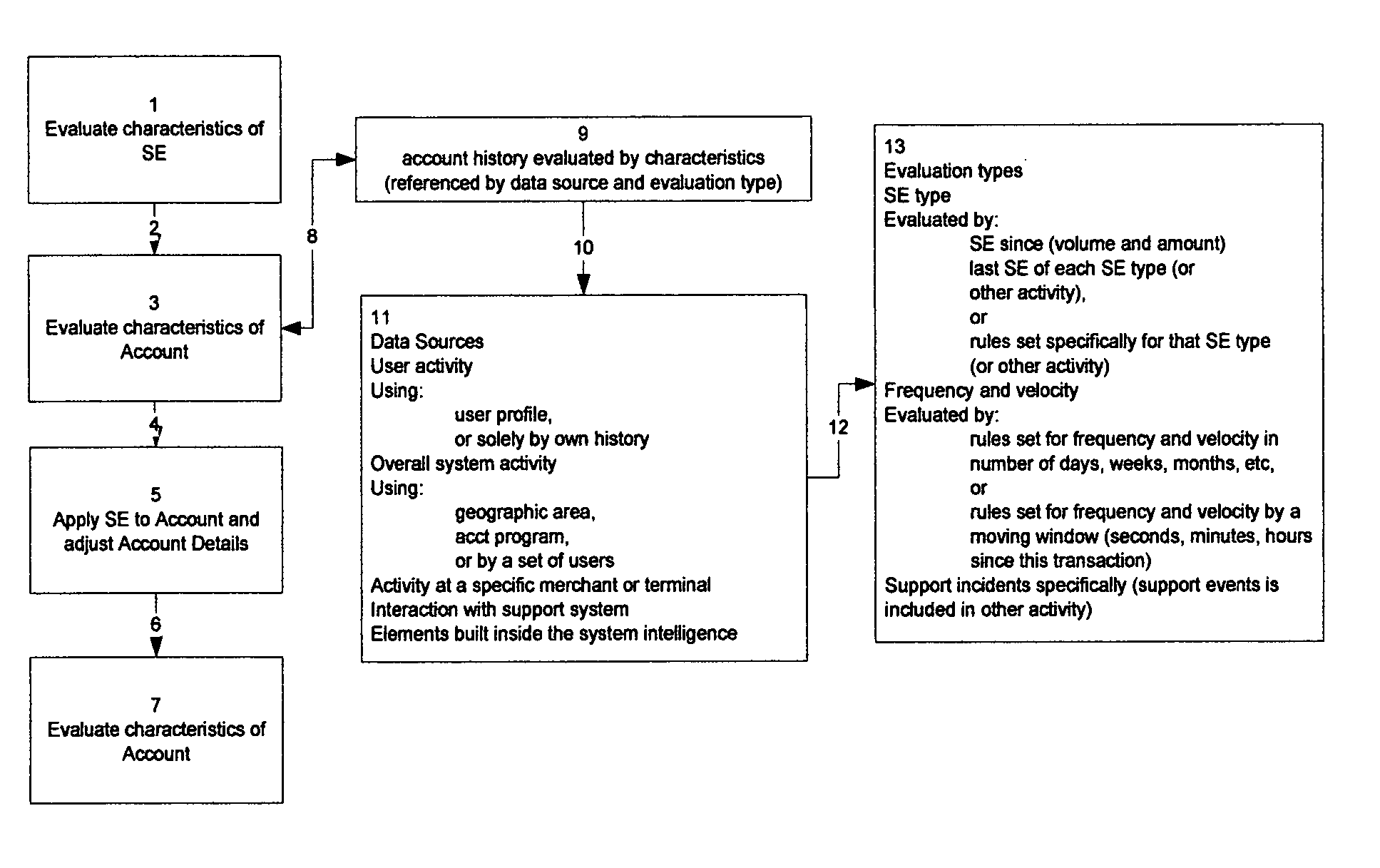

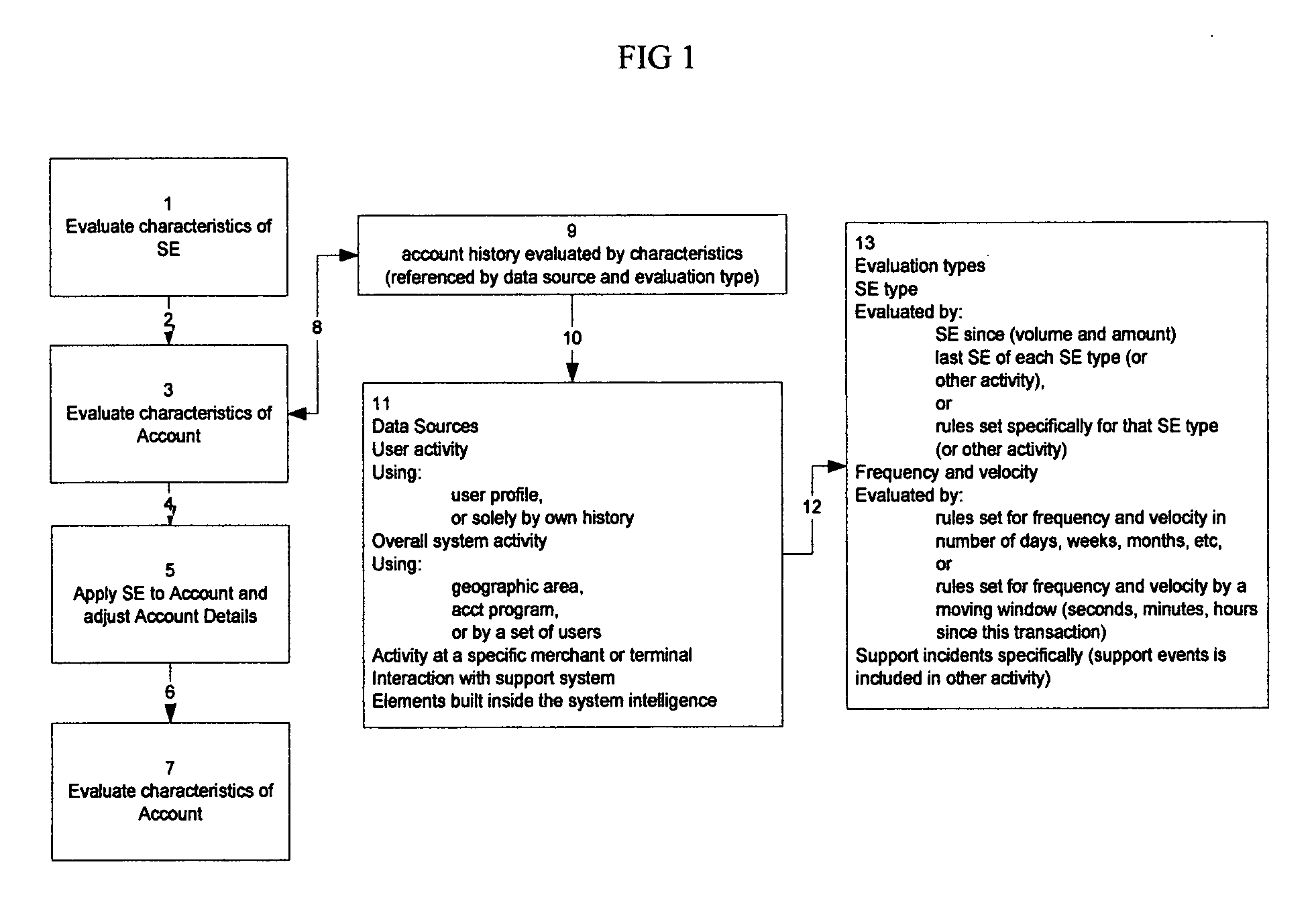

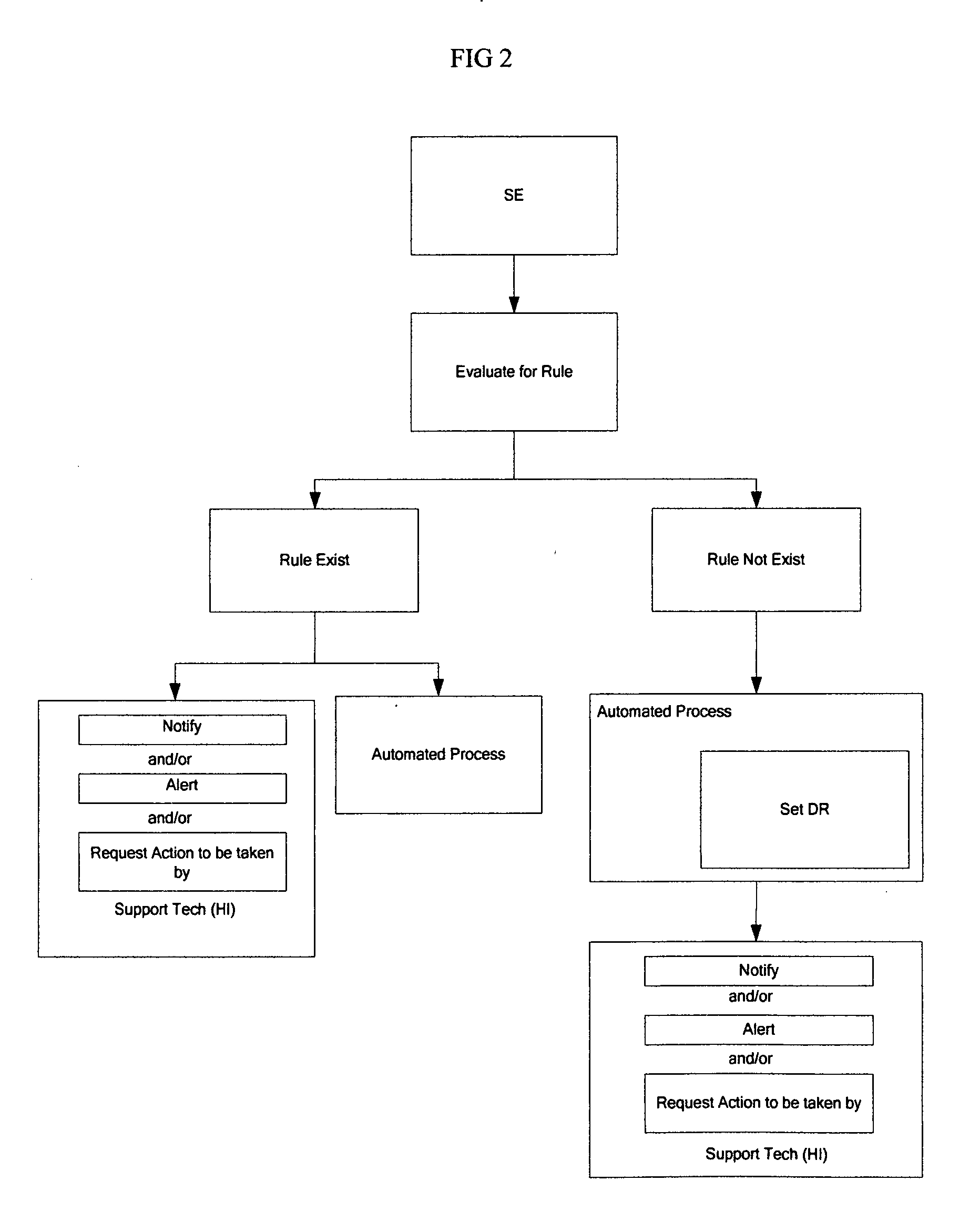

Method and apparatus of customer support through the use of automated assistance technology, live customer support, and predictive account maintenance and management for industries where there are services which relate to a customer account(s).

InactiveUS20050288981A1Maximizing uptimeImprove performanceMarketingSpecial data processing applicationsSupporting systemLibrary science

The present invention generally relates to a customer support methodology which can be enacted with a combination of automated support solutions and support technicians for industries where there are services which relate to a customer account(s). Its main purpose is the effective use and acquisition of data to better understand the customer, the product / service, and the support system in order to better handle support issues that have and could possibly happen. The innovation in customer support methodologies are established in key general areas: profiling, support session routing, authorization, verification, data convergence, data protection, communication, predictive analysis, government compliance, customer satisfaction, and preemptive actions.

Owner:GOBEL MARCUS +1

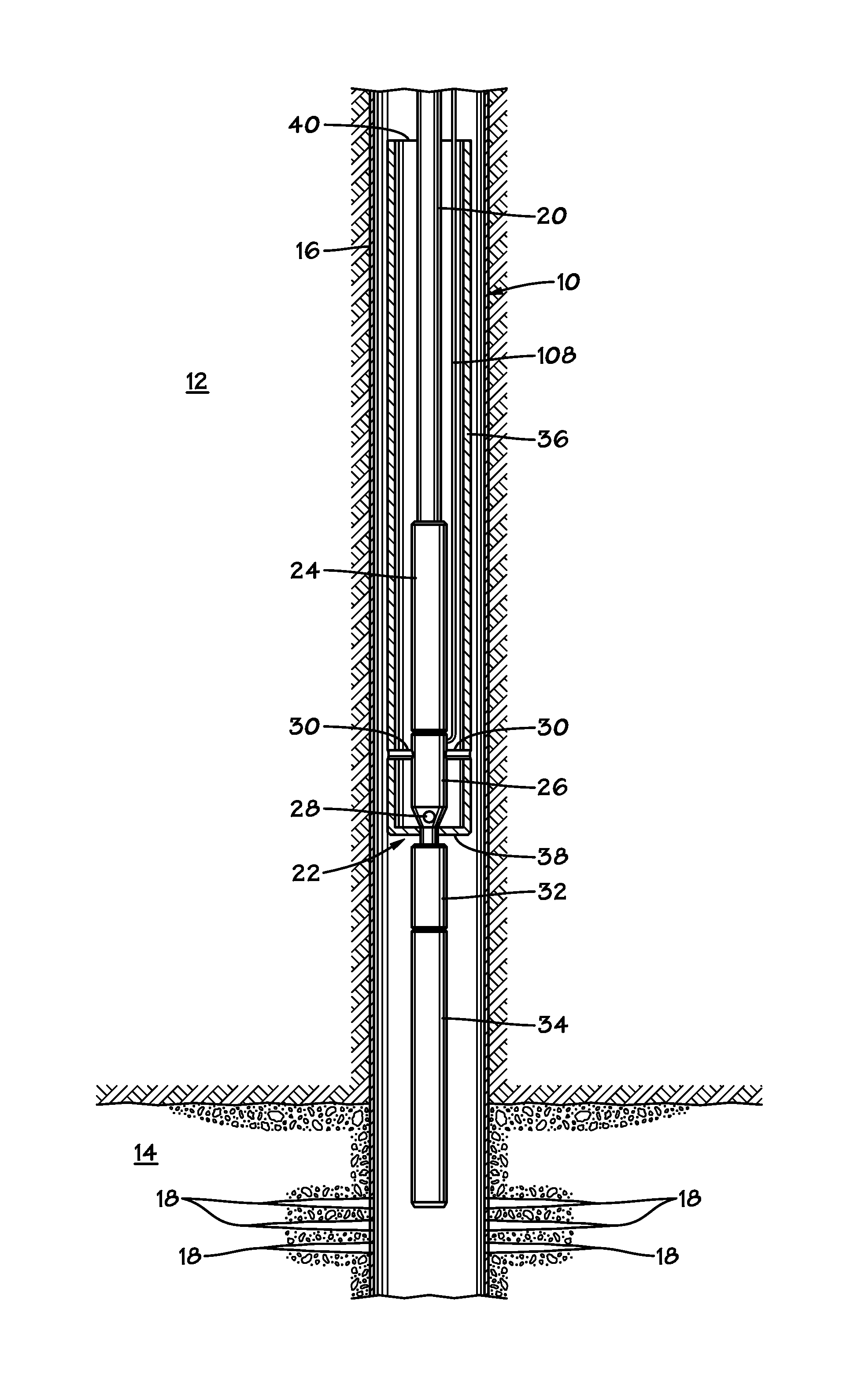

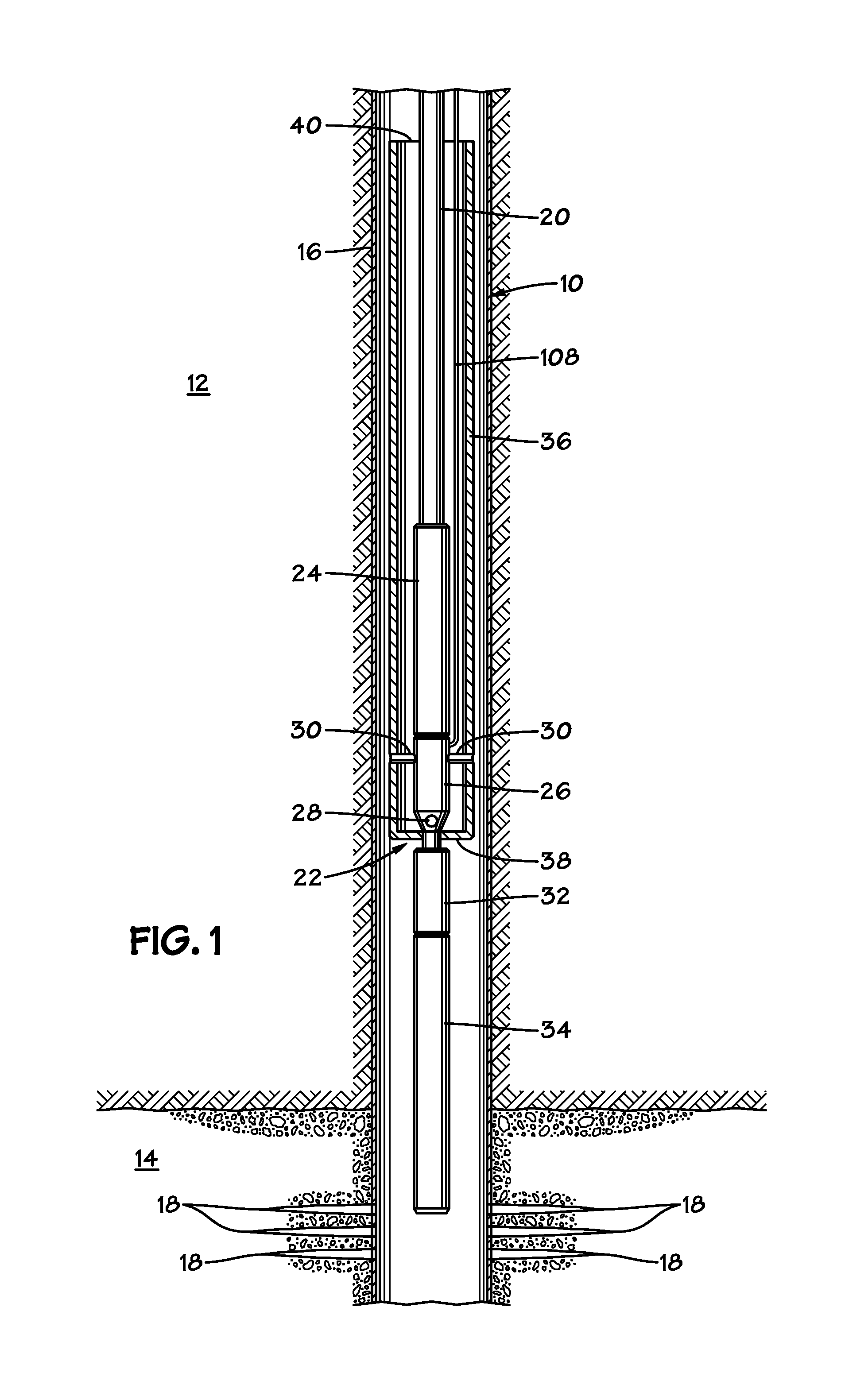

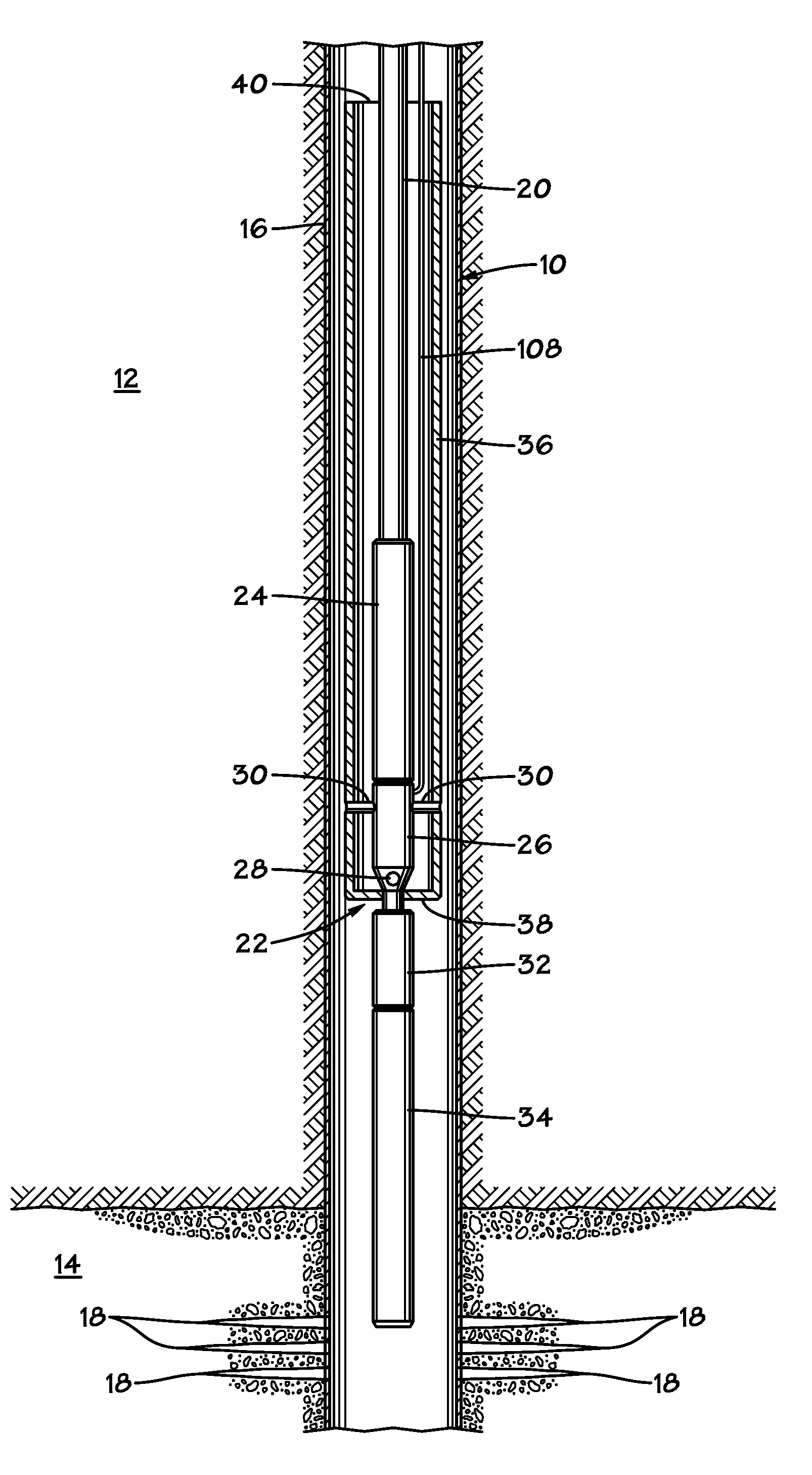

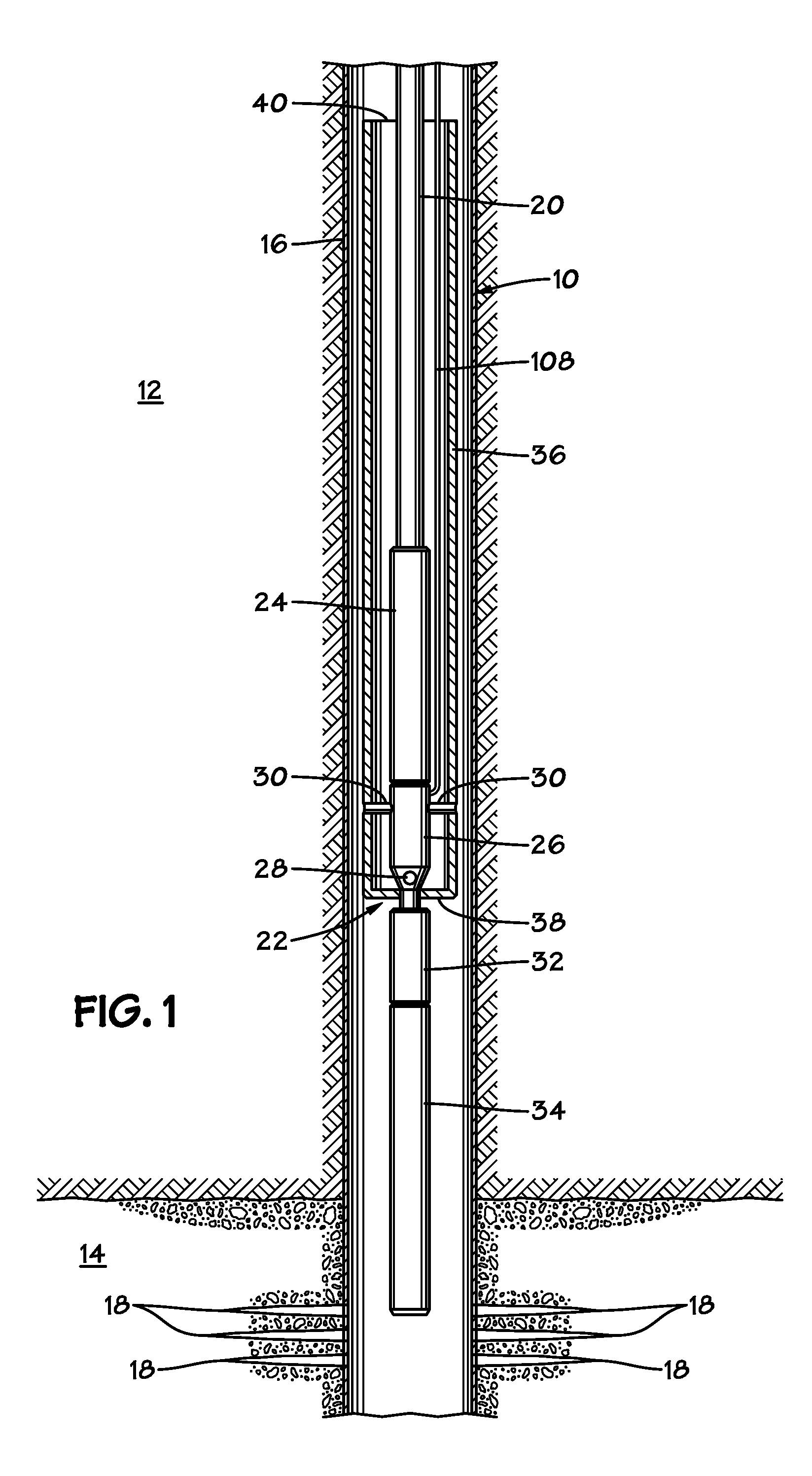

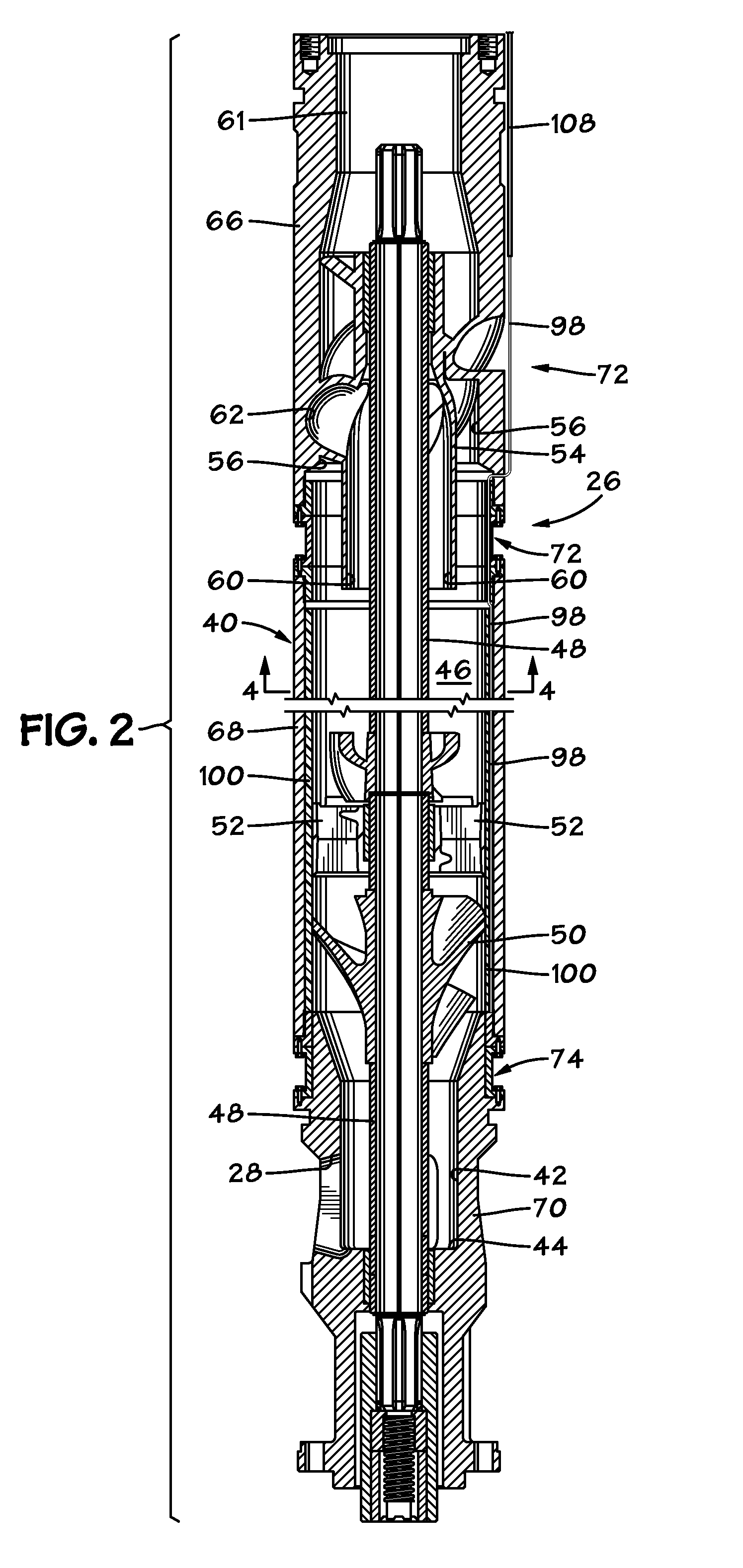

Gas Separators with Fiber Optic Sensors

ActiveUS20140000345A1Increased operating lifeIncrease productionLiquid degasificationForce measurementEngineeringSignal processing

Devices and methods for detecting operational parameters associated with a gas separator used in an electric submersible pump in a wellbore. A fiber optic sensing arrangement is used to detect the operational parameter and includes a fiber optic signal processor and an optic fiber that is associated with the gas separator to provide a signal indicative of the parameter to the signal processor.

Owner:BAKER HUGHES INC

Enhanced status monitoring, storage and reporting for optical transceivers

ActiveUS8886033B2Accurate informationFailed analysisTransmission monitoringTransmission monitoring/testing/fault-measurement systemsTransceiverEngineering

An optical transceiver and methods for using the same are disclosed. The optical transceiver and methods may be useful for providing more accurate information regarding trends in operation of the optical transceiver, predicting an impending failure of the optical transceiver, and providing details of the optical transceiver prior to failure. The optical transceiver generally includes (1) at least one of (i) a receiver configured to receive optical information and (ii) a transmitter configured to transmit optical information, (2) circuitry configured to sample data for one or more operational parameters of the receiver and / or transmitter, (3) logic configured to perform one or more statistical calculations on the sampled data to generate statistical information, and (iv) one or more memories configured to store the sampled data and the statistical information.

Owner:SOURCE PHOTONICS

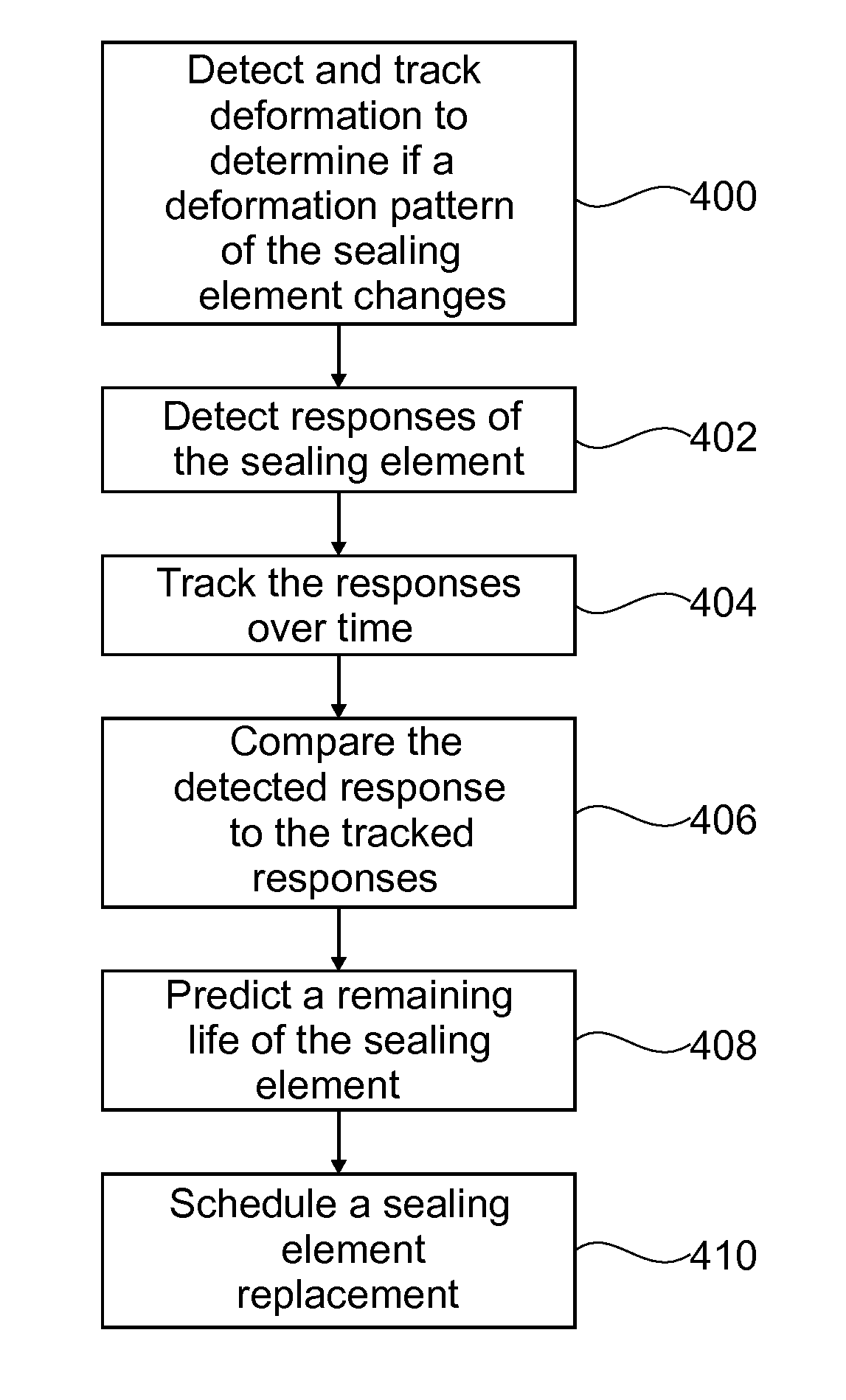

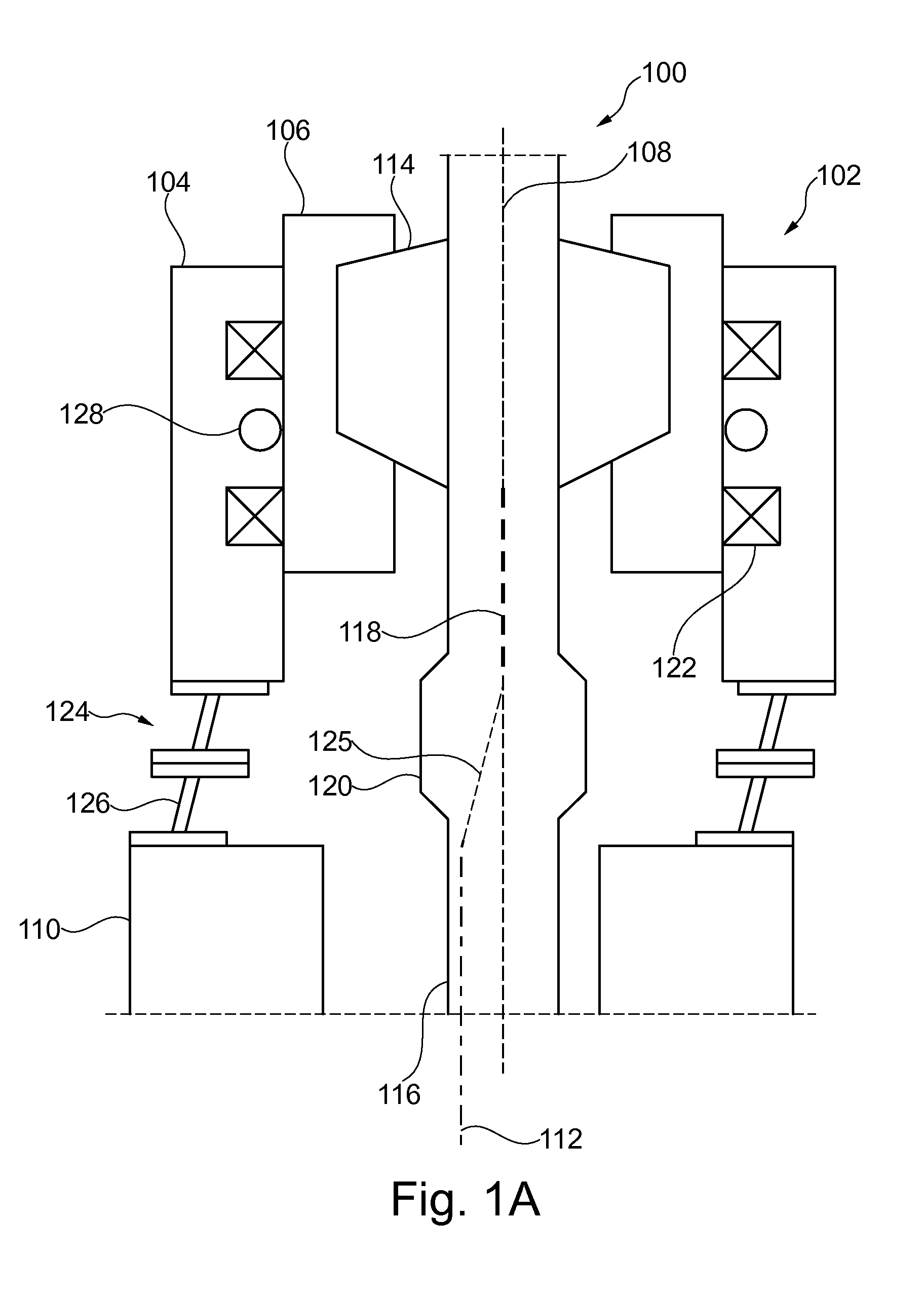

Management & control of a sealing element of a rotating control device

ActiveUS20150285054A1Improve tolerancePredict failureConstructionsMachine sealing rings testingDrilling systemRemaining life

Managing operation of a sealing element is described. In some aspects, failure of the sealing element of a pressure drilling system may be predicted. Deformation of the sealing element as a tool joint is pulled through the sealing element may be detected and tracked to determine if a deformation pattern of sealing element changes. Responses of sealing element due to one or more of stress, strain, temperature, mechanical load, and pressure using a network of sensors around sealing element can be detected. Responses may be tracked over time. Detected responses are compared to tracked responses to identify changes in the symmetry of responses over time or changes in magnitude of responses over time. Changes are associated with fractures occurring within sealing element. A remaining life of sealing element is predicted based on the changes and replacement may be scheduled based at least in part on the predicted remaining life.

Owner:SCHLUMBERGER TECH CORP

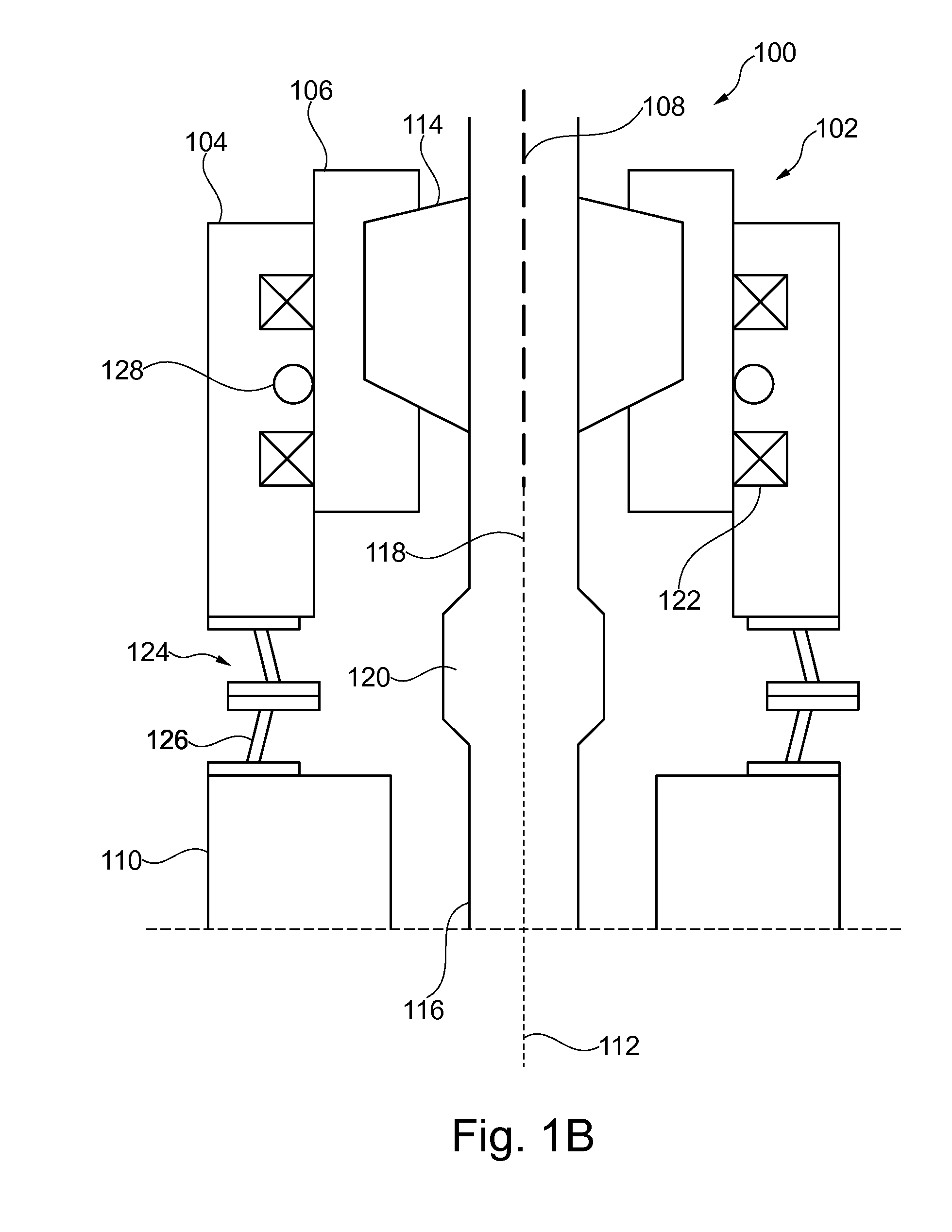

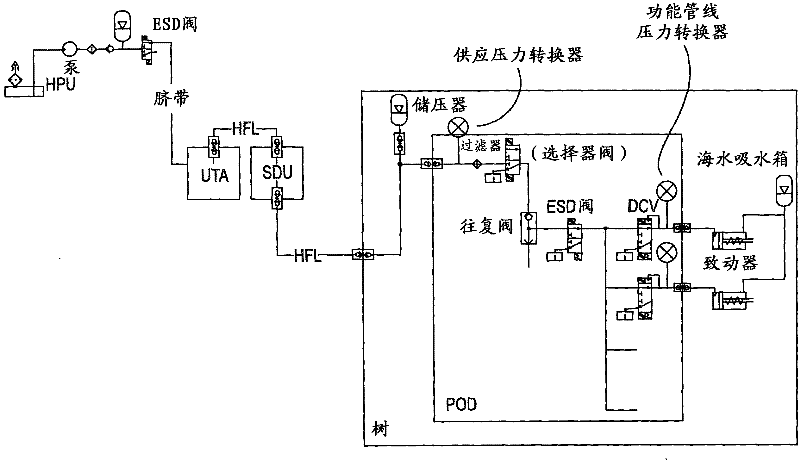

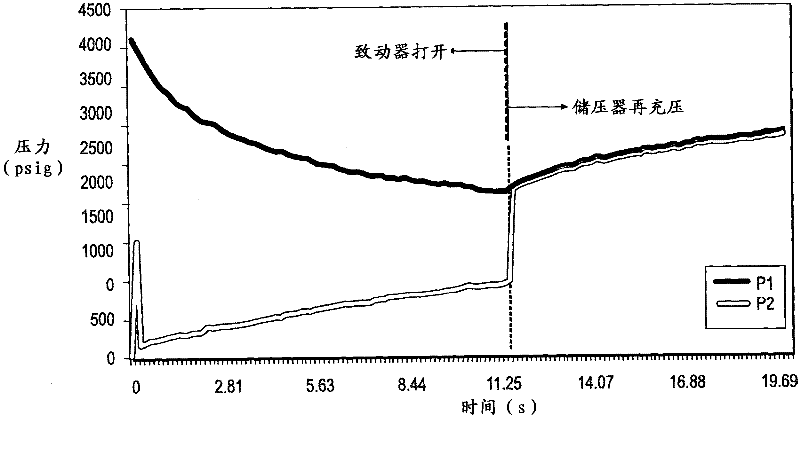

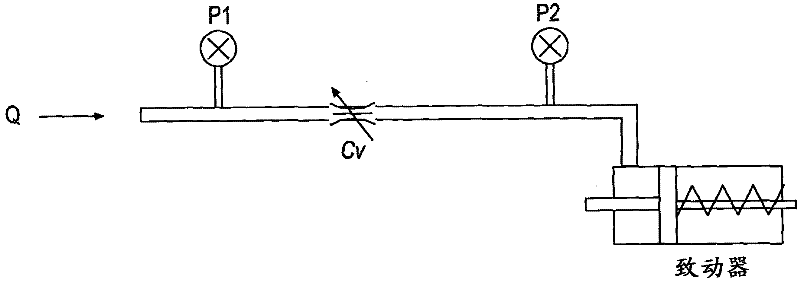

Subsea Control System Diagnostics

InactiveCN102265042APredict failurePredict and prevent failuresFluid-pressure actuator testingMeasurement of fluid loss/gain rateControl systemUltimate tensile strength

Accurate, dependable methods for analyzing operational parameters of subsea control systems and diagnosis / prediction of failures are provided, in particular, methods for detection of leaking and / or clogging in hydraulic control system using recorded pressure signals and evaluating response communication strength (signal amplitude) of field equipment from, for example, subsea control systems. Prediction of failure(s) allows an opportunity to prepare for intervention to minimize the impact of failure before failure occurs, for example, by ordering equipment, tools and / or scheduling an intervention vessel. Similarly, diagnosing a failure drastically shortens the intervention time.

Owner:CHEVROU USA INC

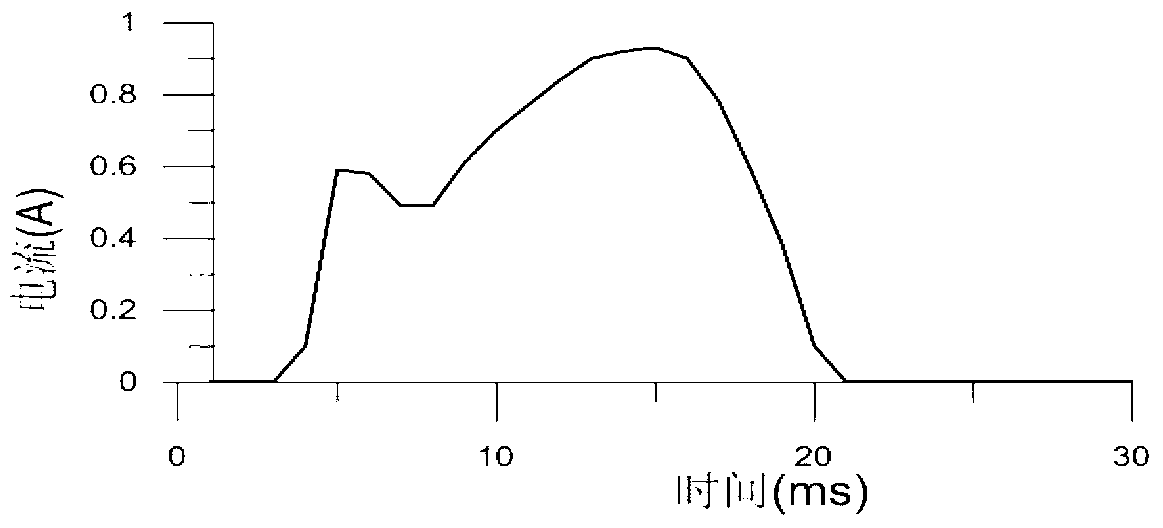

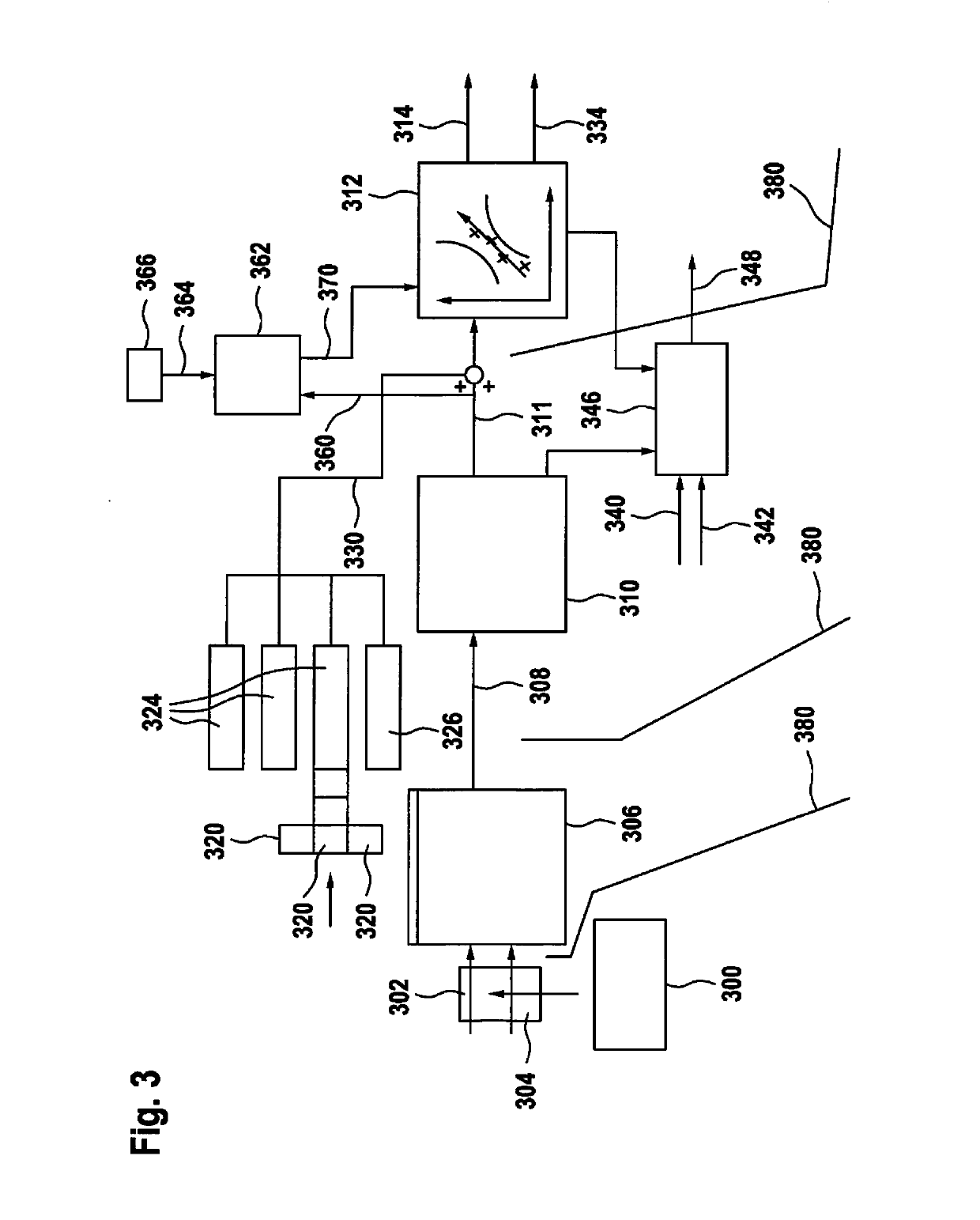

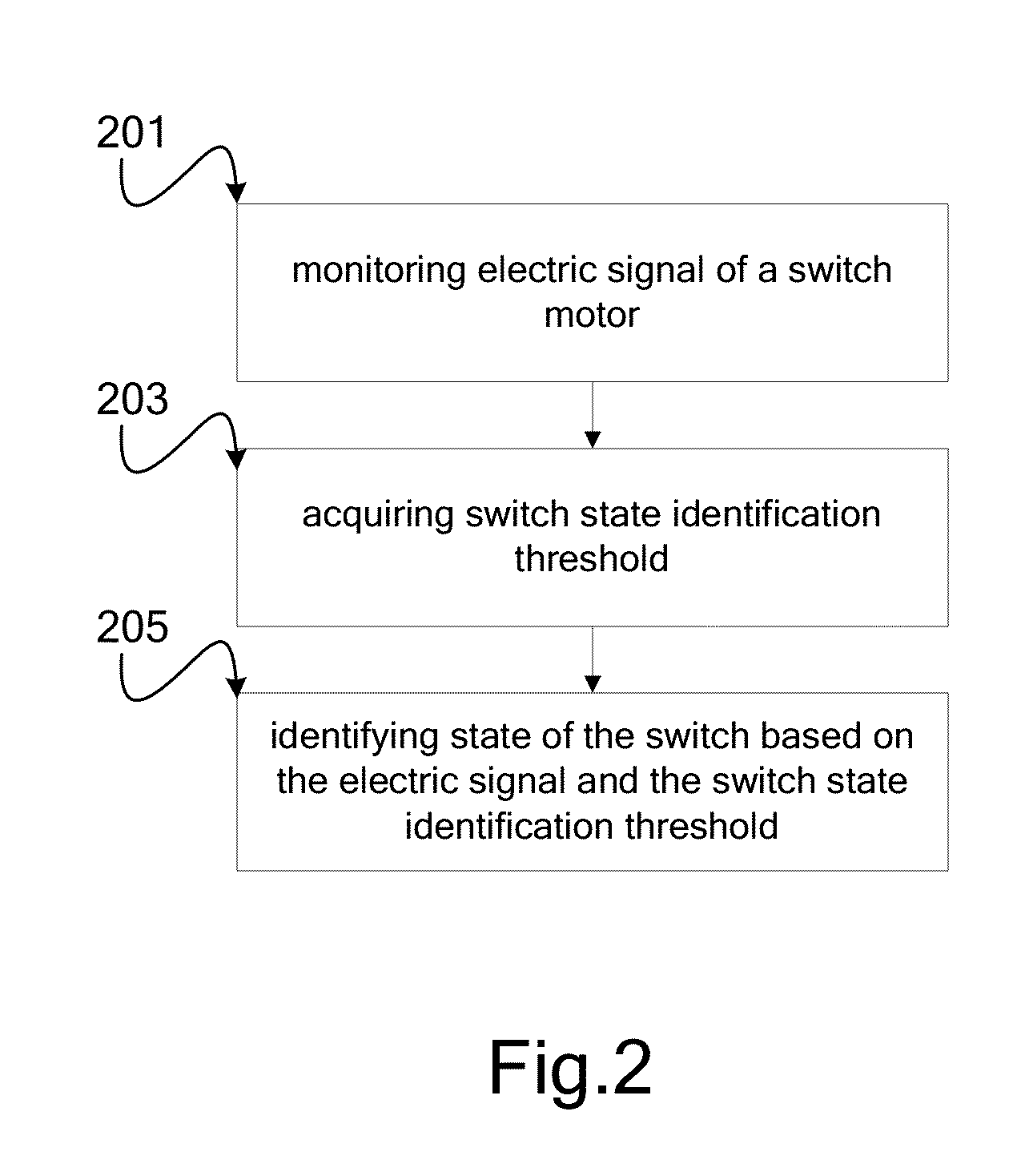

Switch monitoring and railway line management

InactiveUS20140312181A1Reduce switchingPredict failureRail switchesRailway traffic control systemsStable statusElectric machine

A switch monitoring method and a switch monitoring system, a railway line management method and a railway line management system are provided. Electric signal of a switch motor during pulling of the switch can effectively reflect status of the switch, when the switch is in a stable state, electric signal of its motor is very steady during pulling of a switch of the switch; however, when the switch is in an unstable state, there will be different degrees of fluctuation in electric signal of its motor during pulling of the switch. Thus, the invention may be used to identify state of a switch by monitoring electric signal of a switch motor (201,203,205), and further take different measures based on different states of the switch (401,403,405). With these measures, accidents due to switch failure may be effectively reduced, and train delay time may also be reduced through proper line management.

Owner:IBM CORP

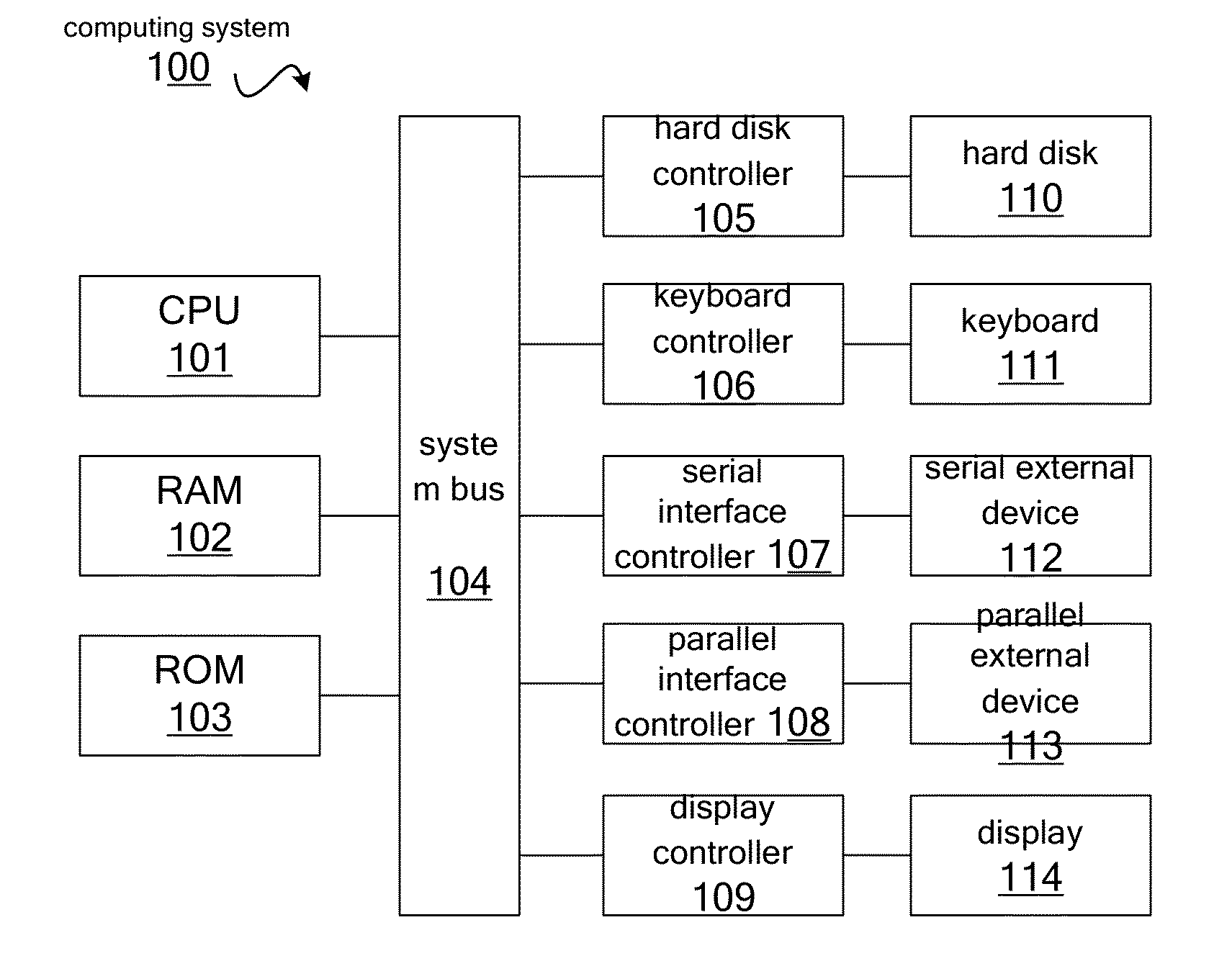

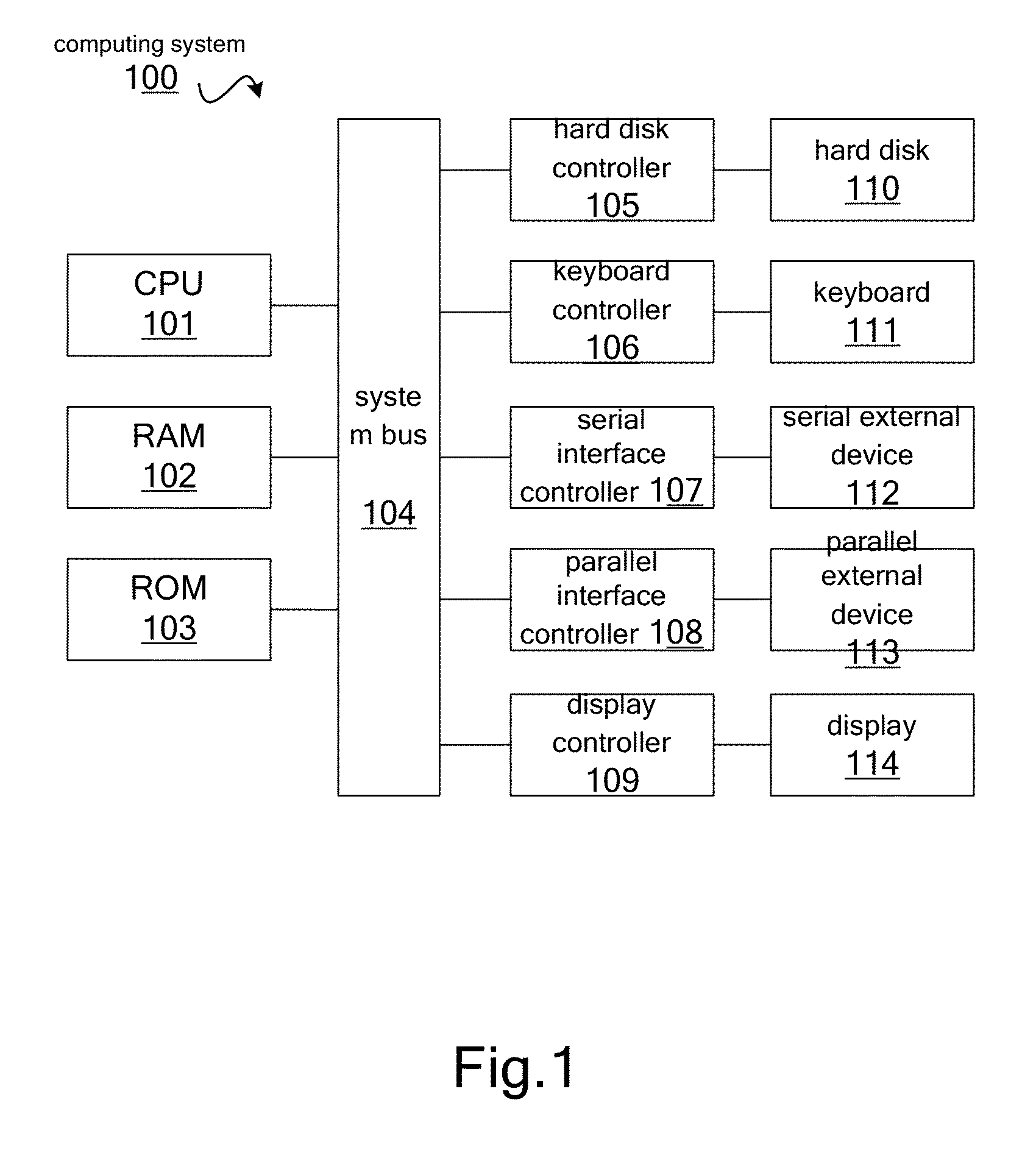

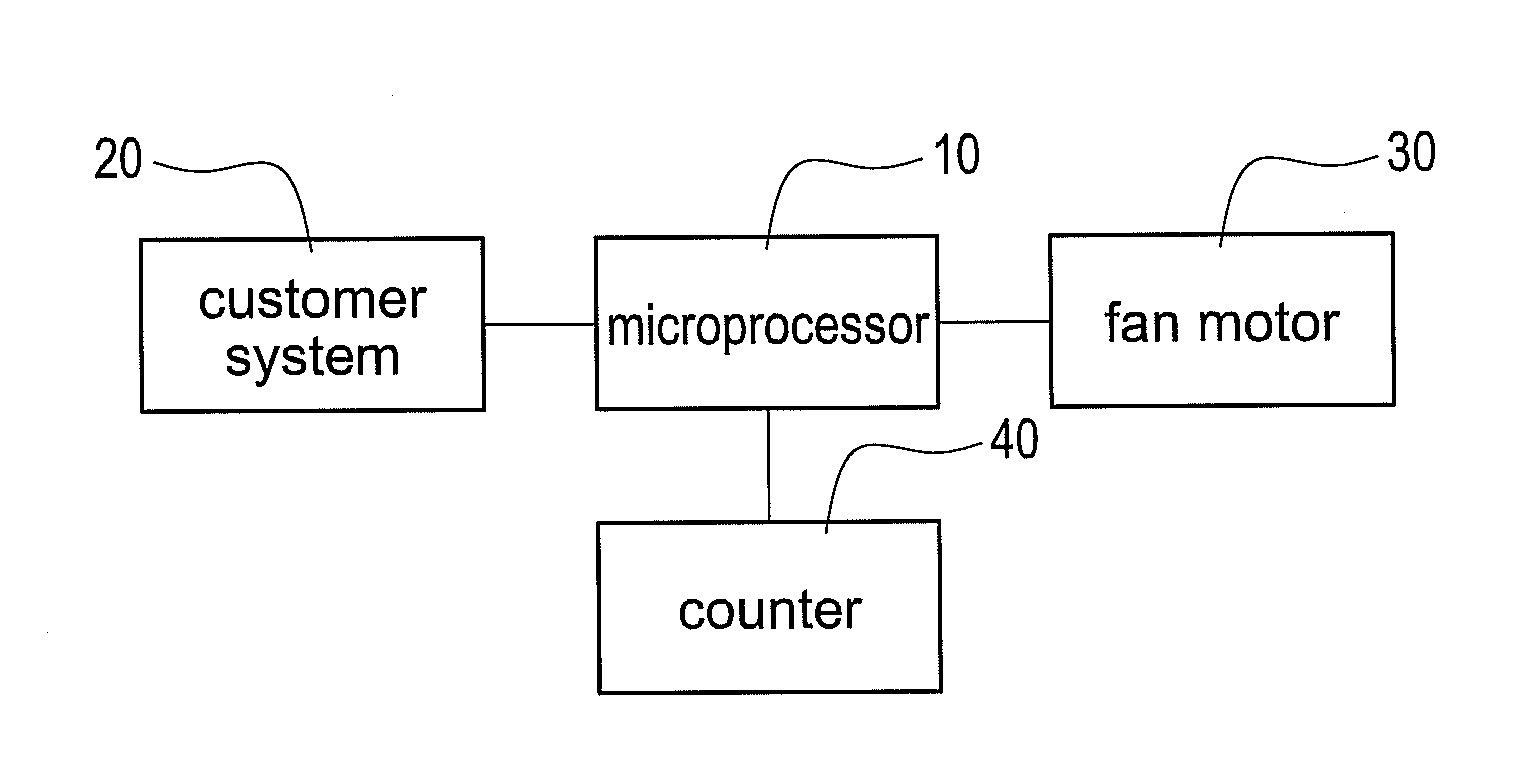

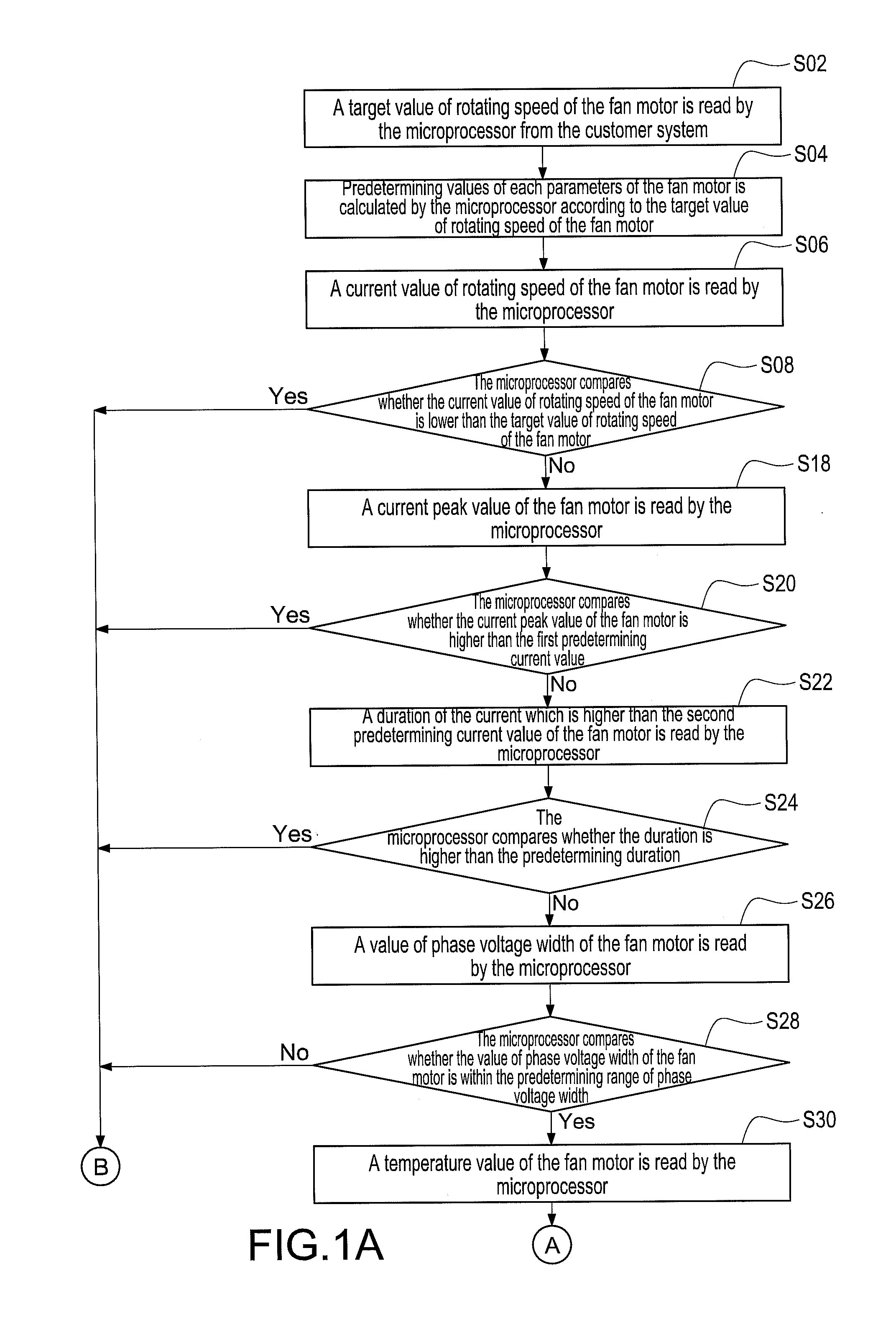

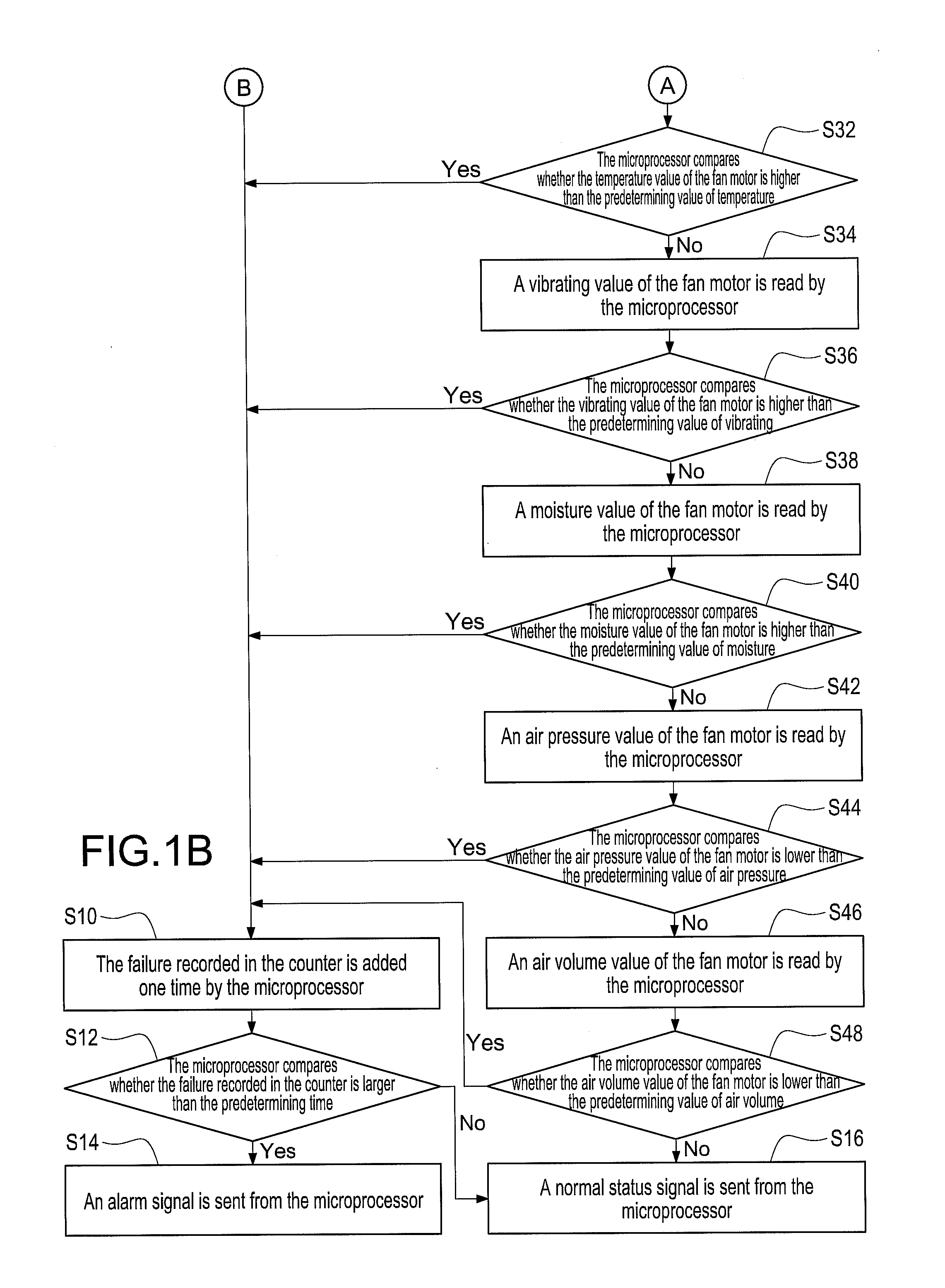

Alerting apparatus for fan failure and method for the same

ActiveUS20120274259A1Predict failureMotor/generator/converter stoppersDC motor speed/torque controlPeak valueControl theory

An alerting method for fan failure first reads a target value of rotating speed of a fan motor. Predetermining values of each parameters of the fan motor is calculated according to the target value of rotating speed of the fan motor. If a current value of rotating speed of the fan motor is lower than the target value of rotating speed of the fan motor, the failure recorded in a counter is added one time. If a current peak value of the fan motor is higher than a first predetermining current value, the failure recorded in the counter is added one time. If the duration of the current which is higher than a second predetermining current value of the fan motor is higher than a predetermining duration, the failure recorded in the counter is added one time. An alarm signal is sent if the failure recorded in the counter is larger than a predetermining time.

Owner:DELTA ELECTRONICS INC

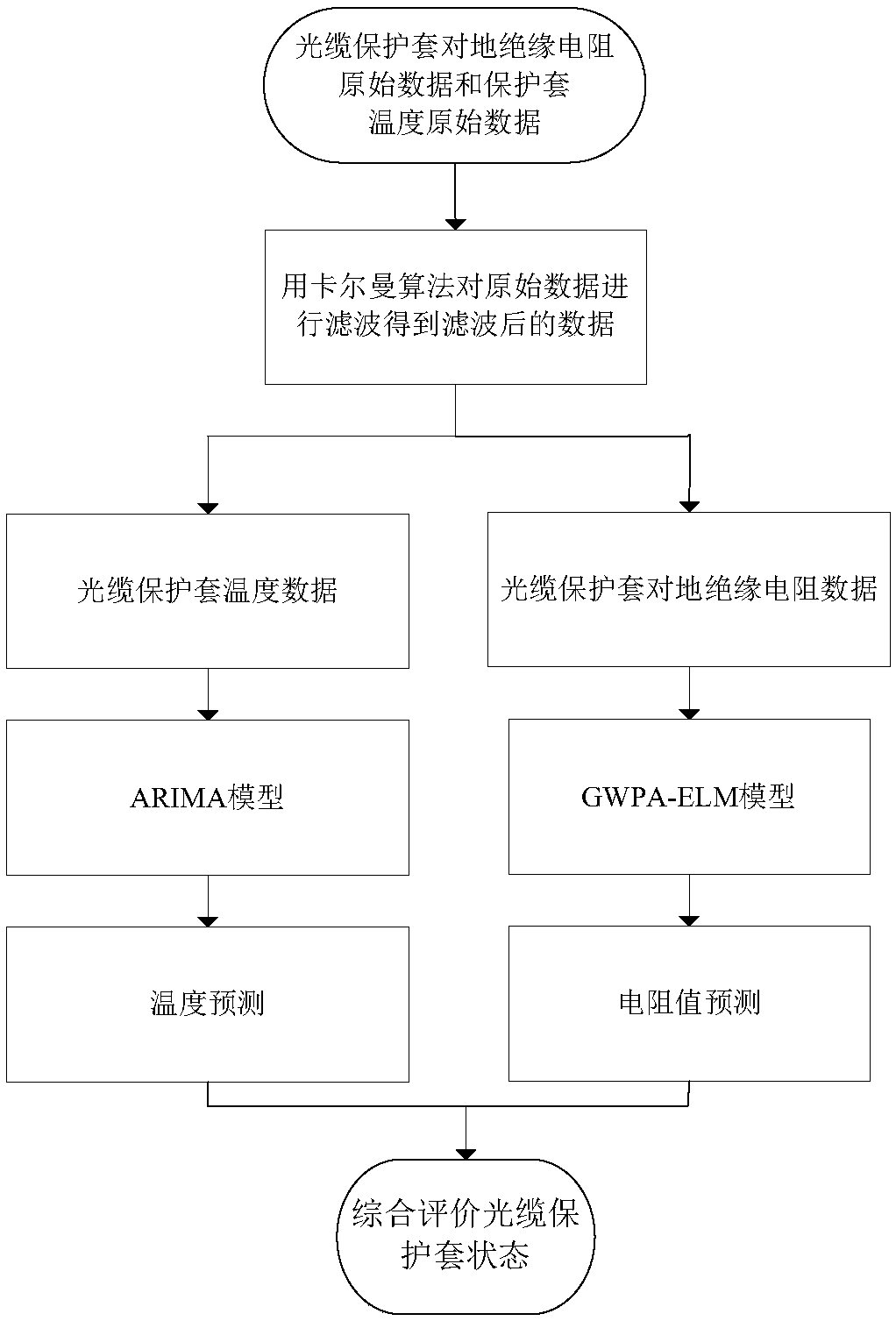

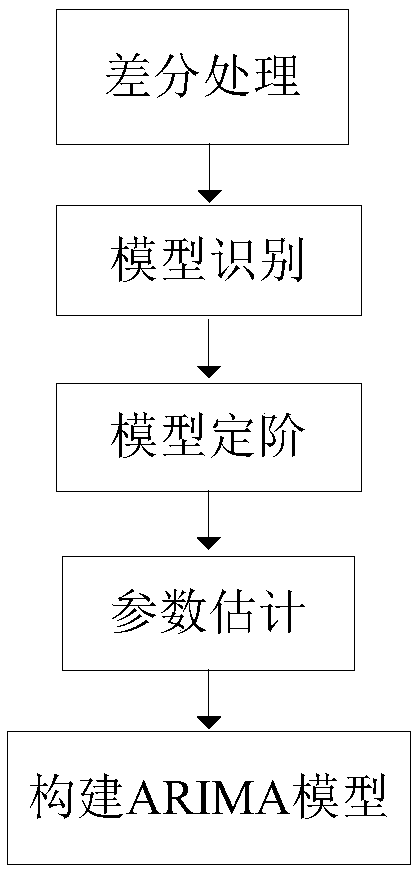

Optical cable fault prediction method based on temperature and resistance

ActiveCN107917734APredict failureDevelop a maintenance strategy in advanceMeasurement devicesElectromagnetic transmissionElectrical resistance and conductancePrediction algorithms

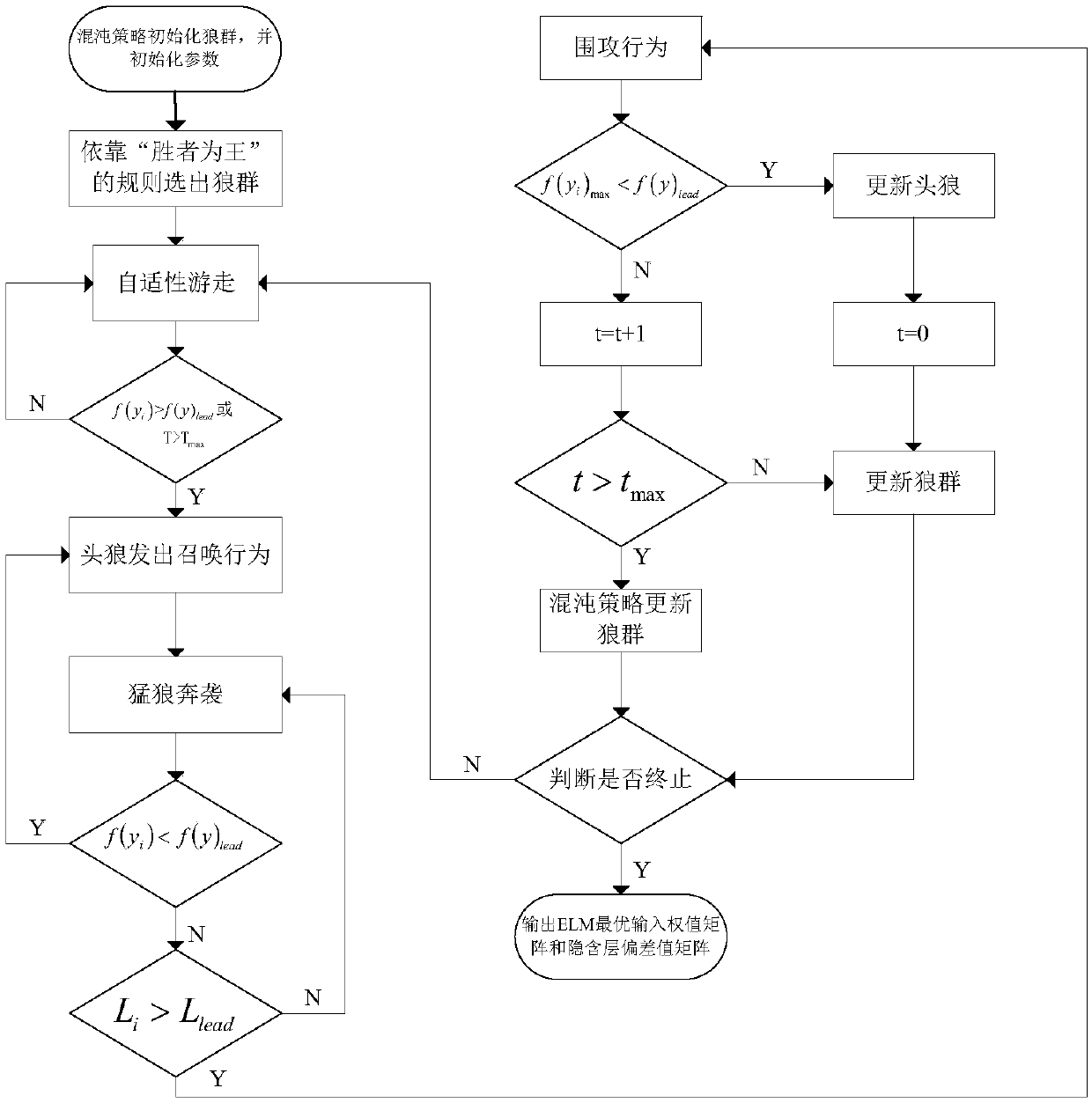

The invention relates to an optical cable fault prediction method based on temperature and resistance, and relates to the technical field of optical cable communication state prediction, solving the problems that the current method only can process the occurred faults in the optical cable line and cannot analyze the grounding insulation resistance value of an optical cable protection sleeve. The optical cable fault prediction method based on temperature and resistance can predict the grounding insulation resistance of the optical cable protection sleeve through an improved Gauss Wolf Pack Algorithm-Extreme Learning Machine (GWPA-ELM) prediction algorithm, can predict the temperature of the optical cable protection sleeve through a difference autoregression moving average model (ARIMA) algorithm, and can evaluate the state of the optical cable protection sleeve through the predicted resistance value and temperature. The optical cable fault prediction method based on temperature and resistance can predict the possibly occurred fault of the optical cable in the future, and can make maintenance strategy in advance.

Owner:国网吉林省电力有限公司信息通信公司

Gas separators with fiber optic sensors

ActiveUS8817266B2MadeIncreased operating lifeForce measurementScattering properties measurementsEngineeringSignal processing

Devices and methods for detecting operational parameters associated with a gas separator used in an electric submersible pump in a wellbore. A fiber optic sensing arrangement is used to detect the operational parameter and includes a fiber optic signal processor and an optic fiber that is associated with the gas separator to provide a signal indicative of the parameter to the signal processor.

Owner:BAKER HUGHES INC

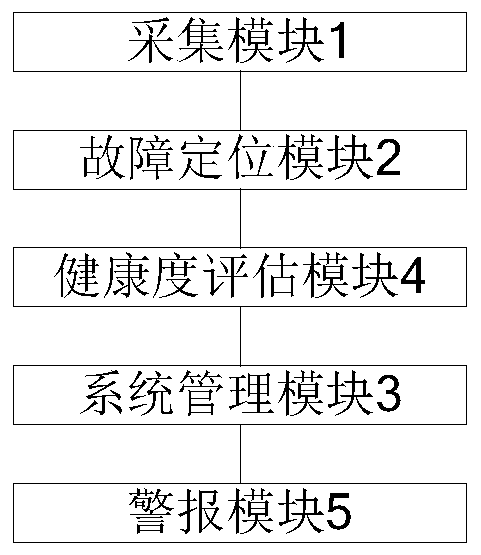

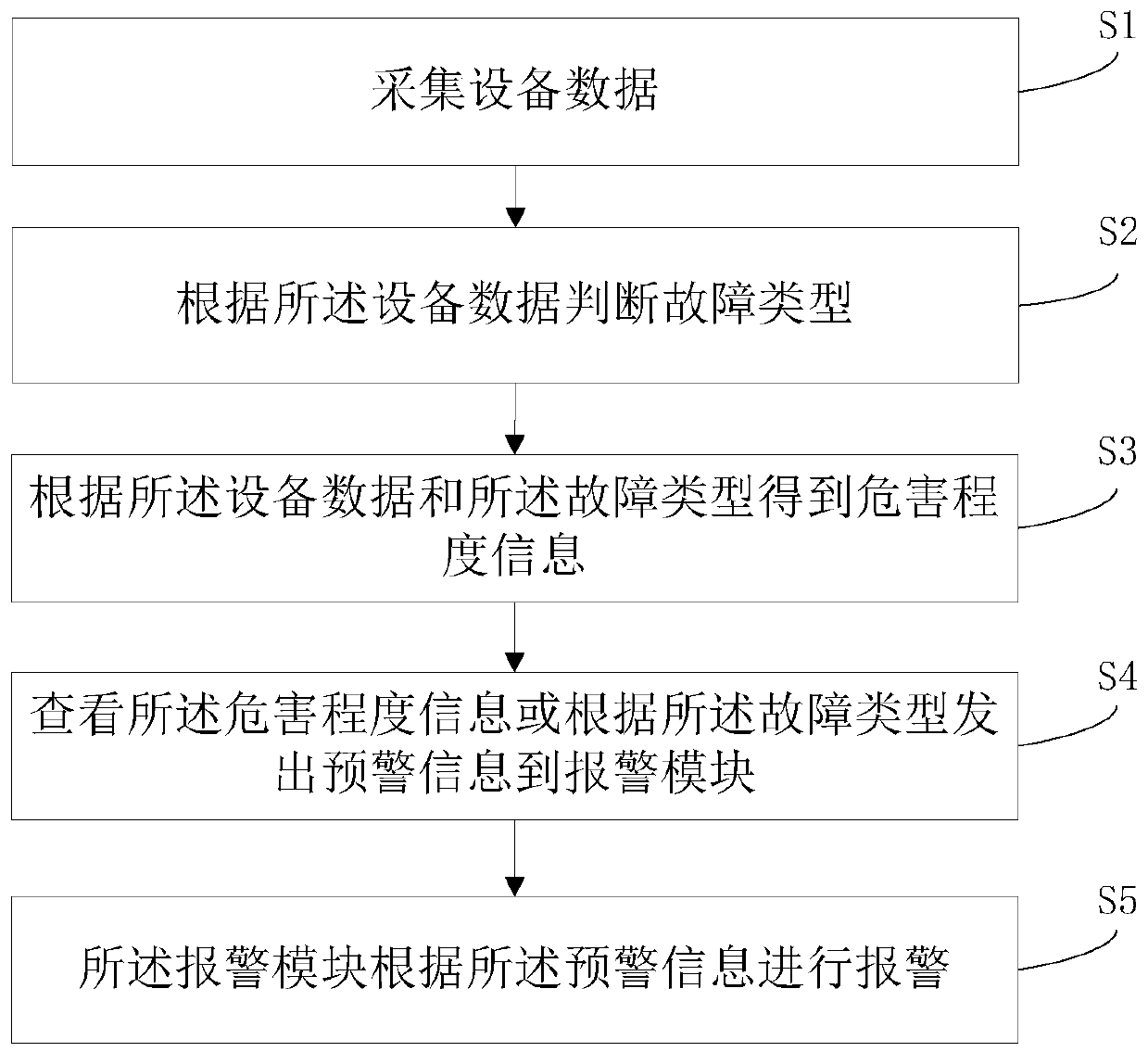

Industrial production equipment fault early-warning system and method

ActiveCN109809149APredict failureAvoid missing warning messages when you are not on siteControl devices for conveyorsEarly warning systemSystems management

The invention relates to an industrial production equipment fault early-warning system and method and relates to the field of electronic data processing. The industrial production equipment fault early-warning system comprises a collecting module, a fault positioning module, a system management module, a health degree assessment module and a warning module, wherein the collecting module is used for collecting equipment data, the fault positioning module is used for judging the fault type according to the equipment data, the health degree assessment module is used for obtaining hazard degree information and sending the hazard degree information to the system management module according to the equipment data and the fault type, the system management module is used for viewing the hazard degree information and is further used for sending early-warning information according to the hazard degree information, and the warning module is used for performing warning according to the early-warning information. By means of the scheme of the industrial production equipment fault early-warning system and method, the technical problem of how to perform early-warning on faults in the production process is solved, and the industrial production equipment fault early-warning system and method are used for performing the early-warning on the possibly-generated faults of production equipment.

Owner:BEIDOU TIANDI CO LTD

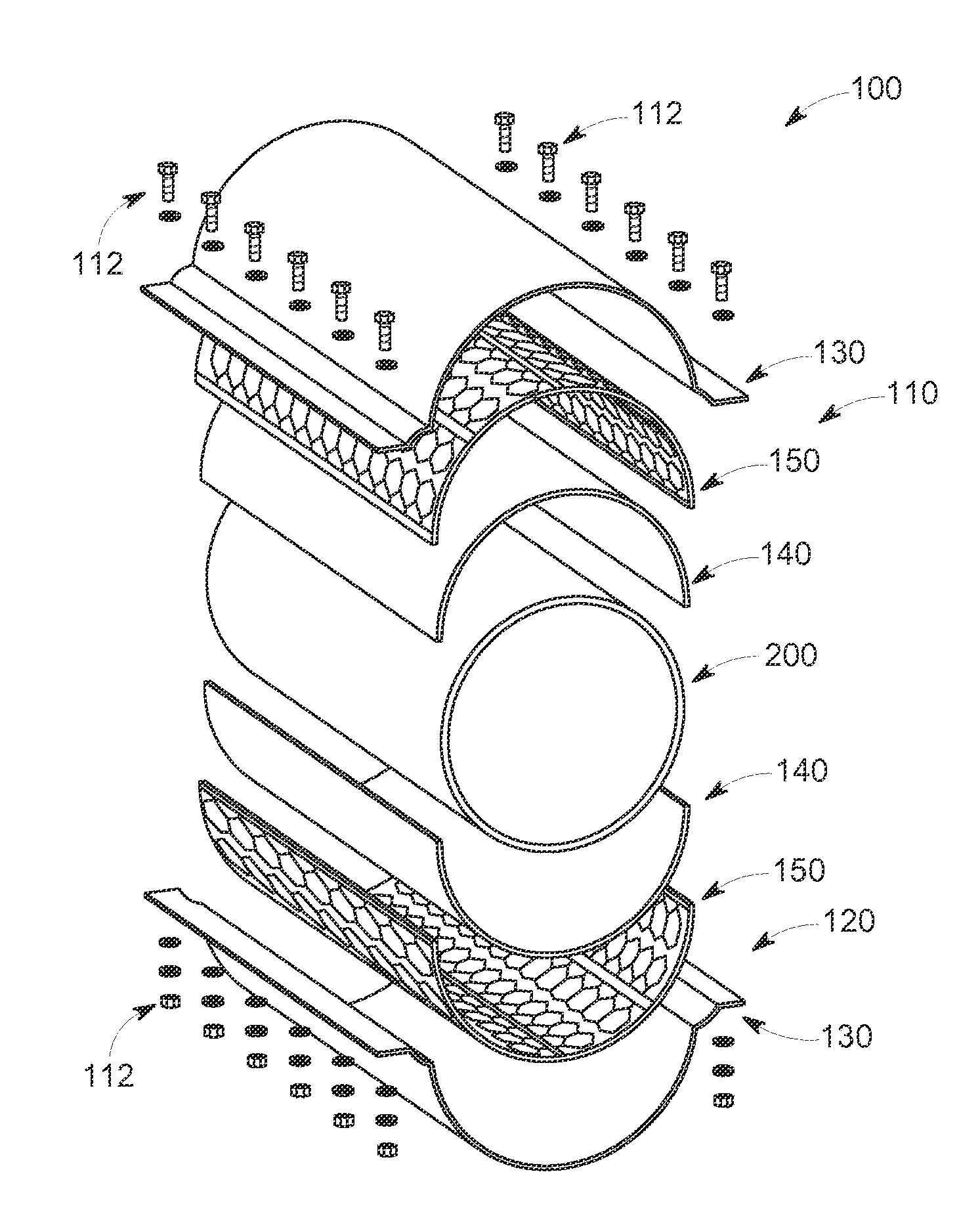

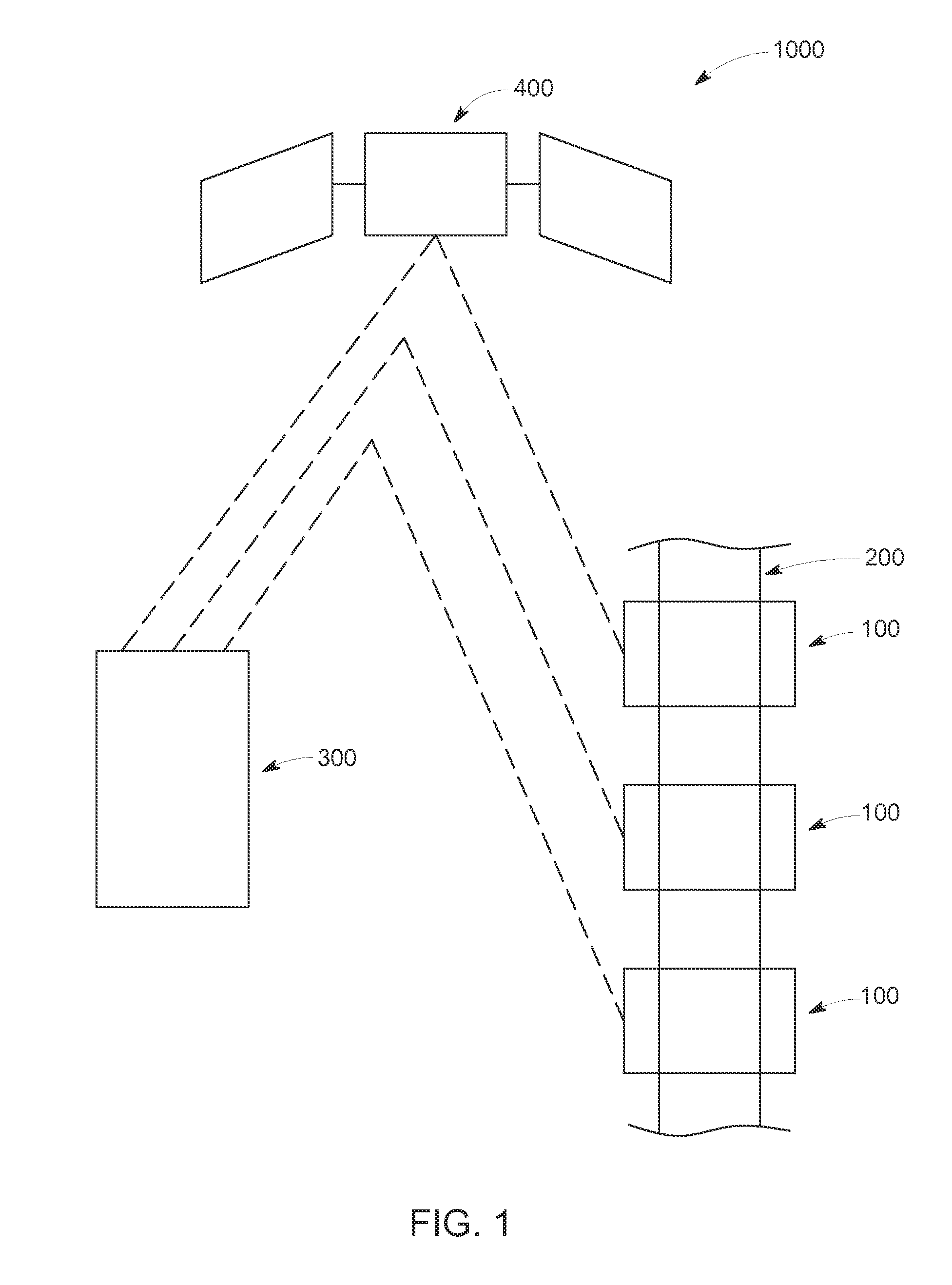

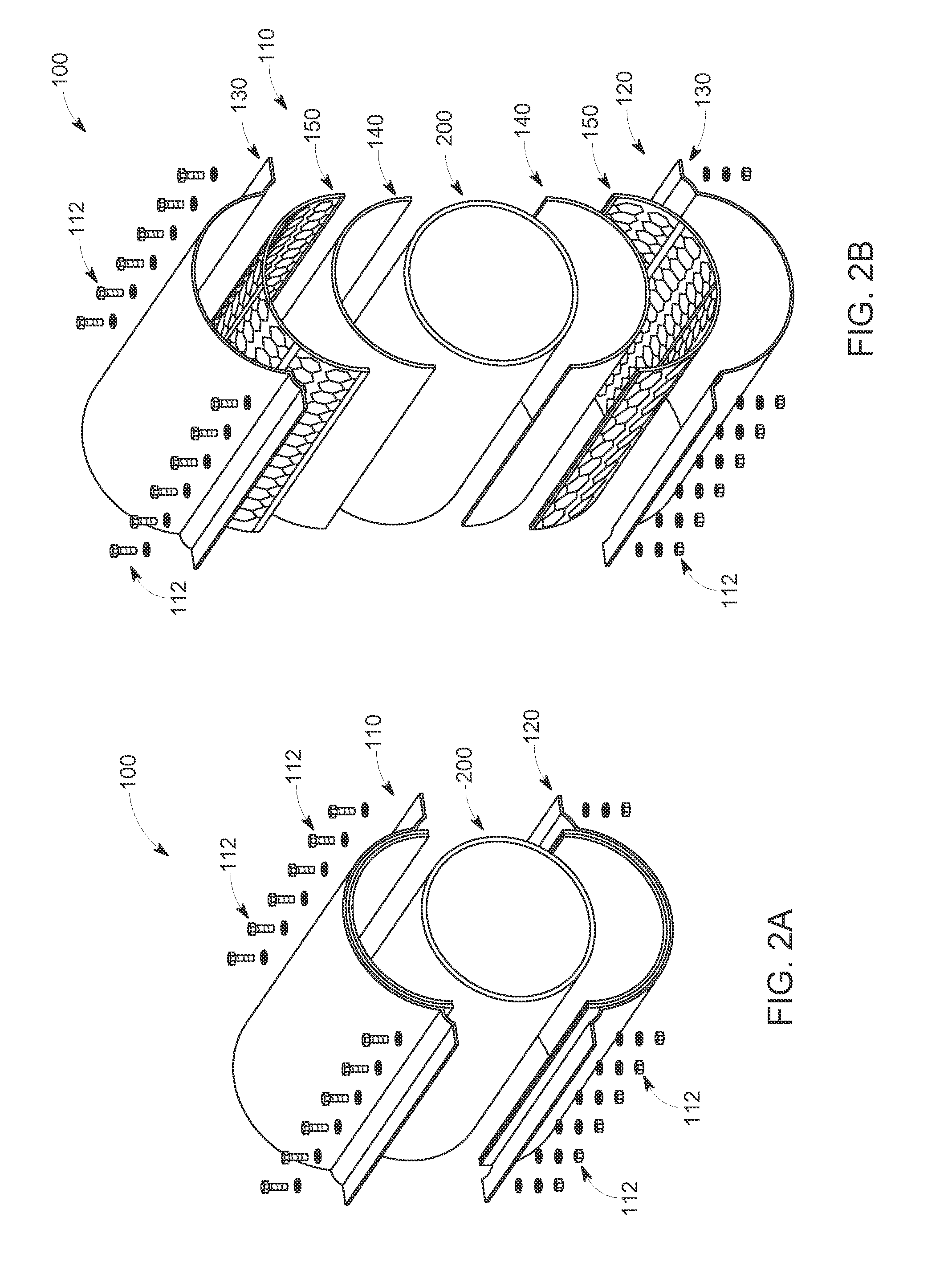

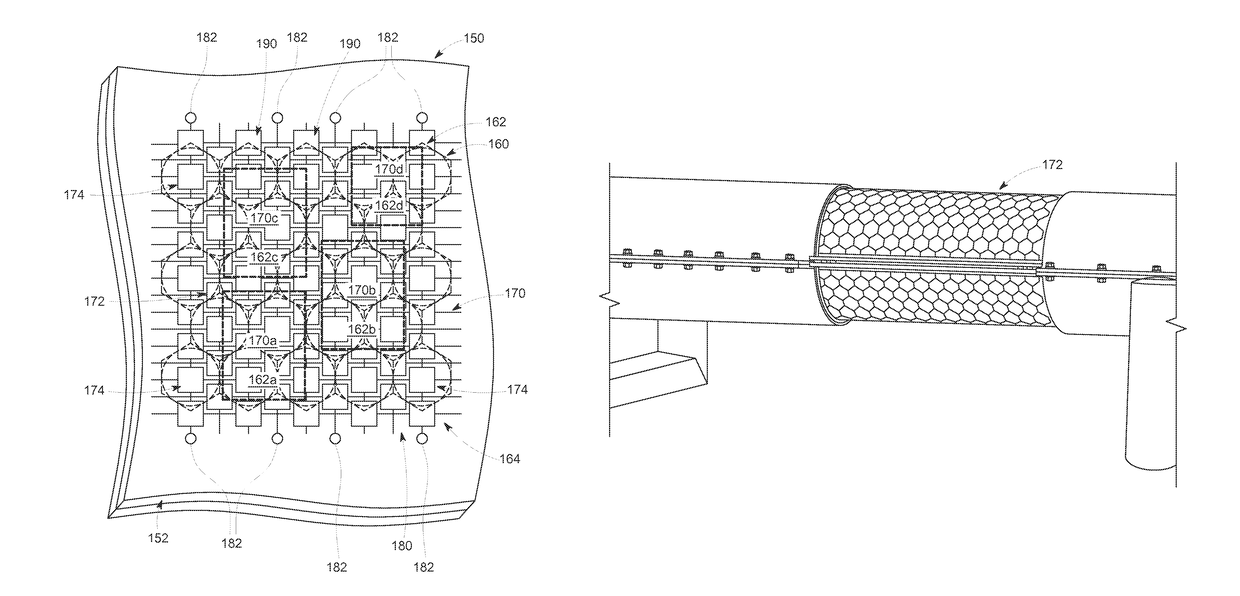

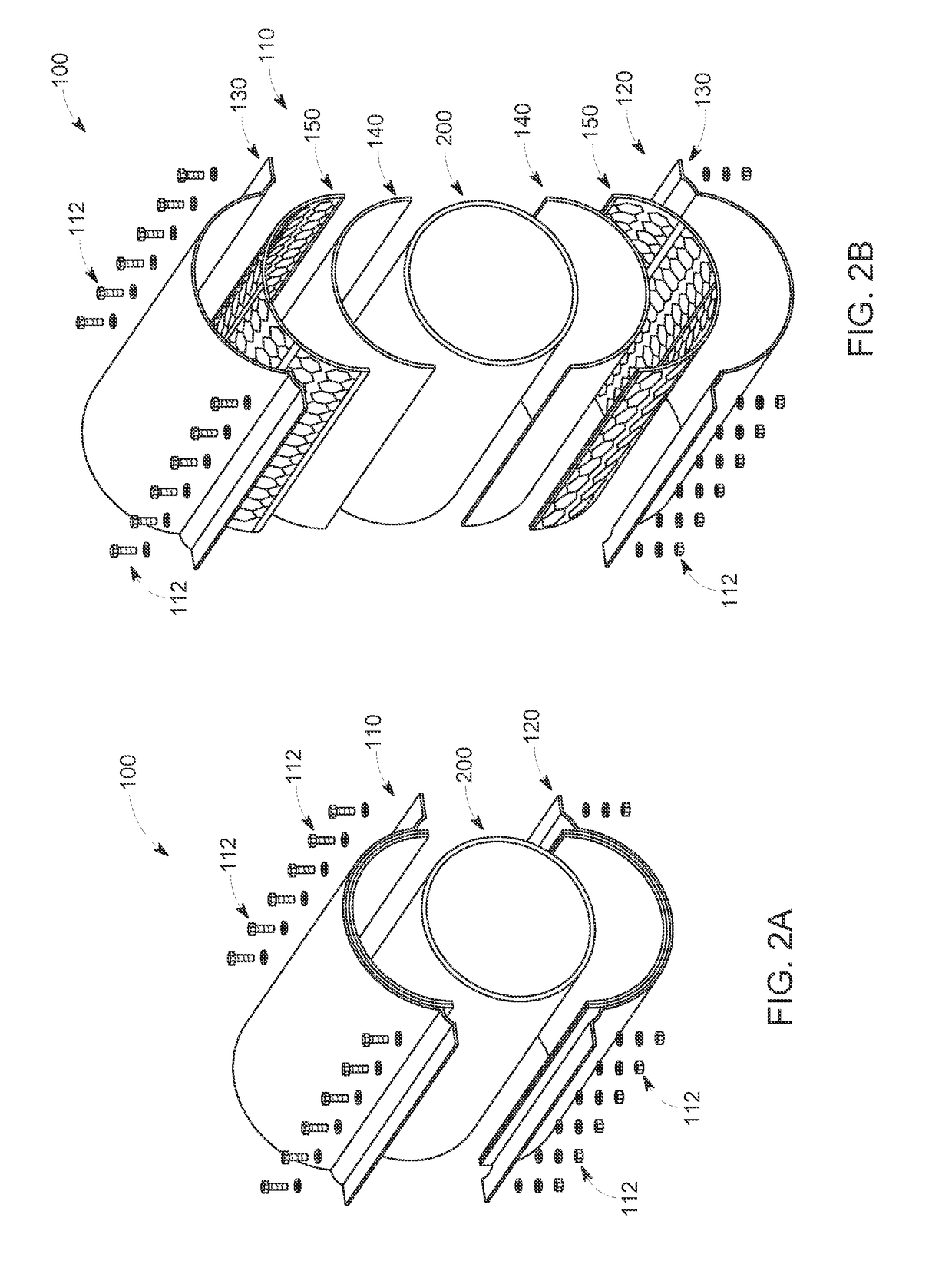

Integrated pipeline protection system

ActiveUS20150136265A1Predict failurePipe elementsFluid-tightness measurementReal-time dataLine tubing

The pipeline protection system includes a plurality of modules and a central control unit. The modules are adapted to be disposed circumferentially around the pipeline and capable of communicating to each other and with the central control unit to generate a plurality of real time data related to the pipeline. The modules are retrofittable configuration that includes sub-modules. Each sub-module includes top and bottom protective casings, and at least one flexible composite layer disposed between the top and bottom protective casings. The flexible composite layer includes an electronic circuitry embedded thereon, and a plurality of sensors coupled to the electronic circuitry to monitor a plurality of parameters associated with the pipeline. The plurality of sensors is configured to generate various real time data, such as pipeline leakage, predict future leakage or failure, and detect any attempt to theft or tempering in the pipeline.

Owner:ZULFIQUAR MOHAMMED

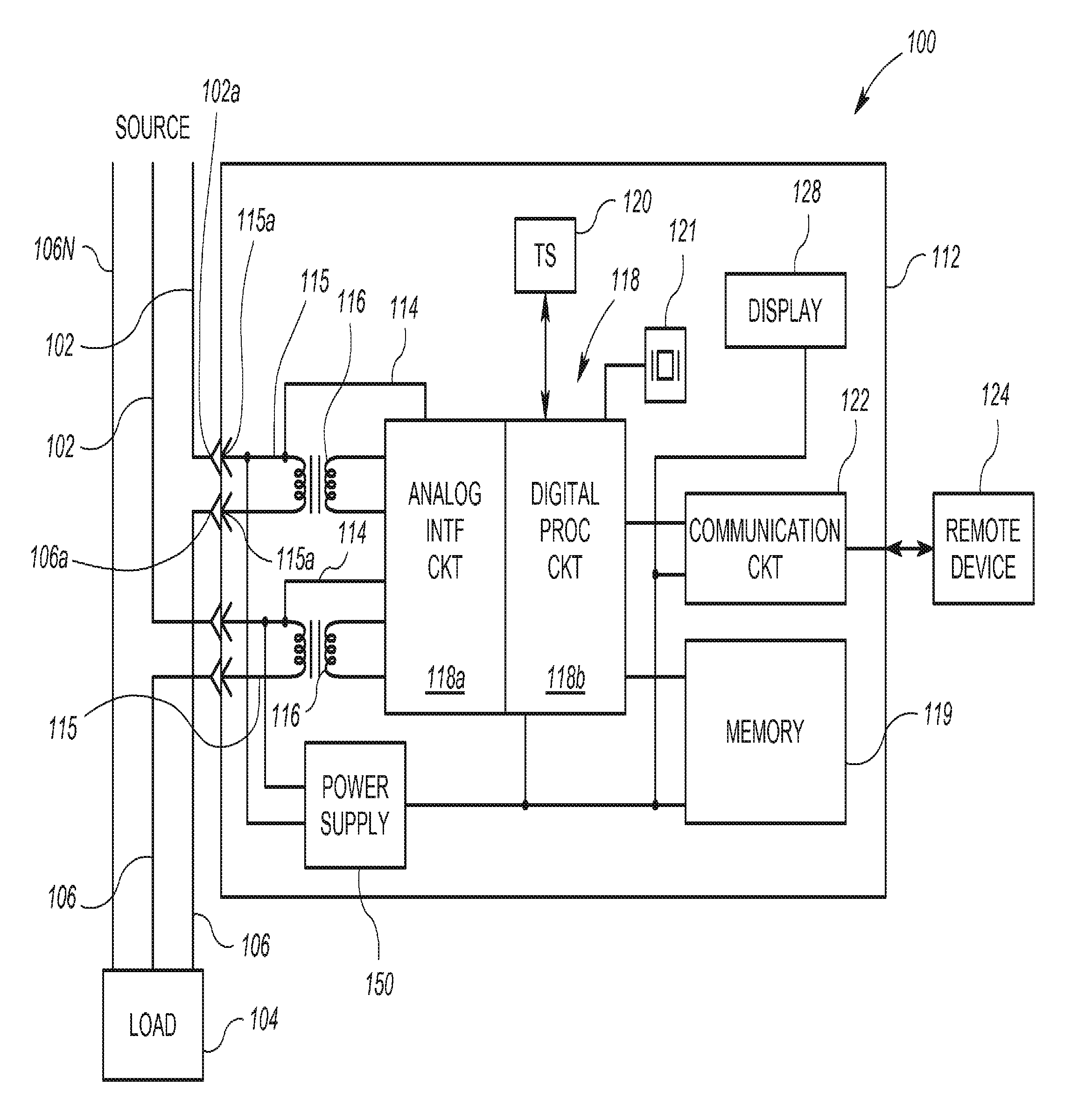

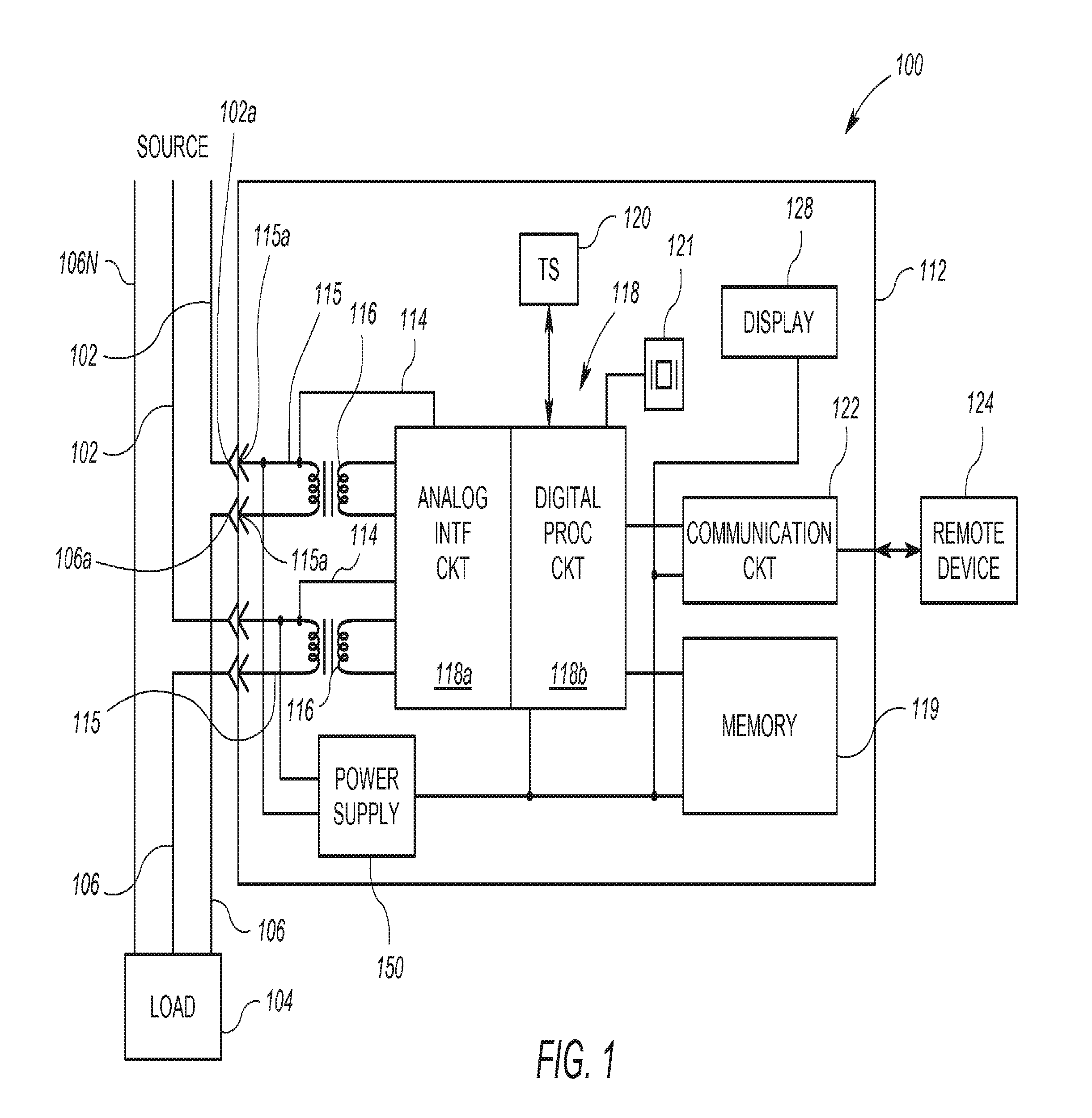

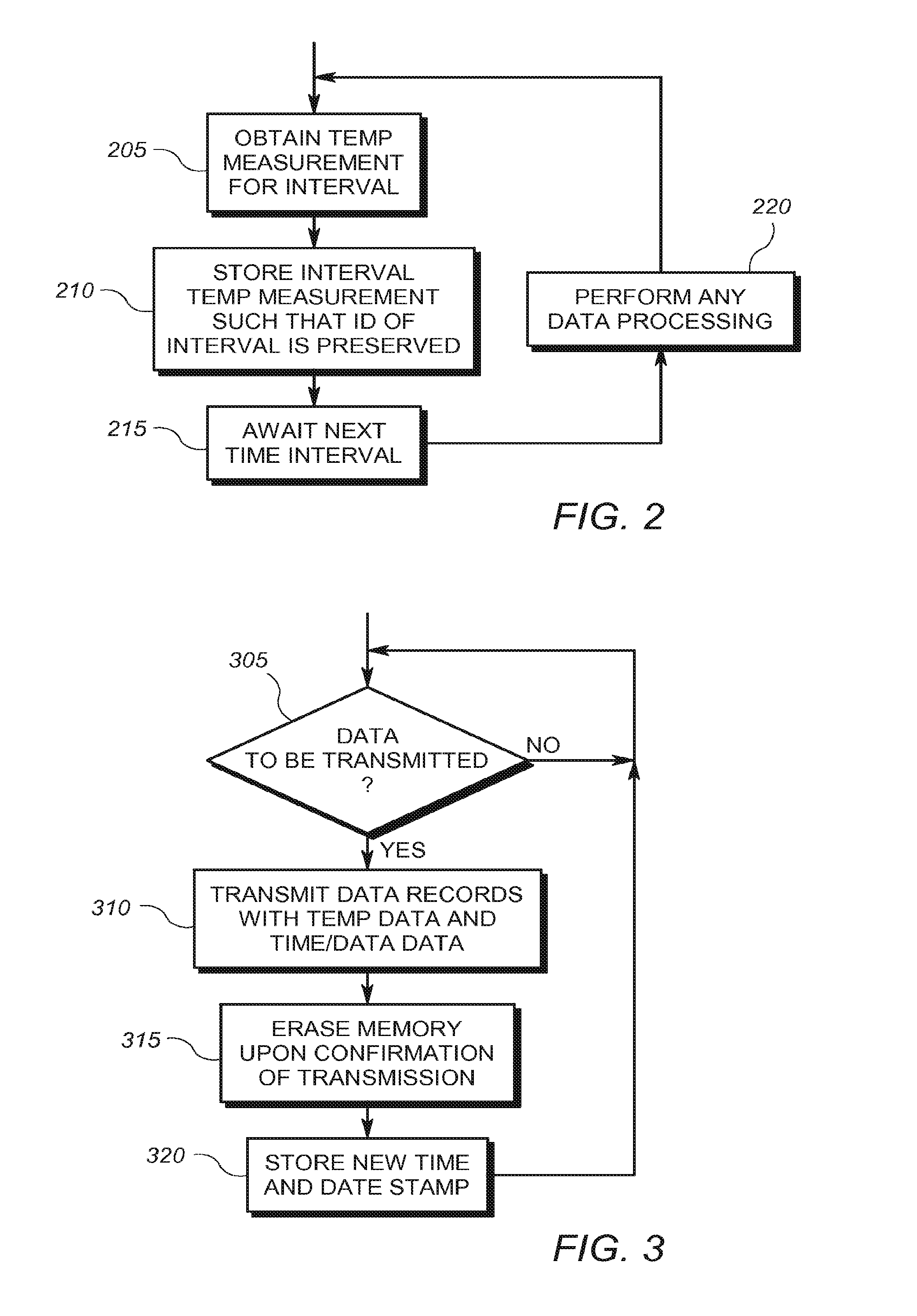

Temperature Profiling in an Electricity Meter

InactiveUS20170016943A1Reduce the number of failuresPredict failureThermometer detailsElectronic circuit testingElectricityEngineering

An arrangement includes a plurality of electricity meters and a control station. Each of the plurality of electricity meter includes a memory storing temperature information regarding the electricity meter, and a communication device. The control station is configured to receive temperature information from each of the plurality of electricity meters, for example, by way of the communication device of the electricity meters. The control station is also configured to process the temperature information from the plurality of electricity meters to generate at least one diagnostic value.

Owner:LANDIS GYR LLC

Integrated pipeline protection system

ActiveUS9732911B2Predict failureFluid-tightness measurementPipeline systemsReal-time dataComputer module

The pipeline protection system includes a plurality of modules and a central control unit. The modules are adapted to be disposed circumferentially around the pipeline and capable of communicating to each other and with the central control unit to generate a plurality of real time data related to the pipeline. The modules are retrofittable configuration that includes sub-modules. Each sub-module includes top and bottom protective casings, and at least one flexible composite layer disposed between the top and bottom protective casings. The flexible composite layer includes an electronic circuitry embedded thereon, and a plurality of sensors coupled to the electronic circuitry to monitor a plurality of parameters associated with the pipeline. The plurality of sensors is configured to generate various real time data, such as pipeline leakage, predict future leakage or failure, and detect any attempt to theft or tempering in the pipeline.

Owner:ZULFIQUAR MOHAMMED

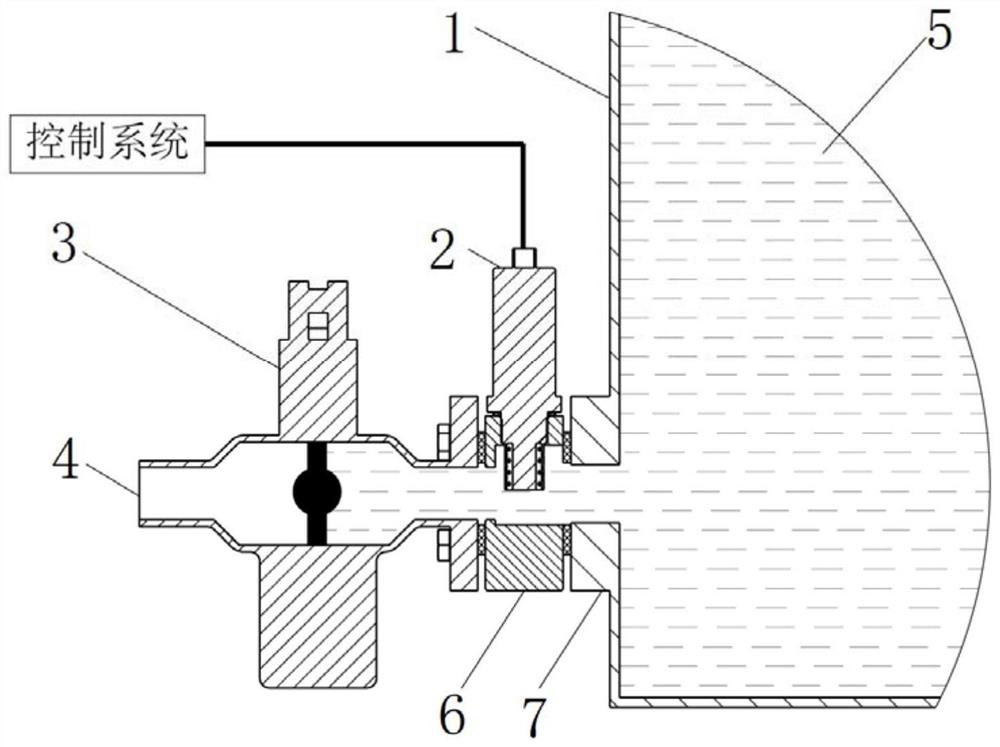

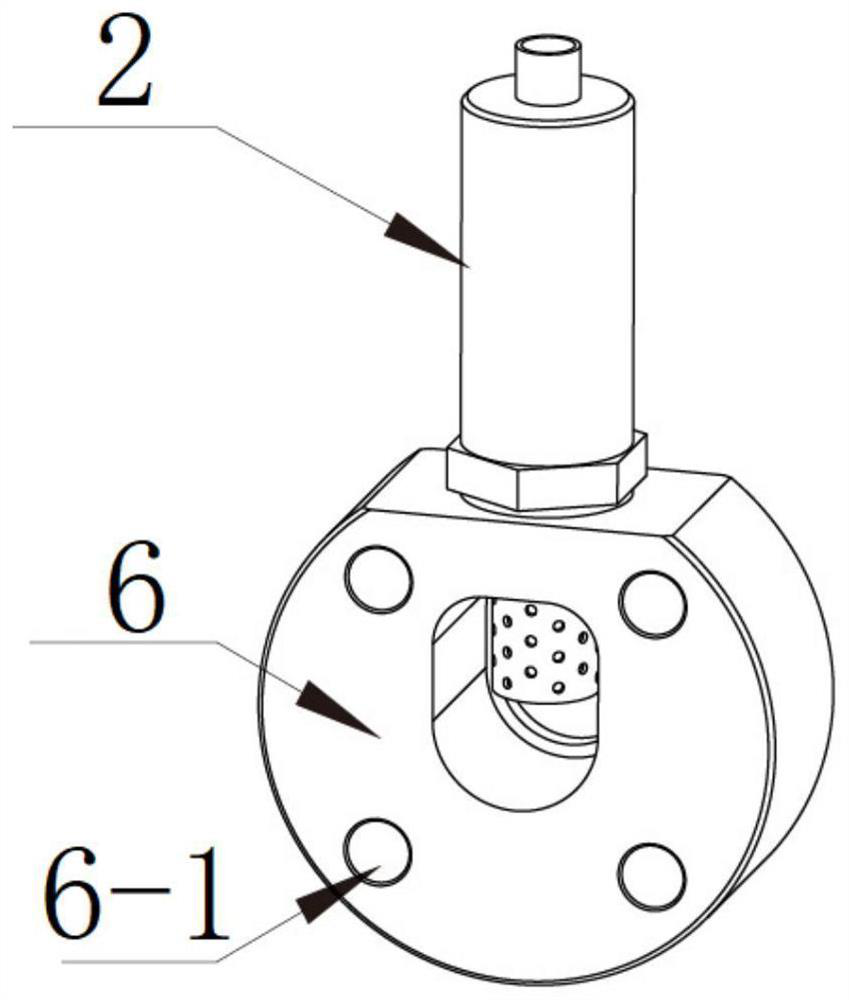

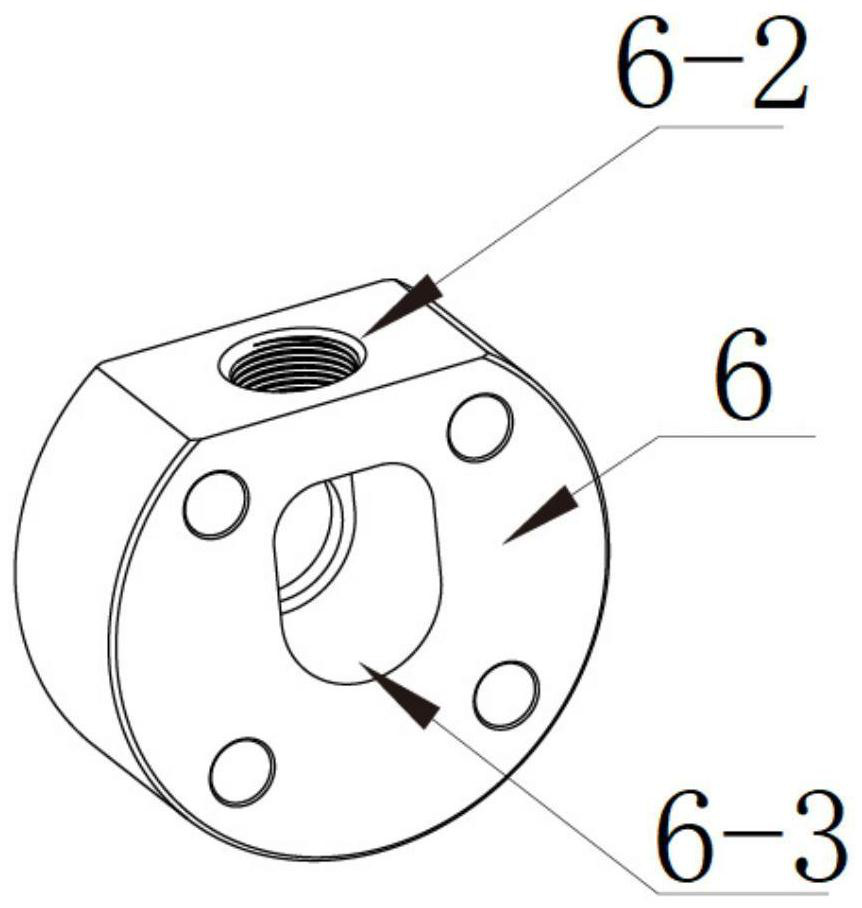

Fuel oil moisture on-line monitoring device

PendingCN111650254AFuel savingPredict equipment failureMaterial capacitanceProcess engineeringFuel oil

The invention discloses a fuel oil moisture on-line monitoring device, which can accurately measure the moisture content change of measured oil on line, display the moisture content value (ppm) of themeasured oil and the moisture change curve of a fuel oil system in different time periods in real time, and assist an operator in judging whether the oil needs to be replaced or not, so that the oilcan be saved, and the equipment failure can be predicted. The device is simple and practical in structure, and the measuring sensor is more convenient to maintain and replace due to the structural characteristics. the device can be easily and economically installed on a newly-built device to be tested or an original device to be tested,; the device can be widely applied to ships and other industries. The device is simple in structure, convenient to use, quick in response and low in price. The moisture content monitoring is fast and accurate. The structure is simple, and installation and maintenance are convenient; the adopted sensor has no movable part, is maintenance-free, is connected with the plunger probe and the tee joint, and has a simple industrial online installation form.

Owner:北京海智元科技有限公司

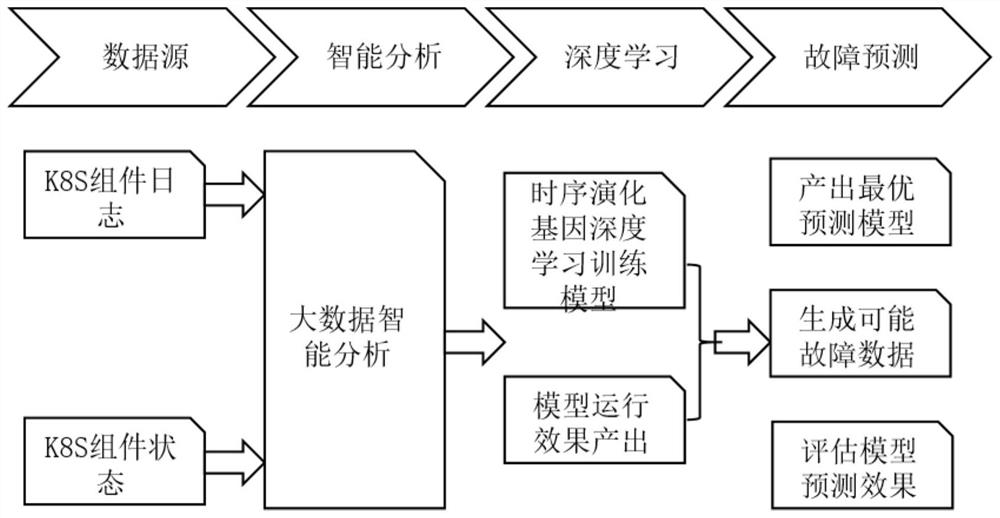

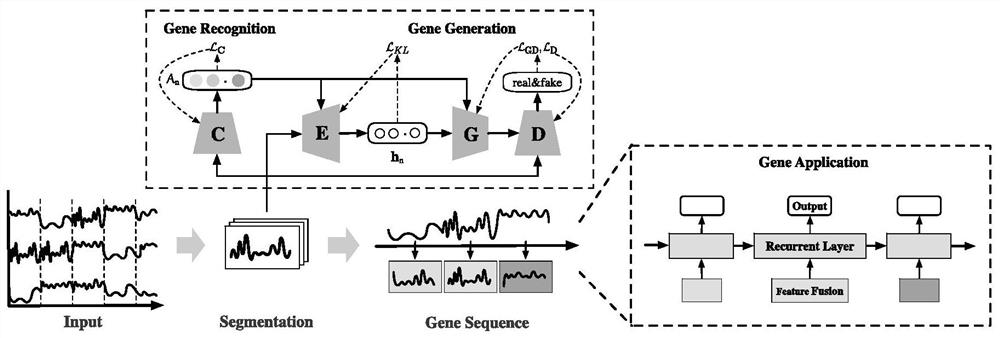

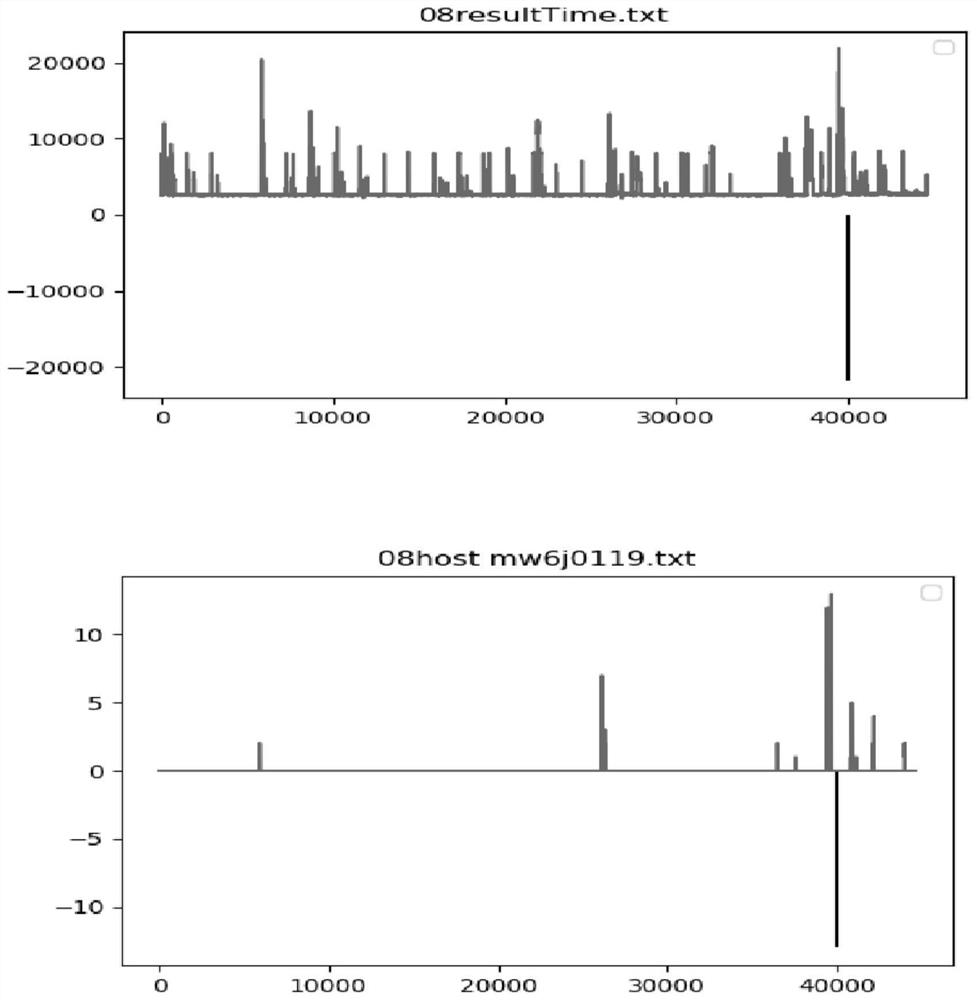

Docker container fault intelligent prediction method based on time sequence evolution gene

PendingCN111934903APredict failureAccurately predict operational failuresData switching networksEnergy efficient computingEngineeringChange prediction

The invention discloses a Docker container fault intelligent prediction method based on a time sequence evolution gene, and the method comprises the steps: carrying out the segmentation of a multi-dimensional time sequence, and dividing the multi-dimensional time sequence into a plurality of segments; clustering the segments to discover a typical mode; for different modes, adopting a conditional adversarial network (CVAE-GAN) to capture distribution characteristics of the modes; and combining the change of the distribution characteristics along with time, and predicting an imminent anomaly. The maintenance level of the Docker of the cloud platform is effectively improved.

Owner:上海伽易信息技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com