Wind turbine generator main shaft bearing fault prediction method

A main shaft bearing and fault prediction technology, applied in the direction of mechanical bearing testing, computer parts, instruments, etc., can solve problems such as easy to cause false alarms, insufficient pertinence, and inability to locate faults to specific components, achieving short time-consuming, classification The effect of high accuracy and improved accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be further described below in conjunction with specific embodiments.

[0046] The method for predicting the fault of the main shaft bearing of the wind turbine provided in this embodiment is based on the historical fault maintenance data of the main shaft bearing of the fan, combined with statistics and machine learning methods, using multiple monitoring indicators of the fan as input variables, and the state of the main shaft bearing as the predicted output Variables, and statistically analyze the predicted values of output variables, and set thresholds for fault prediction; it includes the following steps:

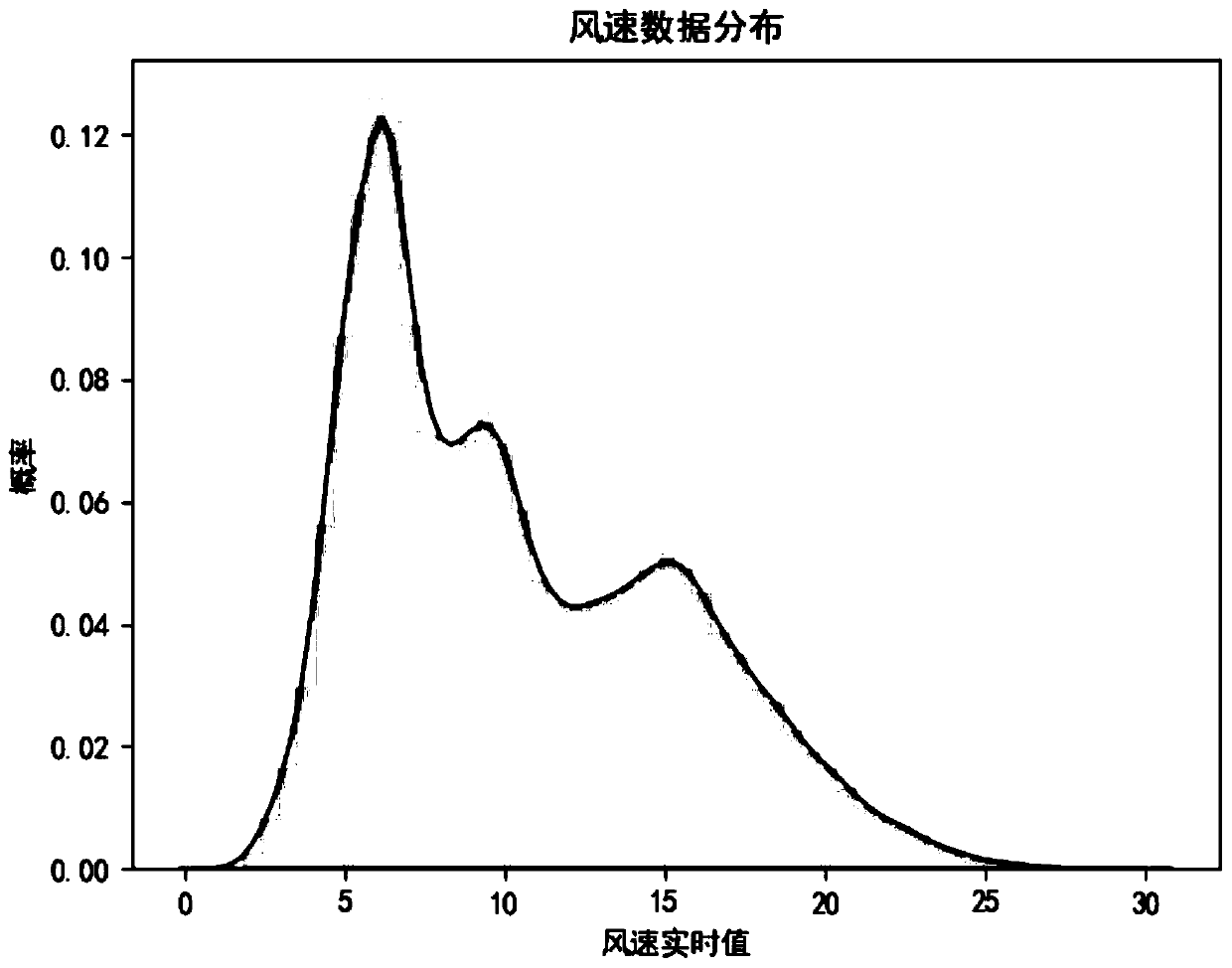

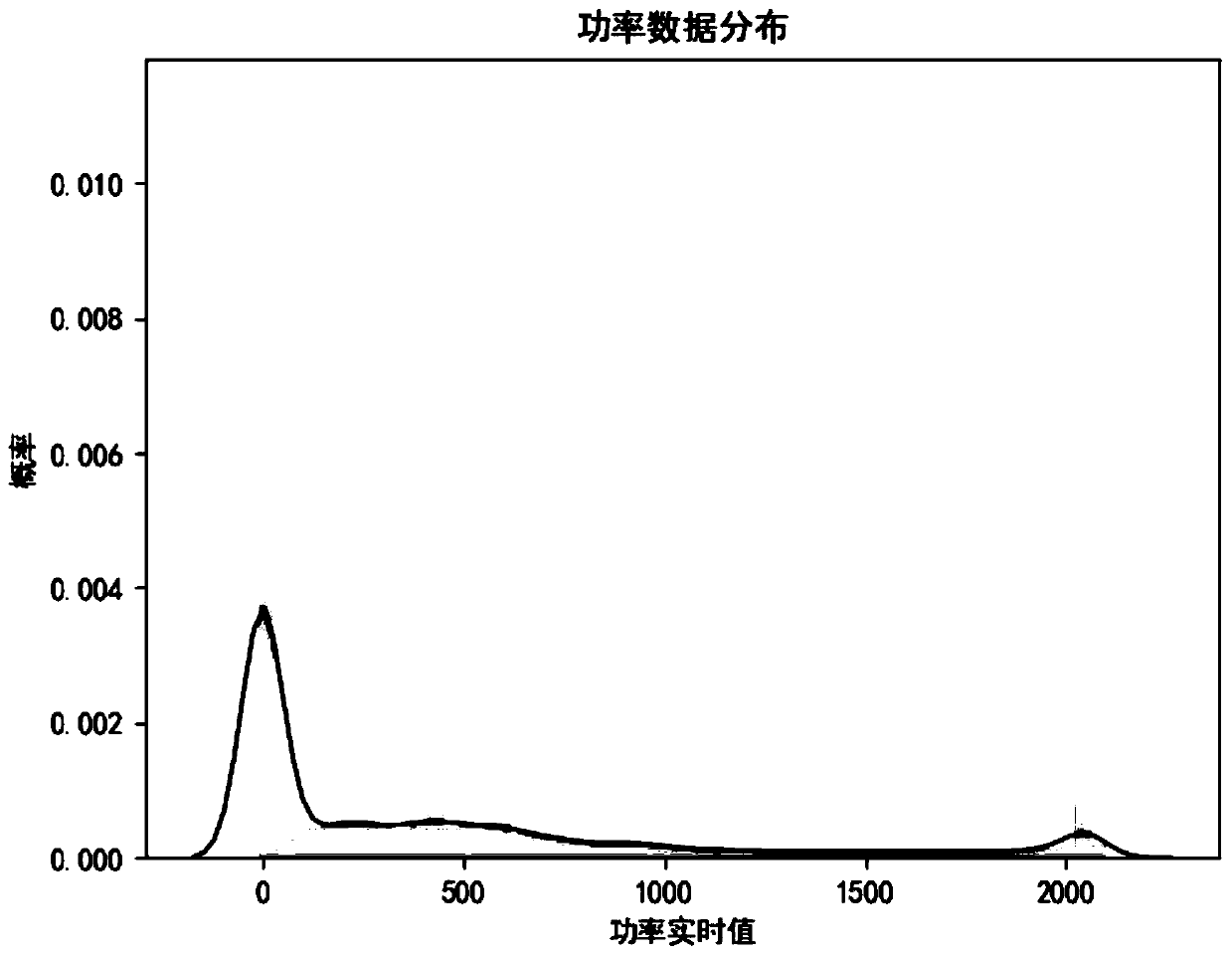

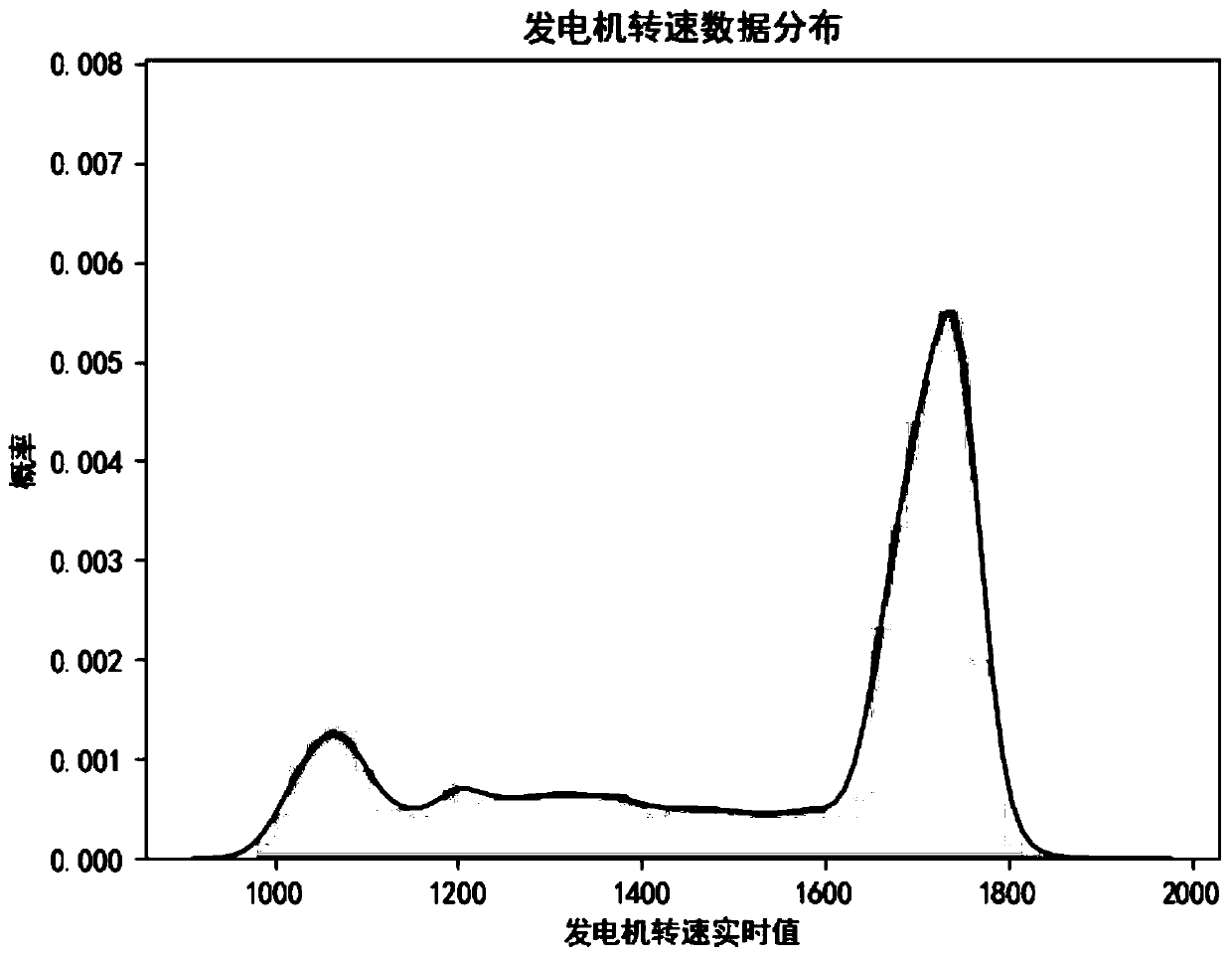

[0047] 1) Data exploration: select the data of the week before the spindle bearing wear failure of the wind turbine, do quality analysis and characteristic analysis of all monitoring indicators, view the data quality and data distribution, etc., refer to the attachment Figure 1a , 1b , 1c and 1d show the data distribution of some monitoring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com