Ship Propulsion Plant Using Hydraulic Thrust Bearing

A technology of thrust bearings and propulsion devices, which is applied in bearings, shafts and bearings, mechanical gear transmissions, etc., can solve the problems of increasing additional space and additional expenses, reducing the concealment of ships in combat, and achieving good shock and noise reduction effects. The effect of saving equipment space and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

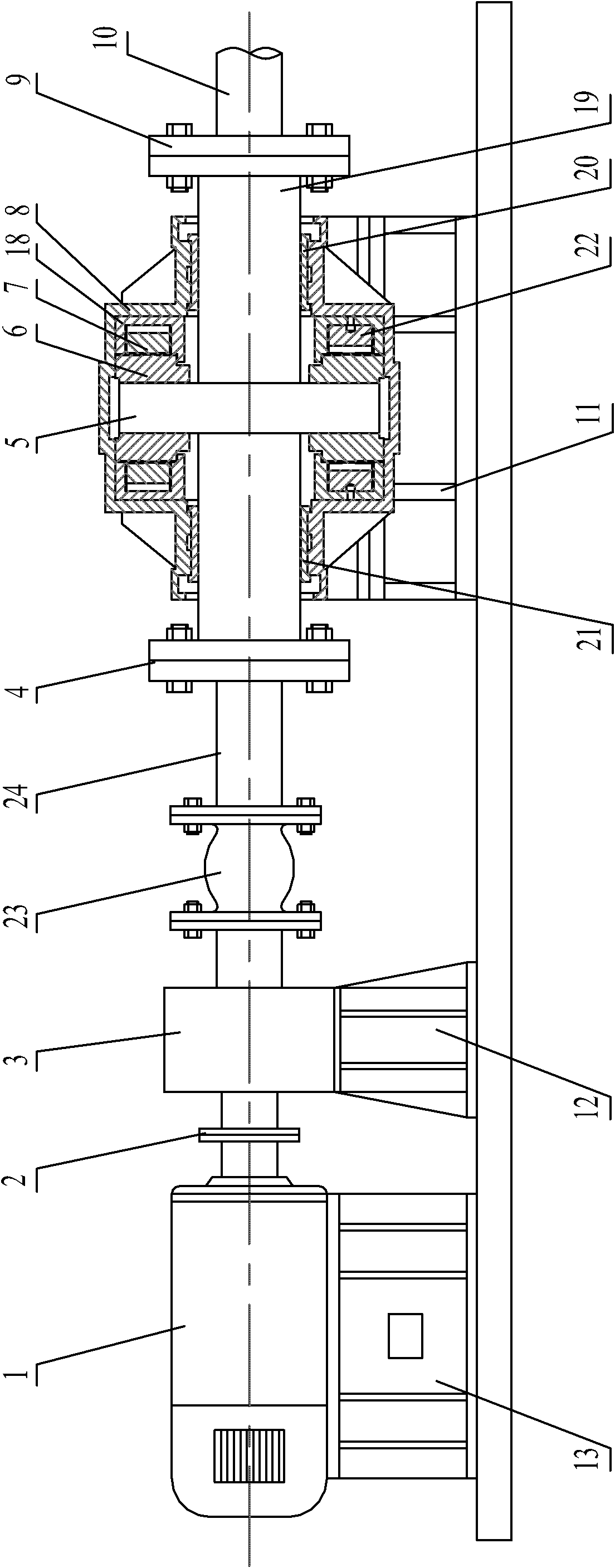

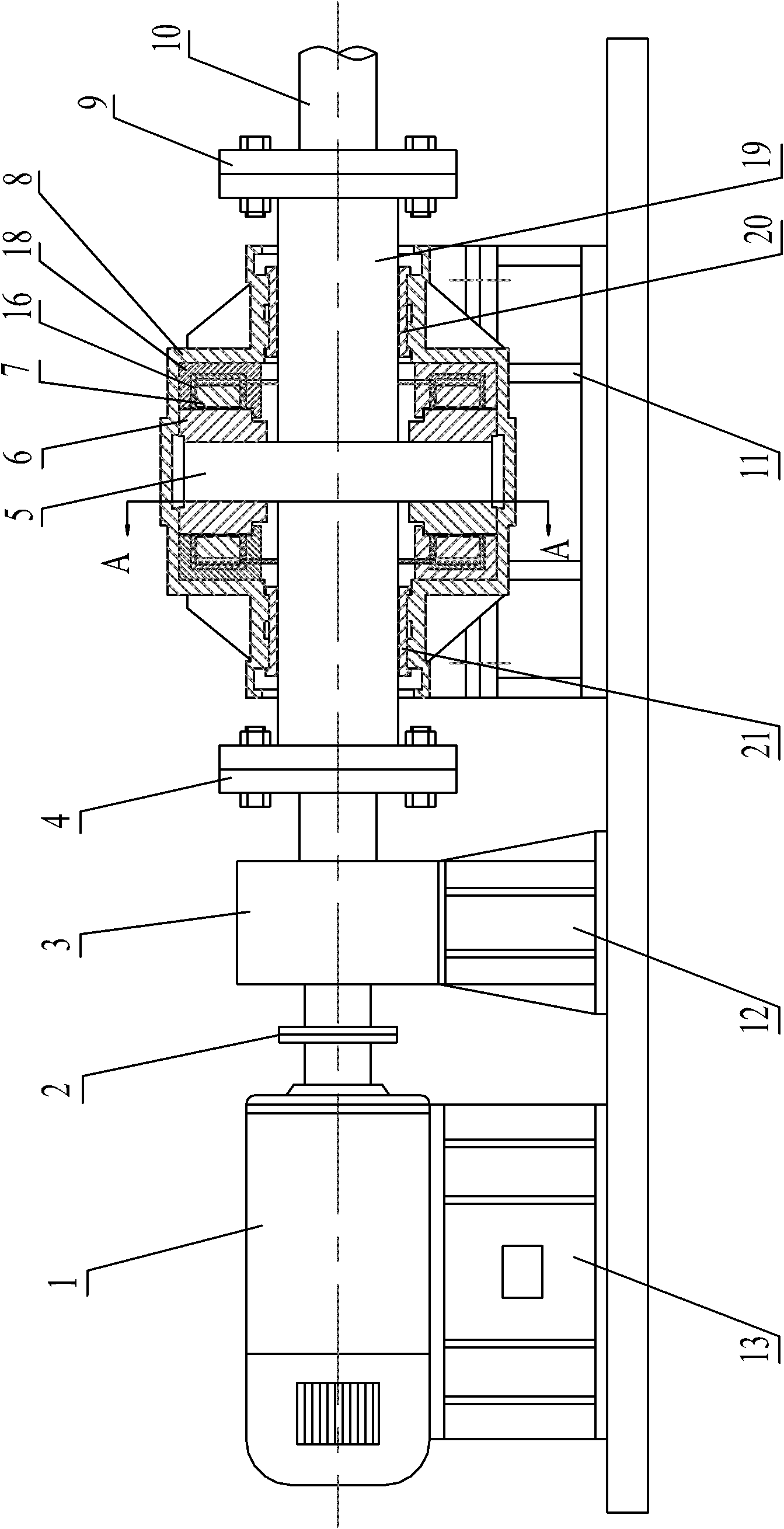

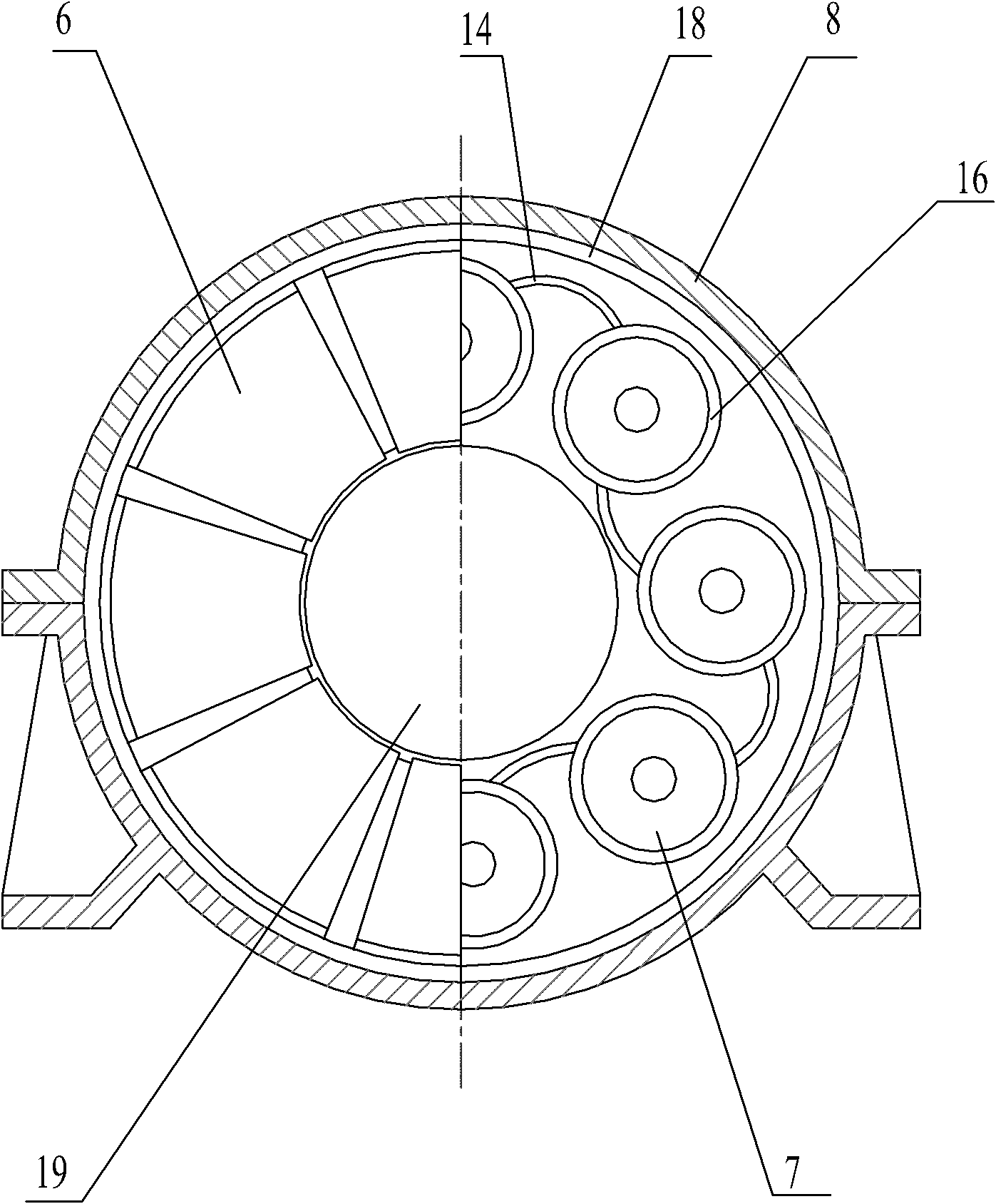

[0026] Figure 2 ~ Figure 4 Combined with a ship propulsion device using hydraulic thrust bearings, including motor 1, gear coupling 2, gearbox 3, flange I 4, hydraulic thrust bearing device, flange II 9 and propulsion shaft 10 . The motor 1 is installed on the flexible support I 13 (same as the prior art), and the gearbox 3 is installed on the flexible support II 12 (same as the prior art), thereby effectively reducing the structural vibration noise of the motor 1 and the gearbox 3 . The motor 1 and the gearbox 3 are connected through a gear coupling 2 .

[0027] The hydraulic thrust bearing device includes a thrust bearing housing 8 which is fixedly connected to a rigid support 11 . The left end face and the right end face of the thrust bearing housing 8 are provided with through holes respectively; after the thrust shaft 19 runs through the thrust bearing housing 8 transversely, the left end of the thrust shaft 19 is connected to the output shaft of the gear box 3 through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com