A straw fertilizer rapid fermentation device

A fermentation device and straw fertilizer technology are applied in the field of straw fertilizer rapid fermentation devices, which can solve the problems of slow fermentation speed, low heat, and inability to meet the requirements for processing a large amount of straw, and achieve the effect of accelerating fermentation and meeting the requirements for processing a large amount of straw.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

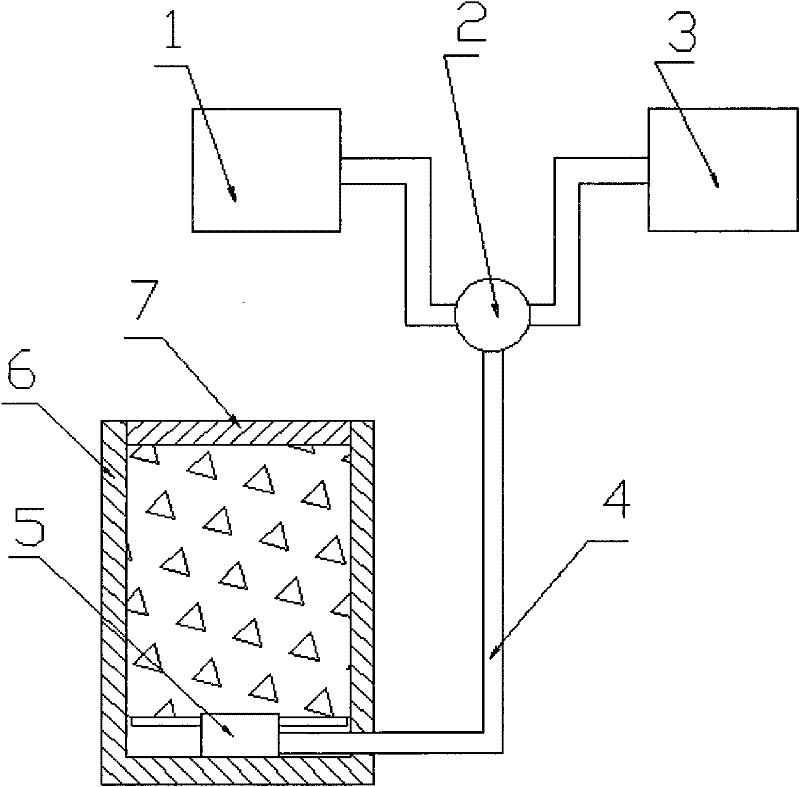

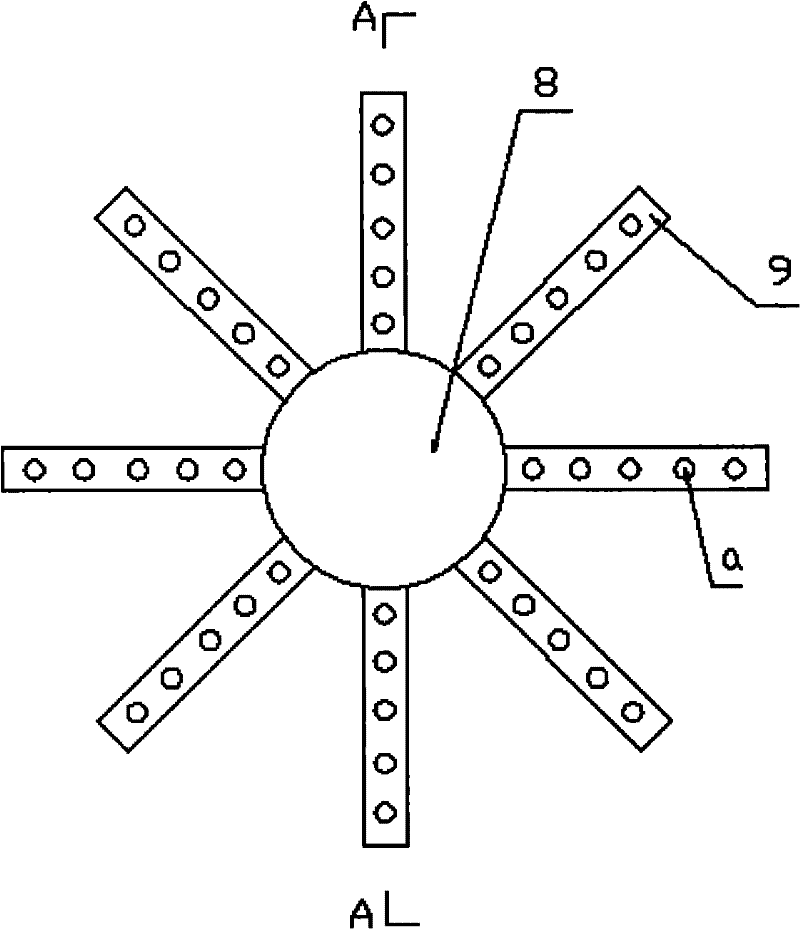

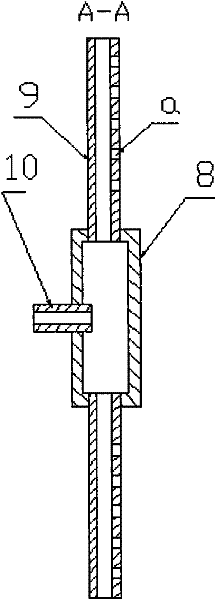

[0010] The fermentation device has a certain number of divergent pipes (9). The divergent pipes (9) are radially arranged on the circumference of the divergent pipe base (8). On the divergent pipes (9), there are densely distributed divergent holes. (a), the pipe joint (1) is installed on the diffuser socket (8) to form the hot air diffuser (5); the hot blast diffuser (5) is installed at the bottom of the fermentation tank (6), and the hot blast diffuser (5) Connect the main pipeline (4) through the pipe joint (10), and connect the three-way valve (2) to the main pipeline (4), the air outlet of the solar hot air device (1), and the air outlet of the electric heating hot air device (3) in sequence . In the weather without sunshine, start the electric heating hot air device (3), and send the hot air generated by the electric heating hot air device (3) into the bottom of the fermentation tank (6) through the three-way valve (2), and the fermentation tank (6) Straw is reserved, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com