A combined hydrogenation process

A combined process and hydrogenation unit technology, which is applied to the combined process of hydrogen refining hydrocarbon oil and hydrogen combined process of hydrogenation units, can solve the problem of wasting hydrogen resources, etc., and achieve low operating costs, low investment, and large operation flexibility. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

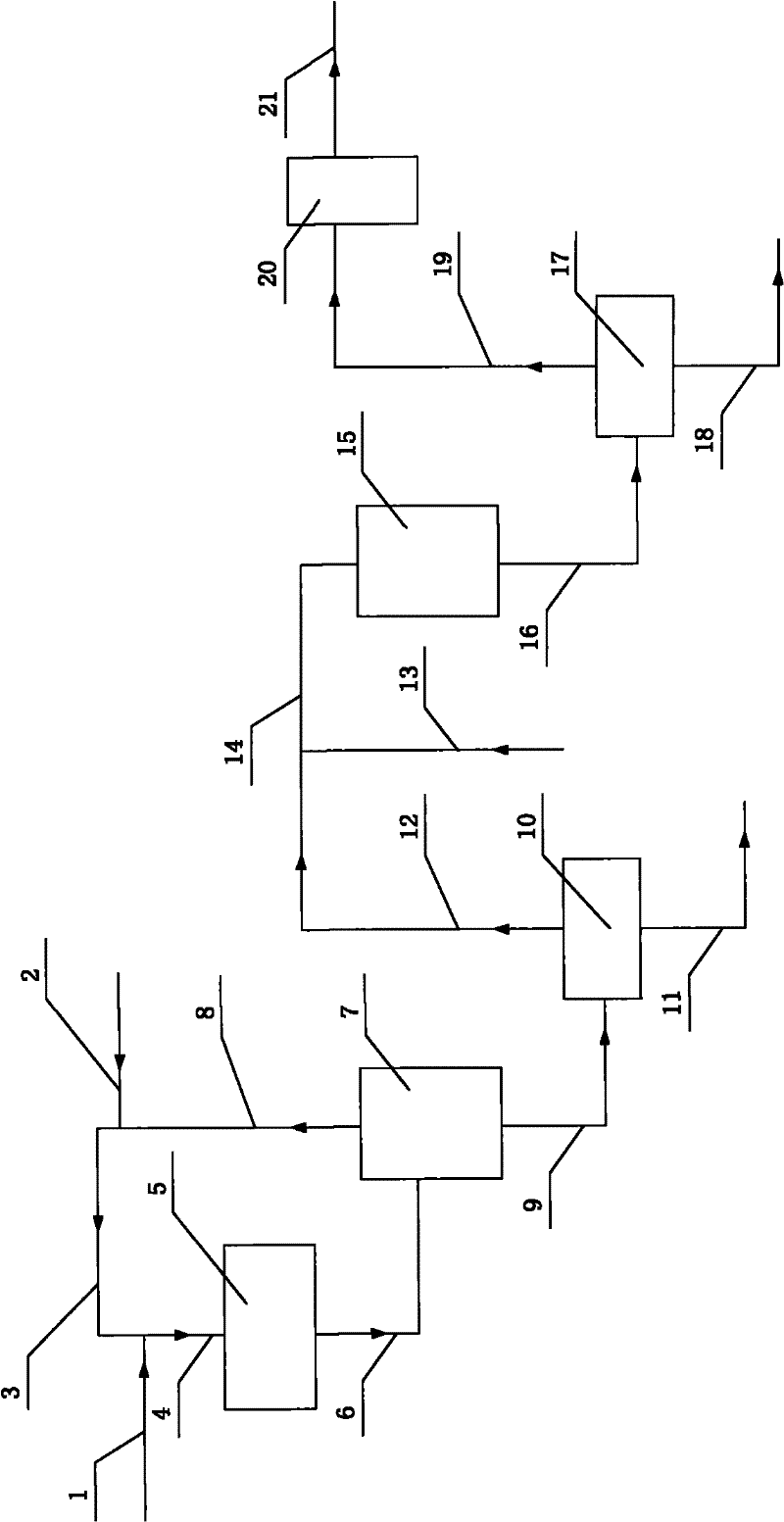

[0033] Such as figure 1 As shown, the combined hydrogenation process consists of a medium-high pressure hydrogenation unit reactor 5, a medium-high pressure hydrogenation unit high-pressure separator 7, a medium-high pressure hydrogenation unit low-pressure separator 10, a low-pressure hydrogenation unit reactor 15, a low-pressure hydrogenation unit gas The liquid separator 17 and the PSA device 20 are composed.

[0034] In the specific implementation process of the present invention, the circulating hydrogen 8 of the medium and high pressure hydrogenation device and the new hydrogen 2 of the medium and high pressure hydrogenation device are mixed to form the mixed hydrogen 3 of the high pressure hydrogenation device, and the fresh raw material oil 1 of the medium and high pressure hydrogenation device is mixed with the high pressure hydrogenation device The mixed hydrogen gas 3 is mixed into the mixed feed 4 of the medium and high pressure hydrogenation device, and the mixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com