Damped anti-seismic filling wallboard for framework

A frame structure and filling wall technology, applied in the direction of walls, anti-seismic, building components, etc., can solve the problems of high rigidity of densely ribbed composite wall panels, adverse effects of structural anti-seismic effects, stress concentration, etc., to reduce earthquake action and lateral stiffness Small, anti-lateral rigidity reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

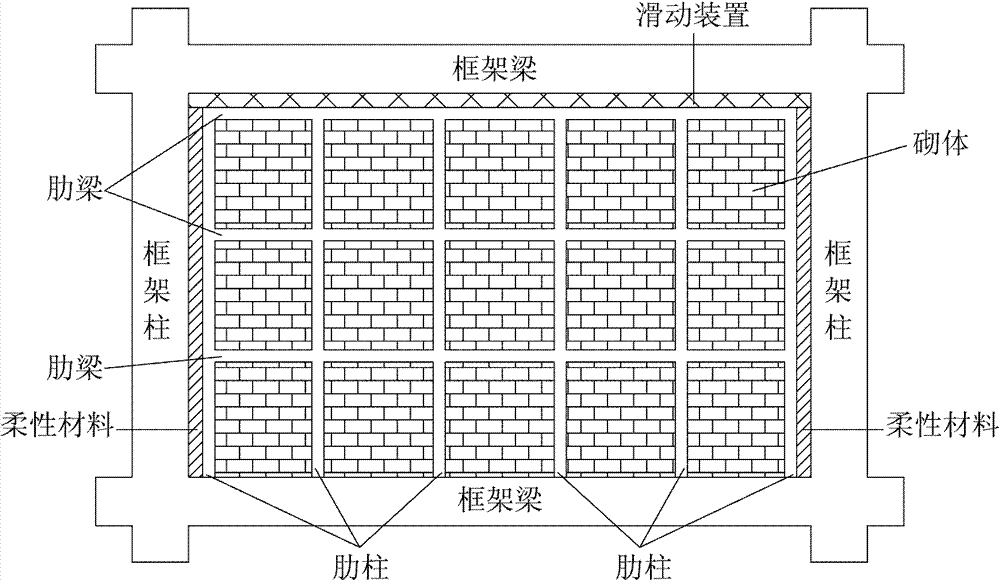

[0026] This example is a concrete frame with a span of 4200mm and a floor height of 3300mm. The cross-sectional size of the frame column is 500mm*500mm, and the cross-sectional size of the frame beam is 300*500mm; the concrete strength grade is C30; Design Code" (GB50010-2002) and "Code for Seismic Design of Buildings" (GB50011-2010). see Figure 3-6 , using small concrete solid blocks to construct damping and anti-seismic filling walls on site, and its structure is as follows:

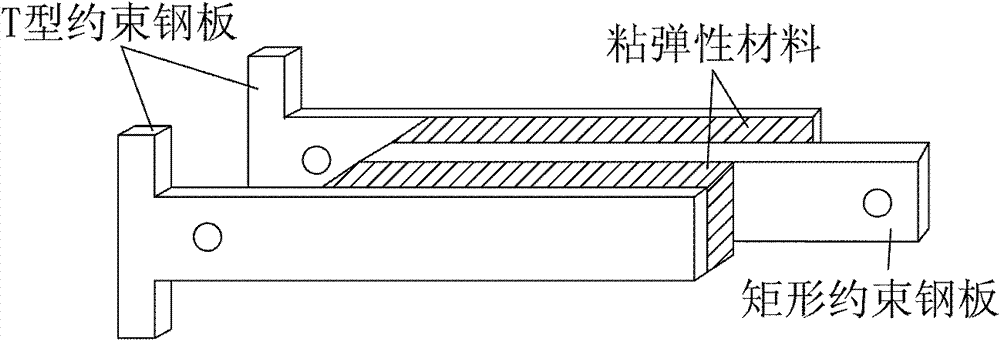

[0027] The entire masonry 1 is set in the space surrounded by the left frame column 6, the right frame column 6', the upper frame beam 7 and the lower frame beam 7', the thickness is 240 mm, and it is vertically built by three masonry units 2, Between the upper and lower two masonry units 2, and between the first masonry unit 2 counting from the upper frame beam 7 and the upper frame beam 7, and between the third masonry unit 2 and the lower frame beam 7', respectively set There is a viscoelastic la...

example 2

[0031] The damping and anti-seismic filling wall described in this example adopts prefabricated concrete wall panels, and the structure and construction method are the same as in Example 1 except for the following.

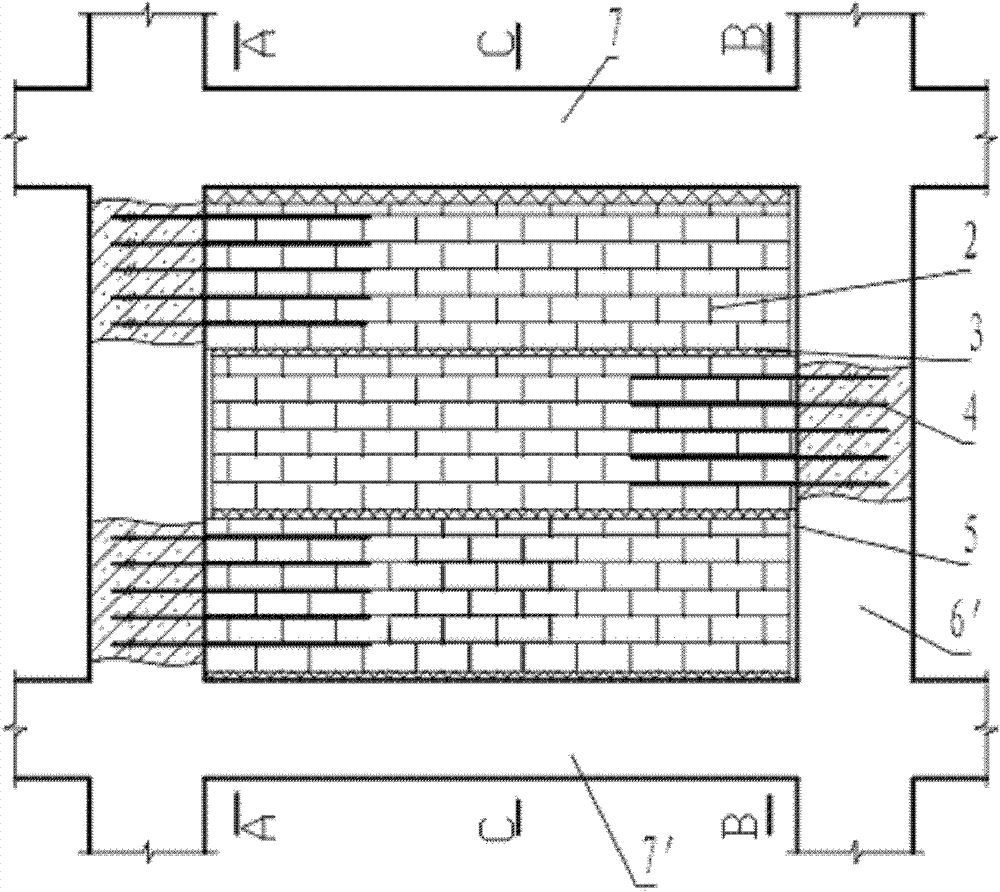

[0032] see Figure 7, the whole masonry 1 is vertically built by four masonry units 2, between the upper and lower two masonry units 2, and between the first masonry unit 2 counted from the upper frame beam 7 and the upper frame beam 7 and the second A viscoelastic layer 3 with a thickness of 5 cm formed by pouring asphalt is provided between the four masonry units 2 and the lower frame beam 7'. Among them, one end of the first and third masonry unit 2 counted from the upper frame beam 7 is connected with the left frame column 6 by anchoring steel bars 4, and a 4cm gap is reserved between the other end and the right frame column 6′. Wide gap 5; one end of the second and fourth masonry unit 2 counted from the upper frame beam 7 is connected with the right frame co...

example 3

[0034] Example 3 (effect test)

[0035] 1. Test piece design

[0036] A, sample test piece is the filling wallboard that above-mentioned embodiment 1 belongs to;

[0037] B, the reference product test piece is constructed according to the scheme described in the specific embodiment of the patent application with the publication number CN101476360A (hereinafter referred to as the dense rib composite wallboard), wherein the main frame is exactly the same as that of Example 1; the dense rib composite wallboard The concrete frame is used as the skeleton; the gap between the frame column and the frame beam is 10mm; Set 4 steel plate-rubber sliding bearings between them; the gap between the ribbed composite wall panels and the frame columns is filled with polystyrene foam plastic plates.

[0038] 2. Construct the finite element model

[0039] According to the actual size and detailed structure of the sample test piece and the control test piece, the finite element models of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com