Shield cutter disk drive hydraulic system

A technology of hydraulic system and shield cutter head, which is applied to fluid pressure actuating devices, mining equipment, earth-moving drilling, etc., can solve the problems of small power-to-volume ratio, large space occupation, and poor overload capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

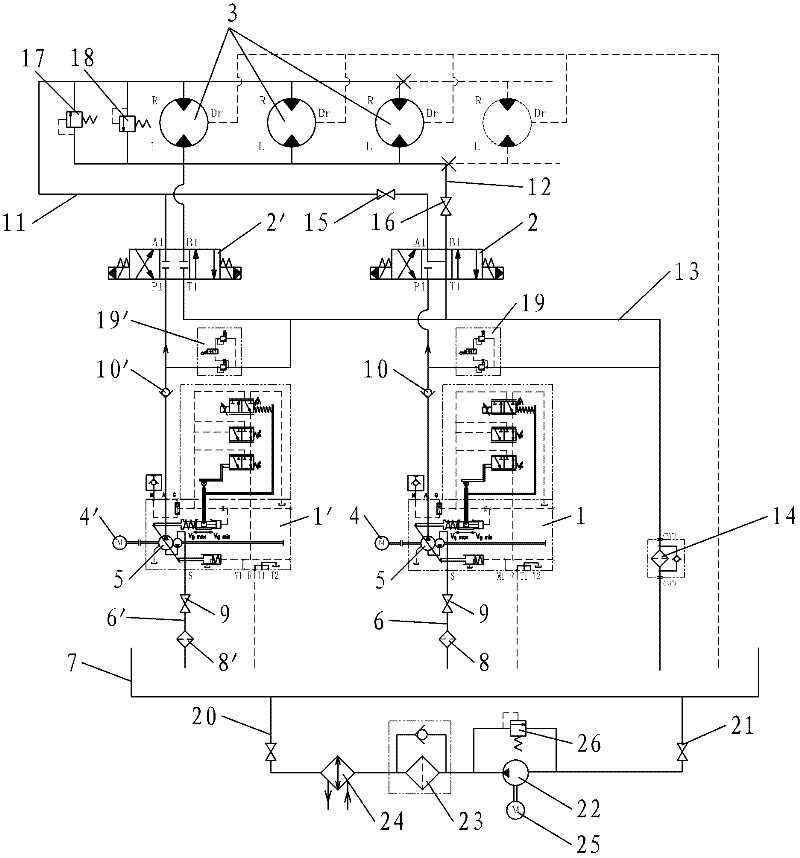

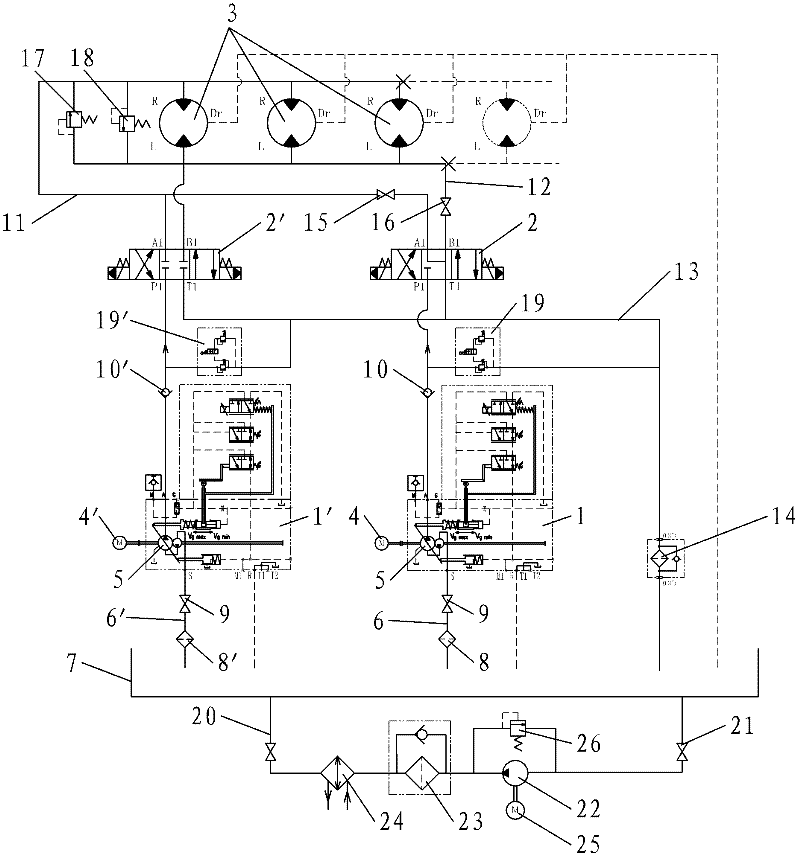

[0016] Such as figure 1 As shown, the shield cutter head drive hydraulic system of the present invention includes two hydraulic pump stations 1, 1', two electro-hydraulic three-position four-way reversing valves 2, 2', several two-way hydraulic motors 3, two hydraulic pumps Stations 1 and 1' have the same structure, including pumping station motors 4 and 4' and plunger-type electro-hydraulic proportional variable pump 5. The plunger-type electro-hydraulic proportional variable pump 5 is a constant power variable pump with pressure cut-off function. The middle position of one of the electro-hydraulic three-position four-way reversing valve 2 is a Y-type function. The oil suction port S of the hydraulic pump station 1, 1' communicates with the oil tank 7 through the oil suction pipeline 6, 6' respectively, and the oil suction pipeline 6, 6' is connected with the oil suction filter 8, 8' and the third high pressure ball valve 9. The oil inlet P1 of the electro-hydraulic three-po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com