An engine plastic intake manifold

A technology of intake manifold and engine, which is applied in the direction of engine components, machine/engine, charging system, etc., and can solve the problem of easy formation of overflow in the inner air passage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

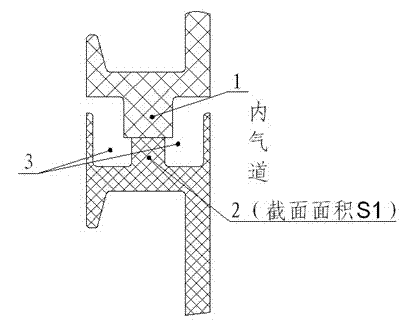

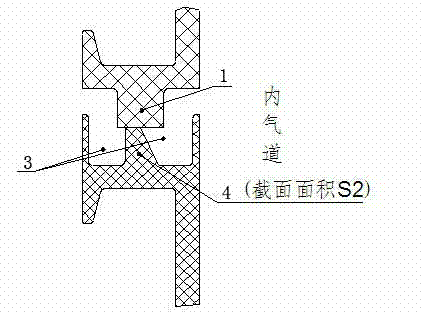

[0011] see figure 2 , the plastic intake manifold is divided into upper and lower parts and welded. In the part that needs to be welded, the structure of the friction rib 1 of the upper piece remains unchanged, and the ordinary welding structure, that is, the welding rib of rectangular section is designed Welding bar 4, the cross-sectional area of the welded bar 4 of trapezoidal cross-section is the same as the cross-sectional area of the welded bar 2 of the original rectangular section (i.e. figure 1 S1 in is equal to figure 2 S2 in ).

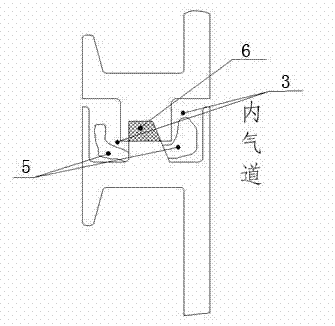

[0012] Such as image 3 As shown, the hot melt 5 generated by the vibration and friction of the trapezoidal cross-section welding rib 4 will be stored in the overflow tank 3 during welding, and 6 in the figure is the welding volume. Because the volume of the overflow tank 3 on the inner air passage side of this structure is larger than the traditional overflow tank volume, that is, the overflow tank on the air passage side in the int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com