vibration device

A vibrating device and vibrator technology, which is applied in the direction of vibrating fluid, engine frame, supporting machine, etc., can solve problems such as workbench inclination, product quality impact, and inconsistent overall tightness of building panels to achieve overall tightness maintenance Consistent, guaranteed product quality, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The vibrating device of the present invention will be described in further detail below through specific examples.

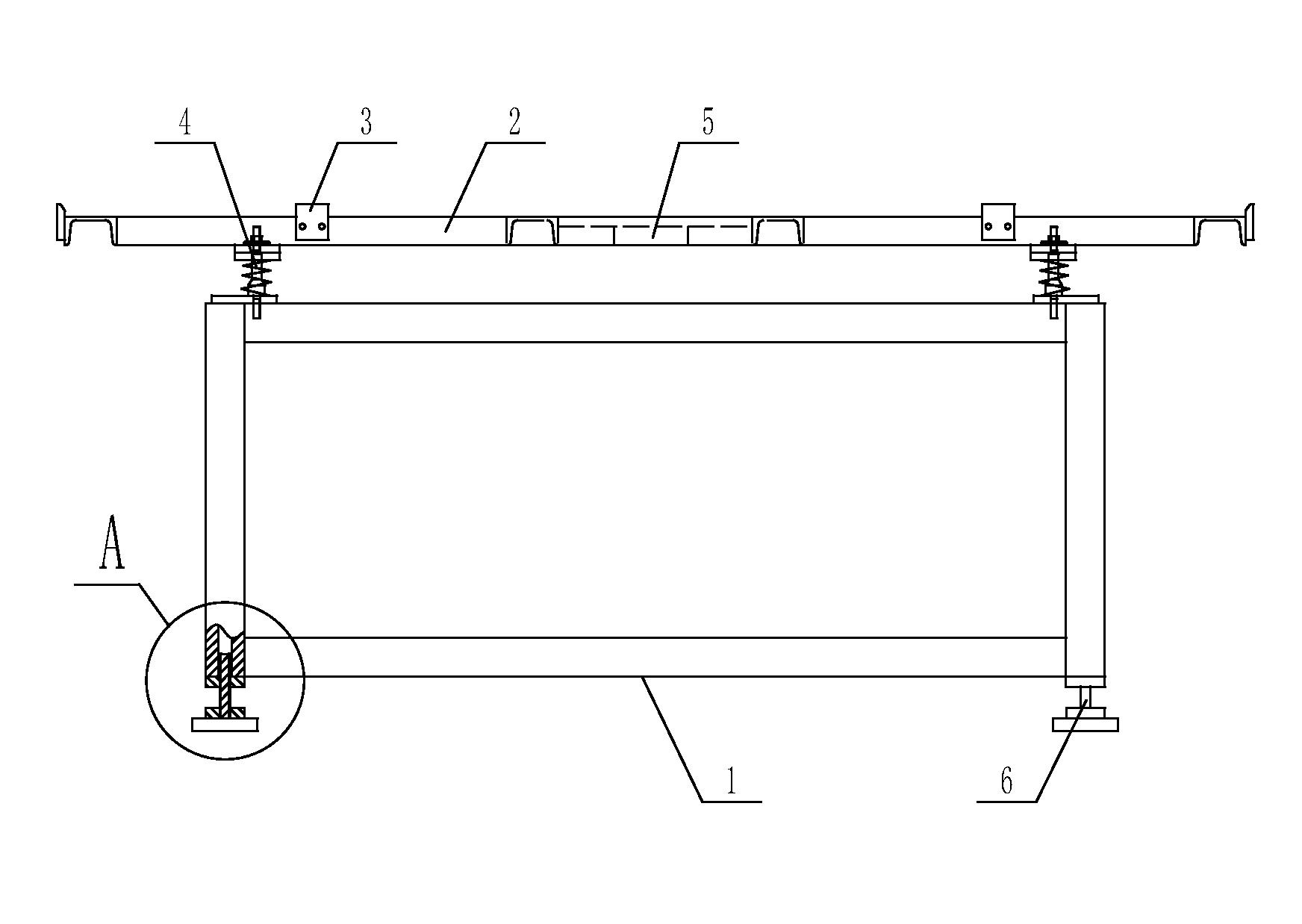

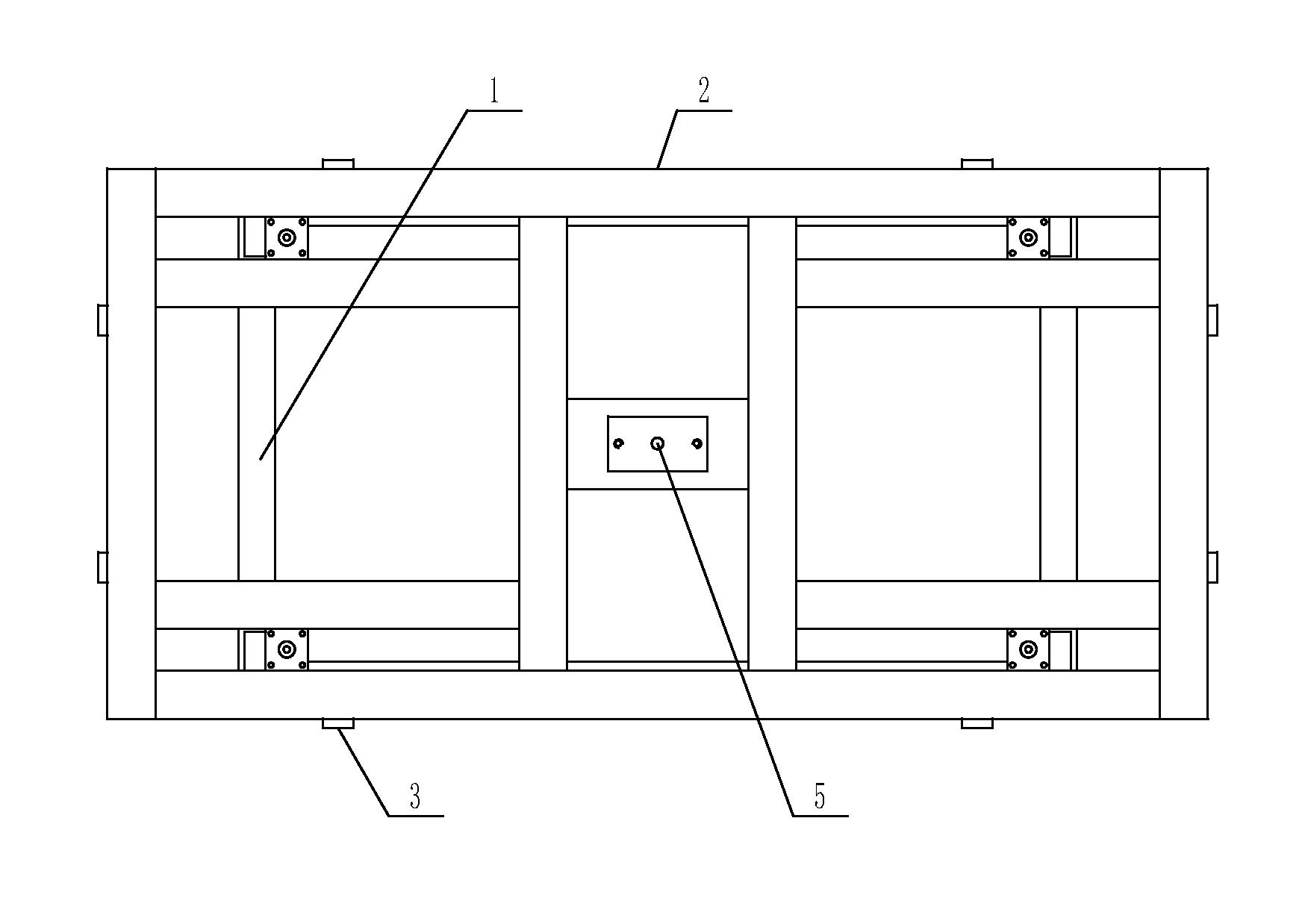

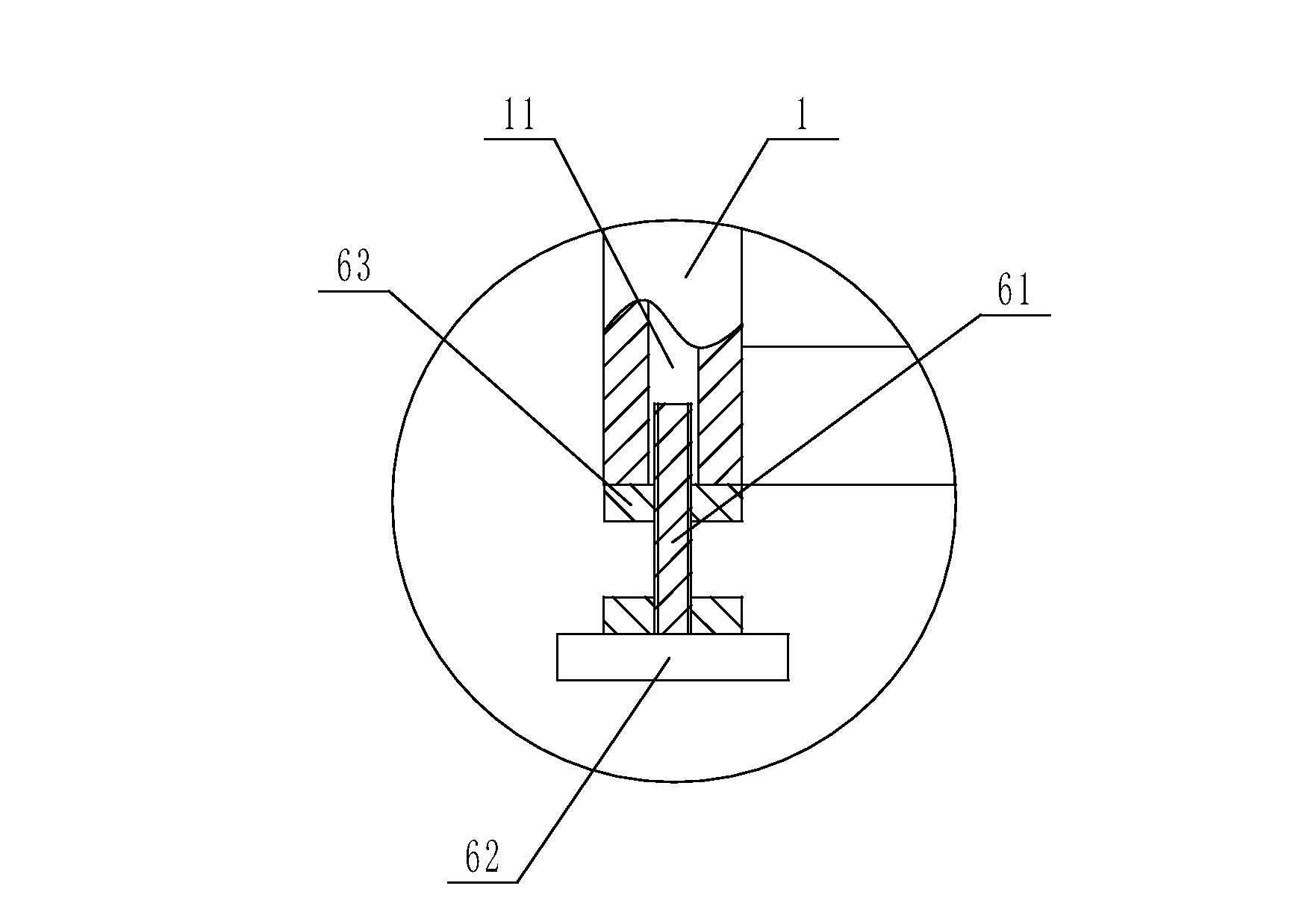

[0013] Such as figure 1 As shown, the vibrating device includes a support 1, a workbench 2 is arranged above the support 1, a total of eight limit blocks 3 are arranged on the four sides of the workbench 2, and two limit blocks 3 are respectively arranged on each side of the workbench 2, The limit block 3 plays the role of limiting the building panel mold, and the installation position of the limit block 3 can be adjusted arbitrarily according to the size of the building panel mold, so that it can adapt to different sizes of building panel molds. At least three shock absorbers 4 are provided, and the two ends of the shock absorbers 4 are respectively connected with the support 1 and the workbench 2, and the workbench 2 is provided with a vibrator 5, and the four corners at the bottom of the support 1 are respectively Adjustment feet 6 are provided, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com