Tyre vulcanizer accuracy detector

A technology of precision detection and tire vulcanization, applied in mechanical measurement devices, angle/taper measurement, instruments, etc., can solve the problems of undetectable, unfavorable, and impacted assembly accuracy, achieve dynamic balance and stable appearance quality, and maintain tire uniformity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below with reference to the accompanying drawings in conjunction with the embodiments, so that those skilled in the art can better understand the present invention and implement it, but the given embodiments are not intended to limit the present invention.

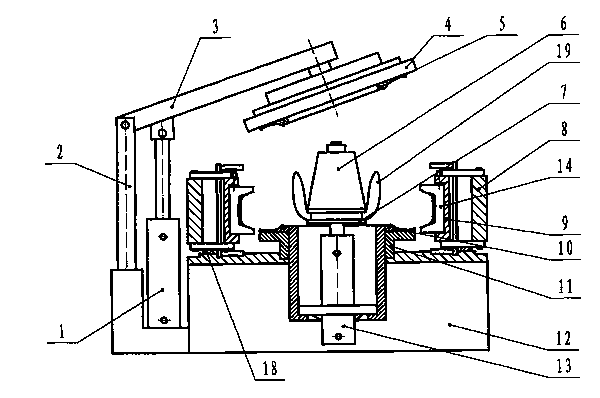

[0029] see Figure 2 to Figure 5 , The tire vulcanizer accuracy detector of the present invention includes a centering base 1 , a deep groove ball bearing 2 , an operating platform 3 , and a measuring instrument bracket 4 .

[0030] The centering base 1 is integrally formed by two upper and lower concentric discs, the diameter of the lower disc is smaller than that of the upper disc, and the part protruding from the periphery of the upper disc serves as an annular handle 101, A threaded hole 102 is opened in the center of the lower disc, and the diameter and thread shape of the threaded hole 102 correspond to the diameter and external thread shape of the central cylind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com