A Diagnosis Method of Bearing Fault

A diagnostic method and fault technology, applied in mechanical bearing testing, instruments, speed/acceleration/shock measurement, etc., can solve problems such as failure of impact feature extraction, difficult real-time monitoring, and large amount of calculation, and achieve good adaptability and calculation The effect of fast speed and simple algorithm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

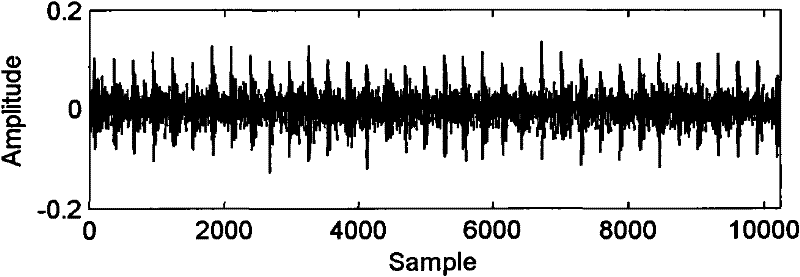

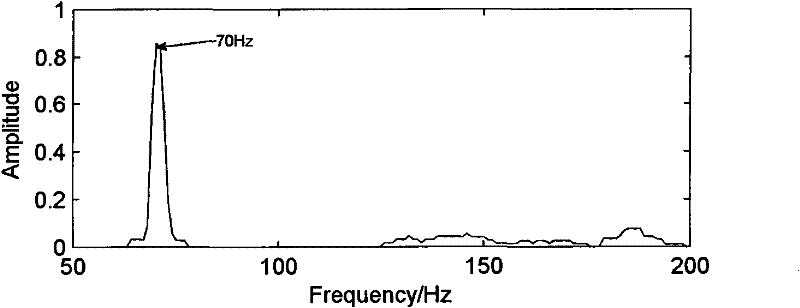

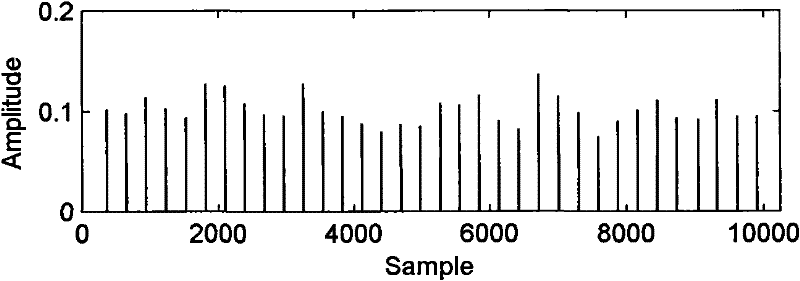

[0057] Such as figure 1 As shown, the time-domain waveform diagram of the vibration acceleration signal of a SKF6025 rolling bearing with an outer ring fault. The vibration acceleration signal is measured by an acceleration sensor installed on the bearing seat. During the experiment, the rotation frequency of the shaft is set to 20Hz, the sampling frequency is 20480Hz, and the sampling length is 10240 points. The fault of the outer ring is that a square groove with a width of 0.2m and a depth of 0.2m is cut on the outer ring by laser cutting. Through calculation, we can know that the fault characteristic frequency of 6205 bearing is 70Hz. Such as figure 2 shown, for figure 1 The shape spectrum of the vibration acceleration signal of the outer ring fault rolling bearing shown has a very obvious peak at the frequency of 70 Hz, so it can be seen that there is a very obvious impact with a period of 70 Hz in the bearing acceleration signal. Such as image 3 Shown is the faul...

Embodiment 2

[0059] Such as Figure 4 As shown, a waveform diagram of the vibration acceleration signal of an SKF6205 rolling bearing with an inner ring fault. During the experiment, the rotation frequency, sampling frequency and sampling length of the shaft are the same as those in Example 1. Through calculation, it can be known that the fault characteristic frequency of the inner ring of the bearing is 108Hz. Such as Figure 5 As shown, it is the shape spectrum of the vibration acceleration signal of the inner ring fault rolling bearing, and there is a very obvious peak at the frequency of 108Hz. Such as Figure 6 As shown, the periodic fault shocks are finally extracted. Therefore, it can be easily judged that there is an inner ring fault in the bearing.

Embodiment 3

[0061] Such as Figure 7 As shown, the time-domain waveform diagram of the vibration acceleration signal of a normal SKF6205 bearing. Such as Figure 8 Shown is its morphological spectrum. The morphological spectrum of the signal shows that it is relatively flat, and there is no peak with a large amplitude, so it can be judged that the bearing is in a normal state.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com