A high-precision geotechnical simple shear instrument and its application method

A high-precision, shear box technology, which is applied in the direction of applying stable shear force to test the strength of materials, can solve the problems of poor reflection, thick stacked rings, and large diameter of displacement sensors, etc., to achieve low cost, Easy-to-implement, simple-structure effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

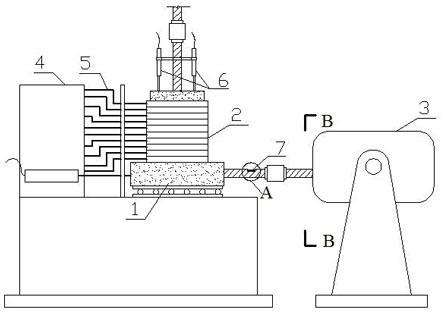

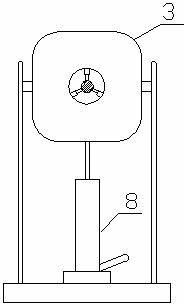

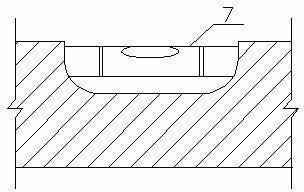

[0032] like Figure 1~5 As shown, a high-precision geotechnical single-shear instrument, its structure is based on the existing single-shear instrument lower shear box (1), upper shear stack ring group (2), and horizontal electromagnetic exciter (3) Add horizontal displacement sensor box (4), displacement sensor connecting rod (5), vertical displacement sensor (6), level pipe (7), jack (8), and place the upper shear stack ring group (2) On the lower shear box (1), grooves are provided on the outer wall of each shear ring inside it, and a plurality of displacement sensors are arranged in the horizontal displacement sensor box (4), wherein the input end of the lowermost displacement sensor is connected to the lower shear The cutting box (1) is connected to measure the shear displacement of the lower shear box (1) during the test, and the input ends of the other sensors correspond to the upper shear stack ring group (2) through the displacement sensor connecting rod (5). The gro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com