A method for continuous laying of multi-layer boards in wood board processing

A technology for wood panels and boards, which is applied in wood processing appliances, wood veneer joining, manufacturing tools, etc., can solve problems such as difficulty in promotion and inappropriate piece-rate management methods, and achieves solutions to wood waste, inconsistency problems, and reduction of The effect of raw material consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

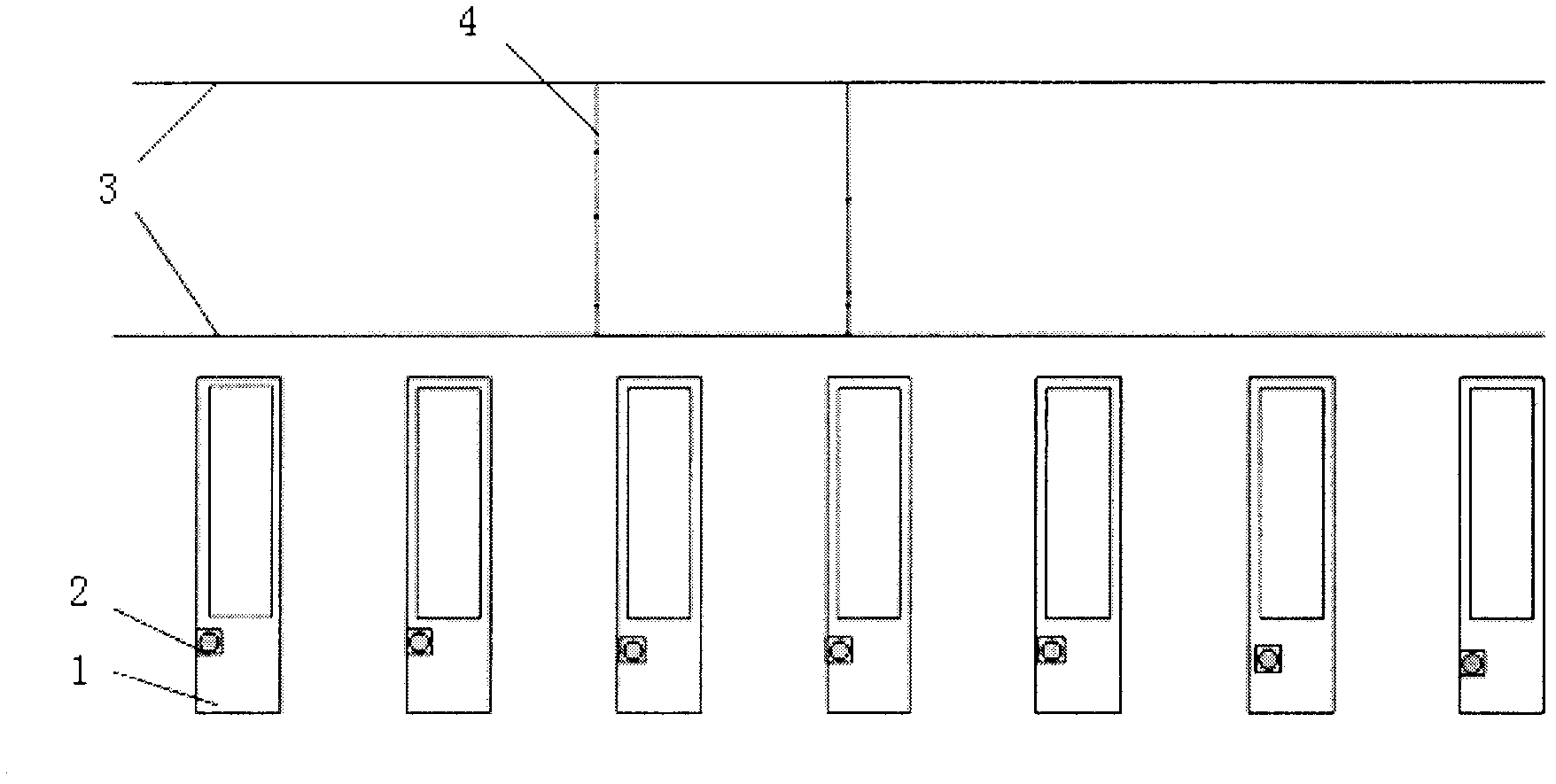

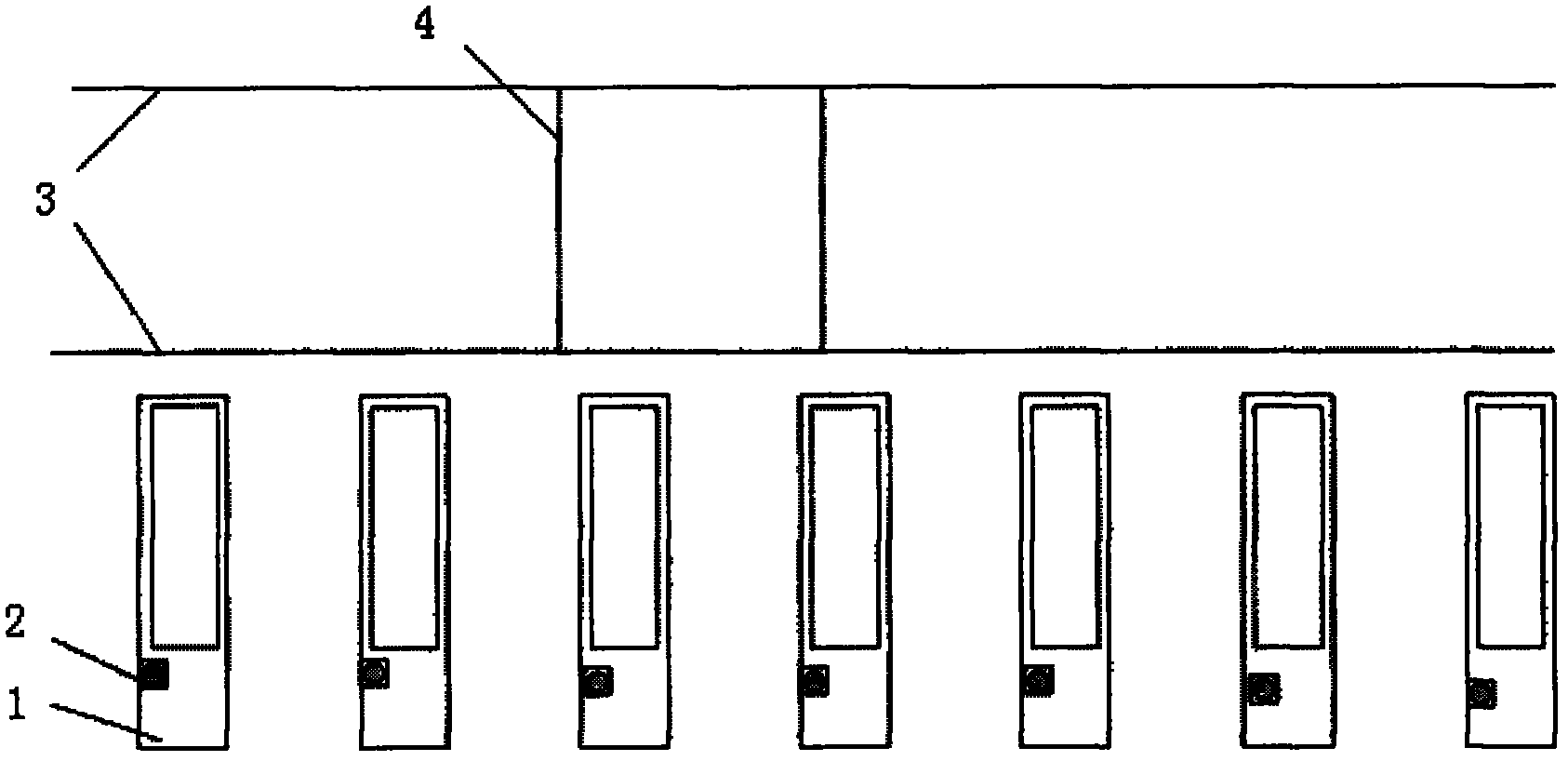

[0011] As shown in the accompanying drawings, a method for continuous laying of multi-layer wood boards in wood board processing, the equipment used includes a guide rail 3, on which an automatic cutting machine 4 that can move along the guide rail is installed, and placed in parallel in front of the automatic cutting machine 4 There are a plurality of workbenches 1 for continuous laying of multi-layer planks, and a button 2 for controlling the work of the automatic cutting machine is set on each workbench; the continuous laying method of multi-layer planks using the above-mentioned equipment is: each worker uses continuous The way of laying out is that the seams between each layer of veneers are staggered from each other in the first length of laying, and then only need to be laid out continuously. The button sends a signal to the automatic cutting machine. After receiving the signal and processing the cutting work of other stations in sequence, the automatic cutting machine m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com