Preform sleeve joint for blow molding machine

A technology of socket joint and blow molding machine, which is applied in the application, household appliances, other household appliances, etc., can solve the problems of easy dew gas in the bottle body and affect the product quality, and achieve the effect of high-yield manufacturing and improving the degree of lubrication.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

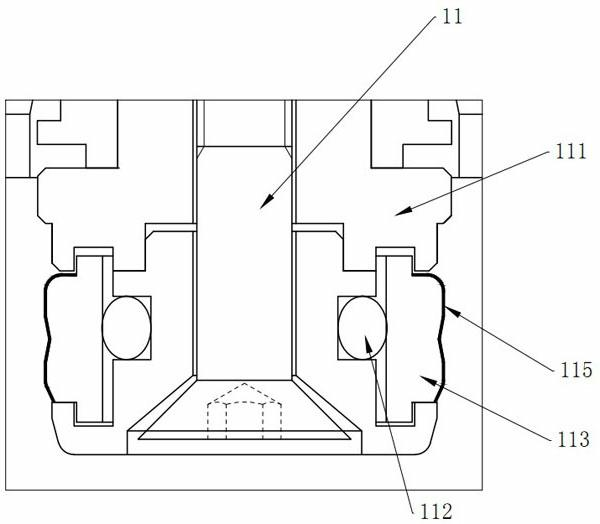

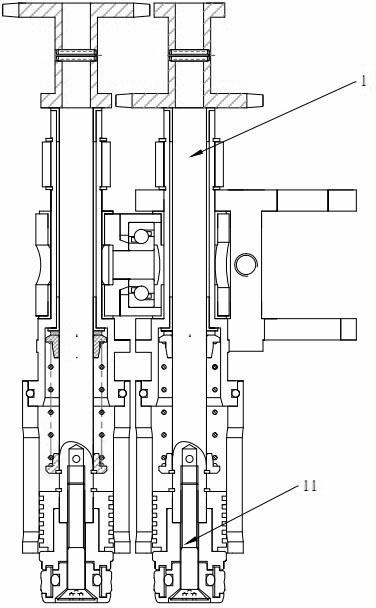

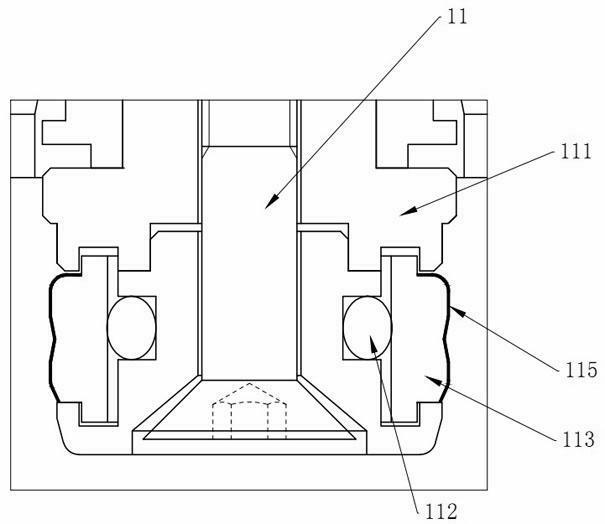

[0012] Such as figure 2 As shown, the preform sleeve joint 11 for the bottle blowing machine of the present invention has a structural composition including a base 111 and an expansion sleeve 113 sleeved on the outside of the base. The base is provided with an elastic O-shaped sealing ring 112 sandwiched between the base 111 and the expansion sleeve 113, and the base 111 is locked to the main structure of the bottle blowing machine by a screw. In particular, at least one layer of wear-resistant and self-lubricating polyether ether ketone film 115 is provided on the outer surface of the expansion sleeve 113 . Since this part is mainly in contact with the mouth of the preform, it must be coated with a polyether ether ketone film.

[0013] In addition, since the outer contour surface of the base is also likely to be in contact with the bottle mouth of the preform during the preform socketing process, because the surface is also coated with a layer of polyether ether that is the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com