A Metal Air Cushion Jet Recycling Ship Structure

A technology of air cushions and ships, which is applied in the direction of air cushions, transportation and packaging, and vehicle parts, etc. It can solve the problems of the load limit of the hovercraft, the amazing energy consumption, the influence of the engine power, etc., so as to reduce the weight of the hull, prevent rollover, and reduce the contact area Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below with an embodiment, but it should be noted that the protection scope of the present invention is not limited to this.

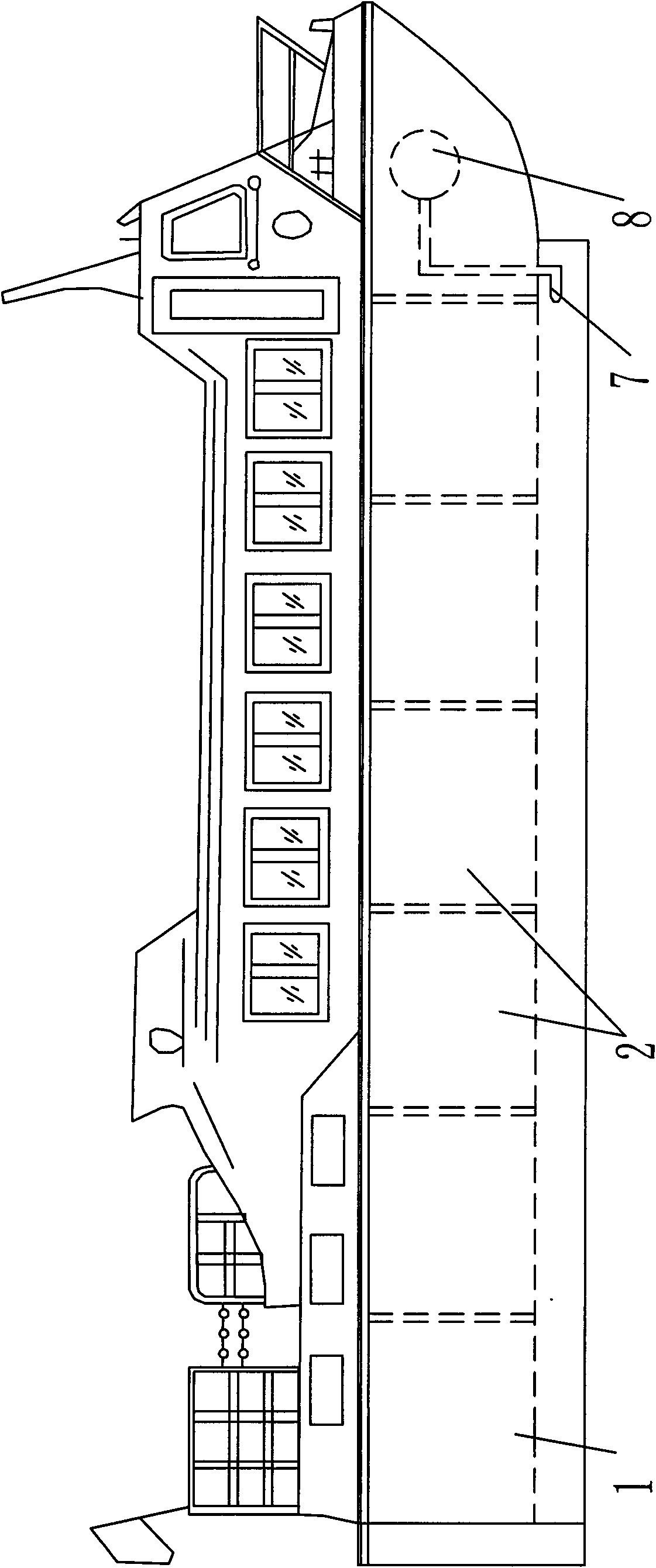

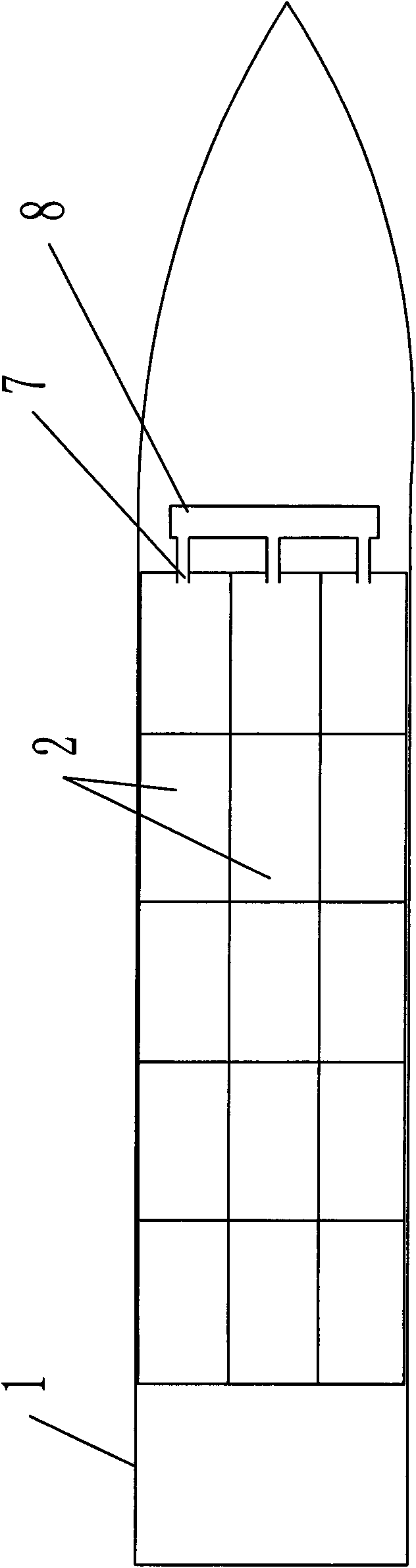

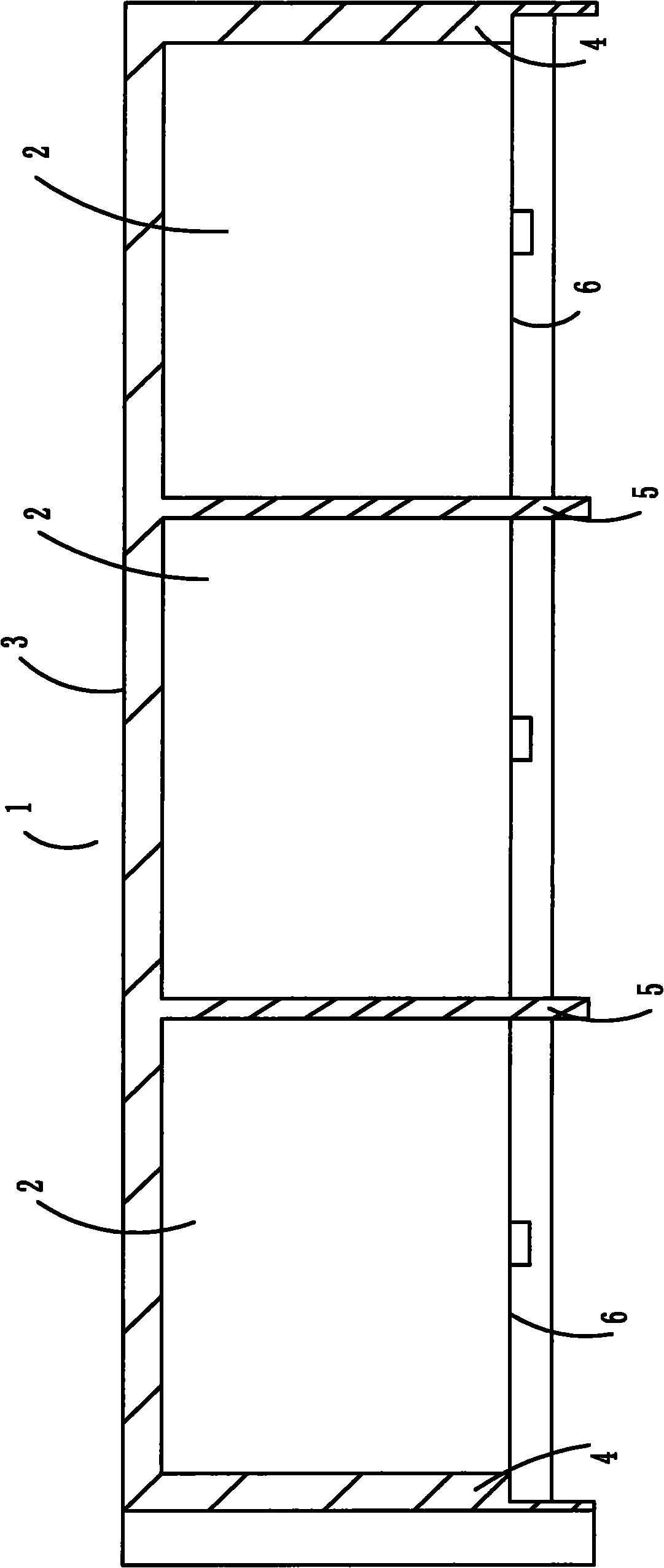

[0021] See Figure 1 to Figure 3 The metal air cushion jet recovery ship structure of this embodiment is a small passenger ship, including the hull 1. The midship of the hull 1 is composed of fifteen independent balanced air tanks 2, and the bottom of each air tank 2 is open; The midship of the hull 1 is also provided with a nozzle 7 and a cylinder 8 connected to each other, and the nozzle 7 is tightly fitted with each air chamber 2. Among them, the air tank 2 is square, which is enclosed by the upper deck 3, the side panels 4 of the hull 1, a plurality of longitudinal partitions 5 and the transverse partition 6, respectively; the bottom of the air tank 2 is at a higher level than the bottom of the hull 1. The horizontal line is high, which can increase the roll angle of the hull 1. The ster...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com