A feeding tray of an automatic feeding device

A technology of automatic feeding and feeding, which is applied to vibrating conveyors, conveyors, conveyor objects, etc., can solve problems such as the inability to guarantee the quality of the insertion shaft of the plastic casing motor cover, different insertion depths, and loose shafts, etc. To achieve the effect of reasonable structure design, reduce labor and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The invention will be described in further detail below in conjunction with the accompanying drawings.

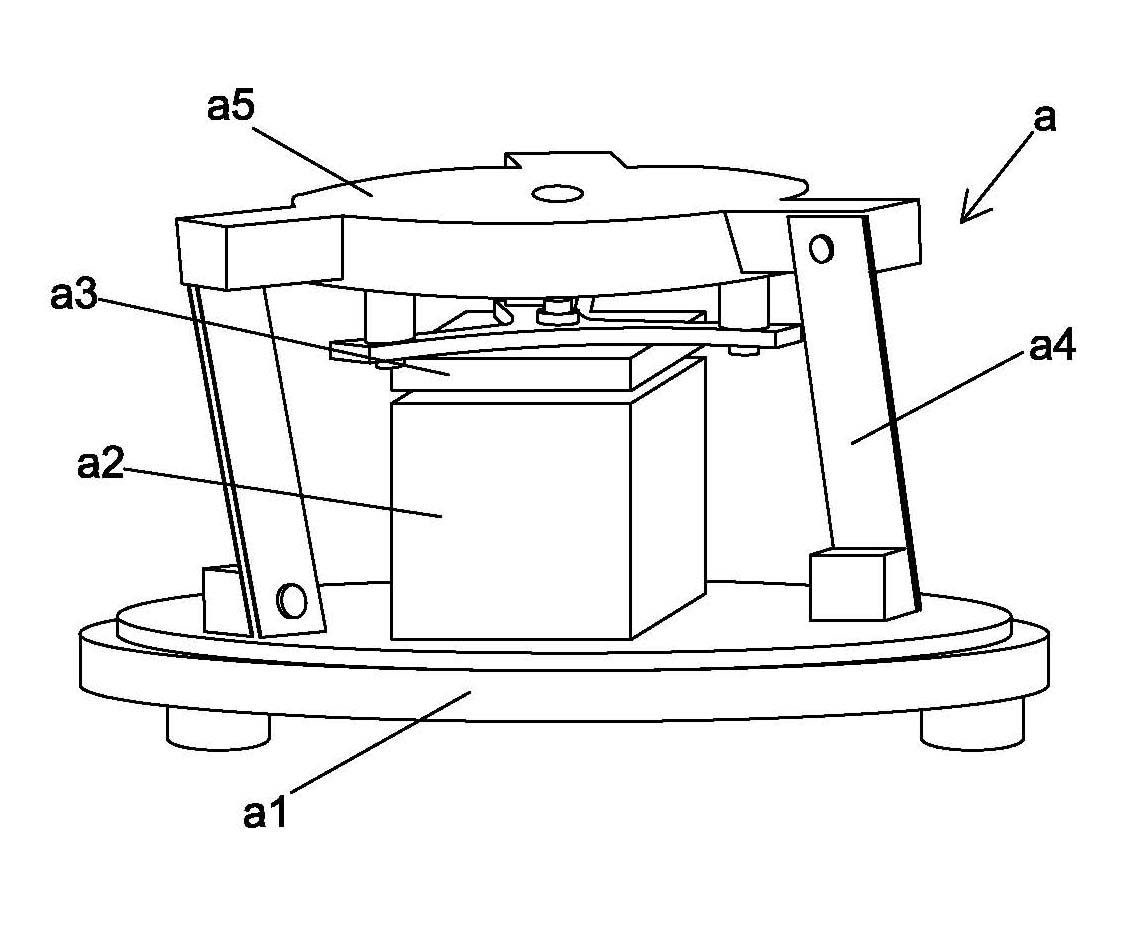

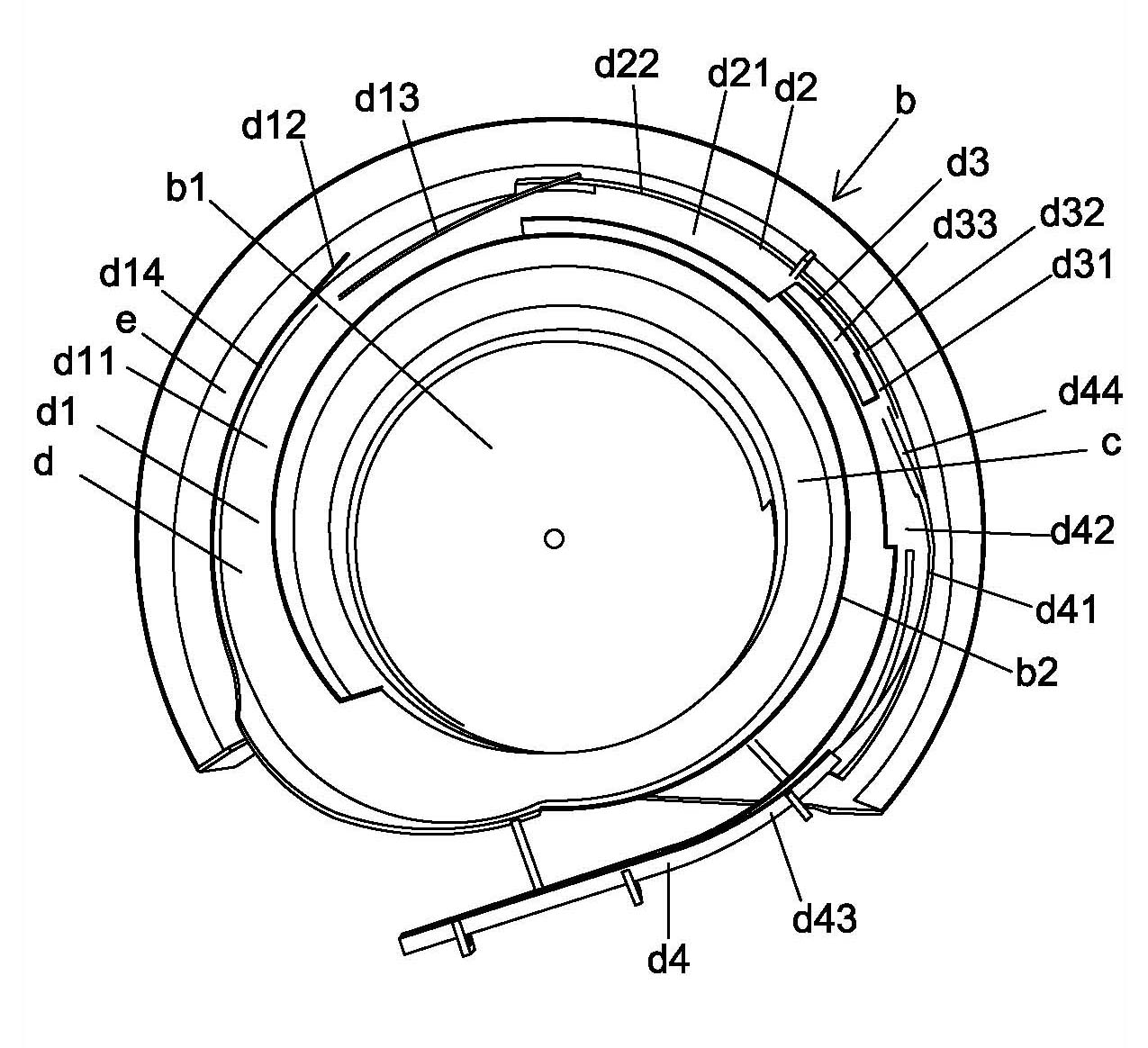

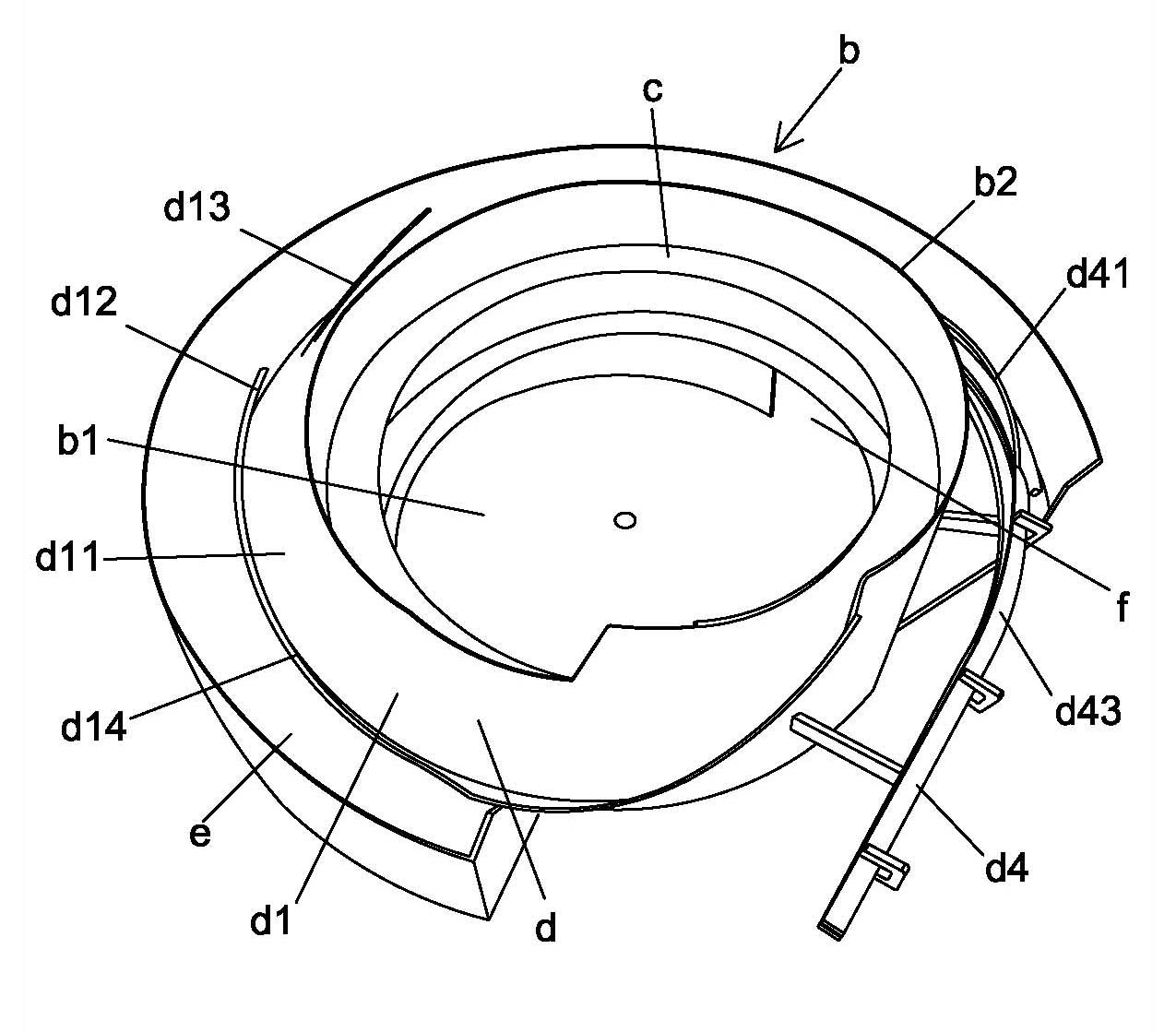

[0018] Such as figure 1 and Figure 5 As shown, a tray of an automatic feeding device is mainly used for an automatic feeding device for the cover plate of a plastic case motor of a microwave oven, including a magnetic vibration host a and a tray b.

[0019] Such as figure 1 As shown: the magnetic vibration host a includes a machine base a1, an electromagnet a2, an armature a3, a vibrating leaf spring a4 and a top seat a5, the electromagnet a2 is installed on the machine base a1, and the armature a3 is installed on the bottom surface of the top seat a5 Above the electromagnet a2, the top seat a5 is suspended above the machine base a1 through more than two vibrating leaf springs a4, and the armature a3 is kept at a certain distance from the electromagnet a2, and the vibrating leaf spring a4 is arranged obliquely; the vibrating leaf spring a4 The angle of inclinatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com