screw compressor

A screw compressor, screw technology, applied in the direction of rotary piston machinery, mechanical equipment, machine/engine, etc., can solve problems such as unrealistic, and achieve the effect of improving vibration attenuation and vibration reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

[0055] (Structure of screw compressor)

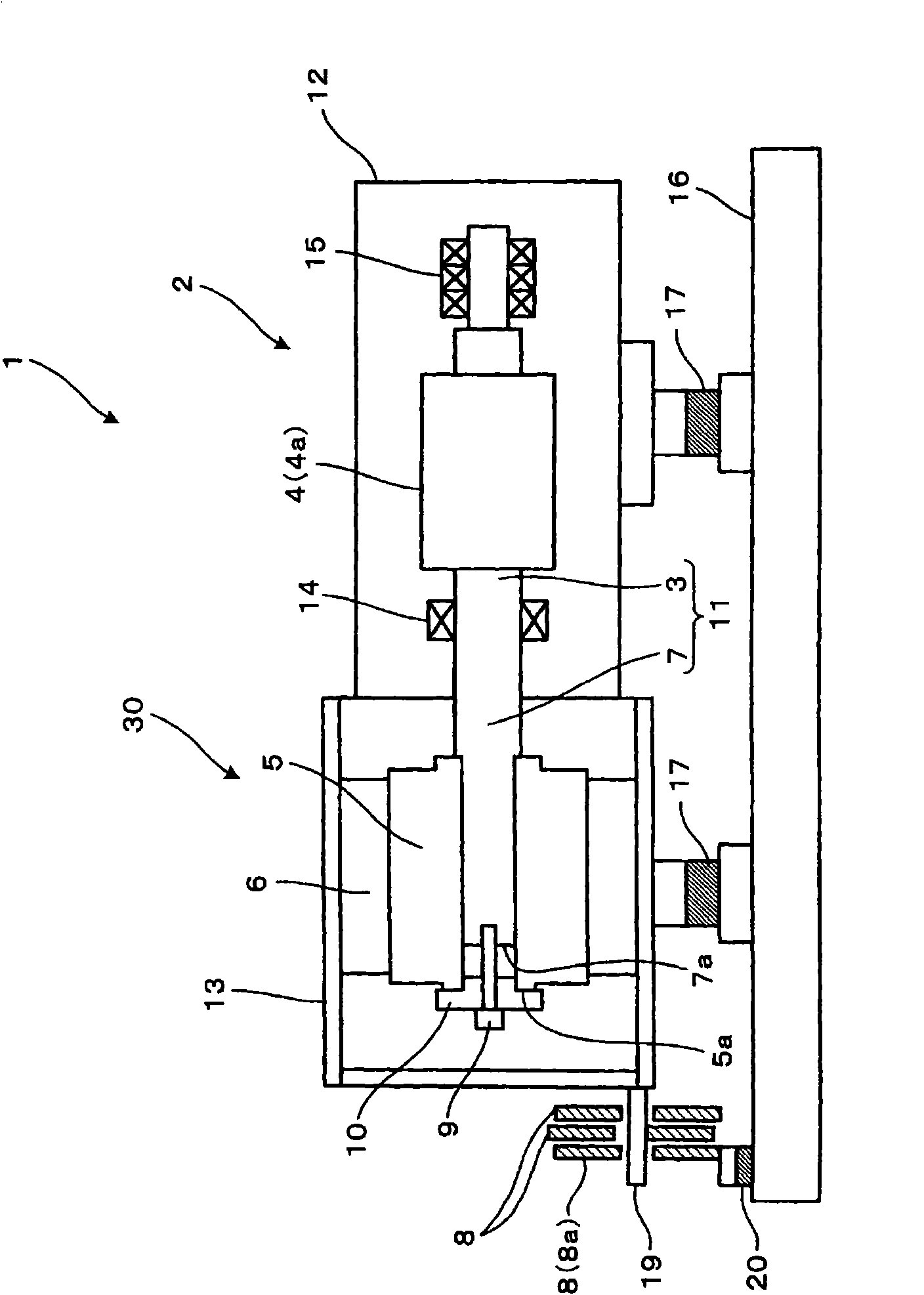

[0056] Such as figure 1 As shown, the screw compressor 1 is a screw compressor of a direct-motor connection structure including a screw body part 2 and a motor part 30 (motor).

[0057] (Screw body part)

[0058] The screw body part 2 has: a pair of male and female screw rotors 4, a screw shaft 3 that is coaxial with the male rotor 4a of the screw rotor 4 and is integrally formed with respect to the male rotor 4a, and a screw housing that accommodates the screw rotor 4 and the screw shaft 3 Body 12. Screw shaft 3 is supported by bearing 14 and bearing 15 two ends.

[0059] The male rotor 4a of the screw rotor 4 and the screw shaft 3 are produced by cutting or the like from a single steel material. It should be noted that the male rotor 4 a and the screw shaft 3 may be separately manufactured and rigidly connected (integrated connection). In addition, the screw shaft 3 and the motor shaft 7 to be described later are also manufacture...

no. 2 approach

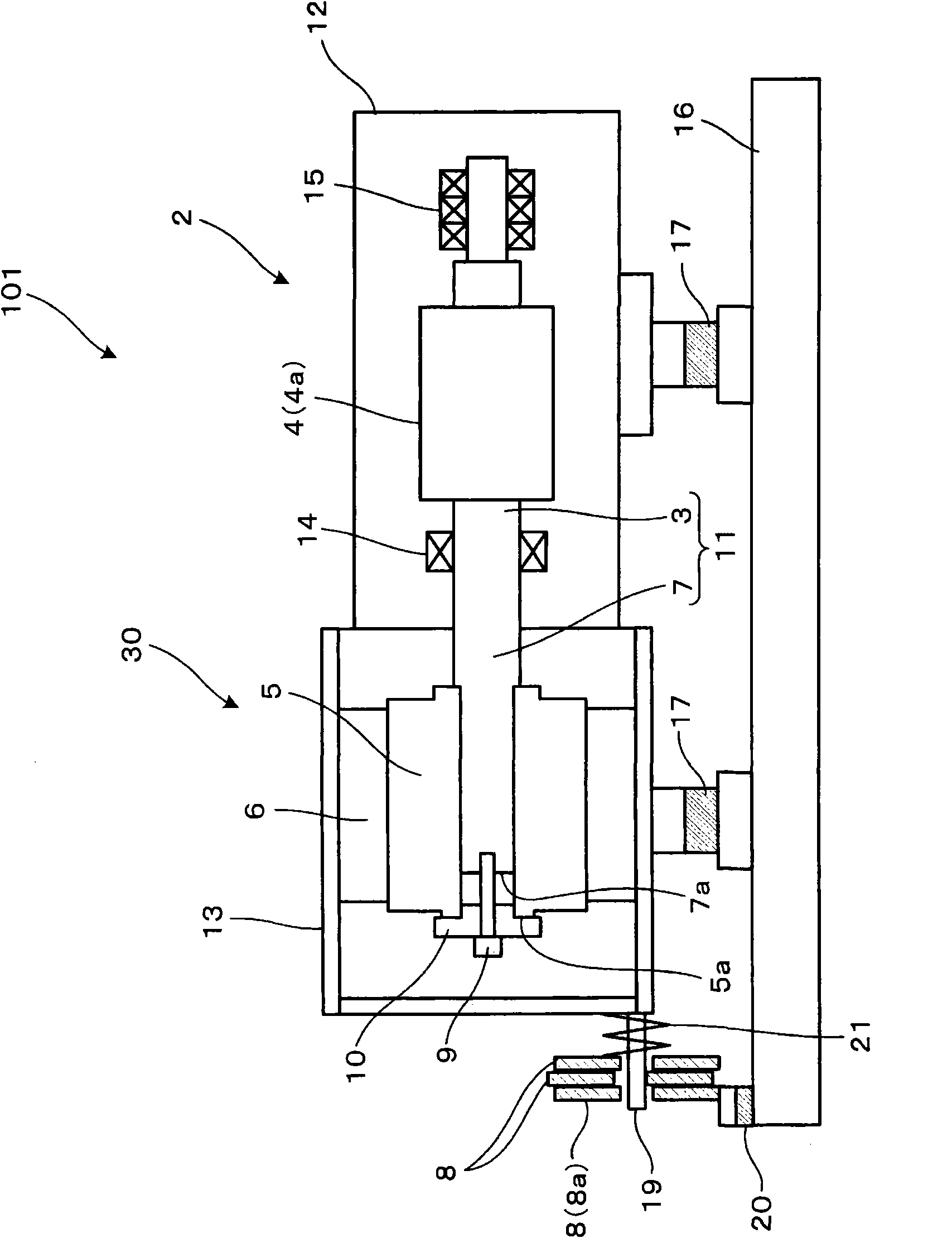

[0078] Next, a screw compressor 101 according to a second embodiment of the present invention will be described. The main differences between the screw compressor 1 of the first embodiment and the screw compressor 101 of this embodiment are: figure 2 As shown, the screw compressor 101 of the present embodiment includes a coil-shaped spring 21 .

[0079] (spring)

[0080] The spring 21 is arranged between the motor housing 13 and the weight 8 that is closest to the motor housing 13 and is not combined with the frame 16 . And, the spring 21 presses the two weights 8 not combined with the machine base 16 to the weight 8a combined with the machine base 16 respectively, wherein the two weights 8 not combined with the machine base 16 are located between the motor housing 13 and the most Between the weight 8a that is far away from the motor housing 13 and combined with the machine base 16 . The weights 8 are in close contact with each other by the spring 21 , and the two weights ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com