Transformer station guiding optical cable optimization laying system

A technology for substations and optical cables, applied in the installation of optical fibers/cables, etc., can solve the problems of heavy optical cable laying workload, shallow pre-buried depth of optical cables, and excessive optical cables, so as to reduce the workload of optical cable laying, improve the overall reliability, and save energy. The effect of total project investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

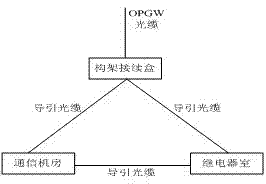

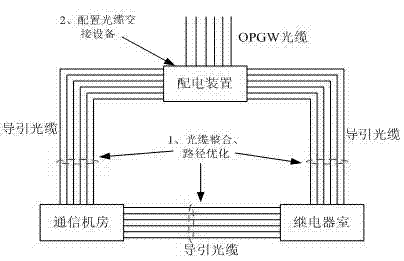

[0028] Example 1: Typical scale 500kV substation

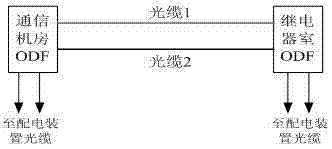

[0029] Substation final output scale: 10 circuits for 500kV lines and 12 circuits for 220kV lines. OPGW optical cable construction is based on 500kV lines with 2 circuits and 1 cable, and 220kV lines with 2 circuits and 1 cable. Before adopting the optimal laying system of substation guide cables, there are 15 guide cables for 500kV OPGW and 18 guide cables for 220kV OPGW. Please refer to Attached Table 1 for details about the laying of guide cables. Please refer to Attachment for the connection diagram of 220kV OPGW guide cables. Figure 7 .

[0030] Attached table 1 Typical 500kV substation guide cable laying table

[0031]

[0032] After adopting the optimized laying system of the substation guide optical cable (take the 220kV part as an example), use a large-core optical cable, set up a reasonable optical cable access convergence point, and configure an optical cable transfer box, and integrate the optical cables ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com