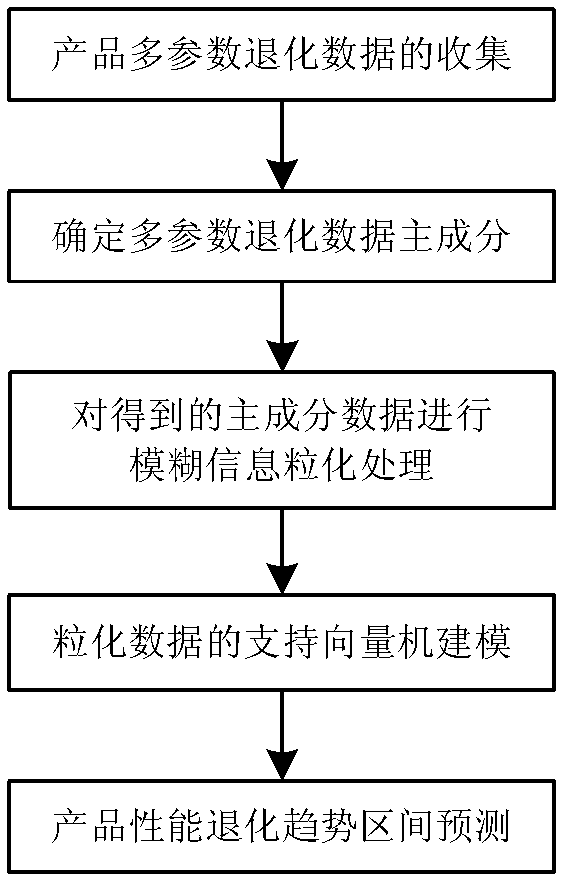

Interval prediction method of product performance degradation based on support vector machine and fuzzy information granulation

A technology of support vector machine and fuzzy information, applied in fuzzy logic-based systems, character and pattern recognition, computer parts, etc., can solve problems such as no consideration, large discrepancies, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

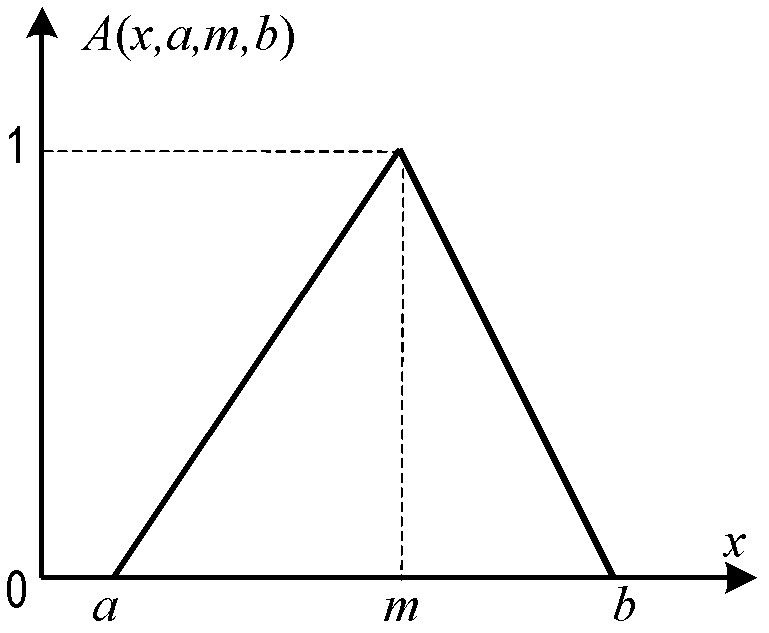

Method used

Image

Examples

Embodiment 1

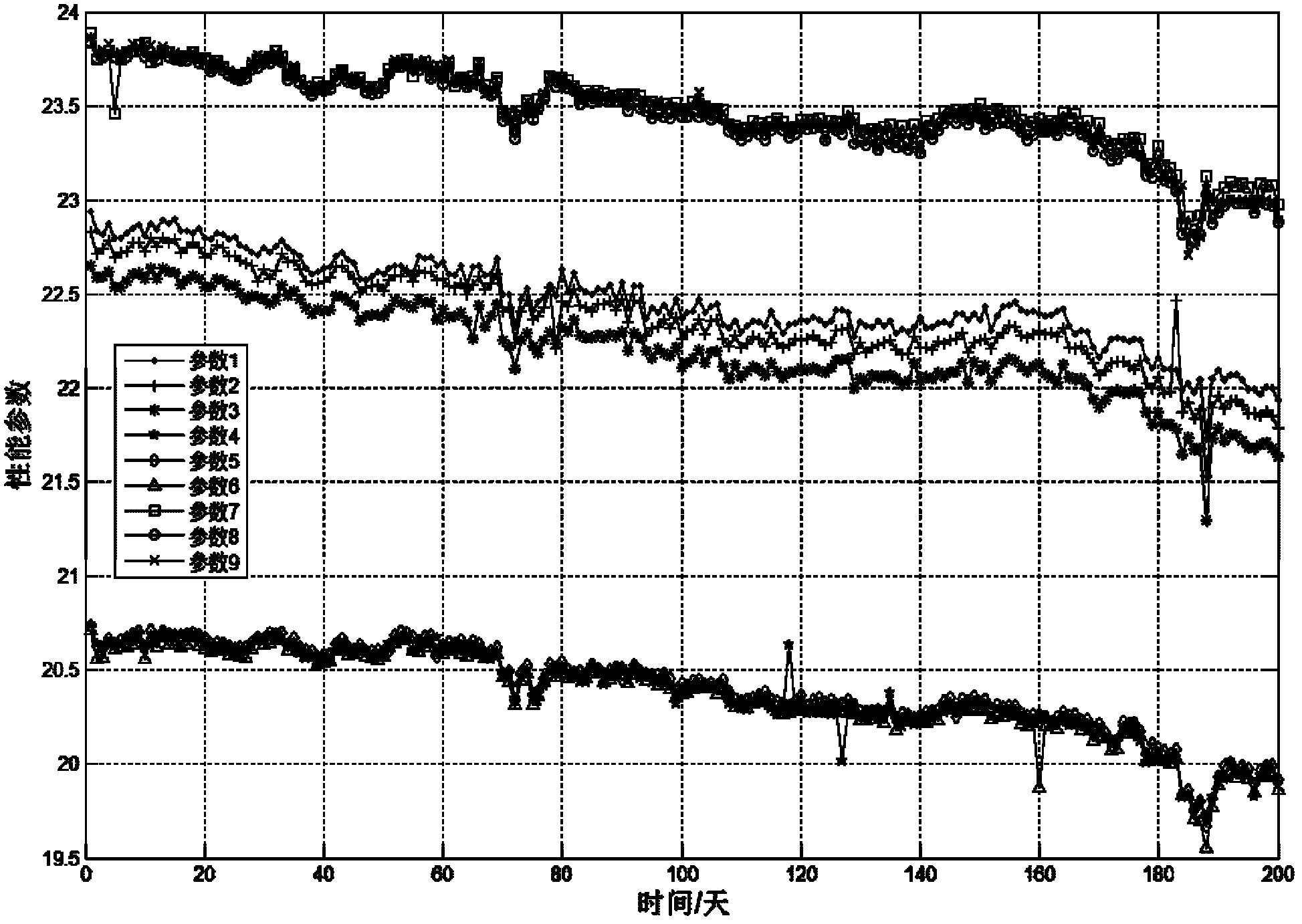

[0090] Taking a microwave electronic product GPZJ-2007 as an example, the product performance degradation interval prediction method based on support vector machine and fuzzy information granulation proposed by the present invention is used to predict its performance state degradation trend and change space. The application steps and methods are as follows:

[0091] Step 1. Collection of product multi-parameter performance degradation data. Through online monitoring, the 9 performance parameters of a certain microwave electronic product GPZJ-2007 are detected once a day, and a total of 9×200 performance parameter observation data are collected, as shown in image 3 shown.

[0092] Step 2. Determine the principal components of the multi-parameter degradation data. Through the above step 2, the cumulative contribution rate of the first principal component is over 90%, so only one variable is selected as the principal component, and the selected principal component is as follows...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com