Waterproof position limit switch

A travel switch and switch group technology, applied in electrical switches, electrical components, circuits, etc., can solve the problems of affecting the safe operation of the system, easy damage to the switch, and jamming of the switch, and achieve a compact structure, easy assembly and adjustment, and intuitive structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

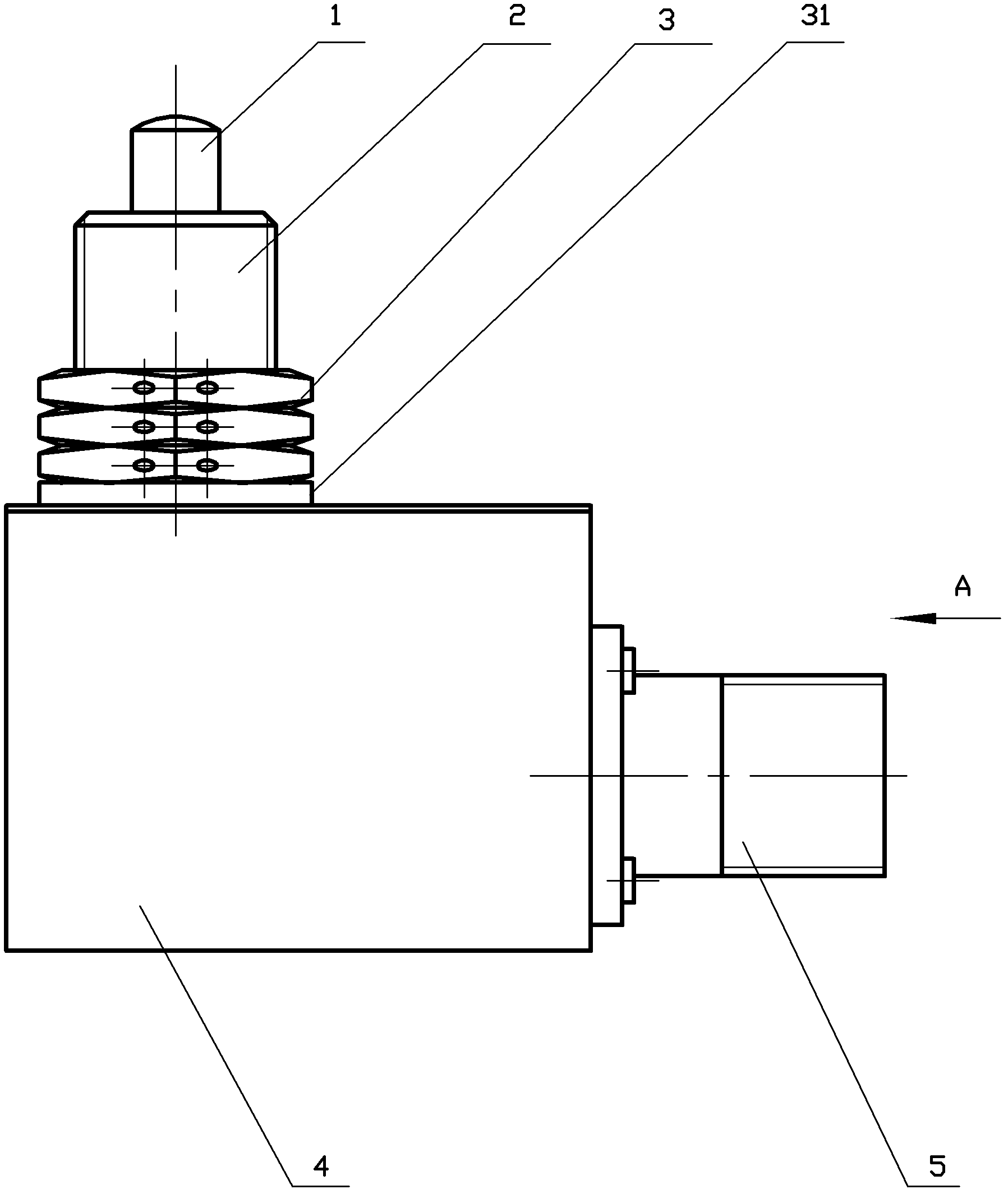

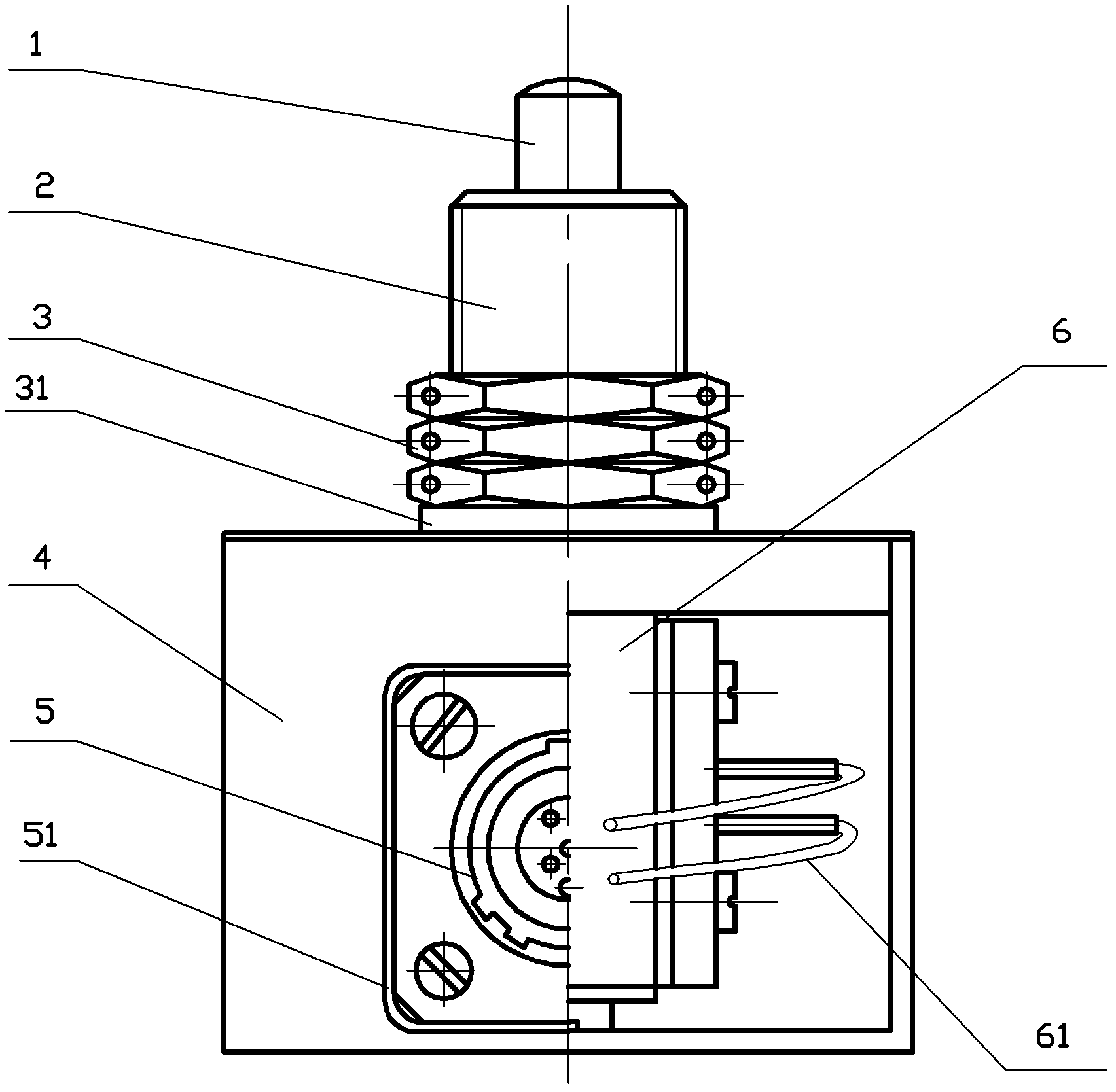

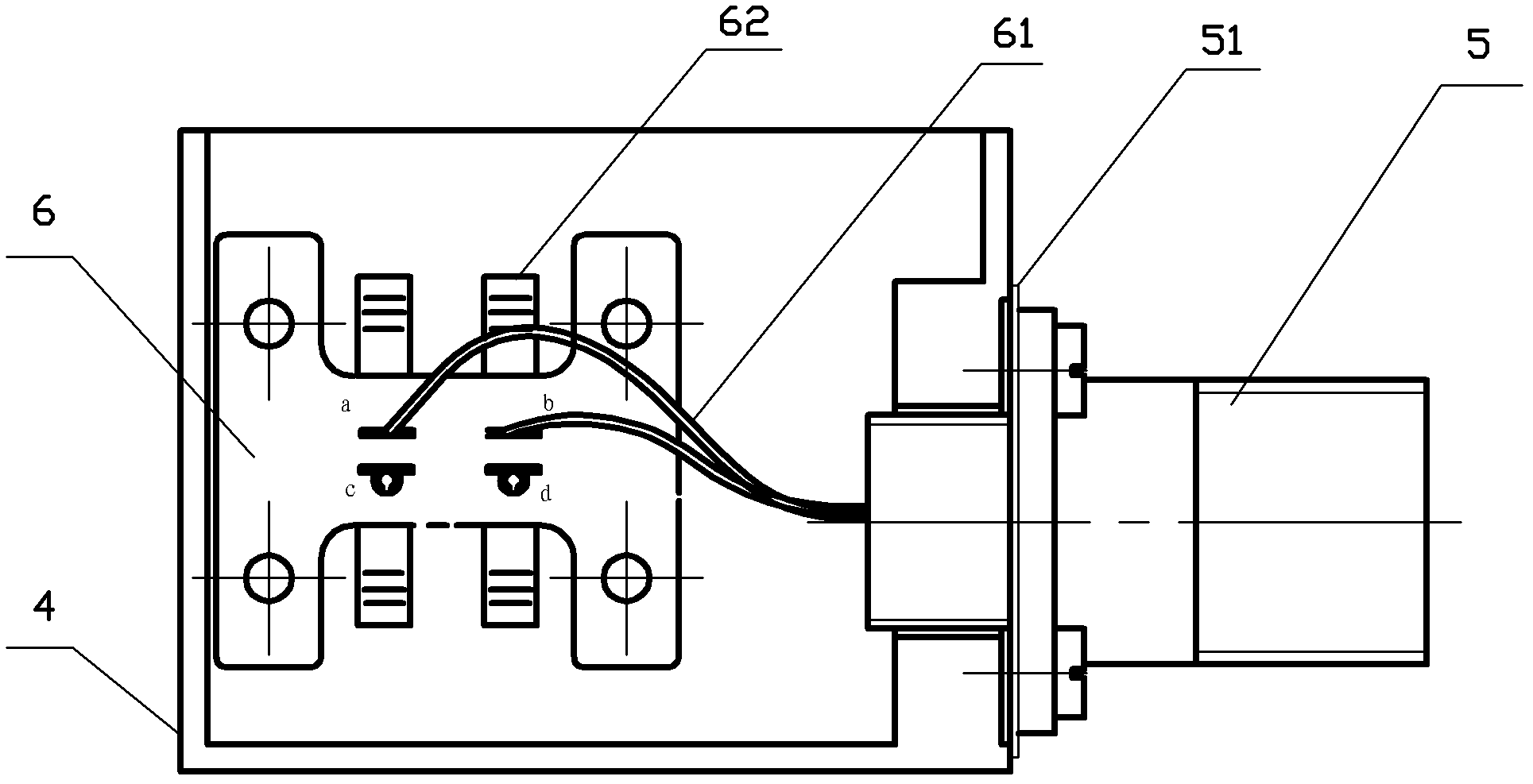

[0023] The overall structure of the waterproof travel switch is as follows: figure 1 , 2 The shown includes a base group and a switch group matched with it. The base group includes a base 4 and a socket 5 with a circuit output interface. The switch group includes a shell 2, a combination button 1, a contact spring group 6 and a compression spring 14. This The base 4 in the scheme is a cuboid, the bottom surface is sealed and connected to the side surface, the side surface has a mounting hole to connect the socket 5, and the top surface is a rectangular opening. Such as Figure 5 As shown, the shell 2 of the switch group includes a button shell 21, a cover plate 22 and a mounting frame 23. The cover plate 22 matches the rectangular opening on the top surface of the base, and the button shell 21 is vertically sealed and connected to the top of the button hole of the cover plate 22. The frame 23 is fixed vertically under the cover plate 22 .

[0024] The inner hole of the butt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com