A kind of diffusion method for preparing polycrystalline silicon solar cell emitter

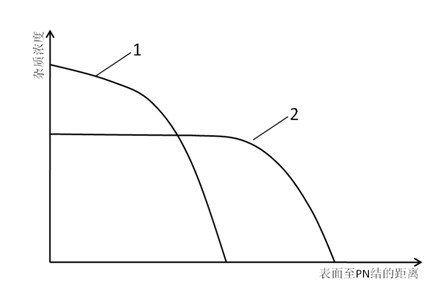

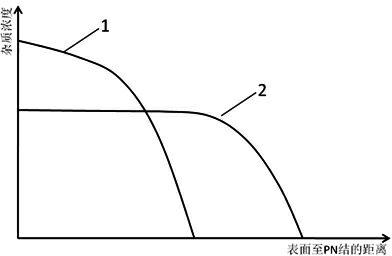

A technology of solar cells and diffusion methods, which is applied in the field of diffusion for preparing high-efficiency emitters of polycrystalline silicon solar cells, can solve the problems of high doping concentration and uneven distribution of phosphorus impurities, achieve uniform distribution of impurities, low concentration of impurities on the surface, and reduce efficiency loss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment

[0017] Raise the temperature to 850°C, pass in a mixed gas of nitrogen and oxygen to oxidize the surface of the silicon wafer, control the flow rate of nitrogen gas to 26L / min, the flow rate of oxygen to 2.6L / min, and the oxidation time to 10min; keep the temperature at 850 °C, using liquid POCl 3 Phosphorus source, control the flow rate of large nitrogen gas to 20L / min, the flow rate of oxygen to 2L / min, the flow rate of small nitrogen gas to 1.5L / min, and the diffusion time to 10min for the first diffusion; keep the temperature at 850°C and use liquid POCl 3 Phosphorus source, control the flow rate of large nitrogen gas to 20L / min, the flow rate of oxygen to 2L / min, the flow rate of small nitrogen gas to 1.5L / min, and the diffusion time to 10min, and perform the second diffusion; keep the temperature at 850°C, use Liquid POCl 3 Phosphorus source, control the flow rate of large nitrogen gas to 20L / min, the flow rate of oxygen to 2L / min, the flow rate of small nitrogen gas t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com