Method for improving performance of electrode thin film and solid oxide fuel cell obtained thereby

A technology of electrode film and performance, applied in the field of solid oxide fuel cells, can solve the problems of limited battery area and thickness, easy to break, poor mechanical strength, etc., and achieve the effect of improving contact effect, reducing rigidity, and stabilizing diffusion speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

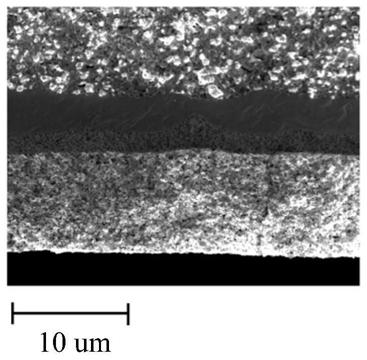

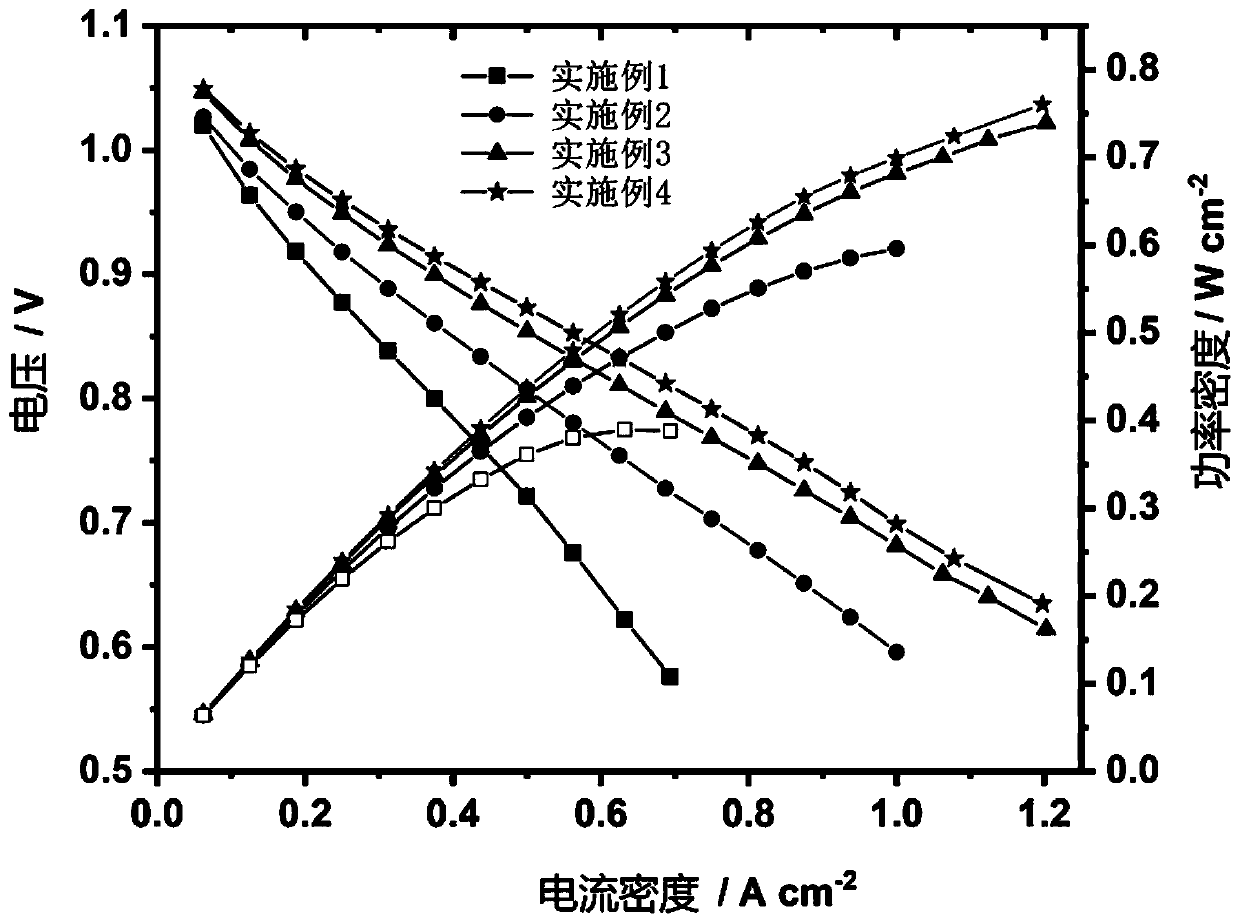

[0032] This embodiment is mainly used as a control experiment group, and the battery used is an anode-supported single fuel cell (battery size 5*5cm 2 ), the battery structure is NiO-YSZ / YSZ / GDC / LSCF, and all preparation methods are routine operations that have been verified by experiments. Electrolyte YSZ layer, GDC barrier layer and LSCF cathode layer were respectively prepared on the anode support layer NiO-YSZ substrate by screen printing method. After repeated printing, a certain thickness of the electrode film is obtained. Then, increase the temperature at a rate of 2 °C / min to 400 °C / min and keep it for 2 hours. After the organic substances in the slurry are completely volatilized, then increase the rate of temperature at 1 °C / min to 900 °C / min and keep it for 2 hours. Finally, cool down to room temperature at a cooling rate of 2°C / min. figure 1It is the sectional view of the untreated battery of this embodiment, and the performance of the untreated electrode thin-fil...

Embodiment 2

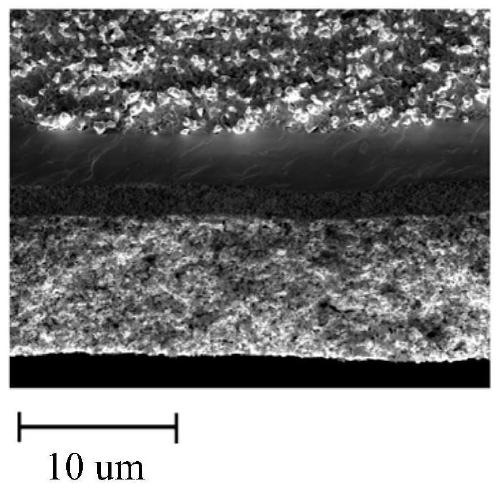

[0034] The battery structure used in this embodiment is the same as that in Embodiment 1. In order to further improve the performance of the battery, in this embodiment, a saturated ethanol steam bath is used to treat the films of all levels prepared by the printing method for the second time. The specific implementation method is as follows: the electrolyte YSZ layer, the GDC barrier layer and the LSCF cathode layer are respectively prepared on the anode support layer NiO-YSZ substrate by the screen printing method, and each layer of film is printed, and first placed in a closed ethanol saturated steam device , keep for 3 minutes, when the film is fully flat and there is no obvious printing grid on the surface, then place it on a flat heating platform at 125°C for pre-curing. The pre-cured film has undergone repeated printing and repeated ethanol saturated steam treatment , to obtain a uniform and flat multi-layer electrode film with a certain thickness. Finally, it is proce...

Embodiment 3

[0036] The battery structure used in this example is the same as that in Example 1. The difference is that different types of organic alcohols are used. In this example, closed propanol saturated steam is used to treat the flatness of the film. The LSCF oxygen electrode was prepared by the screen printing method, and the specific implementation method was as follows: the electrolyte YSZ layer, the GDC barrier layer and the LSCF cathode layer were respectively prepared on the anode support layer NiO-YSZ substrate by the screen printing method, and each layer of film printing was completed. Place it in a closed propanol saturated steam device and keep it for 3 minutes. After the film is fully flat and there is no obvious printing grid on the surface, it is then placed on a flat heating table at 125°C for pre-curing. After pre-curing the film, after Repeated printing and repeated ethanol saturated steam treatment to obtain a uniform and flat multi-layer electrode film with a cer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com