Anhydrous formaldehyde gas preparation device and method

An anhydrous formaldehyde and gas preparation technology, applied in the preparation of heterocyclic compounds, separation/purification of carbonyl compounds, organic chemistry, etc., can solve the problems of unstable diffusion rate, low formaldehyde concentration, cumbersome and time-consuming production process, etc. Simple structure, convenient storage and easy assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

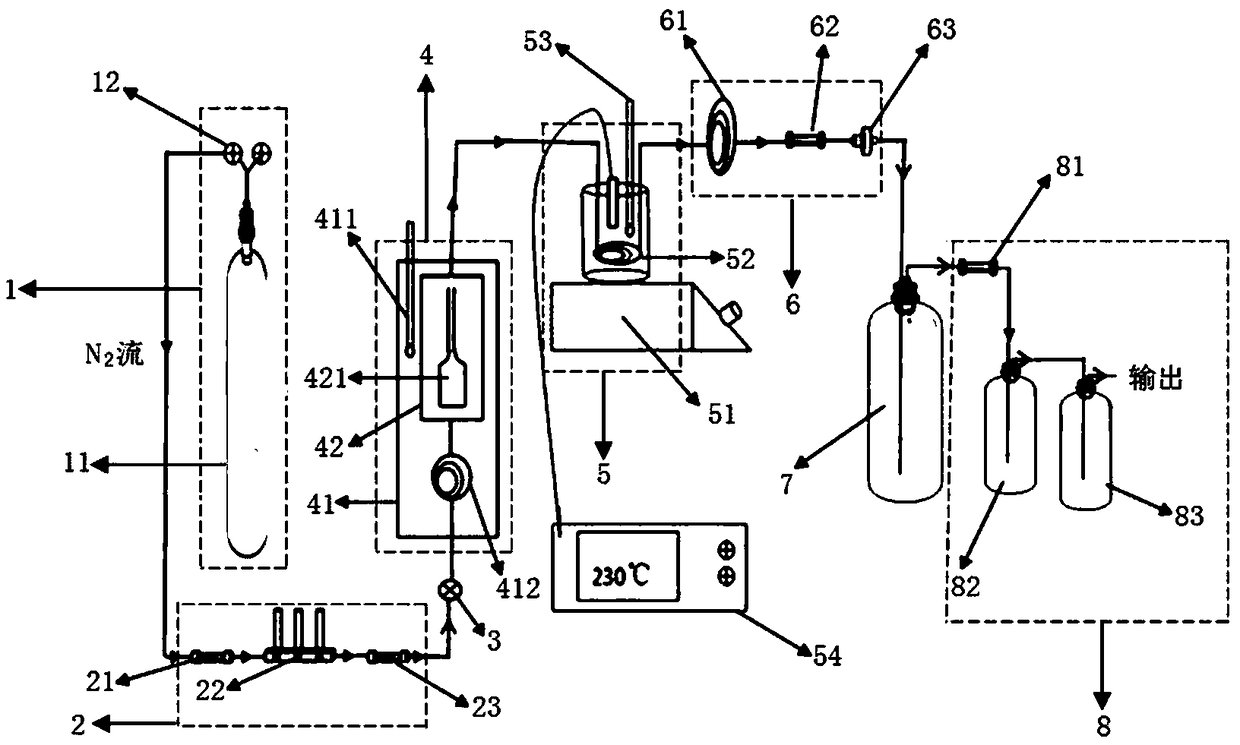

[0054] Embodiment 1 A kind of anhydrous formaldehyde gas preparation device

[0055] An anhydrous formaldehyde gas preparation device, comprising a carrier gas supply assembly 1, a gas drying and purification assembly 2, a flow meter 3, a constant temperature diffusion chamber 4, a high temperature cracking chamber 5, a cooling purification filtration assembly 6, a gas storage bottle 7 and Exhaust gas collection assembly 8.

[0056] The anhydrous formaldehyde gas preparation device of the present invention uses paraformaldehyde as a raw material for the production of anhydrous formaldehyde, and paraformaldehyde is an important chemical product, also known as trioxane. The depolymerization of paraformaldehyde produces formaldehyde monomer, and no water molecules will be generated in this process, so paraformaldehyde is selected as the raw material for preparing formaldehyde monomer. The melting point of paraformaldehyde is 62 ° C. When heated above 62 ° C, it will be converted...

Embodiment 2

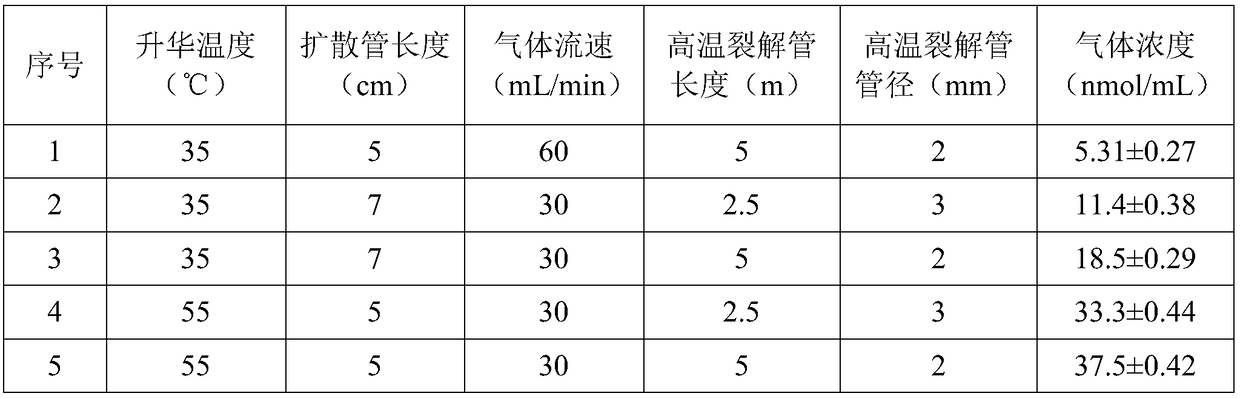

[0083] Embodiment 2 A kind of anhydrous formaldehyde gas preparation process

[0084] A kind of technique that utilizes the device described in embodiment 1 to prepare anhydrous formaldehyde gas, specifically comprises the steps:

[0085] ②The high-purity nitrogen enters the gas circuit system after being dried and purified by the first drying pipe 21, the gas purifier 22 and the second drying pipe 23;

[0086] ②Put 0.5g of paraformaldehyde particles in the diffusion tube 421, seal it with a cover and bake in an oven at 63°C for 1 hour until it completely becomes liquid paraformaldehyde, and gradually lower the temperature to keep the paraformaldehyde diffusion surface in a horizontal state, ensuring that the three POM diffuses at a constant rate, obeying Fick's law of diffusion;

[0087] ③The gas storage bottle 7 is baked in an oven at 110°C for 2 hours to remove the moisture on the inner wall, and after cooling, the bottle is filled with N 2 . Replace the phosphorus pento...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com