Reaction device and method for manufacturing the reaction device

The technology of a reaction device and manufacturing method is applied in the direction of spraying device, measuring device, spraying device, etc., which can solve the problems of cumbersome bonding process, increased etching workload, cumbersome manufacturing process of reaction device, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

[0026] First, refer to Figure 1 to Figure 9 , the structure of the reaction apparatus according to one embodiment of the present invention will be described.

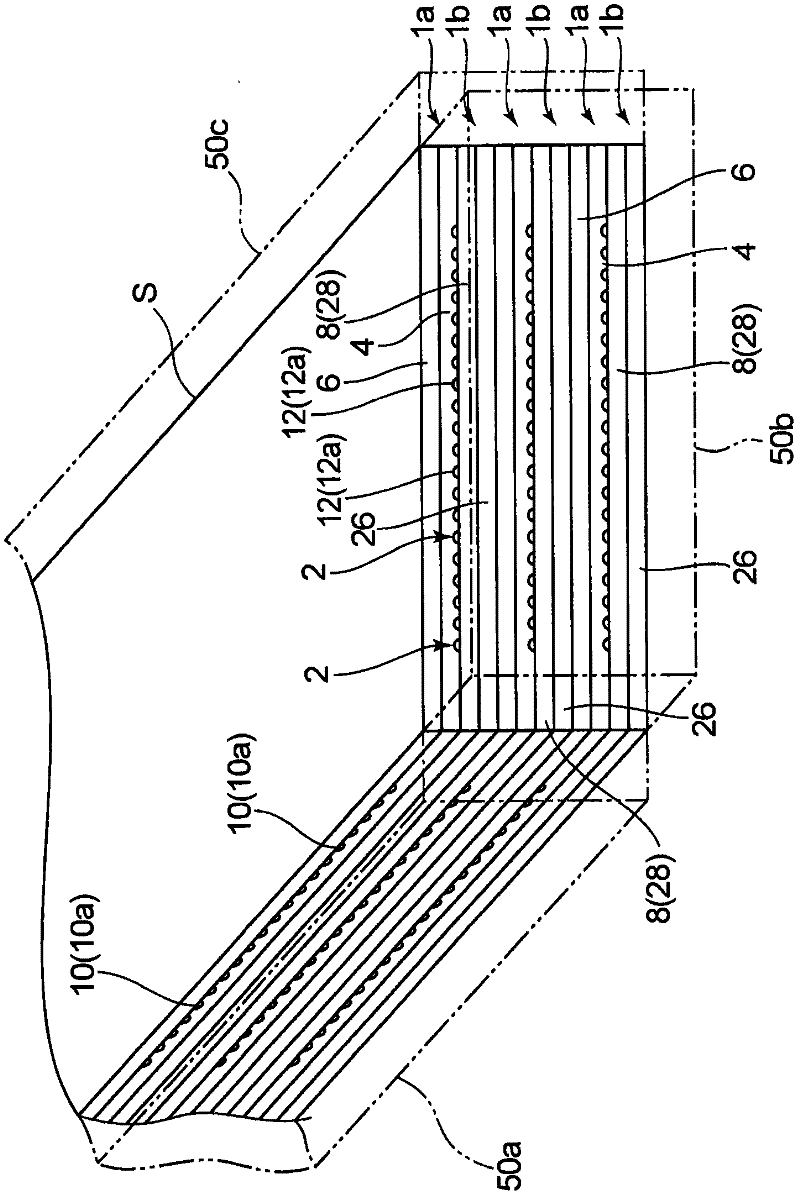

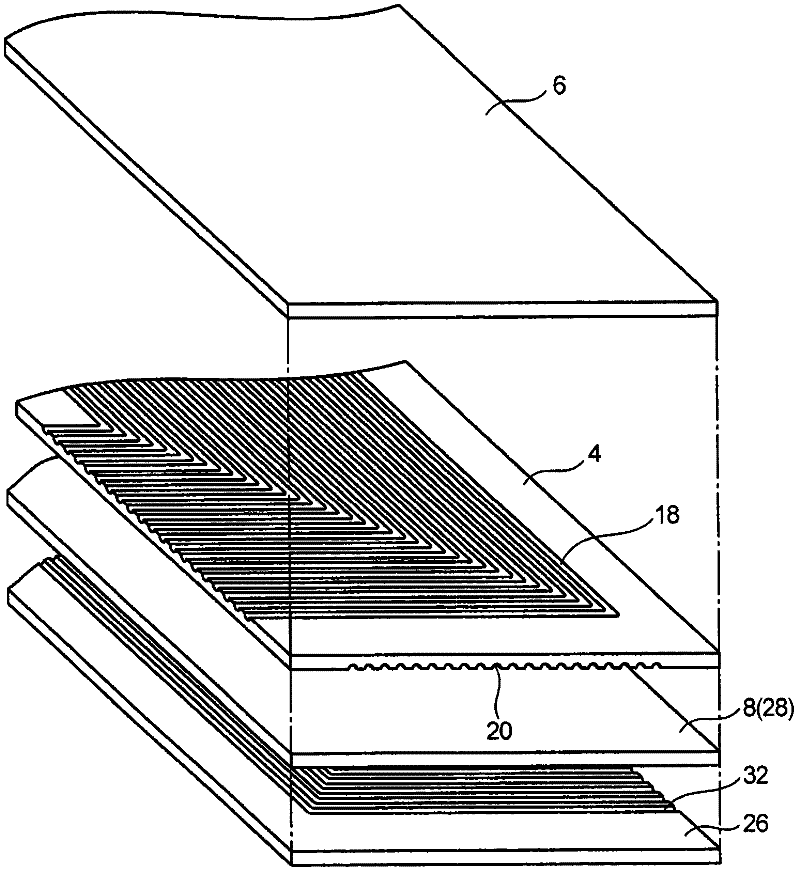

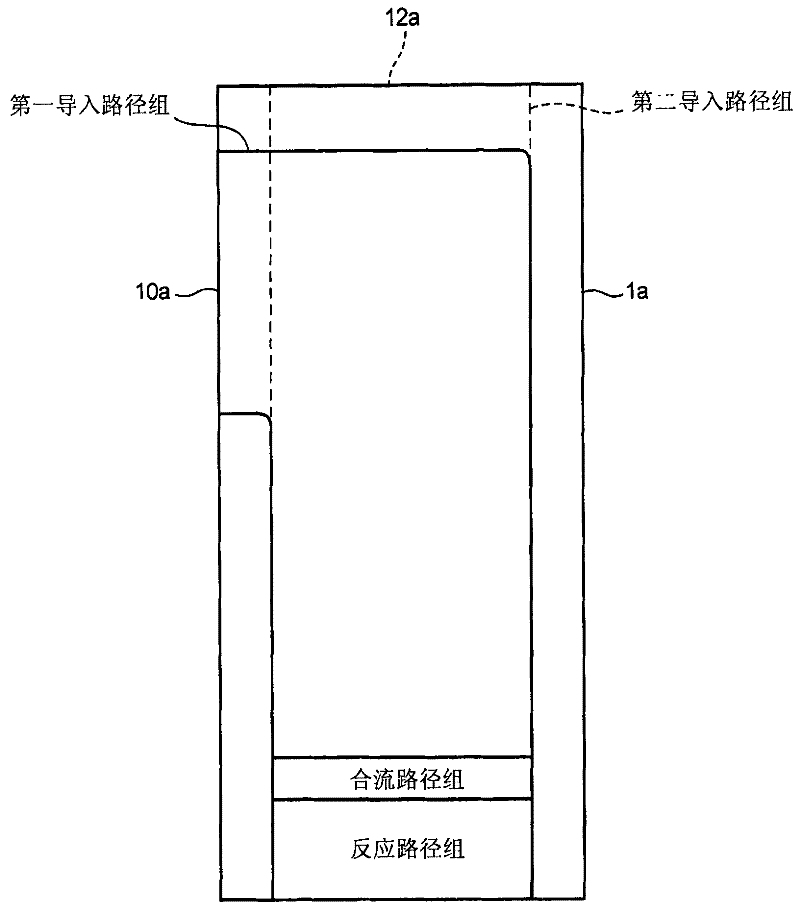

[0027] The reaction device of this embodiment includes figure 1 The flow path device S shown. In this flow path device S, the first flow path structure 1a having a plurality of flow paths 2 through which a reactant flows and the second flow path structure 1b having a plurality of heat medium flow paths through which a heat medium flows are alternately arranged. It is constructed by stacking multiple layers. In addition, the first flow channel structure 1a among the above two flow channel structures 1a, 1b is included in the concept of the flow channel structure of the present invention.

[0028] In addition, the reaction device of this embodiment is generally called a microreactor (microreactor), and the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com