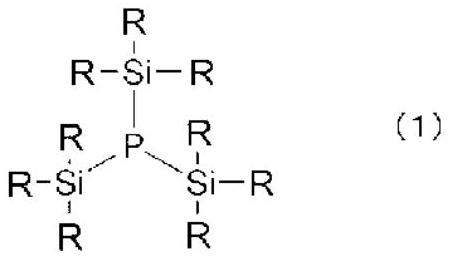

Silyl phosphine compound, method for producing silyl phosphine compound and method for forming InP quantum dot

A technology of silylphosphine and manufacturing method, which is applied in the direction of silicon organic compounds, phosphorus compounds, phosphorus organic compounds, etc., and can solve the problems of cadmium toxicity and high environmental burden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0143] Hereinafter, the present invention will be described in more detail with examples, but the present invention is not limited to these examples. In addition, in the following, as each solvent, a solvent whose moisture content is reduced to 10 ppm or less on a mass basis is used. The moisture content was measured using a Karl Fischer moisture meter (MKC610 manufactured by Kyoto Electronics).

[0144]

[0145] After adding 189.8 kg of toluene to the reaction vessel, 82 kg of triethylamine and 149.5 kg of trimethylsilyl trifluoromethanesulfonate were added, the inside of the reaction vessel was replaced with nitrogen, and the liquid temperature was adjusted to 30°C.

[0146] A stainless steel pressure column with an inner diameter of 25 cm and a length of 2 m was filled with 8.5 kg of granular activated carbon (manufactured by TSURUMI COAL CO., LTD.) to prepare an adsorption tower. 7.5 kg of crude phosphine gas (manufactured by Nippon Chemical Industry Co., Ltd.) with an arsenic...

Embodiment 2

[0188] (Synthesis of InP quantum dots)

[0189] 0.375 mmol of indium myristate was added to 17.8 g of 1-octadecene, and the mixture was heated to 120° C. while stirring under reduced pressure, and degassed for 90 minutes. After degassing, it was cooled to 70°C to obtain a 1-octadecene solution of indium myristate. In addition, 0.25 mmol of tris(trimethylsilyl)phosphine (TMSP) obtained in Example 1 was added to 0.6 g of 1-octadecene to obtain a 1-octadecene solution of TMSP. After heating the obtained 1-octadecene solution of TMSP to 70°C, it was added to the 1-octadecene solution of indium myristate, and the temperature was raised to 300°C while stirring, and then kept for 2 minutes to obtain Red liquid of InP quantum dots.

[0190] (Synthesis of InP / ZnSe / ZnS quantum dots)

[0191] Add 4.5mmol of zinc myristate to 18.6g of 1-octadecene, heat to 120°C while stirring under reduced pressure, and degas for 90 minutes to obtain a 1-octadecene solution of zinc myristate . In the obtai...

Embodiment 3

[0199] (Synthesis of InZnP quantum dots)

[0200] 2.4 mmol of indium myristate and 1.6 mmol of zinc myristate were added to 63.4 g of 1-octadecene, heated to 110° C. while stirring under reduced pressure, and degassed for 90 minutes. After degassing, the temperature was raised to 300°C to obtain a 1-octadecene solution of indium myristate and zinc myristate. In addition, 1.0 mmol of tris(trimethylsilyl)phosphine (TMSP) obtained in Example 1 was added to 2.25 g of 1-octadecene to obtain a 1-octadecene solution of TMSP. The obtained 1-octadecene solution (room temperature) of TMSP was added to the 1-octadecene solution of indium myristate and zinc myristate, and the mixture was kept at 300°C for 30 minutes while stirring to obtain InZnP Crimson liquid with quantum dots.

[0201] (Synthesis of InZnP / ZnSe / ZnS quantum dots)

[0202] Bring the liquid containing InZnP quantum dots to 220°C, add 22.0 mmol of trioctyl phosphine selenide, and heat to 260°C. In addition, 12.0 mmol of zinc m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| relative permittivity | aaaaa | aaaaa |

| relative permittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com