Method for controlling temperature of hot isobaric press and hot isobaric press

A technology of presses, heat, etc., applied in the field of presses, can solve the problems of reducing heating power, preventing separation, stopping convective flow, etc., to achieve the effect of avoiding temperature changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

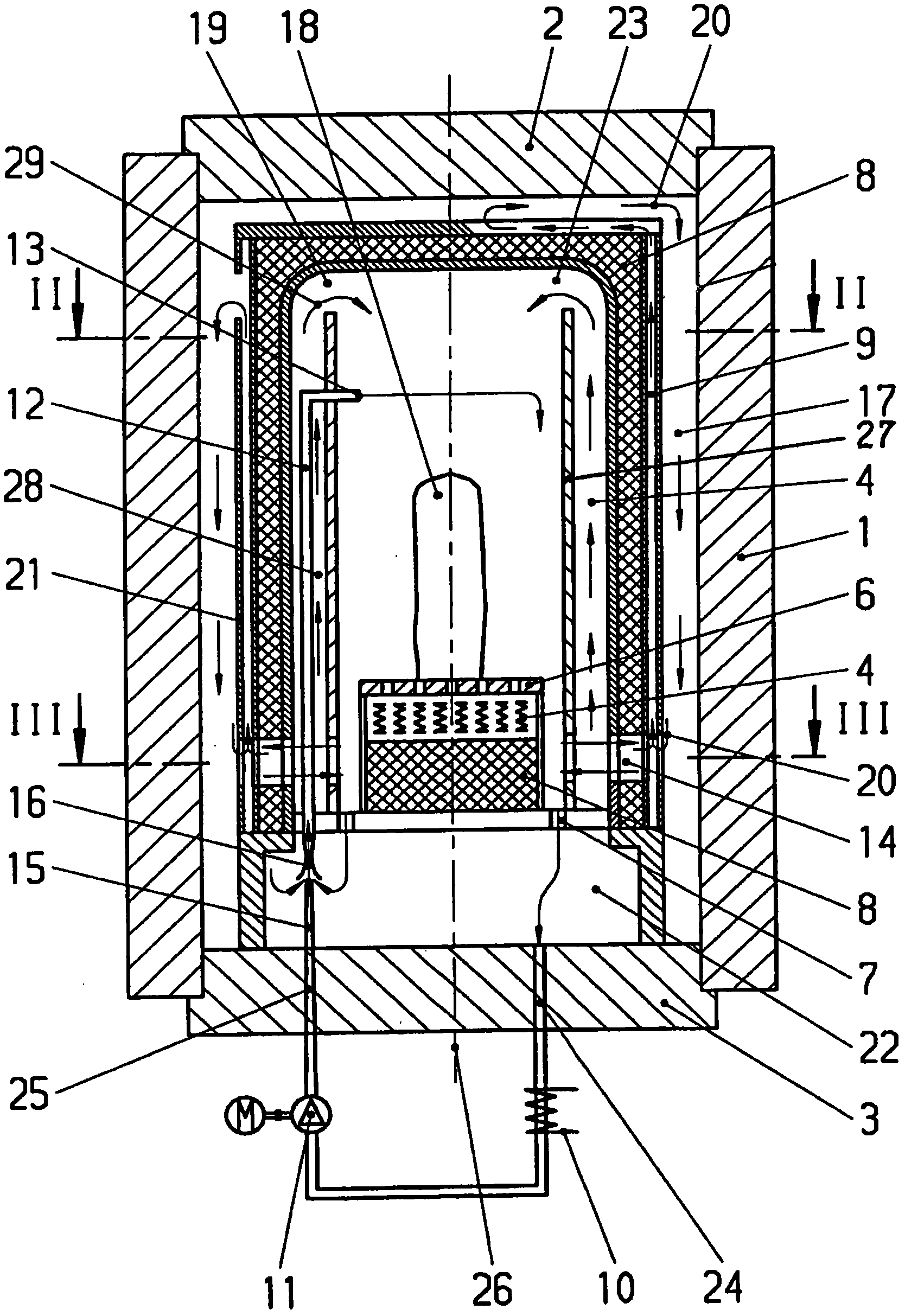

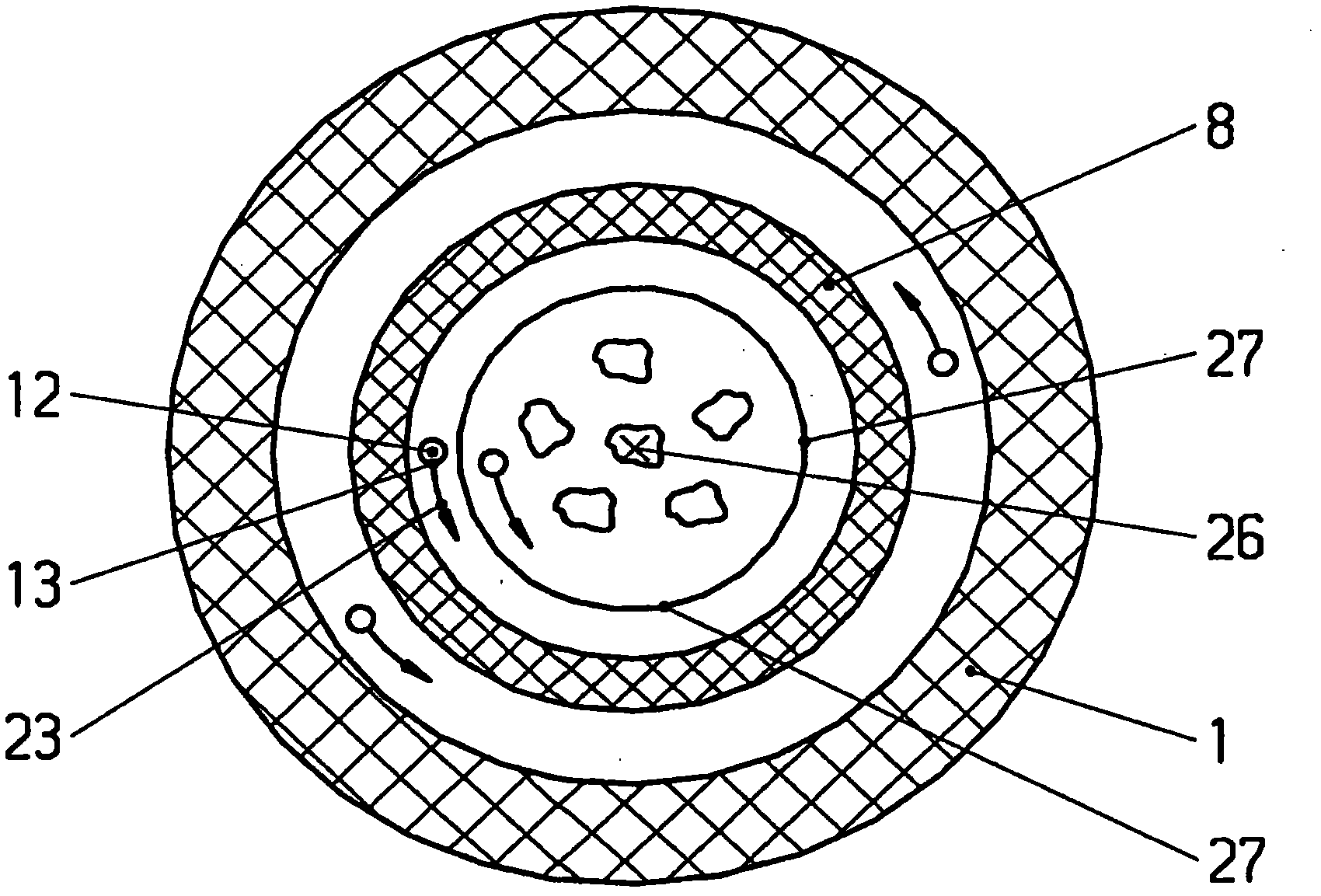

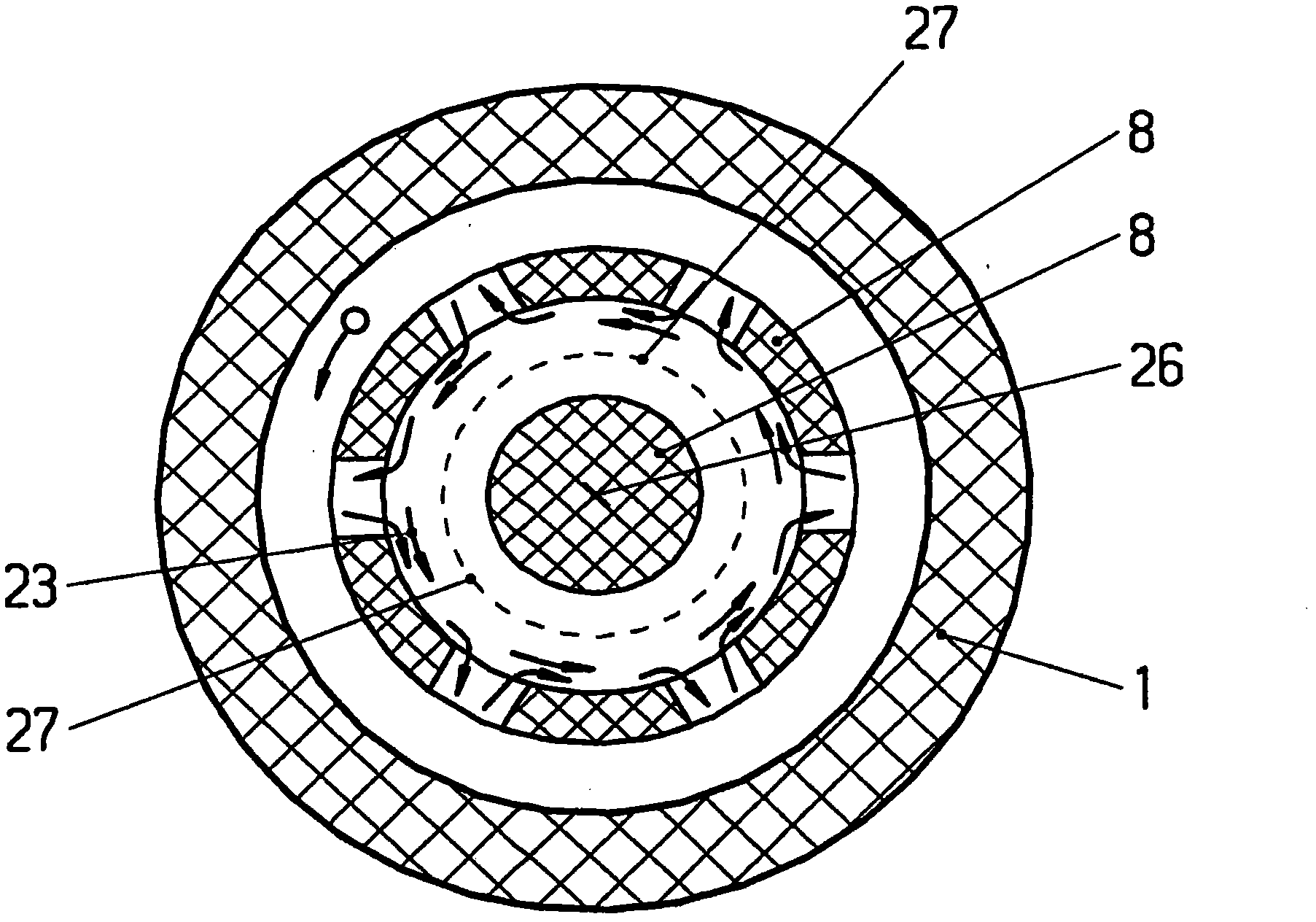

[0023] The pressure vessel 1 shown in the figures has a generally inner charging zone 19 and a thermal insulation 8 arranged between the charging zone 19 and the outer wall of the pressure vessel 1 . In order to form the convection gap 28 , a convection sleeve 27 is arranged in the filling area 19 . The cooling of the pressure vessel 1 as described is explained below. Active heating with a heated fluid or with the aid of heating elements is expedient. Furthermore, within the insulation 8 there is a heating element 4 and a charging device 18 is usually arranged on the charging support plate 6 or, in the case of blocks, by means of a material support (not shown) on the charging support plate 6 . The pressure vessel 1 also has closing caps 2 and 3 which can be used for charging and discharging the pressure vessel 1 , but for the sake of simplicity of description, these are considered to be part of the pressure vessel 1 in the following. Inside the insulator 8 , in the charging ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com