A system and method for comprehensive utilization of waste heat recovery from return air wells in cold mining areas

A waste heat recovery and air return shaft technology, which is applied in mine/tunnel ventilation, mining equipment, earthwork drilling, etc., can solve the problems of bulky equipment, high construction cost, overcooling or overheating, etc., to improve energy utilization rate, The effect of improving heat exchange efficiency and reducing work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

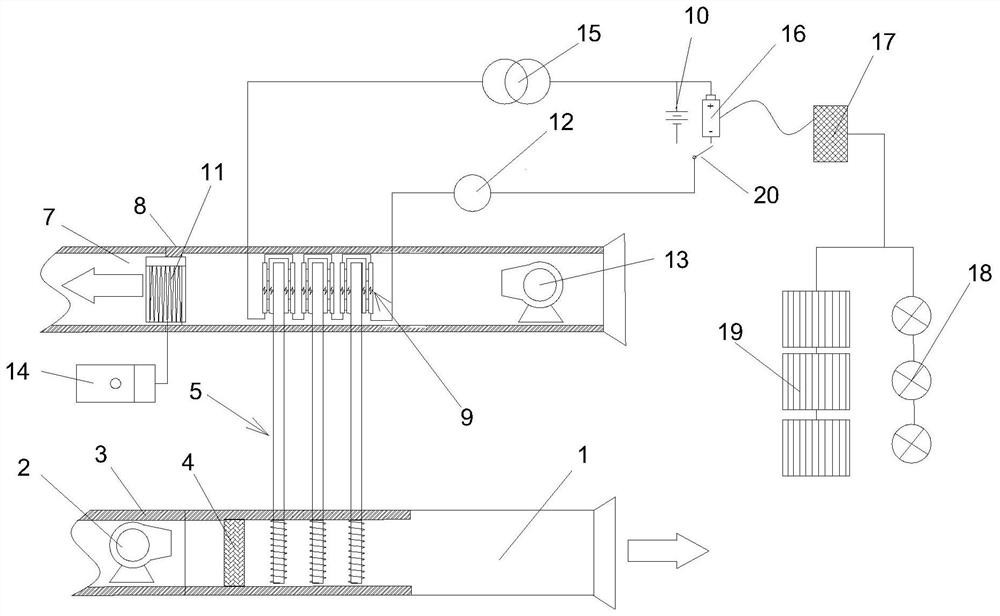

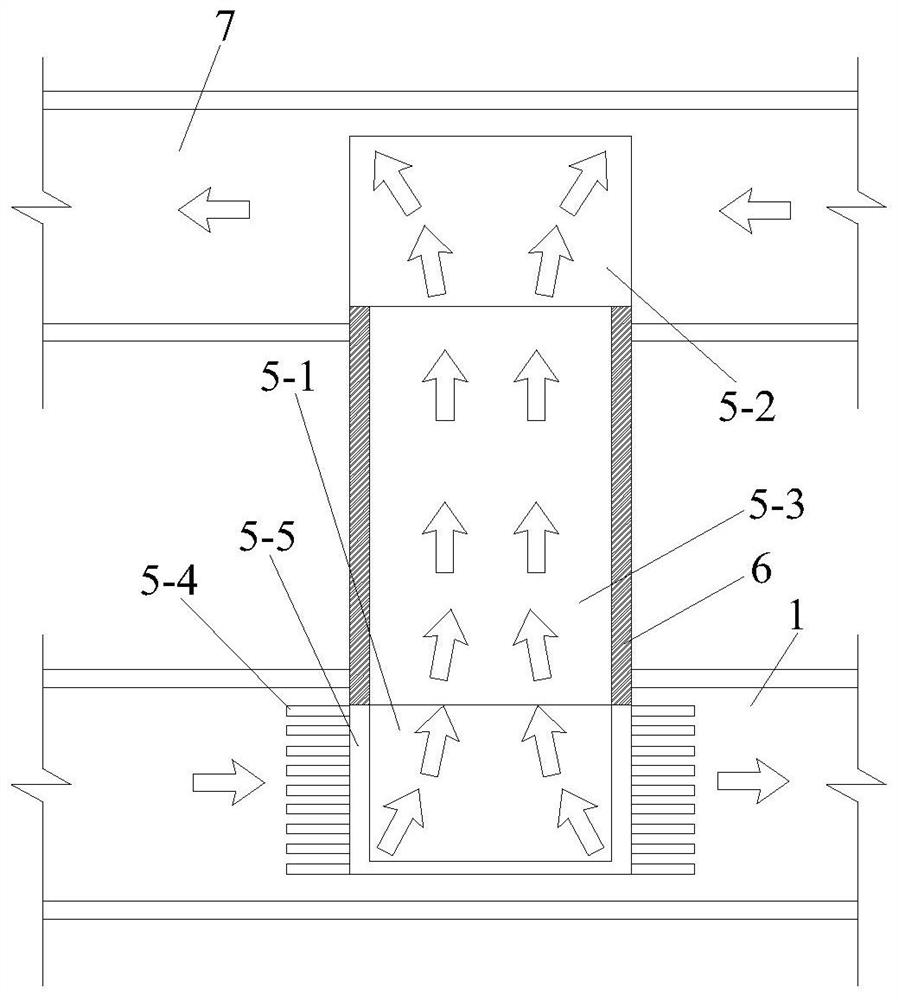

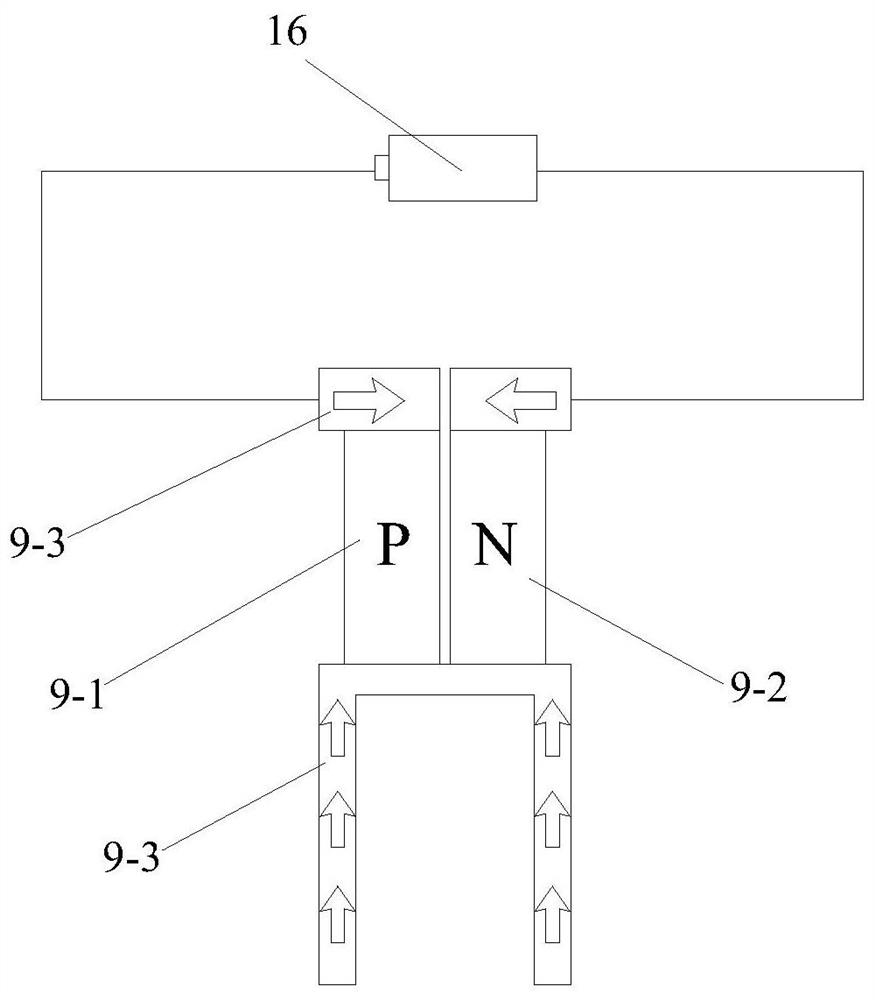

[0051] like Figure 1 to Figure 5 The comprehensive utilization system for waste heat recovery of the return air shaft in the cold mining area shown includes the return air shaft 1, the air intake shaft 7, the waste heat recovery preheating mechanism connected between the return air shaft 1 and the air intake shaft 7, and the air intake shaft The thermoelectric conversion system matched with the waste heat recovery and preheating mechanism in 7, the thermoelectric conversion system is connected with the storage battery 16 and the external power supply 10 through a single-pole double-throw switch 20, the output terminal of the thermoelectric conversion system and the storage battery 16 A voltage stabilizer 15 is connected, the return air shaft 1 is provided with a return air fan 2, the air intake shaft 7 is provided with an air intake fan 13 and an electric auxiliary heater 11, and the thermoelectric conversion system is located in the electric auxiliary heating Between device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com