soybean harvester

A technology for harvesters and soybeans, which is applied to harvesters, cutters, agricultural machinery and implements, etc. It can solve the problems of unsuitable harvesting of soybeans, high equipment cost and use cost, and high loss rate, so as to reduce soybean damage rate and increase friction The effect of small force and small space occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

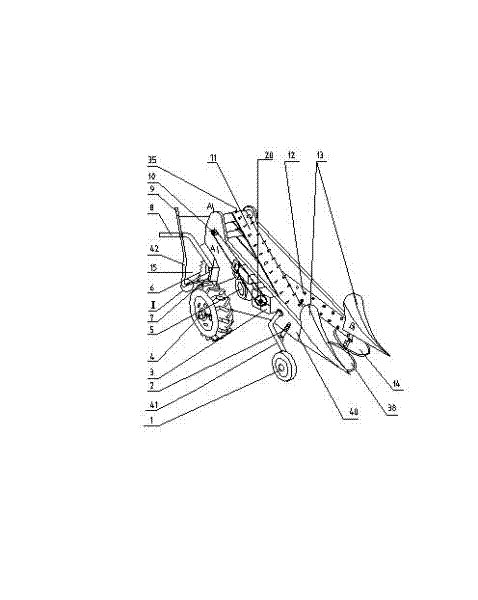

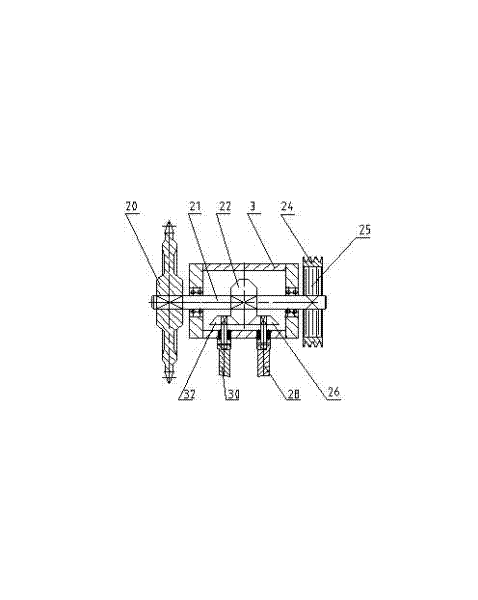

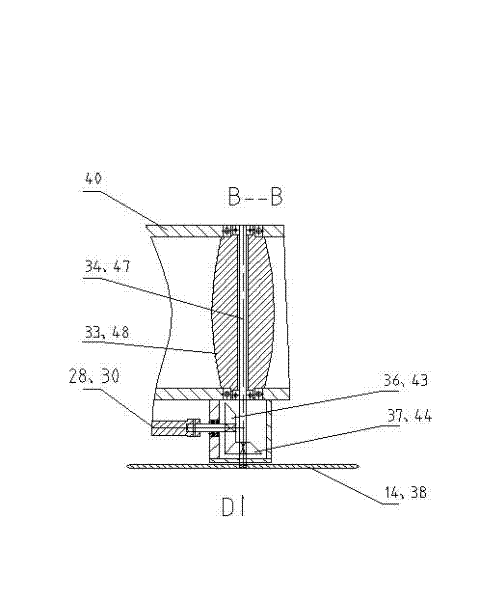

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0020] see Figure 1-Figure 6 , soybean harvester of the present invention comprises body 40, is fixedly connected with engine 5 on body 40, a pair of road wheels 4 that engine speed changer drives, is hinged with forearm shaft 41 on body 40 that is positioned at road wheel 4 front ends, on forearm shaft The two ends of 41 are respectively hinged limited depth wheel 1, and the both sides of body 40 rear end are fixedly connected with handrail 8. Vertically at the front end of the body 40 is a left-handed vertical shaft 47 and a right-handed vertical shaft 34 that are arranged in pairs, and the upper conveyor belt front wheel 48 is sleeved on the top of the left-handed vertical shaft 47, and is nested on the top of the right-handed vertical shaft 34. Conveyor belt front wheel 33 is fixedly connected with left cutter 38 at the lower end of lef...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com