Longitudinal axial flow threshing device

A threshing device and longitudinal axial flow technology, which is applied in threshing equipment, applications, agricultural machinery and implements, etc., can solve the problems that the longitudinal axial flow full-feed combine harvester does not play its role, and is beneficial to installation, layout and separation Good effect, prolonged effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

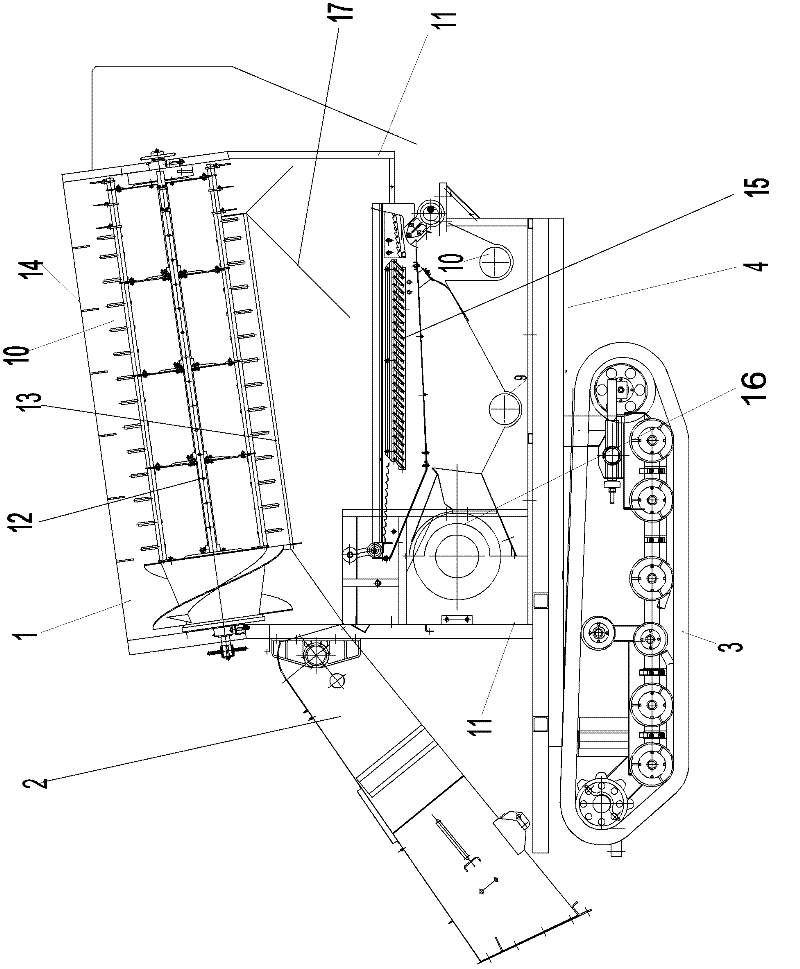

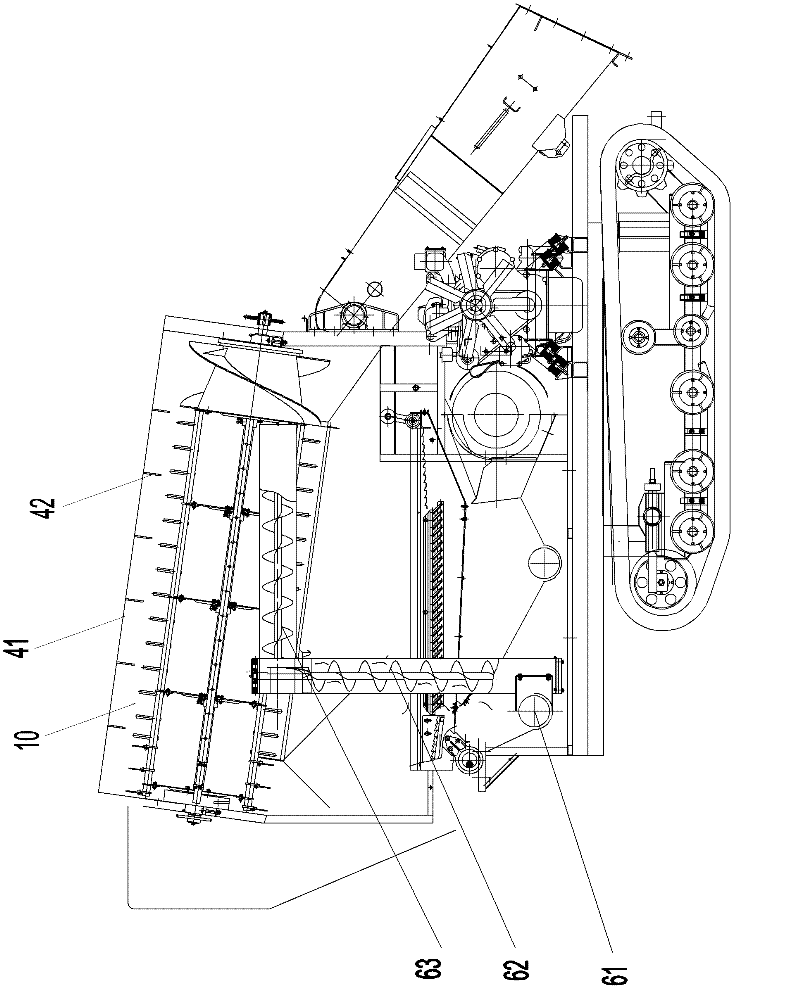

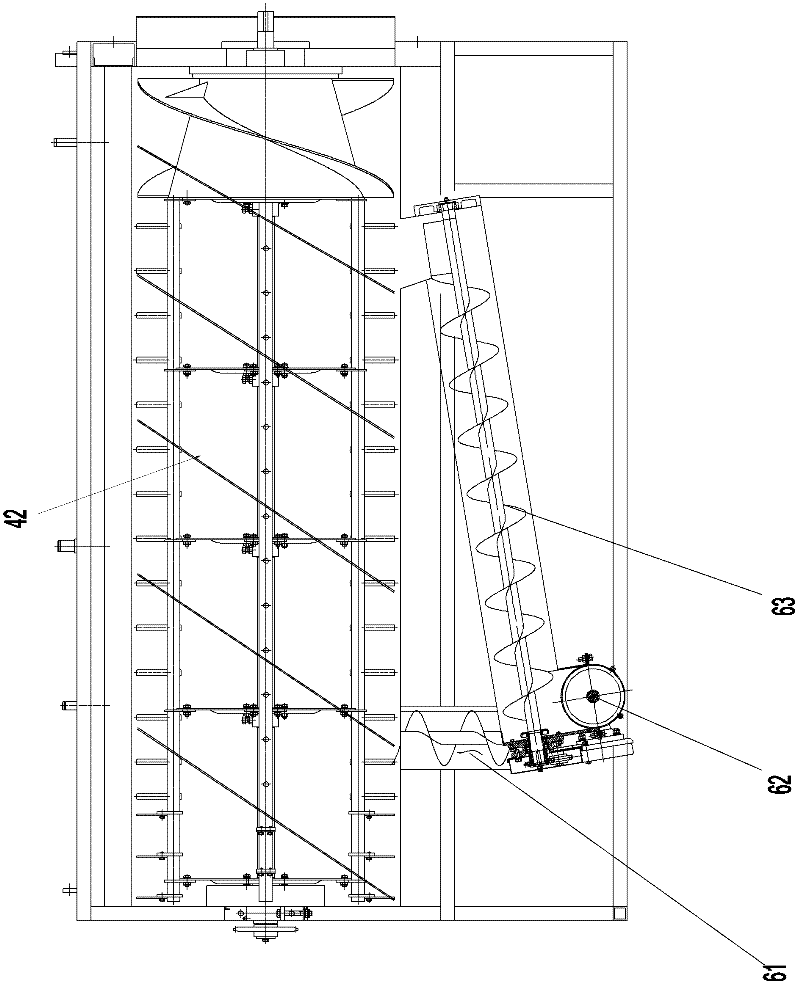

[0016] Such as figure 1 , figure 2 As shown, the longitudinal axial flow threshing device 1 is placed above the underframe 4 on the walking device 3 of the full-feed combine harvester.

[0017] The threshing device is provided with a threshing cylinder 12 and a concave screen 13 arranged at the bottom of the threshing cylinder 12 and wrapped outside the threshing cylinder 12 from below. The top cover 14 is covered on the upper end of the concave screen 13. The threshing assembly formed by the concave plate sieve 13 and the top cover 14 is vertically arranged in the harvester, the front is low and the rear is high, and the concave plate sieve 13 is used as the primary separation screen. The bottom of the described threshing assembly is provided with a cleaning vibrating screen 15 arranged longitudinally along the harvester, the threshing assembly is inclined to the cleaning vibrating screen 15, the front end of the threshing assembly is close to the cleaning vibrating screen,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com