A kind of preparation method of set type yoghurt and prepared set type yoghurt

A technology of coagulation and yogurt, applied in dairy products, milk preparations, applications, etc., can solve problems such as poor texture and curd state, thin tissue state, poor fermentation aroma, etc., to achieve uniform and delicate curds, total The effect of high dry matter content and not easy to syneresis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] A method for preparing coagulated yogurt, comprising: mixing 90-91% of raw milk with a dry matter content of 13-17%, 1-2% of whey protein and 8% of sugar to prepare a fermentation base, inoculating Lactic acid bacteria, filling, and fermenting at 42-45 DEG C for 3-6 hours to prepare coagulated yogurt.

[0022] The content of total dry matter in coagulated yogurt products is an important factor affecting the tissue state of coagulated yogurt. The total dry matter of coagulated yogurt mainly comes from the dry matter of raw milk, sugar and whey protein. Among them, the purpose of adding sugar is to control the acidity, increase the ratio of sweet and sour, and improve the taste. Whey protein is a high-quality protein supplement, which can increase the nutritional content of yogurt, increase the total dry matter content of yogurt, and strengthen the texture of yogurt. Enhances water retention and viscosity. The amount of sugar and whey protein added in a certain volume o...

Embodiment 1

[0038] Example 1: Preparation of the coagulated yogurt of the present invention

[0039] The raw milk that has passed the antibiotic test is taken, and the vacuum degree is reduced by 15KPa at 85° C. and then evaporated for 1-2 s to obtain raw milk with a dry matter content of 15%. After cooling, mix 90.5% of raw milk with 1.5% of whey protein and 8% of white sugar, homogenize at 18-20Mpa and 65-75°C, then heat up to 90-95°C and keep sterilized for 300s. The sterilized fermentation base was cooled to 42-45°C and inoculated with mixed strains of Lyofast Y450A and YO-MIX187 with different bacterial viability ratios, and stirred to make the bacterial viability unit 250DCU / 1000L. Filling, then fermented at 42-45°C for 4-5h, then cooled to below 10°C, and the cooled yogurt was placed at 2-6°C for 10h to obtain coagulated yogurt.

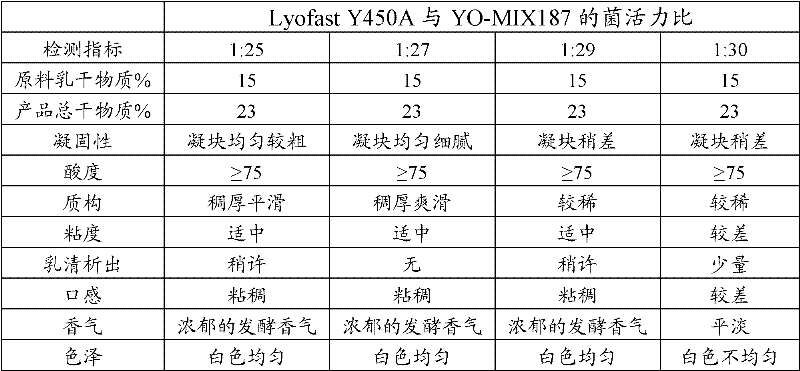

[0040] Take the coagulated yogurt prepared by inoculating the mixed strains of Lyofast Y450A and YO-MIX187 with different bacterial activity ratios, and...

Embodiment 2

[0044] Example 2: Preparation of the coagulated yogurt of the present invention

[0045] Take raw fresh milk that has passed the antibiotic test, reduce the vacuum degree by 8KPa at 85°C and evaporate for 1-2s to obtain raw milk with a dry matter content of 13%. After cooling, mix 90% of raw milk with 2% of whey protein and 8% of white sugar, homogenize at 18-20Mpa and 65-75°C, then heat up to 90-95°C and keep for 300s for sterilization. The sterilized fermentation base was cooled to 42-45°C and inoculated with YO-MIX300, stirred and mixed to make the strain activity unit 125DCU / 1000L. Filling, then fermented at 42-45°C for 5-6 hours, then cooled to below 10°C, and the cooled yogurt was placed at 2-6°C for 12 hours to obtain coagulated yogurt.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com