A New Technology for Drying Soft Capsules

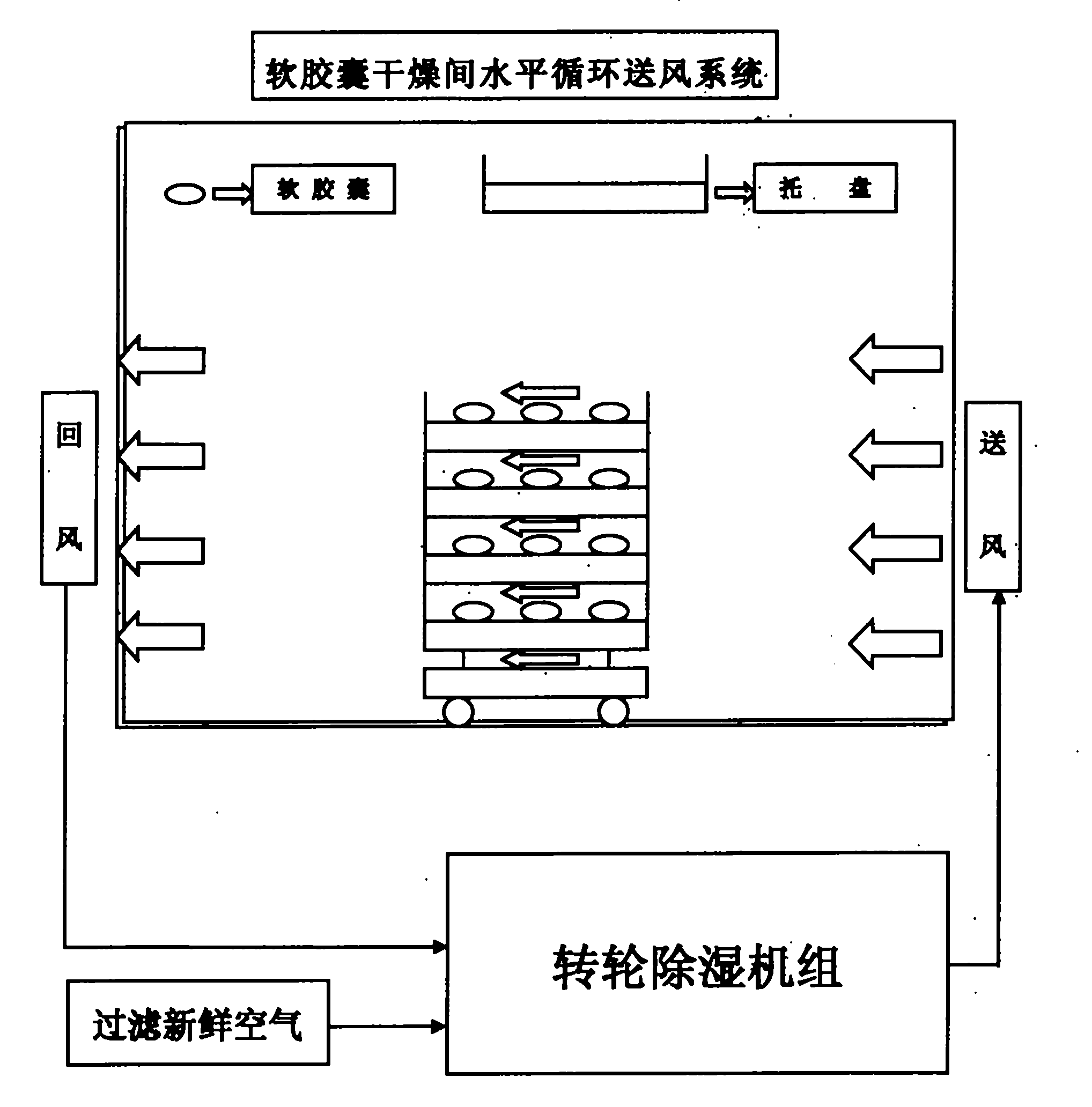

A soft capsule and new technology, applied in the field of soft capsule drug drying, can solve problems such as uneven drying of products, contamination of qualified products on the conveyor belt, uneven drying air supply, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

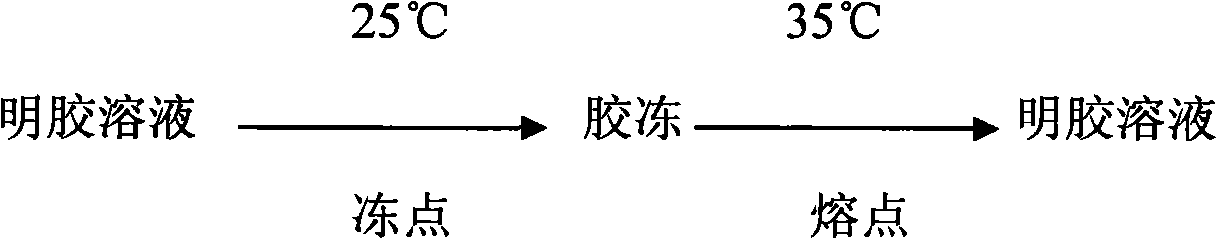

[0025] 1. Soft capsule finalization: Turn on the rotary dehumidifier unit before setting the shape, adjust the humidity of the rotary dehumidifier to 40%, the temperature to 20°C, and control the temperature and humidity of the room to 45-35%, and the temperature to 18-24°C. The capsules were transferred to a sizing tumbler for 2 hours of sizing and drying.

[0026] 2. The soft capsules are dried in a tumbler: the shaped capsules are transferred to a drying tumbler for drying. The drying time is 7 hours, the temperature is 26-32°C, and the humidity is 35-25%. After the drying in the tumbler cage, it was detected that the moisture content of the capsule shell was controlled at 15.6%.

[0027] 3. Tray drying: After the tumbler drying, transfer to the tray for drying, the drying time is 12 hours, the temperature requirement is 20-26°C, and the humidity requirement is 20-30%. Select the unqualified capsules, and after the drying of the tray, the capsules are detected to be 9.6% (...

Embodiment 2

[0029] 1. Soft capsule finalization: Turn on the rotary dehumidifier unit before finalizing, adjust the humidity of the rotary dehumidifier to 42%, the temperature to 19°C, and control the temperature and humidity of the room to 45-35%, and the temperature to 18-24°C. The capsules were transferred to a sizing tumbler for 3 hours of sizing and drying.

[0030] 2. The soft capsules are dried in a tumbler: the shaped capsules are transferred to a drying tumbler for drying. The drying time is 8 hours, the temperature is 26-32°C, and the humidity is 35-25%. After the tumbler drying, the moisture content of the capsule shell was detected to be controlled at 14.8%.

[0031] 3. Tray drying: After the tumbler drying, transfer to the tray for drying, the drying time is 10 hours, the temperature requirement is 20-26°C, and the humidity requirement is 20-30%. Select the unqualified capsules, and after the drying of the tray, the capsules are detected to be 9.2% (the standard of 8% to 12%...

Embodiment 3

[0033] 1. Soft capsule finalization: Turn on the rotary dehumidifier unit before finalizing, adjust the humidity of the rotary dehumidifier to 39%, the temperature to 21°C, and control the temperature and humidity of the room to 45-35%, and the temperature to 18-24°C. The capsules were transferred to a sizing tumbler for 4 hours of sizing and drying.

[0034] 2. The soft capsules are dried in a tumbler: the shaped capsules are transferred to a drying tumbler for drying. The drying time is 6 hours, the temperature is 26-32°C, and the humidity is 35-25%. After the tumbler drying was finished, it was detected that the capsule shell moisture was controlled at 14.2%.

[0035] 3. Tray drying: After the tumbler drying, transfer to the tray for drying, the drying time is 11 hours, the temperature requirement is 20-26°C, and the humidity requirement is 20-30%. Select the unqualified capsules, and after the drying of the tray, the capsules are detected to be 8.9% (the company accepts p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com